Sizes and decor

The sizes of PVC panels vary depending on their type.

Therefore, before choosing the desired option, it would be useful to familiarize yourself with what the panels can be in size. After all, depending on this, you can choose the most optimal option for a particular interior. Dimensions of plastic lining:

- thickness – from 8 to 12 mm;

- length – from 300 to 1200 mm;

- width – from 100 to 500 mm.

Dimensions of panels for tiles:

- thickness – from 0.5 to 1 millimeter;

- length – up to 1000 millimeters;

- Width – 500-1000 mm.

Sandwich panels dimensions:

- thickness – from 10 to 32 mm;

- width – from 900 to 1,500 mm;

- length – up to 3,000 mm.

In addition to size, the panels also differ in their decorative appearance. The coating of the panels differs, which can be glossy or matte. They can be colored, patterned or even embossed. For example, lining is most often white matte or glossy; sheet panels can even imitate tiles in their appearance.

Depending on the type of coating, the panel can be matte or glossy. There are also differences depending on the application of paint to the surface of the panel. For example, a pattern is applied to a white panel, and then it is painted in colors using a special paint roller. After this, a colorless ultraviolet varnish is applied as a protective layer.

Of course, today it is completely easy to choose finishing options, even if the interior design requires something special. For example, if the interior has a marine or country theme, then panels with an imitation of cut stone would be an excellent option. PVC options with images of natural slate look amazingly realistic. This solution is especially relevant for the bathroom.

Very sophisticated and subtle options among plastic tiles are also not uncommon. You can choose blue marble models. A few suitable decorative elements, and a room with such tiles will be the height of elegance. Of course, the most common color is white or panels with a pattern. However, dark colors have also shown that they are in considerable demand.

Among those in demand are red shades, transparent panels, and imitation bamboo. Wide and thin sheets of panels look especially impressive, giving the walls the most smooth and luxurious look. It is worth noting that wood-effect panels (especially pine) have also proven to be one of the most popular.

Mirror PVC can be an amazing decoration, which instantly gives the room an attractive look. They are actually polystyrene glass that is attached to a frame. Moreover, a pattern, perforation or it will have a holographic effect can be applied to its surface.

Panda panels have an exclusive design. They have very high quality and bright designs. Moreover, the images are visible very clearly, it is not difficult to see even the smallest details. The interiors of a bathroom, hallway, kitchen or living room with such panels will be chic. After all, the collections feature one main drawing and from one to five additional ones.

Chic wenge color options would also be an excellent solution. Their rich dark brown color, approaching black, will bring a real tropical note. An instant transformation can be achieved using black and white patterns on PVC. For those who like something brighter and more luxurious, there are options in combination with a golden hue.

There are a huge variety of PVC decorative designs. It is enough just to choose a suitable variation for a specific interior.

Examples in the interior

Numerous room design samples allow you to quickly select the most suitable option. Today it is easy to find interesting options that will suit both the Provence style and the loft style. Very original design ideas can be realized using panels with photo printing.

The design of the hallway of a room with panels will be very interesting and bright. Moreover, you can choose bright PVC sheets with floral or abstract patterns that will look great against the background of wooden furniture. An excellent option for a spacious corridor would be panels with a picture, shaded with a not too catchy pattern. In this case, it is best to give preference to bright and rich shades to make the space seem lighter and more welcoming. For those who value elegance and modesty, wood-look panels will be an indispensable option for decorating the hallway.

It’s even easier to choose an interesting interior for the bathroom. Panels with a pattern similar to small mosaics or marble look ideal. They fill the bathroom space with a special charm. And you can give them a little pretentiousness by using moldings with gold and silver elements. Panels with 3D images of a marine theme can transform a familiar bathroom into a tropical oasis.

A kitchen area finished with cladding panels can look bright, practical and modern at the same time. For the main part of the walls (preferably the top), it is better to choose a color that is not too flashy, but the smaller part can be lined with panels with a bright pattern. In this case, the working part can be highlighted in a different color, conditionally dividing the kitchen into a zone. As for the choice of colors and shades, everything is entirely individual.

For more information about decorative PVC panels, see the following video.

Brief summary

Today, plastic panels are very often used when decorating premises. This is due to the presence of many advantages of this finishing material. It is a harmless finishing material and has a beautiful appearance.

Diverse in color and design. Easy to install, allows you to cover even hard-to-reach places.

In order to decorate a room with plastic panels, you need to prepare the walls, make spatial markings, arrange the sheathing, install the starting and finishing profiles, install the strips, make the facing of the slopes, and also install the baseboards.

As a rule, plastic panels are used to decorate rooms such as balconies, bathrooms, hallways and living rooms.

Advantages and disadvantages

This material has become so popular due to its many advantages.

- Versatility. Typically, PVC panels are used as finishing for walls and ceilings. This material can be used to trim the edges of doors and windows, used in showers and bathtubs, and also under steps to create interesting shapes. Summer residents use this building material to form garden beds.

- Installation is quick and easy. Ordinary homeowners can now decorate a wall or any other surface. The work is done quickly and easily with smooth walls or ceilings. In such situations, they are secured with “liquid nails.” To make curved surfaces smoother, you should use a metal or wooden frame.

- Easy to care for. PVC panels can be wiped with a regular soapy rag, but you should be careful at the joints of the panels, because these areas are weak.

- Such panels are absolutely environmentally friendly. This material is non-toxic and does not release harmful substances into the environment.

- Strength. This indicator depends on the right choice. For ceilings, this material is a little lighter.

- There is sound and heat insulation. These panels create good sound insulation and do not let cold into the room.

- A large number of colors and shades. The standard color of PVC is white, but manufacturers have created a huge number of colors to suit every consumer’s taste. At the moment, panels with patterns or imitation of the texture of stone or wood are popular.

- Moisture resistance. Thanks to their smooth surface, they do not retain moisture. Since the material has no pores, dirt, mold and other harmful microorganisms do not linger on its surface. Therefore, they are often used in rooms where there is high humidity.

- Resistant to sudden temperature changes. Plastic panels can withstand temperatures from -50 to +50 degrees Celsius.

Just like other building materials, PVC panels also have disadvantages.

- Instability to ultraviolet rays. After a certain period of time, white plastic panels may turn yellow and lose their original appearance.

- Instability to impacts. Such panels can withstand some loads, but they are not protected from dents or scratches on the surface of the material.

- The material contains chalk, which is a determining component of the strength of the product. The amount of chalk in the panels is determined solely by the manufacturer.

- Characteristic smell. When purchasing and using the panels, a specific smell is present for several days, but then it completely disappears.

- This plastic cannot be called absolutely safe, as many manufacturers claim. It should not be used to decorate children's rooms.

What to consider when choosing?

When purchasing material for cladding ceilings or walls, pay attention to the following aspects:

- the correct geometry of each canvas - without waves or distortions;

- uniformity and quality of coloring, color saturation of all lamellas;

- absence of chips, cracks, scratches and other damage;

- matching pattern.

To purchase high-quality finishing materials, go to a large hardware store. This will help you avoid buying defective PVC lamellas and problems with them - from unsatisfactory results in repairs to the release of harmful substances into the air.

The photo shows sheet plastic for ceramic tiles

Properties and characteristics

PVC panels contain polyvinyl chloride, which is a lightweight and high-quality material. Due to this, the ceilings in rooms, offices and supermarkets are often covered with these panels. Also, interesting patterns are depicted on PVC panels using lamination, thermal printing and other modern technologies. After this, a matte or glossy varnish is applied to this material, which protects the material.

Thanks to this treatment, the panel does not wear out quickly and is very resistant to ultraviolet rays, as well as to any damage, for example, it is protected from scratches. For the safety of human health and his family, no harmful chemical components are used in the production of such polyvinyl chloride panels. Also, when painting surfaces, only water-based paints are used, which is also absolutely safe.

There is a difference between the plastic panels used on walls and ceilings. It lies in the fact that wall-mounted options are a little stronger, and they are also not flexible, so such panels can withstand heavy mechanical loads. Also, the options for walls are thicker than for ceilings. The more polyvinyl chloride, the thicker the panel. The stiffening ribs located inside the PVC wall panels are 1 mm thick, so cutting them with a knife will not be so easy.

The length of this material is 3 meters, the width is only 10 cm, and sometimes it can reach up to 12.5 cm. Plastic lining can be used for both external and internal treatment of premises. In total, two types of this material have become popular on the market. These are “Polka” and “European”. The “polka” has a small locking connection, while the “European” has a much wider one.

External PVC panels have a seam. This is due to the fact that the material has a high coefficient of linear expansion. Therefore, the lining, which was not installed indoors, must change due to changes in temperature conditions. There is also another feature of façade lining. It lies in the fact that the coloring of raw materials in various colors occurs during production, and is not applied on top as in other types. Because of this, the lining retains its original color longer.

Sheet panels consisting of plastic are wider than those of plastic lining. Their length ranges from 105 to 405 cm. These panels are the most famous and consumed. Sometimes the surface of the sheets is sent for special treatment, but not everyone does this, but only some good manufacturers. Thanks to this operation, the panels become stronger and more stable.

Sheet panels can be mounted using glue and nails. The cracks can be sealed with a sealant of the appropriate color or with a narrow lath. Conventional panels have a length of 260 and 270 cm, sometimes even 300 cm, and a width of about 25 cm. But you can also use panels with a width of 50 cm for finishing rooms. The varnished and painted side of the outer surface also forms a seam, which is not very noticeable when it takes on a assembled appearance.

There are also GOST sandwich PVC panels, which are modern and have high performance. The peculiarity of these panels is the presence of two sheets of plastic. Polyurethane foam or expanded polystyrene foam are used as various added substances; they give the material thermal insulation properties. The degree of flammability of products is indicated on the packaging. Plastic lining has the highest coefficient.

How to decorate a kitchen?

You can cover the working wall in the kitchen with PVC panels yourself; to do this, prepare the necessary tools, purchase the material and study the instructions.

The photo shows an option to visually increase the ceiling using finishing

Tools and materials

To install a plastic wall, you need a minimum of tools that can be found in every household:

- pencil and tape measure;

- building level;

- knife and scissors;

- hammer drill or impact drill;

- self-tapping dowel;

- screwdriver and screws, staples and stapler or glue (depending on the type of fastening).

Step-by-step instruction

When everything you need is at hand, we begin finishing. There are 2 methods of attaching slats: with lathing and directly on the wall. Let's look at each installation method step by step.

Frame method:

- Clean the wall surfaces and coat with an antifungal agent.

- Treat wooden or metal slats for the frame with an antiseptic and moisture protection.

- Mark the wall, starting from the bottom above the proposed baseboard, using a level.

- Install external profiles on the top, bottom and sides of the frame.

- Fasten the internal profiles across the future panels. They should be mounted at a distance of no more than 50 cm from each other.

- Place the first plank in the corner, having previously cut the side groove near the adjacent wall. Secure with a self-tapping screw or bracket.

- Insert the second into the groove of the first and secure.

- Repeat as many times as necessary.

- Cut the last part to the required size, place it in the profile and install it in place.

- Install fittings - external and internal corners, plinth.

How to fasten PVC using clamps, see the instructions:

Frameless method:

- Remove old coating.

- Putty and prime the walls, they should be perfectly smooth.

- Cut the side groove of the first kitchen wall panel and clean the back side.

- Apply glue to the lamella in 25 cm increments.

- Attach it to the wall.

- Repeat for the remaining planks, inserting the next one into the groove of the installed one.

For installation without a frame, use special glue for plastic, sealant or liquid nails.

Varieties and applications

At the moment, three types of PVC panels have gained popularity in the building materials market.

- Rack and pinion. To attach this type of panel directly to the wall surface, you must use a metal bracket. This panel has a length from 1 to 12.5 meters, a width from 15 to 30 centimeters, and a thickness of no more than 1 centimeter. If you use this type to decorate a room, it will visually look higher or lower, depending on the position of the panels themselves.

- Under the tiles. The size of this species can range from 30 cm to 1 meter. The method for finishing a room is the same as for slatted panels, but differs in its result. Such PVC panels can be laid out in an interesting pattern in the bathroom or kitchen.

- Leafy. These panels are recognized as the best of all the above types. To install this material on walls or ceilings, you will need glue and nails. The thickness of the sheet panels ranges from 3 to 6 millimeters.

PVC panels can also be divided according to their decorative properties.

- Seamless. Such panels are very popular and look expensive. Seamless panels with a matte surface look great. They are available for both flooring and furniture.

- Embossed. They look exactly the same as wooden ones, but their price is much lower. Moreover, they can be used even if the walls have some curvature. Embossed laminated panels offer a very accurate imitation of textures.

There are also several types of panels depending on the design.

Single color. They are ideal for finishing rooms where practicality and minimalism are valued. To add originality and beauty to a single-color solution, you can make multi-colored shelves yourself or use paintings.

With an image

Such panels often imitate the appearance of stone or fabric, but there are also those that attract attention with a spectacular print, for example, clouds. But difficulties may arise when installing them, since it will be necessary to accurately calculate their position, then the drawing will turn out to be seamless.

PVC panels are used in bathrooms, showers, and kitchens; they are also often used for finishing offices, restaurants, supermarkets, schools, gyms, hospitals and other premises.

General principles of panel installation

To perform high-quality installation, no special skills are required - only the accuracy of calculations and accuracy during work are important.

You will need the usual tools:

- screws and screwdriver

- hacksaw

- stationery knife and sharp scissors

- roulette and level

- wooden slats or metal profile

- square and pencil

Having prepared all the necessary materials, you must first prepare the walls correctly

Preparatory stage

It is very important to completely clear the walls of the previous coating and level it quite carefully, since even small deformations (this is especially true for the walls of an old house) can significantly affect the quality of the future coating - the elements will stick out, and then may even become deformed due to uneven load to the edges.

Preparing the wall for installation is as follows:

- thorough removal of all residues from wallpaper or other old covering;

- surface leveling;

- treatment with an antiseptic composition (this is especially important for the kitchen and bath).

NOTE. If the panels are to be installed using glue, then the alignment of the walls is carried out especially carefully. In the case of fastening to profiles, small (within a centimeter) irregularities are not critical.

After this, you need to mark the wall, and the work can only be done using a level, since even the slightest mistakes are undesirable. The sequence of actions will be as follows:

- The bottom row of the frame is mounted - it rises slightly above the floor (1-2 cm) to ensure the panels fit as tightly as possible to the wall.

- Using a level and a square, make a mark with a pencil and rise up half a meter - at this distance another frame element will stand.

- In this way they rise to the very ceiling. As a result, all lines should run at the same distance, strictly parallel.

Frame installation

The sheathing is installed along the marked lines. If it is made of wood, then the slats must be additionally soaked in a disinfectant. The dowels are installed at intervals of approximately 50 cm, after which the slats are fixed to them.

All work is performed only with the help of a level.

ADVICE. If the wall has obvious unevenness, you can put chips or wooden wedges of appropriate sizes into the recesses.

Panel installation

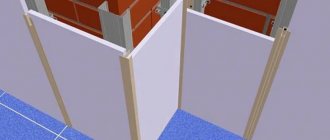

Fixing always starts from the corner, as shown in the figure.

All measurements are taken with a construction tape with an accuracy of up to a millimeter. If there are discrepancies, they are eliminated with a hacksaw, and protruding fragments of the edges can be trimmed later with a stationery knife or sharp scissors.

Fastening PVC wall panels from a corner looks schematically like this.

Each subsequent panel is mounted in a special groove of the previous one, the joint is pressed tightly so that there are not even small gaps left, and then they are fixed to the profile.

ADVICE. Ordinary silicone can help in bridging the gaps between the joints of the panels - you need to slightly lubricate the edges of the panels, and you should apply it carefully so that at the end of the work there are no streaks on the surface of the wall.

Upon completion of installation, you need to make all the necessary household holes (for pipes, sockets, lamps) using a regular stationery knife.

Installation of moldings

Finally, when all the panels are mounted, all that remains is to attach the molding, which will give the structure reliability and a visual solidity effect.

These elements are installed around the perimeter, as well as along all seams by inserting into the corresponding grooves.

The panels can be mounted not only using the frame method described here (creating a frame from wooden slats or a metal profile and then installing panels on it), but also using glue. However, the frame method has its undeniable advantages:

- This is a more reliable type of installation - the panels will last much longer.

- You can cut any household holes in panels that are firmly attached to the frame.

- Particularly careful preliminary work on leveling the walls is not required.

Video instructions for installing PVC wall panels on a loggia

Installation of PVC panels on the ceiling

Once the frame is installed, you can begin installing the panels themselves. You need to start work from the outermost strip; it is attached to the corner, to the transverse material using self-tapping screws. So, the next panel will be installed in the groove of the previous one. This procedure should continue until the opposite wall is completely processed.

If necessary, the last panel can be cut, but only when it is not the right size. Since the material is fragile, it is prone to scratches, cracks or dents. Therefore, when working with panels, you should not press hard. It is recommended to take a utility knife and can also be used to move the panels in the desired direction.

After the last panel has been attached, you can begin installing the baseboard. It is secured using “liquid nails,” which are applied to the interior and attached to the ceiling. Afterwards you need to hold them for 10 seconds, and carefully remove the excess glue. “Liquid nails” dry quite quickly, so excess substances should be removed from the surface quickly.

Installation features

Installation of PVC panels on the walls in the bathroom can be done in two ways:

- Using glue (most often special glue “liquid nails” is used)

The glue must dry fairly quickly and not leave any streaks (that is, remain completely transparent). In addition, it is required to be resistant to constant moisture.

It is applied to the surface in a checkerboard pattern in rather large drops.

Video recommendations for choosing the right glue

- Installation on profiles - this option is more labor-intensive, but on the other hand, this design will last much longer. Moreover, since we are talking about a room such as a bathtub, it is better to choose metal profiles. If wooden ones are used, they must be additionally treated with a special varnish so that moisture does not penetrate into the material.

- Marking the bathtub and cutting the products accordingly using a sharp knife.

- Next, the profiles are attached to the corners using self-tapping screws and a screwdriver.

- Then the panels are mounted on the profiles, which are inserted into each other using grooves and protrusions.

The sequence of actions in this case will be something like this:

You can learn more about this process here.

Wall treatment

Owners of houses or apartments can quickly make the interior of a bathroom or toilet practical and cozy, and all this thanks to PVC wall panels. They are very easy to wash and will last for many years. Wall installation is very similar to ceiling installation.

A frame is also installed on the wall, which has already been treated with antimicrobial agents. It can be plastic or metal. This is at the discretion of the user. The first panel is inserted together with the corner into the profile, followed by other products. They are fixed on metal guides. To do this, use a claymore. The last panel is glued into a U-shaped corner. After this procedure, you can begin installing the corners and making slopes. Dismantling is carried out in a similar sequence.

When the panels are installed, you need to cut a hole where the locations for switches and sockets were previously marked. Such places are difficult to clean and paint. The panel can be made in the form of a panel and various crafts can be hung on it.

Working with plastic panels

The technology of finishing with plastic panels involves careful preparation of the base for finishing, spatial markings, arrangement of sheathing, installation of starting and finishing profiles, installation of planks, facing of slopes, as well as installation of baseboards.

Next, let's look at the instructions on how to make paneling. You should start preparing the walls by removing the old coating so that the new coating has a more aesthetic appearance and there are no unevenness.

Then a layer of antiseptic coating is applied to prevent the emergence of microorganisms harmful to human health.

Properties and characteristics

To understand what PVC panels are, you should first find out what these three letters hide behind them. In fact, everything is extremely simple - they stand for polyvinyl chloride (organic polymer). This is a type of plastic with its own advantages and disadvantages.

This polymer material is used for finishing, and it is worth noting that recently it has clearly become very popular. The composition of polyvinyl chloride includes chlorine (57%), carbon (42%), hydrogen with impurities (about 1%). It is very rare, but still occurs, that lead is added to PVC as a stabilizer. Of course, because of this component, rumors arose that the panels are harmful to health. However, today lead is replaced by zinc and calcium in equal parts, and therefore they are completely harmless.

PVC panels are produced in standard sizes according to GOST. Thus, the length of the panels is 2700, 3000 and 6000 millimeters, and the width is 100, 250 and 375 millimeters. As for thickness, it depends on the manufacturer and model, and its value varies from 1 to 30 millimeters.

PVC can be used at temperatures from -50 to +60 degrees. Moreover, it is advisable to use the panels for interior decoration. This is due to the fact that the temperature difference in the rooms during the day is not too strong. Of course, there are types of panels, for example for finishing a balcony, that are resistant to extreme cold or sunlight. In addition, they calmly tolerate temperature changes.

The strength of the panels depends on the percentage of polyvinyl chloride they contain. The strength is also affected by the number of stiffeners. Moreover, the ribs should not be visible through the front side of the panel.

The colors and textures of PVC panels are completely unlimited. Today you can find both white classics and wood or stone styles, and you can get absolutely any shade to order. It is worth noting that when painting this finishing material, water-based paints are used.

The surface of the panels can be either matte or glossy. The manufacturing technology is the same - varnishing; after glossing, the panels simply undergo additional processing. This coating not only has a decorative function, but also a protective one. After this treatment, the material becomes antistatic, wear-resistant, resistant to mechanical damage (scratches), and also better tolerates ultraviolet radiation.

Polyvinyl chloride lining is used for finishing walls and ceilings in residential premises, offices, and shopping malls. Moreover, in apartments they can be used everywhere, including the hallway, bathroom, kitchen, and living rooms. Of course, most often they are still used in the bathroom and kitchen. The panels are also used for finishing slopes on windows, as well as loggias and balconies.

Such extensive use of this finishing material is primarily due to the fact that it is easy to care for and even easier to install. The light weight allows you to decorate both walls and ceiling with such panels even alone. Moreover, they are sold in very convenient packaging, which greatly facilitates their transportation.

Another important property of PVC panels is that they have a low degree of flammability. This allows them to be used without undue embarrassment, in particular in the kitchen, even next to a gas stove

Recommendations when working with finishing materials

Plastic panels are used to decorate balconies, bathrooms, living rooms, and hallways. For other rooms, more breathable finishing materials are used.

Plastic panels should be used in rooms with good ventilation. In bedrooms, the use of plastic is possible only for certain sections of the walls.

It is not advisable to use this finishing material for decorating walls in kitchen areas.

Criterias of choice

When purchasing PVC panels, you should pay attention to the cost of the product. The higher the price, the better the product

In order not to make a mistake in your choice and not to be deceived, it is worth familiarizing yourself with some aspects of the purchase.

The thickness of the panel is required. The universal thickness of vinyl for walls should not exceed 10 mm, and if you need to choose a building material for the ceiling, then you should pay attention to a thinner one. Front surface strength

This is important and necessary so that the building material can withstand damage and impacts, and at the same time there are no dents or scratches left on it. If stiffening ribs are visible from the outside, then it is better not to use such panels for lining walls. It is better to use them for ceilings, but such work will not look very good or of high quality. Number of ribs, their position and stiffness

The rigidity of a building material greatly depends on the number of ribs. The largest distance that can be between them should not exceed 10 mm.

- The uniformity of the paint covering the surface of the material indicates how the paint was applied to the panel. Most manufacturers coat the surface from the front side rather than adding color to the resin composition. This is bad because while working with the material, the paint can easily peel off the surface. Also, due to such a PVC coating, the panel may burn out, and the paint will be unevenly distributed, which is another disadvantage of such work by the manufacturer.

- When purchasing building material in a store, you need to inquire about its weight. This can help determine the stiffness of the ribs and the wall thickness of the material. The optimal weight of PVC panels should be 1.1–1.5 kg/sq.m. m.

- Are the panels firmly connected? It is better to check the strength of the connection of PVC panels when considering the product.

- What percentage of chalk does the material contain? Many professionals claim that the percentage of chalk in a product should not exceed 20%. If this percentage is higher, then there is a high probability that this material is quite fragile. Chalk is very accessible and not expensive, so some manufacturers, in order to reduce the cost of their products, add more of it than required by regulations. By bending the corner of the product, you can check the amount of chalk in it. If there is no white stripe left on the plastic, then the panel contains the required amount of chalk.

- Panels containing toxins. There is nothing wrong if the sealed lining has a characteristic, but not too pungent odor. But if a specific smell comes from the panels that are displayed as a sample, then it immediately becomes clear that this material contains toxic substances and it is better not to purchase it.

- Brand. If the product is from a reputable seller, then chances are good that the material is of fairly good quality. After all, in order to earn such fame, the manufacturer worked for a long time on the quality of its product, and values its reputation, therefore it offers only high-quality products for wall and floor use.

- Product decor. Facing panels must be heat transfer. They belong to economy class. Thanks to thermal printing, you can choose a variety of decor. The drawing is not afraid of exposure to ultraviolet radiation, and also does not wear off over time. Frieze options are in demand as they come in a variety of prints. Typically, such products imitate the surface of marble, tiles or natural wood.

How to choose the right panels for the bathroom

When choosing panels for a bathroom, you need to take into account the features of this room - the features of utilities (pipes of various shapes and diameters), the nature of the surface, etc.

When inspecting a product in a store, you need to pay special attention not only to the stated characteristics, but also to the appearance:

- uniform coating of the surface with paint (plain or in the form of a pattern)

- absence of any defects (notches, cracks, chips);

- tightness of the joint between parts.

IMPORTANT. Even small defects significantly deteriorate the quality of the product - there is a high probability that when installing the panel, the cracks will only increase, and its service life will be significantly shorter.