Home » Building a house

Alexander Korovaev 04/30/2020

14380 Views

The canopy over the entrance is the most important architectural element of any building. After all, it performs not only an aesthetic, but also a protective function. To make your own canopy over the porch, you can use materials that can withstand significant wind and snow loads.

Is it necessary to build a canopy over the porch?

Canopies made of polycarbonate and metal profiles

A canopy (canopy) over a porch is a structure consisting of a durable frame attached to a wall or supports, and a roofing covering. A building without a canopy looks unfinished. But still, the main purpose of such a structure is to protect the front door from rain, snow and melt water.

A canopy is needed not only to prevent moisture flowing from the roof from getting into your collar when opening and closing the door with a key. The accumulation of water in this place is extremely dangerous even during minor frosts. After all, the risk of slipping when entering without a visor is very high. It is also protection against icicles that appear during a thaw.

When it rains, without it, it will not be very convenient for you to open and close the front door with an umbrella in your hands. Plus, in extreme heat, the metal door handle will not heat up in the sun. The canopy will also help protect the entrance structure from premature fading and loss of color.

Basic requirements for canopies

Method of fastening to the wall of a building

In order for the visor to perform the required functions and be absolutely safe, when creating it you should adhere to the following rules:

- for its manufacture it is necessary to select only durable materials that are maximally resistant to wind and snow loads

- pay special attention to the strength of the frame fastening; it is attached to the wall using 6-8 strong metal anchors; when using heavy roofing materials or assembling products with a length of 2 m or more, the use of supports in the form of racks is required; support pillars are concreted to a depth of 0.8-1.5 m; further work is allowed to begin only a week after the concrete has been strengthened

- roof slopes must be at an angle of at least 20°; the best option is a tilt of 30-50°

- additional waterproofing is required in places where the canopy is connected to the wall

- to avoid the formation of ice, a rain and melt water drainage system should be provided; You can use both storage tanks and storm drains or gutters

- the length of the canopy is 60 cm wider than the front door, that is, it should retreat from it on both sides by 30 cm

- canopy width – at least 70 cm

- so that the visor does not interfere with the door opening and closing freely, it is necessary to make an indentation of 30 cm from its top

- when installing a thin, flexible roof, the load-bearing sheathing is made continuous

- since such a structure is part of the building, it must be fully consistent with its general style

It is better to build a canopy over the porch at the same time as arranging the roof of the house. You can save money by using leftover material. Plus, the roof of the building and the canopy, made in the same color shade, will look much more advantageous.

Installation options

The easiest way is to install straight awnings. Even a person who has never done this can cope with such a task. But you need to remember that there must be a slope here, and this is especially true for large terraces and canopies. There will be less precipitation in the form of rain and snow on the roof.

Gable awnings at the dacha will perfectly decorate the house, and they can be covered with tiles and slate. The reliability of such a massive roof will be ensured by support pillars.

If desired, the canopy can be made three-wheeled or rounded. It is better to take materials that are flexible and easy to install.

But the main thing is that the canopy fits harmoniously into the composition of the home and fulfills its function, protecting the door and creating convenience when entering the house.

Types of visors

Types of canopies

To make canopies over the entrance to a building, you can use a variety of types of materials: from environmentally friendly wood to translucent polycarbonate, corrugated sheets, metal or flexible tiles. The most important thing is that the structure is strong and reliable. Metal corners, pipes or thick blocks of wood are often used as a frame. When hanging lightweight polycarbonate structures, the use of aluminum profiles is allowed.

In shape they can be single-, double-, multi-sloped, domed, arched, semicircular (awnings). Visors can have a complex, including multi-level shape.

Depending on the materials of manufacture and the chosen style, canopies over the porch can be made in the form of:

- lightweight structures attached only to the wall of the building

- canopies with additional reinforcement in the form of metal supports or wooden beams

Tree

Wooden canopy attached only to the wall of the building

- Working with this environmentally friendly material is not difficult - it is light in weight and can be easily processed, and when impregnated with special compounds it can last at least 40-50 years.

- Moreover, wood can be used not only to make a frame, but also a roof. For this, a board is used, as well as various types of wooden tiles: shingles, shingles, ploughshares.

- However, it makes sense to make a canopy over the porch (photo) from a similar material if the building is decorated in the same style. In other cases, it is better to replace wood with a more practical and durable material.

Slate

Colored slate roof

- Inexpensive asbestos-cement slate, which is not afraid of moisture, rotting and corrosion, is an excellent roofing material that can serve faithfully for many decades. But still, due to its large weight, it is not worth using it to cover the visor. After all, such a roof will require additional supports.

- Attaching the frame only to the wall of the house will not be enough. You will need to install strong supports. Otherwise, if this material falls down under its own weight one day, injury will be inevitable.

- It is better to replace traditional slate with Euro slate made of cellulose impregnated with bitumen, which has less weight, or slate made of plastic. Since both of these materials are painted in bright colors, a structure made from them will look more attractive.

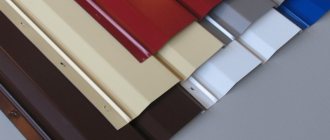

Corrugated sheeting and metal tiles

Canopy made of metal tiles

- To increase rigidity, these types of roofing are made from specially shaped sheets in the form of waves or small-height trapezoids. Construction stores sell corrugated sheets and metal tiles in different colors.

- Steel sheets are not afraid of fire, heat, frost and have minimal weight. However, their windage (the ability to resist gusts of wind) leaves much to be desired. Therefore, if you do not want the canopy to be torn off during strong gusts of wind, its shape must be carefully considered.

- Another significant disadvantage of such roofing materials is low sound insulation. To prevent the sounds of rain, amplified by a metal surface, from getting on your nerves, take care of the soundproofing substrate.

Polycarbonate

Arched polycarbonate canopy

- Using this flexible material, you can create any kind, including arched structures or structures of arbitrary shapes. Another advantage is its low weight - the mass of 1 square meter. m of polycarbonate is only 1.5 kg. The strength of thin, lightweight sheets is achieved through layers stitched together by numerous stiffening ribs. Upon closer inspection, this design resembles a honeycomb with many cells.

- Polycarbonate is ideally combined with many modern finishing materials: facing bricks, metal, vinyl siding, clinker tiles, plaster. The disadvantages of the material include high windage and low ultraviolet resistance.

- Teach that its strength depends on the thickness of the sheets. To create canopies you will need polycarbonate with a thickness of 6-8 mm. Thin sheets usually used to create greenhouses will not work.

Soft tiles

Soft tile canopy

- A material based on fiberglass and bitumen, covered with a coating of fine stone chips. Very attractive in appearance, easy to process, light in weight and available in a wide range of colors.

- Using small fragments of tiles, you can make a canopy of any, even the most complex, unusual shapes. Perhaps it has only one drawback - its high cost.

To make the product last longer, when making the frame, be sure to treat the wood with anti-rot agents, and the metal with anti-corrosion agents.

How to choose material

By choosing the right material, you can easily create a suitable design for your home. When choosing, it is worth considering the design features of the building. The most commonly used materials are:

- metal tiles;

- slate;

- profiled sheet

Slate is suitable for making a canopy for both wooden and brick houses. Metal tiles are more often used when creating a canopy for a brick building.

If the structure has a complex shape, it is necessary to use roofing materials such as flexible tiles and polycarbonate.

Making a polycarbonate visor in stages

A canopy over a porch of the simplest form can be mounted even without much experience. If you know how and love to work with wood or metal, then you will be able to handle even the most complex products.

Product drawing

It is hardly possible to do without this stage of work. Even if you have some experience, a pre-drawn diagram indicating the dimensions of the product will allow you to avoid annoying mistakes. You can develop visor sketches yourself or use ready-made ones, of which there are plenty on the Internet.

Shape of polycarbonate products

After choosing the shape of the product, you need to arm yourself with a tape measure and measure the width of the front door. Now you need to add 60 cm to this size - you will get the width of the future visor. The height is chosen arbitrarily - you should focus mainly on the architectural features of the building itself. Just remember that to ensure normal water flow and snow removal, the canopy is made with a slope of at least 20°.

When designing a canopy over a polycarbonate porch, it is worth taking into account the standard width of polycarbonate sheets. It is equal to 210 cm. The width of such sheets can be 300, 600 or even 120 cm.

It is necessary to calculate not only the length, width of the product, the dimensions of the struts, but also the number of jumpers. In order for the visor to fit tightly to the frame, a distance of 30 cm must be left between them.

Frame assembly

The metal frame is assembled by welding or fasteners. The metal is pre-cleaned of rust and dirt. After assembly is completed, it is primed and painted.

When making a frame for a gable canopy over the porch of a house, parts located at right angles are secured in a clamp or vice before welding. It is not worth making a seam in one pass. It is better to make several spot tacks, check the correct location of the parts, align them if necessary, and only then finish welding.

To increase the rigidity of the structure, it is necessary to weld several transverse strips . Their number depends on the size of the visor. The last to be attached are the crossbars under the sheathing.

Drawing of a simple arched canopy

When making a canopy of an arched or other complex shape, metal pipes are bent with a pipe bender. You can also bend metal by making cuts every 30-40 cm along the entire length of the pipe. After it is bent, such slots are again connected by welding. Subsequently, they are cleaned of scale with a grinder, primed and painted. For larger canopies, stops and connecting beams are used. The number of stiffeners directly depends on the size of the visor.

To attach a small canopy to a wall, 4 anchors are enough. To do this, holes are pre-drilled in the corners of the metal frame, the diameter of which is equal to the diameter of the anchors, and appropriate markings are made on the wall.

For large canopies, racks are prepared and welded to the frame. They are deepened into the ground by 0.5 m and filled with concrete mortar. Part of the pipes going into the ground is coated with bitumen mastic to protect against rust.

Products of complex shapes in combination with forged metal look very attractive. They are quite difficult to manufacture. It is better to buy such a canopy over a polycarbonate porch ready-made. You can attach it to the wall yourself.

To illuminate the entrance to the building, you can use spotlights mounted in the cladding of the structure.

Wall mounting methods

There are several such methods, you can use a visor:

- weld to the fittings built into the wall; it is laid in the masonry at the stage of construction of the building

- secure to U-shaped brackets; This method is only permissible for installing light awnings

- fasten with anchor bolts (the most common method)

Polycarbonate fastening

Schematic drawing of a gable polycarbonate canopy

Sheets of this material are connected to each other using special profiles . The polycarbonate is attached to the frame with self-tapping screws equipped with thermal washers. To prevent the polycarbonate from cracking during thermal expansion due to temperature changes, you should not screw the screws too tightly.

To protect against raindrops and snow, the ends are also covered with a profile. To ensure a tight fit of the material, it is necessary to provide a silicone or rubber layer between the frame and the roof.

To prevent moisture from entering, the places where the canopy is attached to the wall should be sealed . To do this, use special mastics, roofing silicone or other materials with similar properties. You can also use rubber or pieces of flexible roofing material.

At the junction of the canopy and the porch, it is necessary to attach a fender strip , otherwise water will flow down the wall. This method is used for installing any type of roof, including polycarbonate.

To create arched structures, you need to buy polycarbonate with straight honeycombs. It is not recommended to bend material with honeycombs in the form of triangles.

Roof type

The porch roof consists of a frame and covering. Remember one rule - a frame made of the same materials as the supports for the canopy will be durable. A modern canopy can combine various materials. There are several universal types of roofs, differing in their characteristics:

- a pitched roof can be small in size, the background wall rests on the wall of the building, moves forward, ensuring precipitation drains.

- The gable and arched structure has slopes on both sides.

- the third type of roof is made in the form of a tent. It is practical as it protects the porch from moisture from all sides.

- The gable roof has 3 sides, this provides reliable protection from precipitation.

If you have decided on the type of roof, you can purchase materials and master the work algorithm.

Canopy made of corrugated sheets

How to make a canopy over a porch from profiled metal sheets? The manufacturing process of such a structure is similar to the previous one. Since corrugated sheeting has more weight than polycarbonate, the use of an aluminum profile to assemble the frame in this case is unacceptable. It is assembled only from a metal corner, pipes or wooden blocks.

Canopy made of corrugated sheets

Since metal sheets conduct sounds well, the visor must be soundproofed. Otherwise, the sound of drops falling on a metal surface will constantly get on your nerves. Polystyrene foam with low soundproofing properties should not be purchased. It is better to use mineral wool.

Profiled sheets should have an average thickness and wave height of 20-60 mm. To fasten one sheet you will need 11-12 screws with a wide head, always galvanized, equipped with a plastic or rubber gasket.

To install the barrier strip, which serves as protection against moisture, the wall is pre-drilled to a depth of 5-7 mm. The edge of the plank is inserted into the resulting recess and screwed to the wall. Its second edge should lie on the roof. The joint is sealed with mastic and laid with a rubber seal.

Wooden canopy

The simplest wooden frame

You will need two types of bars: with a cross-section of 75x75 mm for making supports and rafters with a cross-section of 15x15 mm for arranging the sheathing. To protect against premature rotting, they are pre-treated with bitumen.

You will also need a 25 mm board to create a roof or wooden tiles. Anchor bolts are used to fasten the product to the wall, and staples and screws are used to assemble the sheathing. The roof is mounted on slate nails or self-tapping screws.

Making a canopy with support posts

To make a canopy over a wooden porch:

- A wooden block is attached above the door using metal anchors. The distance between fasteners is 40-50 cm.

- The horizontal position of the bar is verified with a building level. For fastening the rafters, grooves are pre-prepared in it.

- Side, vertically located bars are also mounted on the anchor bolts.

- The struts, which serve as a stop for the visor, and a crossbar located horizontally are screwed to the block attached to the wall using metal brackets.

- The front beam of the sheathing is mounted to the horizontally running crossbar. The rear beam is attached to the ends of the vertically extending beams.

- To install the sheathing, the ends of the slats are cut at the desired angle and secured with self-tapping screws. You can, on the contrary, not cut off the slats, but cut grooves for them in the rafters.

- Roofing material begins to be laid from the free edge

Installation Tips

When installing a canopy on the front door with your own hands, difficulties often arise with the choice of material and work. Here are some helpful tips to help you get it right:

- The most reliable fastener used to install brackets is an anchor. Metal spacers are suitable for concrete and brick walls, chemical spacers are suitable for aerated concrete. The canopy is attached to a wooden wall with nails of at least 15 cm.

- If soft tiles are used for the roof of a door canopy, then the sheathing should be solid, made of boards 2 cm thick. For metal or polycarbonate profiles, a distance of about 50 cm between its elements is allowed, since these materials also do not bend under the weight of snow. Arched roofs are limited to the connection of trusses and beams.

- When installing polycarbonate, the roof must have technological gaps between the individual parts (4-5 mm). To protect them from the penetration of precipitation, they are covered with a special profile. The edges of cellular polycarbonate must be protected with edge elements. The film should be removed from the sheets only after installation.

When making a forged frame with your own hands, you need to draw a pattern in the shape of a right triangle on the brackets. Decorative elements are arranged so that the load axis on the lever passes through the maximum number of interconnected parts. To support it on the wall, it is better to make a corner from a corrugated pipe onto which to weld the pattern elements.

The main mistakes made when making a canopy

Canopy over the garage entrance

If you have never encountered making a canopy over a porch, it would be a good idea to listen to the advice of experts.

The most common mistakes made when assembling such structures are:

- insufficient width and length of the structure: a small canopy will not perform its main function - protecting the front door from wind, rain, snow

- low strength: the canopy must withstand not only its own weight, but also the mass of snow; otherwise the structure may sag and then collapse

- lack of anti-corrosion and anti-rot treatment: no matter how decorative such a structure is, it will not last long; In the future, for preventive purposes, protective treatment should be carried out once a year.

- small number of fasteners: it is better not to skimp on fasteners even when building small structures to avoid their collapse

How much do ready-made visors cost?

Complex shaped design with metal finishing

If you are not confident in your own abilities, you can buy a canopy over the porch already assembled. There are many companies involved in their production in each region.

The cost of the product depends on the type and complexity of the design. The simplest polycarbonate canopy with a bent forged frame will cost 7-8 thousand rubles. Visors of complex shape cost from 25 to 50 thousand rubles. Work on their installation is paid separately.

When choosing a canopy, you should choose more durable products with a monolithic frame assembled by welding. Modular products will have to be assembled yourself.

Anyone who knows how and loves to work with metal should watch a video on how to make a forged visor:

VIDEO: How to make a canopy over the front door with your own hands

Canopy over the porch: what types are there, design, drawings, step-by-step instructions for making it yourself (80 Photos & Videos) + Reviews

Beautiful examples for inspiration

The spectacular appearance of the canopy largely depends on the base: welded or forged structures covered with tinted glass or polycarbonate are an ideal option that will fit into any style and decorate the area.

The second option is to play with shapes or colors. For example, a visor in the shape of a wave or a wonderful shell is a wonderful accent to the exterior.

As for color, play with contrast. A dark canopy looks better on a light wall; on a dark wall, on the contrary, a light or colored one looks better.

When designing a small entrance design, try to combine aesthetics and functionality: then the appearance of the porch will delight you for many years to come.