In order to regulate the water supply, water supply systems are equipped with valves and mixers. Like any other product, these products fail from time to time. Most often this occurs due to wear of the valve head parts (also called the valve axle box). There is no need to rush to replace the mixer, because... In many cases, the problem can be fixed on your own.

- How to remove the crane axle box

What is a crane axle box

The faucet box is the main part of the valve mixer (its core). Thanks to this simple device, the water flow can be quickly turned on, off and adjusted. By changing the hot and cold pressure, you can easily set the desired temperature of the outlet stream. The valve head consists of a stem and seals: they are protected on top by a metal housing equipped with a threaded seat.

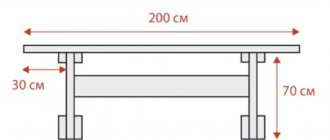

Location of the faucet axlebox in the mixer and diagram of its structure

Fault categories

First, let's list the main categories into which common problems with shut-off valves can be classified.

Let us clarify: within the framework of this article we will consider only malfunctions of screw valves. Ball ones fail very rarely, while cork ones are actually not used in private and apartment buildings.

- Water is leaking from under the valve stem.

- The faucet or mixer lever does not turn off the water.

- Water does not flow when the faucet taps are open.

- Water does not switch to shower.

Types of crane axle boxes

Currently, household faucets on the market for plumbing products are equipped with three types of faucet axle boxes:

- Worm-based.

- Ceramic.

- Ball ones.

They are distinguished primarily by the number of revolutions that must be made by the valve to open or close the water. The worm mechanism has to be rotated several times, while the ceramic and ball device closes in half a turn.

Worm

Old-style designs, so named because of the specificity of the rotary rod shaft. The outer part of the body is equipped with a thread, which allows it to be connected to the mixer. For convenience, there are also special niches for a wrench.

Worm-type crane axle box

Internal cores come in two varieties:

- With guides for a movable type shut-off valve.

- Threaded. To cut turns, the opposite direction with respect to the worm shaft is selected.

Due to the presence of a rubber insert in the devices, they are also called rubber. The operation of units of this type is simple: a rotating flywheel transmits force to a threaded gear, which moves the rod with a rubber gasket. The result is a tight fit of the valve disc to the special inner seat. This leads to blocking of water flow.

The device of a worm-type crane axle box

To restore the water supply, it is necessary to rotate the tap in the opposite direction: after a gap appears between the valve assemblies, liquid is able to flow out of the pipe. The force of pressure is directly dependent on the size of the gap from the plate to the saddle. The use of a worm gear allows you to very accurately regulate the pressure, because The rod moves very slowly when the flywheel rotates.

Worm-type valve axlebox in open (left) and closed (right) position

In addition, the advantages of worm-mounted crane axle boxes also include the following characteristics:

- Availability. There is a wide range of rubber valve heads on sale, which makes it easy to choose the right option for any mixer model.

- Easy maintenance and replacement. Repair activities, due to their simplicity, are often carried out on their own.

- Possibility of self-production of rubber inserts. Gaskets can be cut from rubber of suitable thickness.

- Inexpensive cost. The cheapest option among other analog valve heads.

There are also disadvantages:

- Rapid wear of components.

- To adjust the water flow, you have to rotate the flywheel for quite a long time.

Ceramic

These models were developed as an alternative to rubber crane axle boxes, offering superior durability, reliability and wear resistance. The ceramic valve box consists of a housing, inside of which there is a static ceramic disk with a series of holes. The rotary rod is equipped with an identical insert. When the valve is turned 90 degrees, the channels of both gaskets are combined, which opens the way for water.

Ceramic crane axle box

The accuracy of the passage of liquid exclusively through the channels intended for this purpose is achieved by the good seal of the ceramic circles. To regulate or block the flow, it is enough to carry out small manipulations of the valve. This allows you to either partially combine or completely overlap channels.

Ceramic faucet axle boxes in the mixer

Strengths of ceramic axle boxes:

- Durability. The need to repair a part occurs extremely rarely. It often happens that its service life coincides with the service life of the mixer itself.

- Control speed. Here, as in the case of a worm head, you do not need to rotate the flywheel for a long time, applying effort. To completely shut off, just turn the valve half a turn. Another thing is that the accuracy of the settings suffers, but this skill usually comes with experience.

- Easy repair and replacement. As with rubber models, this does not require any special plumbing skills.

- Quiet operation.

Weak sides:

- Increased requirements for water quality in the pipeline. The presence of sand and other impurities in the liquid negatively affects the ceramic surface: axle boxes quickly fail under such conditions. To maximize the service life of the ceramic faucet head, the water supply system is equipped with filter units to clean the water from dirt.

- Expensive . You have to pay more for a mixer with a ceramic axle than for rubber counterparts. However, due to its durability, the cost of the device will pay off over the next few years.

Valve heads can differ in the following characteristics:

- Different manufacturer (foreign or domestic models).

- The maximum possible temperature and pressure of the fluid.

- The speed of passage of the water flow.

- Number of slots on the valve stem (20 or 24).

- Dimensions. When replacing, it is recommended to bring the old axle box with you.

- Thread type: 3/8, 3/4 and 1/2 inches. The most common products are the latter type.

Ball

They have a very simple design: a regular metal ball acts as a valve blocking the flow. To completely stop the flow of water, you need to turn the valve only 1/4 turn. Ball axle boxes are mainly equipped with taps on the supply pipe: they are not used inside mixers.

Ball valve axlebox

How to remove the crane axle box

When undertaking repairs to the faucet axlebox, the water in the system must be completely turned off. After this, prepare the necessary tools: flat and Phillips screwdrivers, pliers, a set of keys.

The flywheel is dismantled by simply pulling it up. This opens access to the fixing bolt, after unscrewing which the valve can be easily removed. Sometimes it sticks to the mixer body: this problem can be eliminated by carefully tapping it with one of the keys.

After removing the valve, clean the threads and flywheel. Next, use a 17 key (or manually, depending on the type of mixer) to remove the decorative trim of the faucet. This frees up access to the crane box. To unscrew it, you will need an adjustable wrench: rotate it counterclockwise, holding the body. To clean the threads of the mixer, a cord brush is usually used.

Instructions for removing the faucet box from the mixer

You can watch the video for more details on how to remove the faucet axle from the mixer:

Further repair actions depend on the type of fault.

Replacing the valve flywheel

It should be remembered that the crane flywheel

can only be replaced with a similar one.

Its inner surface is shaped in such a way as to prevent the lock washer

.

Sometimes screw

, securing

the flywheel

, does not turn.

Then you should hit the end of the screwdriver with the blade in the screw slot 3-4 times. If the screw does not budge in this case, unscrew the head

and break

the flywheel

if it is earthenware, or cut it with a hacksaw if it is plastic.

Now the faceted end of the rod

You can place the edge on the hammer head and hit the opposite edge with another hammer.

After this, you should unscrew the screw

with pliers.

If it breaks off, you can grind off the protruding part of the screw with a file, tap the end of the screw, drill and cut a new thread

.

Wear of the crane axle box gasket

Most often, leaks in a faucet with a ceramic head are due to the fact that the silicone gasket loses its functionality. The problem can be solved by either replacing or repairing the seal. In the first case, the worn gasket is simply removed from the seating recess, replacing it with a new one (it is recommended to lubricate it with a waterproof lubricant).

Replacing the crane axle box gasket

As for repairs, after removing the faucet box from the mixer body, its missing height is increased using a thin layer of silicone. After this, the head is screwed back in.

Blitz tips

Tip 1. If the thread is soured (sticky), the latter can be treated with a chemical, for example, WD-40. After 15–30 minutes, in most cases the axle box can be unscrewed.

Tip 2. If there is no waterproof lubricant, it can be replaced with graphite.

Tip 3. Most often, faucet axles fail on cheap faucets, about the quality of which you can say: “it’s not cheap, but cheap.”

Tip 4. You should not neglect installing a mechanical cleaning filter, especially if water meters are installed, this will save nerves, time and money in the future.

DIY faucet repair

Hygienic shower for toilet - types and installation methods

Debris got between the ceramic plates

If there is sand or other foreign particles in the space between the ceramic surfaces, this will inevitably lead to a violation of the tightness of the joint. As a result, the axle box will begin to leak. To eliminate the malfunction, it is necessary to dismantle and disassemble the head. Its plates are thoroughly cleaned and lubricated with a waterproof substance. When putting the assembly back together, it is important not to confuse the top and bottom of the plates. Sometimes scratches can be found on the surface of the discs: in this case, only replacing the parts with new ones will help.

The device of a ceramic crane axle box

You can see more details on how a ceramic crane axle box is disassembled in the video:

Another option is to remove scratches and chips by grinding the ceramic base. This is done using fine abrasive powder (it is also used for grinding car valves and sharpening tools). The material consists of aluminum oxide and silicon carbide. The appropriate grit in this case is 1200.

Before starting the procedure, the powder is poured onto some glass, using machine oil as a solvent. Next, take the damaged plate and begin to rub it on the glass in a circular motion. After the scratches disappear, the circle is washed with water.

Pressure washer wear

The pressure washer (it can be propylene, fluoroplastic or caprolon) acts as a compensator for possible gaps between the ceramic discs. During the operation of the crane axlebox, this seal constantly experiences loads, leading to its gradual wear. Due to the reduction in the thickness of the pressure washer, the tightness of the bypass units is reduced: water begins to seep into the resulting gap.

To replace this part, you will need to completely disassemble the valve box, removing the retaining ring, rod and removing the plastic washer. After installing a new element, the plates need to be cleaned and lubricated. If a new washer of suitable size has not been found, the old gasket is built up by gluing electrical tape to its surface. Another option is to place a thin circle of polyethylene under the washer.

Pressure washer repair

You can see more details about repairing the crane axle box pressure washer in the video:

Repair of worm axle box

Rubber valve heads typically leak for the following reasons:

- There were problems with the thread.

- The rubber gaskets are worn out.

- Mechanical damage.

If the worm gear is heavily worn, and the body or rod of the valve box is covered with cracks, the product needs to be replaced. Water seeping through the faucet from under the shut-off device indicates the need to replace the O-ring. If the tap leaks, the rubber cuff that acts as a valve seal must be replaced.

The operating procedure is as follows:

- Removing the locking part. When disassembling the mixer, you need to proceed exactly as in the case of a ceramic axle box.

- Cleaning threaded areas and washing the element from dirt.

- Removing the worn gasket from the rod. Before this, remove the screw holding the seal. Some older models do not have this, and the gasket is held in place by a groove or hole in the surface of the rubber.

Removing the gasket from the worm axle box - Installation of the entire cuff. Before this, it is recommended to lubricate it with a waterproof compound (silicone sealant works well). It happens that it is not possible to find a new part that matches the size. In this case, they buy a wider product, and cut off the protruding parts with a sharp knife (it is advisable to chamfer the edges of the seal at an angle of 45 degrees).

Installing a new gasket on a worm gear valve

When reassembling the mixer, it is advisable to immediately replace the O-ring and lubricate the worm gear. These simple measures will delay the next repair.

You can watch the video for more information about worm-mounted valve axle boxes, as well as about replacing the gasket and cutting out a new gasket:

Replacing the valve stem

Please remember that the head housing

is also not eternal, but the thread along which

the rod thread

wears out more slowly.

Therefore, the body can withstand two or three rod

.

When changing the rod

, perform the following steps:

- first of all, you should turn off the water;

- then open the tap to check whether water is flowing or not;

- if there is no water, turn out the tap head with a wrench or an adjustable wrench;

- the flywheel on the rod can be dismountable;

- The cap must be removed from the stem, otherwise the jaws of the key will not be able to cover the edges of the head.

Slitting valves

have some tricks in repair:

- first you need to shut off the flow of water to the head with a valve; it can be located here, under the washbasin;

- after this, you should unscrew the valve head, first turning the stem out a little;

- the flywheel must then be removed;

- after separating the valve head from the body, push out the lock washer;

- then you need to press the tetrahedral end of the rod on which the flywheel is fixed;

- the rod and spindle should come out of the head housing.

Sometimes, in order to disassemble the valve head, you have to hit the end of the stem on a wooden board.

ATTENTION! Under no circumstances should you strike with the end of the rod.

on any steel object, because

the edges and first threads

will become clogged .

After disassembly into the annular grooves of the rod

you should put on new

oil seals

, removing the old worn ones.

The rod and spindle

will fit into the body more easily if you lightly lubricate the protruding parts of the new

seals

. If they are missing, you can wind a few threads under the existing ones, preferably linen.

Another option is possible - rings

and install them instead of

the old seals

.

One of the troubles is worn out rod threads

.

In this case, the flywheel

begins to rotate.

The best solution is to install a new rod

. To do this you need:

- disassemble (unscrew) the head and push out the faulty rod;

- after this, a new rod should be inserted;

- screw in the head.

Rod with spindle

They will fit into the housing more easily if you lightly

lubricate

the protruding parts of the oil seal.

rod at hand

, then you can get by with temporary measures.

For example, attach a flywheel

to the faucet body with wire.

True, it will no longer be possible to use it, but at least until the stem

with a new one

the tap

will not leak.

There are other ways to temporarily get rid of a leak. Let's say on the stock

There's still a little bit of the whole carving left.

Then you can install a gasket

on the valve stem and

the valve

will protrude more from

the stem

. You can also use wire or washers for this purpose.

Useful advice - if the valve stem

It is better not to repair it, but simply replace it with a new one.

Is it possible to replace the worm axle box in a mixer with a ceramic one?

Considering the fact that ceramic valve heads are more practical and durable, in some cases they are tried to be installed in the body of a worm mixer. When choosing a suitable replacement option, they are guided primarily by the dimensions of the seat (meaning the diameter of the lower part of the valve head).

It is also important to understand the design of the flywheel pin. Foreign-made products are equipped with notches in this area. In domestic valve boxes, a steel tetrahedron is used. Therefore, when installing an imported ceramic axlebox, the flywheel will also need to be replaced. As for matching the length, there are fewer problems: most of these products have the same dimensions. In this case, inserting a ceramic head instead of a rubber head is quite simple.