Not everyone has the opportunity to purchase expensive waterproof laminate. The cheaper moisture-resistant one has protection for the top surface, but the joints, locks and sides of the slats do not have any protection. As a result, when moisture gets in, deformation begins, causing the floor covering to fail. You can cope with this problem using sealant for laminate joints.

Do I need sealant for parquet boards?

A specialized mixture helps to close technological gaps in hard-to-reach places, for example, when the material bypasses communication pipes, where the element adjoins the door threshold. Some craftsmen even call the solution a “lifesaver”, this is due to the good characteristics of the composition.

It is plastic and quite thoroughly fills any gaps that could cause damage to the floors, as well as lead to unpleasant drafts that drag down the feet of the building's residents.

If you buy the first brand you come across, you won’t be able to avoid problems; we’re talking about such excesses as:

- Due to the mixture, the full closing of the lock provided on the facing element may be blocked.

- If the composition is applied incorrectly, laying the laminate with a sealant leads to the lamellas being deformed.

- A low-quality product will make the seal much lower.

There have been cases when people blamed the solution for the fact that because of it, vapors accumulated under the floors, gradually turning into drops of moisture, this liquid affecting the structure of the material. The parquet simply swelled, and the pine backing was also damaged.

What does sealant do when laying laminate flooring?

There are many more positive aspects to this approach to installing floor coverings; it is important to correctly follow the technology for installing the elements, as well as to use only proven brands of products.

As a result of the work, the homeowner will be able to completely protect the slats from copious amounts of spilled water; in 80% of cases, swelling of the material occurred due to an overturned vase of flowers or a basin with liquid when cleaning the room.

In most situations, the mixture can relieve the owner of the building from unpleasant creaks in the floors, which will make spending time in the rooms much more comfortable.

The main causes of laminate damage

- High humidity . Due to improper wet cleaning, leaking water pipes, and contact with animal urine. Leads to swelling and soaking of laminated panels. A significant part of the preventive work should be carried out at the stage of laying the laminate: waterproofing the floor before laying the floor covering, sealing the seams during installation.

- Mechanical damage to the top layer as a result of moving furniture and other heavy objects, or falling heavy objects onto the floor.

- Mechanical damage to the top layer as a result of the use of mobile furniture (furniture on wheels: computer chairs, roll-out sofas, serving carts, etc.).

- Mechanical damage to the laminate under carpets due to the abrasive effect created by accumulated dust under carpets and carpet runners in areas with heavy traffic.

- Mechanical damage due to the use of cleaning equipment with rotating brushes and mechanisms.

So what treatment product should you choose when laying and using laminate flooring?

Types of sealants for laminate seams

On sale you can find several varieties of compositions that have their own characteristics and positive characteristics; the range of products is really large.

But only a close acquaintance with the solutions will help you fully understand the strengths and weaknesses of the models; information about each variety should be given separately.

Having learned all the nuances, each person will be able to understand whether a sealant is needed for laminate joints or whether they can do without it, while saving the budget for repairs.

Silicone mixture model

The list of immediately noticeable positive performance qualities included the following features of the solution:

- Excellent viscosity, when applied to the material the product does not spread, and it becomes very comfortable to work with.

- Resistance to high temperatures can pleasantly surprise; when faced with boiling water, the seams will not even change in size, which acrylic gel for laminate joints cannot boast of.

- Elasticity is not lost for a long time, as consumers of the product have noticed, the period reaches 20 years of constant use of the floors.

Most often, silicone is purchased to coat the joints between slats in the kitchen or hallway, where the coating is often at risk of deformation due to liquid.

It should be clearly understood that when sealing, the outer seam is involved, the mixture getting into the locking joint will lead to incomplete closure, such mistakes must be avoided in every possible way.

Acrylic composition

Having treated the joints of the laminate with sealant, the master will be able to tightly seal the technological gap, which can allow spilled water to pass through and accumulate pathogens.

Any floor repair that involves installing parquet boards is rarely possible without an acrylic model, although this type is slightly inferior in plasticity to silicone. A distinctive feature of the product is the abundance of color palette; you can choose a shade at your personal discretion, based on the material you have already purchased.

At the same time, the seams will look aesthetically pleasing, will not attract the attention of guests, and will also fully perform protective functions. It is important to remember that the seam turns out to be quite rigid; under strong mechanical stress, the joint can crumble, and contact with boiling water will lead to erosion.

Wax specialized glue

This brand contains plasticizers, thickeners and mineral paraffins; you can find convenient tubes and tubes on the shelves. The working mass is perfectly smoothed along the seam; any tool that the master likes and does not scratch the material is suitable for these purposes.

Excessive drying of the finished layer was not noticed; the mixture is also ready for exposure to temperatures; unlike acrylic bases, thermal destruction does not occur.

It should be remembered that when cleaning, which includes adding aggressive cleaning agents, the dried solution is gradually washed away.

Some home owners decide to treat the entire floor area, but such steps must be taken only if there is a sufficient amount of sealant; repair costs will increase.

The seams are re-grouted every 2 months, which complicates the care of the coating when choosing wax to protect it from moisture.

Cork sealant

When thinking about the question of which laminate sealant is best to purchase for repairs, you should pay attention to this particular model. Liquid cork, according to most experts, is considered an excellent option due to its environmental friendliness, ease of application and technical characteristics.

The mixture consists of cork chips and fairly sticky silicone; this tandem provides decent adhesion, as well as protection from moisture penetration.

The resulting vapors under the floors will gradually penetrate through the structure of the seam and come out, while the substrate, as well as the lamellas themselves, will not rot.

The solution is 3 times softer than a silicone or acrylic product sample; at the time of shrinkage due to temperature changes, the risk of defects is significantly reduced.

Gel for laying laminate

A new product on the construction market instantly became popular; the mixture of a thickener and modified resins based on silicon gel is very durable and resistant to any impact.

When the temperature increases, the layer does not thicken, excessive hardness was not noticed, and the material does not burn. When washing floors with aggressive agents, consumers did not notice the seams being washed out; there are many positive aspects to this type of sealant.

The presence of stains on the coating is excluded, the composition is transparent, so the aesthetics of the joints are at a decent level, the solution is able to penetrate even the smallest cracks.

It is important to apply the gel correctly; the laminate joints are sealed on a dry base; then, in addition to protecting against moisture, the layer will push out existing water particles from the thickness of the lamellas or lining.

Homemade materials

Most often, people take components such as PVC dust and silicone, gradually kneading a homemade solution to the desired consistency.

You can find a combination of cork shavings and oil or pentaphthalic varnishes, and some craftsmen personally brew entire wax compositions. The effectiveness of such products will be lower than that of purchased models, but the cost comes to the fore, especially when the budget for repairs is minimal.

Failure to comply with the proportions will lead to swelling of the lamellas, because the varnishes also contain liquid; caution must be exercised with this point. Without experience in preparing it yourself or precise instructions, it would be stupid to take on making the mixture.

Sealing laminate joints with chamfer – TYTAN gel (Video)

In 2022, I accepted an order to lay flooring on an area of 80 m2. During the conversation, it became clear that the flooring needed to be done using a threshold-free method and one of the wishes was to partially seal the laminate joints. And the coating was Egger Pro brand, chamfered with a new Unifit lock and 8 mm thick.

The laminate has already been purchased and I gave the final instructions for purchasing the necessary additional materials. He recommended a substrate, mentioned garbage bags, and advised which sealant was best to use for chamfering.

I had already encountered TYTAN gel before, but I used it to process chamfered edges on a laminate without a chamfer. Its advantage in terms of removing excess is its greater elasticity and the ability to remove squeezed-out residue without additional waiting than Bostik gel. Sealant Titan and advised.

How to choose the best laminate seam sealant

Among the varieties of companies producing liquid stopper, the “BOSTIK3070” model is popular; this solution copes well with most of the tasks set by the master.

When it comes to gel, you should choose the German mixture Click Guard or Click Protect made in Sweden, both compositions provide reliable protection against moisture and have a long service life.

Among wax models, Roci AquaStop is most often purchased; this sealant will also help get rid of squeaks in floors. Before going to a specialized store, you should familiarize yourself with the rating, which will be presented at the end of the article.

Thanks to detailed descriptions of popular brands from different manufacturers, it will be possible to identify the leaders, and at the time of purchase, personally read the brief provided by the manufacturer on the packaging.

Which manufacturer should you choose?

Today it is easy to find offers from domestic and imported manufacturers. There are several main brands among each of them that are quite high quality.

Domestic manufacturers

Masterfix

The best representative among domestic brands. Extremely versatile and easy to use.

This sealant can be used for simultaneous work with several materials. The release form is tubes, which accordingly requires special equipment for application. Sold in 390 ml packs. Available in different colors for different types of wood.

Important! This composition is also suitable for restoring the surface when chips and cracks appear, as well as for attaching various decorative elements.

Main characteristics:

- Resistant to a wide range of temperatures;

- Work with constant contact with water is unacceptable;

- Not recommended for use in cold weather.

Protect Click

Another domestic manufacturer, originally from St. Petersburg. The product is colorless and is available in regular tubes, each containing 125 grams. sealant, which is enough to treat 10 m2 of coverage area.

Partially polymerizes in 15 minutes, final drying occurs within 24 hours.

Main characteristics:

- Resistant to a wide range of temperatures;

- Work with constant contact with water is unacceptable;

- The composition contains polyesters; it is necessary to work when the room is ventilated;

- Not recommended for use in cold weather.

Application of sealant

The mixture is used in two cases, when the initial laying of lamellas and immediate forced repair of the coating are carried out. To understand the algorithm of the master’s actions, as well as to repeat the work personally and not pay professionals, it is worth analyzing both approaches separately.

In addition to thoroughly preparing the base, you don’t need a lot of tools; you often have a small mallet, a spatula for leveling the layer and a rag to wipe off the excess that is squeezed out.

When laying laminate

Initially, experienced veneerers lubricate the upper part of the interlocking element of the parquet board with the composition; there is no need to wait for it to harden; you should immediately begin joining the two pieces.

Any excess that appears is wiped off after 15 minutes so that the specialized solution penetrates into the structure of the material and also fills microcracks, if any, on the lamellas.

To carry out the manipulations, an ordinary clean rag or a plastic scraper is suitable; metal spatulas can scratch the lining; it is better to avoid using them.

The sealant is considered safe for human health, but some people may experience discomfort due to a specific odor; room ventilation will help neutralize such manifestations.

When repairing a laminated surface

Although the composition is not intended exclusively for such purposes, its structure allows you to easily eliminate damage to floors.

Minor scratches or cracks near the wall can easily be covered with a silicone, acrylic or cork model, which increases the degree of protection of the coating from moisture penetration under the material.

Colored versions are popular, they can completely fill the space and make the pothole completely invisible; the shade is selected taking into account the design of the parquet.

Most craftsmen distribute the composition with a small slide, so that at the moment of hardening, they carefully remove the desired part of the sealant, and then sand the layer with microfiber, bringing the appearance to an ideal state.

Carpet for laminate flooring

Laminate is a self-sufficient floor covering and does not necessarily need to be covered with anything on top. But if you're not a minimalist and want a cozier room, don't be afraid to use rugs !

When using carpeting in areas with heavy traffic, noticeable abrasions may appear on the laminate as a result of the abrasive effect of dust and dirt accumulated under the carpeting. You should ensure the cleanliness of the carpet itself and the floor underneath it.

- Choose carpeting with a soft backing , for example: felt, wool, bamboo yarn, etc.

- Undesirable base material (hard), for example: jute, bamboo mats.

- On a waterproof basis You should not use products based on rubber or caoutchouc, they can leave stains that are difficult to remove.

Rubber mat

Pay attention to products based on polypropylene, polyethylene, polyvinyl chloride or PVC, etc.

- Door mat at the entrance. It must be placed at the entrance.

Entrance mat to trap dirt

The mat will retain street dirt, sand, and small pebbles accumulated on the soles of shoes, thereby protecting your flooring from possible damage.

Most popular brands

The rating of noteworthy mixture options was compiled taking into account consumer reviews, as well as expert opinions.

Professional builders always use only high-quality components in their work in order to provide the customer with a good result; the floors must last a long time, otherwise the authority of the team will instantly drop.

| Nomination | place | Name of product | price |

| The best sealants for parquet and laminate | 1 | Bostik Clic Protect | 342 ₽ |

| 2 | GAP FILLER Vermeister | 493 ₽ | |

| 3 | KIM TEC Parkett Laminate | 200 ₽ | |

| 4 | MasterTeks ProfiMaster | 149 ₽ | |

| 5 | Click Guard | 279 ₽ | |

| 6 | TYTAN 17171 | 229 ₽ | |

| 7 | SOUDAL sealant for floors, parquet, laminate | 403 ₽ | |

| 8 | Pufas Click-Safe | 488 ₽ | |

| Best Tile Sealants | 1 | Quelyd 007 | 477 ₽ |

| 2 | Krass sealant, silicone, for kitchen and bath, 8711595055604 | 198 ₽ | |

| 3 | Silicone sanitary sealant Tytan UPG | 360 ₽ | |

| 4 | Silicone sanitary sealant Soudal | 297 ₽ |

Pets and laminate flooring

Many dog owners are concerned about the problem of sharp nails scratching their laminate flooring. Don't call this feature of pets a problem! The high-quality laminate has a wear-resistant layer that is scratch-resistant. But less expensive laminate brands won't hold up against your pet's claws.

Therefore, if you have pets with large claws, then:

- choose a laminate resistant to mechanical damage of 32-33 strength class;

- with the inclusion of corundum crystals (aluminum oxide) in the coating composition of the lamellas for greater wear resistance;

- with an embossed or textured finish that will prevent your pet from slipping on the surface and provide better grip;

- The thickness of the lamellas must be at least 10mm.

Also, where the animal is feeding, place a rubber (silicone) mat under its bowl to protect the floor surface from spills.

Animals and laminate

It happens that a pet, once in a new home for it, begins to actively mark its territory. What to do in this case and how to get rid of stains and the smell of urine on laminate flooring? Here are some proven methods:

- Make a strong solution of water and laundry soap and wipe the marked area in two or three approaches, then wipe dry;

- Mix acetic acid with water (a teaspoon per glass of water) and, moistening the desired area with a soft cloth, wait a minute, then wipe with a slightly damp cloth. The vinegar smell will discourage the animal from marking in this particular place;

- Using a deodorant with active enzymes (available at any pet store);

- Application of soda: pour the marked areas for an hour, then with a well-wrung cloth soaked in a solution of hydrogen peroxide and water, remove the soda from the laminate and wipe dry.

- Do not use chlorine-containing preparations - this will harm not only the laminate, but also the animal;

- If you don’t want to do this yourself or don’t know how, call specialists from a professional cleaning company;

- If a puddle of urine has been on the laminate for more than 12-16 hours - it has already saturated the lamellas and eaten into the coating - then the above remedies are no longer effective. In this case, it is necessary to replace a fragment of the laminate floor.

Application technology

The place where the fixing agent will be applied is thoroughly cleaned, after which it is necessary to distribute the sealant in an even layer along the entire line of contact of the two lamellas.

In rare cases, a mallet is used to press down and tightly press the locking connection; most often, the elements are easily snapped into place by hand.

Upon completion of the work, you can additionally walk along the resulting joints to be sure of the protection of the material, which can become unusable due to moisture penetration into the structure.

The excess is not removed immediately, the mixture should fill the voids, 10-15 minutes will be enough, after this time the residue is removed with a clean rag.

Instructions for use

Proper use of sealant for laminated boards is characterized by complete environmental safety of the floor covering, protecting it from moisture ingress into the crevice space between the panels, allowing you to disassemble and re-lay elements and significantly increases the service life of the laminate.

Do not apply sealant to the lock groove

Processing the joints strengthens the old floor covering and also facilitates the installation of new laminated boards. An important point in installation is the formation of joints and the process of adhesion of putty to the side surfaces. It is enough to apply the sealant, then wait the time specified by the manufacturer of the composition (about a quarter of an hour) and carefully remove the excess with a dry cloth, water or special means.

It will not be possible to lay the laminate without trimming, and it is impossible to cut it with bare hands. You can find out about the power tools used for cutting material on our website: .

What factors complicate laminate joining?

The quality of production of lamellas comes to the fore; if it is insufficient, then the interlocking connections will have differences in size. Even half a millimeter is enough for the master to have difficulties when installing the cladding.

Irregularities in the base also often lead to excesses; if excessive force is applied when hammering in an element, the edge easily breaks off, after which these damages have to be further leveled out.

The hygroscopicity of the laminate changes due to improper storage; as soon as several boards are saturated with moisture, it will be problematic to connect them with dry specimens; this fact should always be remembered if the purchase of components is made long before the start of repairs.

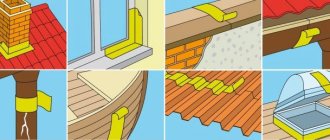

Sealing the deformation gap

The sealant will help to reliably seal the expansion joints that are created after laying the covering along the walls. Without this, moisture may seep inside, and all efforts to seal the side parts of the slats will be in vain. The work is carried out in the following stages:

- wipe the laminate with a damp cloth on the side that will be near the wall;

- seal the deformation gap with construction tape so that the product does not get on the front side of the laminate;

- fill the seam with sealant, smooth it with a rubber spatula immediately after application;

- Remove the tape and carefully wipe the finished seam with a damp cloth.

When installing, do not fasten the lamellas too tightly, otherwise they may warp during operation. The locks must be latched so that they do not move freely later. Despite the slow speed of work when using sealant, the quality of the floor covering will be much higher, the laminate will last longer and without complaints.

Special mastic

It is used on undamaged laminate flooring to protect it from future damage. Mastic is sold both as a spray and as an emulsion. There are no difficulties with use - the material is simply rubbed into the surface (for example, using a sponge). Although the emulsion is more difficult to apply, it provides better protection for the slats.

It is better to apply the product with a sponge

Note! When applying mastic, make sure that no unattractive stains remain on the surface. As a rule, they appear due to poor rubbing of the composition (this must be done along the fibers of the laminate).

You need to apply the mastic carefully.

A water-based emulsion, by the way, is somewhat easier to rub in. Simply dilute it with water according to the instructions and apply to the floor covering. In other words, you will wash the floor with the prepared mixture and let it dry.

Important information! Interestingly, mastic is not only glossy, but also matte. Regardless of the type, mastic protects equally effectively. Here you just need to decide what the resulting gender should be.

Master Class. How to use mastic

Step 1. First, purchase mastic and carefully read the manufacturer's instructions. Then proceed to prepare the floor - sweep it, remove debris, wash it thoroughly and wait until it is completely dry.

Floor preparation

Step 2. Next, arm yourself with a sponge (you can take a small rag with a little lint) and mastic itself. Apply a little mixture to a rag to gradually treat the laminate.

Preparation for applying mastic

Step 3. Gently rub the mastic in, moving in the direction of the pattern. Make sure that there are no untreated areas or places where the composition has been applied poorly. Do everything in stages, that is, start from the far corner of the room and gradually move towards the exit.

Rubbing in mastic

Step 4. After finishing the treatment, wait for the mastic to dry and remove any excess by wiping the floor. It would seem that everything is extremely simple, but in reality it is painstaking work that requires a lot of time and effort.

The floor is wiped after the mastic has dried

Note! After completing the treatment, try not to walk on the coating for at least a few more hours.