Factors affecting paint consumption

The amount of material to be treated may vary for different surfaces. For example, if you need to paint a smooth wall, then 2 layers will be enough, but for textured surfaces you may need more layers and, accordingly, dye.

In addition, the following factors affect paint consumption:

- Type of dye. Depending on the components, different material consumption may be required per 1 m² of treated area.

- Condition and type of substrate. Depending on the type of main surface (plaster, wood, tiles, paper wallpaper for painting), the dye consumption will vary.

- Covering power . The consumption per 1 m² of any coloring material differs for each composition: for example, dark surfaces require more layers.

- Viscosity _ Depending on the type of dye, this value is different for each type of paint with a uniform consistency.

- Tool for work . Since rollers are mainly used, the size of the pile will also determine the cost of the material. This also includes paint brushes.

- Tonality . It's easy to change the paint color by simply adding the desired color. In this case, the amount of pigment dyes added should be measured carefully in order to obtain the desired shade as a result.

- Plasticizers-additives . With their help, the coating dries faster and at the same time does not fade, crack or peel.

Painting after whitewashing

Here you can also add the provision of a microclimate in the room. For example, in rooms with high humidity, the treated surface will take longer to dry, but its consumption can be reduced due to the constant concentration of moisture in the air. If you create an elevated temperature in the room, the layers will dry faster, but the consumption of the coloring material may also increase.

Pay attention to: How to choose the right paint for floor tiles.

Separately, you need to take into account the type of paintwork - internal or external. For example, for finishing facade walls, the material consumption will be higher due to the higher rate of moisture evaporation. And this will require applying additional layers to the surface.

Peculiarities

The tonality of water-based paint changes quite flexibly, you just need to add color to it. Special additives help avoid peeling, cracking and fading; The applied layer dries very quickly. Emulsion dye easily and comfortably applies to a variety of surfaces, even wallpaper; it is used for painting walls and ceilings.

This type of coating is necessary for both street and interior work. The paint is formed by combining water with specially selected pigments. When the water evaporates, only substances “responsible” for color will remain on the surface. Ease of use, solid protective characteristics, excellent resistance to moisture and ultraviolet radiation - all this speaks in favor of water-based paint. Therefore, it is very important to calculate its quantity and accurately take into account all circumstances and factors.

The condition of the substrate (previous layer) is of great importance when calculating the actual need for paint. Any manufacturer always writes on the label and on the packaging how much coloring composition needs to be used to cover 1 square meter. m of surface. But all these figures refer only to ideal conditions, and with ordinary renovations in an apartment or house it is rarely possible to achieve the ideal.

Consumption rates

In reality, it is not always possible to obtain the values indicated on the packaging. There are such nuances as wall porosity, adhesion, and indoor microclimate. Therefore, both the number of layers for painting surfaces and paint consumption may differ from those declared by the manufacturer.

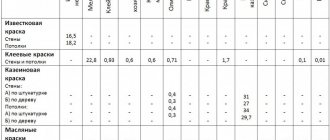

However, there are standard consumption rates for each type of material per square meter of surface:

| Main component | Consumption per 1 layer, g/m² | Consumption for 2 and subsequent layers, g/m² |

| Acrylic | 250 | 150 |

| Silicone | 300 | 150 |

| Silicate | 400 | 350 |

| Latex | 600 | 400 |

| Polyvinyl acetate | 550 | 350 |

The values indicated in the table are given without taking into account the characteristics of a particular type of material. This implies that the coloring material is applied to a carefully prepared surface.

Types of emulsion paints

Emulsion dyes vary in their composition and can be:

- acrylic;

- silicone and silicate;

- based on latex and polyvinyl acetate.

Each type has its own properties and scope of application.

Acrylic paint

Acrylic emulsion

Acrylic emulsion is the most popular due to its advantages : moisture resistance, resistance to mechanical stress, durability and good performance characteristics. Paints based on acrylic resins can be used for exterior work, for example, when finishing the facade of a house.

Coating for the first time requires more consumption due to the fact that the dye is partially absorbed into the surface being treated.

Silicone emulsion

The dye base is silicone

, which is mixed with other components and creates a vapor-permeable coating.

The scope of application of silicone-based emulsion is the treatment of floor coverings . Advantages include moisture resistance and the ability to fill cracks and crevices no larger than 2 mm when applied . This coloring material is in demand when finishing interior spaces in two layers.

Pay attention to: Painting ceiling tiles: selection of paint and tools, surface preparation and painting technology

The difference in the amount of paint for the first and second layers is due to the fact that the initial coating is a base coating and penetrates the porous surface, creating a uniform, smooth structure, as a result of which part of the dye “goes” into the wall.

Silicate emulsion

The dye is based on liquid glass , so the surface treated with this material is impact-resistant and resistant to mechanical stress.

The disadvantage of silicate emulsion is its poor resistance to moisture, so this dye is not suitable for walls in rooms with high humidity, such as bathrooms and kitchens.

Although the basecoat forms a strong film, the material has a high drying rate, and reapplying a recoat requires almost the same consumption.

Latex emulsion

The dye contains polymer substances, thanks to which the latex emulsion does not require special preparation of the base surface. The features include the ability to perform a priming function: before applying the main coating, the latex emulsion can be diluted with water in a ratio of 1:5.

Latex paints dry faster, can have a matte or glossy appearance, and are used for both exterior and interior applications.

Polyvinyl acetate emulsion

Polyvinyl acetate emulsion

It contains PVA glue, which is characterized by reduced moisture resistance. Therefore, a dye based on polyvinyl acetate can be used , for example, when treating ceilings of dry non-residential premises.

In addition to PVA glue, the material may contain cement or slaked lime. It is recommended to apply it to brick or concrete surfaces.

Features and composition of water-dispersion paint

Paints of this type have their own characteristics, which give them different qualities and properties. What they have in common is that each type of dispersion paint is a white thick substance consisting of solid particles dissolved in the liquid component. Color is given to it using pigments, which can be added by the manufacturer, or you can do it yourself.

Water-dispersed acrylic paint is a material that contains various polymers and resins. Water plays the role of a solvent for them. This important feature makes these paints more durable and environmentally friendly; they contain no toxic volatile substances.

What's included:

- The main ingredient is a substance that forms a protective film on the surface of the coating. It ensures the durability of the coating and its quality.

- Pigments that color white acrylic composition in various shades.

- Natural or synthetic fillers (marble chips, talc, etc.). They are part of water-dispersion paint and give the compositions certain qualities.

- Other additives give paint additional properties, such as reducing drying time after application to surfaces.

Measurements of the room and calculation of the area of the surface to be painted

In order to determine the required amount of dye, it is necessary to measure the area to be treated. To do this, you need to know the dimensions of the wall (length, height) and window and door openings, i.e. those areas that do not require painting.

By determining the total surface area and subtracting the area of windows and doors from it, you can obtain the value of the processed surface. Based on the calculation of the material required to consume water-based paint per 1 m2 of wall in 2 times, you can obtain the total amount of material required for painting.

Pay attention to: Removing paint and varnish from concrete walls: methods, materials, technology

Advantages and disadvantages

Water-dispersed acrylic paint for walls and ceilings, used for interior and exterior work, has numerous advantages. Below are the advantages of using this material:

The material has numerous advantages, but there are also several disadvantages to consider. These are not disadvantages, rather features, but you definitely need to know about them.

An example of calculating the area of the walls of a room

As an example, we consider a bathroom measuring 2x3x2.5 m, having 1 window measuring 0.9x1.2 m and a doorway measuring 0.9x1.7 m.

The calculation is made using the following technology:

- First, the total area of the room is calculated: Stotal = AxBxH, m², where A is the length of wall 1, B is the length of wall 2, H is the height of the wall, m. Stot = (A1+A2)xH + (B1+B2)xH = (2 +2)x2.5+(3+3)x2.5 = 25 m².

- Then the areas of the window and door are calculated: Sok = Aok x Vok = 0.9x1.2 = 1.08 m²; Sdv = Adv x Vdv = 0.9x1.7 = 1.53 m².

- The area of the door and window is subtracted from the total area: S = Stotal – Sok – Sdv = 25 – 1.08 – 1.53 = 22.39 m² – this will be the area of the wall for painting.

To determine the total material consumption, the obtained value must be multiplied by the specified amount of paint 1 kg/m² and add 5-7% of the reserve.

For example, take acrylic-based paint:

- The consumption for 1 layer will be: 0.25x22.39+5% = 5.88 kg.

- The consumption for the 2nd layer will be: 0.15x22.39+5% = 3.53 kg.

- The total consumption will be: 5.88 + 3.53 = 9.41 kg.