With the help of finishing materials, which are presented in a huge range on the market, you can bring any design solutions to life. Natural materials are safe for health, but sometimes they are too heavy and “eat up” space, and their cost is not affordable for everyone. Fortunately, with the help of modern technologies, materials are produced that not only look natural, but also simplify repairs. One of the interesting and relevant options in modern design is decorative brick panels for interior decoration.

PVC panels

Made from modern artificial material - polyvinyl chloride - with the addition of softeners. The untreated material is white. After giving the product a textured pattern that matches the brickwork, a special technology is used to paint it in the desired shades. Polyvinyl chloride has excellent sound-proofing and heat-insulating properties.

Decorating the walls with PVC brick panels allows you not to think about extraneous sounds and noises.

The material is absolutely safe for the health of others, which is why brick-like wall slabs for interior decoration are gaining popularity. The surface of PVC panels is easy to clean, which allows them to be used for finishing work in the kitchen.

Imitation

It completely imitates stonework. The imitation is so high quality that from a distance you might think that the wall was actually lined with stone. They are made of metal siding.

The advantages of this type include:

- fire resistance;

- resistance to sudden changes in temperature;

- moisture resistance.

Such coatings are characterized by heavy weight. That is why you need to put a lot of effort into installing brick panels on the wall.

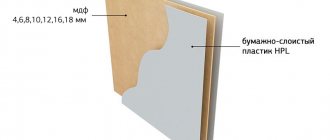

MDF panels

Such products are made from wood chips, which are pressed under high pressure. Processing under high temperature makes the material more durable and reliable. Thanks to this, MDF panels have high quality characteristics. This finishing material is not afraid of temperature changes and even moisture accumulation, therefore it is considered an ideal option for cladding the kitchen area, hallway and bathroom.

Fiber cement

This type is characterized by relative flexibility and strength.

The manufacturing process consists of several stages:

- creating a mixture;

- shaping;

- drying;

- applying a protective and finishing layer.

The composition includes cellulose, which gives the finish strength and resistance to moisture.

The main characteristics include:

- linear type deformation – about 2%;

- density – 1.5 kg per 1m3;

- resistance to sub-zero temperatures and fire;

- maximum 20% moisture absorption.

Gypsum products

Gypsum panels that look like brick look especially good in the interior; they most accurately convey the texture of this material, so such an imitation is practically indistinguishable from a real brick wall. Another advantage of gypsum products is absolute fire safety.

USEFUL INFORMATION: Do you know enough about vinyl wallpaper?

However, it should be remembered that gypsum is afraid of moisture, so this finish is only suitable for dry rooms.

Another feature of gypsum boards is their fairly considerable weight. So, for example, a 50 × 50 × 3 cm slab weighs 4 kg.

Care

The surface finished with PVC panels looks quite beautiful, but the service life of the building material depends on the organization of proper care for it, which, based on the characteristics of the material, is thorough and careful.

Contaminated areas are best removed with a cloth and soapy water. Do not use alkaline or acid-based powders or cleaners to avoid damaging the decorative finish.

If repair work is necessary, the damaged panel can be easily removed from the general fabric and replaced with a new analogue. Just remember that such work does not require haste.

Variety of shapes

Brick wall panels can be of different shapes:

- The typesetting form of products imitating brick is a rectangular tile. Ideal for partial wall cladding when precise selection of patterns is required.

- The slatted panel is available in the form of planks of various widths.

- Sheet products are produced in the form of slabs with an area of 3 to 8 m2. This option is more technologically advanced during installation, as it allows you to simultaneously cover a larger area.

Advantages and disadvantages of wall panels

The popularity of brick panels for interior wall decoration is explained by their high quality characteristics, including:

- Resistance to high humidity.

- Ability to withstand sudden changes in temperature.

- Resistance to solar radiation, the color of the facing material does not change even when directly exposed to the sun's rays.

The listed parameters provide many advantages to finished products:

- Acceptable price.

- High-quality imitation of real brick.

- Versatility of application, which makes it possible to organically combine panels with different facing materials.

- Easy and simple installation.

- Maintainability.

- High sound and heat insulation.

- Long-term operation.

But, like all building and finishing materials, brick wall slabs have their drawbacks:

- At high temperatures, the material can be deformed, so you should not use such cladding near sources of open fire.

- Despite the declared strength, brick slabs are not able to withstand strong mechanical stress, which can lead to dents or scratches.

Material characteristics

Comparing PVC panels with other materials used for finishing external walls, one immediately notices the main performance characteristics that allowed them to gain a leading position. These include:

- The ability to maintain its properties under changes in temperature. There are panels used at temperatures of 115 degrees above zero;

- The presence of a decorative pattern on the top surface, applied in several ways - lamination, offset and thermal printing;

- the decorative surface is protected with a special varnish composition that creates a matte or glossy finish;

- the surface is resistant to ultraviolet radiation, mechanical damage, chemical compounds and atmospheric conditions;

- the standard length of the material is 3 m, but longer options are also available;

- width size varies from 25 to 50 cm;

- The thickness of the panel does not exceed 1.2 cm.

Price

The price of brick panels depends on several factors, which include:

- Material – MDF is usually more expensive than PVC.

- Manufacturer - Chinese and Malaysian products are the cheapest, Russian ones are somewhat more expensive, products from Europe and the USA can be 2 or more times more expensive.

- Brand awareness.

- The complexity of the drawing.

- The quality of the paints used.

USEFUL INFORMATION: Improved wall plaster: we follow the requirements of SNiP

Features of choosing panels for brick

When using the described products that imitate brick, it is important to take into account the advice of experts:

- Brick-like wall panels are often used when decorating recreation rooms. However, the brickwork of an ancient castle can exert emotional pressure due to the lack of comfort.

- In one-room apartments, one wall is lined with materials imitating brick, choosing soft, non-aggressive tones. This option does not overload the interior.

- When partially cladding walls, you can use brick-like slabs in bright colors. This will help highlight any area and create an interesting accent in the room. It is worth remembering that you should not use products made of MDF and PVC when finishing fireplaces in order to avoid deformation of the material.

- It is not recommended to use red brick cladding material for finishing living rooms. This can disrupt the calm emotional atmosphere in the apartment.

- Brick wall panels in white and light gray shades fit perfectly into an interior dominated by pastel colors. However, in the bedroom, the walls of which are lined with such panels, you will feel “chill”.

- When choosing a finishing color, you should take into account the area of the room, its lighting and the chosen style solution.

Basement

Mounting the basement imitation on the wall is not difficult. They are practical and inexpensive. Polyvinyl chloride is used in production. It is combined with stabilizers and biological and chemical reagents. This is necessary so that the base coverings do not fade in the sun and resist negative atmospheric manifestations. This type of cladding is fire resistant.

To produce base sheets, a special mold is used. A real brick wall is used as the basis. Basement siding completely replicates the masonry, including unevenness and chips.

Main characteristics of this cladding:

- resistance to mechanical, natural and chemical influences, corrosion;

- impressive thickness;

- unpretentiousness;

- average service life is about 50 years.

Wall decoration with brick panels

Installation of panels can be carried out in two ways:

- In the first case, the slab is glued directly to the wall surface. At the same time, due to the flexibility of the product, minor irregularities are hidden. The adhesive composition is selected depending on the material from which the slabs are made. Pasting begins from the corner, checking the evenness of the location using a building level. If necessary, the wall panel can be easily trimmed with a fine-toothed file.

- The second method is to install the slab on the frame. This option is especially relevant when finishing walls that have significant curvature. To mount the frame, you can use wooden slats or a metal profile. Assembly of the frame begins with attaching the guide profile to the floor and ceiling. Then, maintaining a certain step, vertical wall profiles are attached to the wall. Brick-like wall panels for interior decoration are fastened using self-tapping screws.

Important! To prevent premature damage to the finishing boards during operation, it is recommended to place the profiles at a distance of 40 cm. You can first fasten a sheet of plywood to the frame and place a wall panel on top of it.

A brick wall in the interior is an excellent design solution. A decorative panel imitating brick allows you to create the desired interior at low material and time costs. Convenient and practical panels transform the room, reproducing the structure of natural material and simplifying repairs.

With insulation

Such models have a polyurethane foam or polystyrene foam base. It is an effective insulation material. The top layer is made of clinker tiles, which creates an imitation of clinker masonry. Clinker is obtained from clay, which is pre-fired at a temperature of at least 1200°C.

The insulation layer can be 60-100 mm thick. The layer of clinker tiles in the coating with insulation is at least 15 mm.