The method of exterior finishing of a house is a complex issue that requires significant financial and labor costs.

Solving it requires an understanding of the meaning and features of the functioning of the finishing layer.

One of the most convenient and relatively inexpensive ways to decorate a home is siding.

It has high decorative qualities, provides reliable external protection of wall materials and promotes ventilation of the wall cake and timely release of steam. In addition, siding installation can be done with your own hands, as carefully as possible, without dirt and stains from various solutions.

Description of material

Vinyl siding is made from polyvinyl chloride. Covering the foundation with basement siding is often done to imitate stone (natural or decorative), brick (silicate or red) and various types of wood. During the manufacturing process, the design is transferred from a prepared natural cast, resulting in the color matching the natural texture of the materials as closely as possible. Finishing the base with siding can be done using single-color panels; they can be easily painted on top in pleasant colors.

The best decorative look is created by simultaneously covering the base and walls. Processing panels of the same color is not always the best option; panels with imitation brick or stone on the bottom and wood on the walls go well. Depending on the purpose of the material, siding cladding is divided into basement and wall types. For the foundation, the sheets are thicker - 2.5-3 mm, and 1.5 mm panels are laid on the walls.

Siding is not only an environmentally friendly type of building decoration, but also very economical.

Basement work places increased demands on the material:

- high strength, since it will be affected by various negative influences and there is a risk of impacts;

- immunity to ultraviolet radiation. To prevent the casing of the base from fading with corrugated sheets, special components are added to the composition;

- high quality of raw materials and finished composition.

By combining the listed qualities, the durability of the material and resistance to various negative phenomena are achieved: temperature changes, mechanical damage, UV radiation, etc. Finishing the base with siding meets the stated requirements.

Basement siding is available in different sizes. Common dimensions (ratio of length to panel width):

- 1.22x0.47 m;

- 1.265x0.51 m;

- 1.13x0.47 m;

- 1.14x0.395 m;

- 1.15x0.52 m;

- 2.44x0.24 m.

Due to the variety of sizes, it is easy to choose convenient panel dimensions, and the material itself is quite cheap. Manufacturers guarantee the service life of the cladding for 50 years. If you install and maintain siding correctly, it will last another 50 years. Installation and installation of basement siding is carried out with your own hands, and subsequent care is limited to cleaning it from dust with a soap solution.

According to the installation method, types of basement siding can be horizontal and vertical

Due to the lightness of the material, it practically does not weigh down the building, therefore, reinforcement of the foundation is not required. The indicator is especially useful for processing the base of a house on screw piles, which are operated in conditions of watery or loose soil. Finishing a pile foundation with basement siding can be done with the additional installation of a thermal insulation film. The weight of 1 m2 of completed cladding material is only 3.5 kg. For comparison, artificial stone weighs 35 kg/m2, and facing brick - 190 kg/m2.

Types of raw materials for external cladding of the foundation of a private house with photos

Siding for the base varies in material and appearance. The most common materials are:

PVC – vinyl

The main advantage is low price . This material is easily installed in place and is not subject to deformation. However, it cannot withstand strong impacts, which lead to cracks and breakage.

Metal

Resistant to severe damage, withstands changes in ambient temperature. It is considered elite among sidings.

Fiber cement

Withstands all types of negative influences, but should not be dropped from a great height, as it may break into small pieces. The heavy weight causes difficulties during installation and transportation.

Wood

Rarely used in cladding due to its high cost . It has good thermal insulation properties, can withstand temperature changes, and with proper treatment lasts a long time without losing its original properties.

Covering the base with siding - pros and cons

Finishing the base with siding has become increasingly widespread due to the abundance of advantages of the material. It is ideal for covering walls and foundations.

Advantages:

- durability. Due to its resistance to most negative influences, the material retains its performance characteristics for a long time - 50-100 years;

- siding has high vandal resistance;

- immunity to microorganisms;

- mechanical strength. The material can withstand various impacts due to the built-in metal base and dense finishing coating;

- weather resistance. Snowfalls, rains and fogs do not harm the siding. Operating temperature range from -50°C to 50°C;

Installing basement siding is not a particularly complicated process.

- weightlessness. The lightness of the material eliminates additional costs for strengthening the foundation and simplifies the installation process;

- possibility of additional insulation of the facade. Thermal insulation materials, including bulk mineral wool and thick foam plastic, can be easily placed under the coating;

- a wide range of. The variety of colors and textures leads to the possibility of creating a unique look. The most common option is siding the base with stone, but there are other types of imitation. Modern production technologies create a realistic pattern that is difficult to distinguish from the natural one;

- quick and easy repair. When comparing the time required for plastering, laying stone over siding will speed up the work by 2-3 times. Repair is carried out by simply replacing the strip;

- ease of work even with walls with complex geometry. Work with rectilinear facades is extremely simple; round or multifaceted buildings are a little more complicated.

If you install basement siding yourself, there are several disadvantages to consider:

- After the cladding, the dimensions of the building will be increased. Losses are 10-40 cm, depending on the presence of irregularities, the type of insulation and the design of the panels. If complex cladding with metal siding is carried out, this parameter is of little importance, but when processing the base separately, a further method of leveling should be considered;

- It is important to buy all additional accessories exclusively from branded manufacturers: fasteners, corners, starting levels. Be sure to purchase the material in reserve to eliminate the need for constant trips to the store;

- Panel cutting should be done confidently but with caution. It is recommended to use scissors with a hydraulic element, a grinder or a hacksaw. It is better to practice beforehand so as not to cause damage to large pieces.

Please note that facing a private house with siding involves the use of a large number of screws or nails

The development of skills occurs during installation; you can begin work without prior preparation. The benefits of the coating clearly outweigh the relative disadvantages.

Prices

Products from Alta Profile (Russia) are not inferior in quality to European ones. Specializes in the type that imitates natural stone. The price ranges from 138 to 500 rubles per panel. The FineBer company uses German technology, their products cost 470 rubles per piece. The Canadian manufacturer Remico sells panels for 270-310 rubles per piece. The American company Nailite is famous for its high-quality material. Color saturation lasts 25 years, based on the type of imitation p

Material calculation and purchase of additional parts

Do-it-yourself installation of basement siding is possible only with the correct calculation and preparation of materials. To determine the required amount of materials, the area to be processed is initially calculated using the formula: height * length.

Before covering the foundation of a house with corrugated sheets or any other material, you should find out the square footage of all areas and add them together. Next, the square footage of the material in the package is calculated. The resulting number shows the number of required packs without taking into account trimmings. You should buy siding with a reserve of at least 10%.

Which to choose

When thinking about choosing basement siding, you should adhere to one of its main characteristics - strength. The thickness of the panel fades into the background here. You should pay attention to the quality of the connection. The reliability of the design will depend on this.

The appearance of the sheet surface should not have dents, cracks, or scratches. Make sure the color scheme of the sheets is the same.

The price should not be too expensive, but it should not be too cheap either. The golden mean will be the best option. Reviews about the product play an important role. Many companies have established themselves in the market as good manufacturers producing quality products.

What else is needed to cover the base with siding?

For fastening products the following can be used:

- metal profile for vertical and horizontal lathing. To calculate, you should measure the length of the surface and, taking into account the dimensions of the profile, determine the quantity. The metal is fixed overlapping each other by 40-50 cm;

Installation of the sheathing begins with the installation of the planks you have chosen: wooden or metal

- self-tapping screws The basement siding must be secured with self-tapping screws; they will also be required during the installation of the sheathing;

- auxiliary elements: modules, sockets, corners;

- thermal insulation material. An optional but useful layer, usually the amount of siding is comparable to insulation;

- tools: screwdriver, grinder, construction knife, metal scissors, hammer, level, tape measure and ruler.

It is better to buy all the materials at one time so as not to be distracted from work to purchase small items. The cost of different types of siding varies widely. You can choose basement siding for either 400 rubles/m2 or 1200 rubles/m2.

General provisions

It would be fair to pay a little attention to the reasons for choosing siding as a basement finish:

Advantages

- Good water-repellent properties. This is a primary requirement for any façade cladding with plinth panels.

- Beautiful appearance, imitating a natural, more expensive coating.

Assortment of imitations

- Affordable price. Combined with do-it-yourself installation, you can save a lot of money.

- Simplicity of installation work. Since installing plinth panels is not difficult, you can do without hired specialists.

- Ease of care. It is enough to wash the surface with water from a hose to restore it to its former aesthetics.

- Strength and durability.

- Can be used in combination with insulation.

Installation diagram of additional insulating material

Siding installation rules

Before proceeding directly with the installation, you should familiarize yourself with the basic postulates of finishing work:

- The sections are installed from left to right.

- It must be taken into account that when the temperature changes, the linear dimensions of the panels also change.

To compensate for such deformations, appropriate gaps should be left between finishing products:

- 1 degree Celsius – 15 mm;

- 16 degrees Celsius – 12 mm;

- 32 degrees Celsius – 10 mm.

Advice: if you need to install siding in the cold season, try to keep the panels in a warm room before work. This will significantly increase the flexibility of the material.

- Before starting work, check the evenness of the walls with a level. If irregularities are detected, they must be eliminated.

Advice: if leveling the wall is problematic, then you can install the sheathing in increments of 25 cm. This design will hide all surface defects.

- Nails or screws must enter the surface to be treated at a distance of at least one centimeter.

Fastening diagram

- Materials that can “breathe” are used for insulation. Foil should be excluded.

- Due to the effect of thermal expansion, a gap of about a millimeter must be left between the panel and the cap of the fixing element.

Maintaining the required clearance with a penny

- There is no need to install more than two corners at a time, because this will cause you to lose the opportunity for further adjustment and alignment of the finish.

How to prepare a house for siding installation

Step-by-step instructions for installing basement siding with your own hands always begin with the preparation stage. Application of building materials does not require careful or special preparation. It can be installed even on dilapidated shingle houses. Such walls cannot be plastered, it is forbidden to install any heavy cladding on them, so siding is the best solution.

To cover the walls, there is no need for preliminary stripping, plastering or priming; it is enough to check the evenness of the wall and the absence of protruding elements.

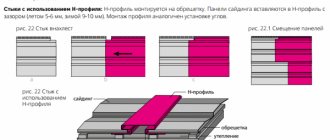

After inspection and removal of protrusions, a frame or sheathing is formed. Most often, the sheathing is installed using a metal profile or wooden beam. The manufacturer allows installation of the material directly on the wall, but it must have an ideal plane and consist of a material into which fasteners can be easily inserted.

From the outside, the profile strips are attached to the base using dowels and screws

If part of the house is being processed, it is necessary to make a metal sheathing; it will last longer, otherwise there is a risk of the wood collapsing before the siding fails. You can use not only a metal profile, but also wood with impregnation to protect against rot.

Possible errors during the work process

The most common mistakes when installing siding panels are:

- building a crooked frame due to uneven walls;

- overtightened screws resulting in the siding moving in waves due to thermal expansion;

- the locks are not latched - the problem is common when installing the material by non-specialists;

- the building material is mounted without a frame, fastened directly to the wall - due to the fact that there is no ventilation gap between the surface of the siding and the wall, condensation forms, which in the future will lead to large costs;

- building a wooden frame without treating it with antiseptic agents - condensation that forms when temperature changes between the frame and the wall can cause rapid destruction of the wooden base, which will cause additional costs.

All these shortcomings should be taken into account when finishing the basement with siding.

How lathing is done

Installation work should begin from the ground. The first profile is the most important; it is leveled and screwed to the wall at a distance of 5-10 cm from the surface. If a concrete blind area is installed around the perimeter of the building, you can begin installation directly from the level of the blind area. The metal is fastened with self-tapping screws screwed into the wall, if its material allows for a reliable connection.

The distance between the profiles depends on the purpose of the work. If you plan to lay insulation, the distance is calculated for comfortable installation of thermal insulation. For simple installation, it is recommended to install the profile in 50 cm increments to obtain even squares.

The greatest attention is paid to the corners. If desired, you can make a curly shape of the corners from the profile.

Installation instructions for basement siding

Installation procedure:

- Laying the first panel. This is the most important stage; the greatest attention is paid to it in order to align the sheet perfectly evenly.

As soon as all work on installing the sheathing is completed, we begin installing the siding panels - Siding set. All subsequent panels are assembled along the edge of the first sheet. The installation of starting rails, which are attached to the profile with self-tapping screws, will help simplify installation.

- Panel fitting. Most likely, trimming of elements will be required on the sides, corners and roof. The best result will come with complete repetition of the edges and patterns of the base.

All plates are secured with self-tapping screws; they should not be screwed in too tightly. It is better to leave 1 mm to the surface of the panel to prevent deformation.

Which to choose

When thinking about choosing basement siding, you should adhere to one of its main characteristics - strength. The thickness of the panel fades into the background here. You should pay attention to the quality of the connection. The reliability of the design will depend on this.

The appearance of the sheet surface should not have dents, cracks, or scratches. Make sure the color scheme of the sheets is the same.

The price should not be too expensive, but it should not be too cheap either. The golden mean will be the best option.

Product reviews play an important role.

Many companies have established themselves in the market as good manufacturers producing quality products.

Installation of siding panels

Installation work should always begin from the left, moving to the right. The panels are inserted level with the previous element so that they rest against the groove. At least 5 screws are used for fastening: 4 in the corners and 1 in the center. It is important to monitor the integrity of the coating; any gaps will lead to wear and tear of the insulation and accelerate the destruction of the siding.

The application procedure includes several basic rules:

- the last row is always installed after installing the final beam;

- To prevent deformation and swelling, tension on the panels should be avoided;

- It is better to start application from the bottom;

- when installing panels under window sills, finishing strips should be installed first;

- If it is necessary to create holes for a gas pipe or heating, it is recommended to create a slot 6 mm larger than the diameter of the pipe.