Brick finishing will always be relevant. This method of cladding facades allows you to give them a solid and respectable appearance. A brick building is a reliable and solid structure, most desirable for any homeowner. In addition, “brick-like” finishing materials make it possible to disguise the unsightliness of the façade walls and protect it from the adverse effects of the environment.

Brick finish

Imitation of brickwork

Specifications

Metal brick siding in some positions has the same characteristics as other types of metal siding, but some of its properties have significant differences, in particular, the dimensions of the panels are much more convenient for working alone than other types of siding.

Main qualities:

- Panel width - up to 50 cm;

- Panel length - up to 1.3 m;

- Operating temperature range from -50° to +60°;

- Durability (calculated) - 60 cycles;

- Profile height - 12-14 mm;

- Sheet thickness - 0.8-1.2 mm.

Siding-clad house: reliability and aesthetics

Any home should not only be cozy and aesthetically pleasing inside, but also make a pleasant impression on the outside. And here you can’t do without finishing. Plastering and painting walls give a good result, but such a coating has a rather limited period of maintaining aesthetics. A good alternative to the above method of decorating the facades of buildings is siding.

Even a dilapidated old building can be transformed into a modern architectural structure with the help of siding.

Decorating houses with brick, stone, and wood siding is becoming increasingly popular. And this is no coincidence, since the panels seriously compete with natural materials used for cladding buildings in terms of quality and installation process. With siding, everything is much simpler, since you do not need to have the professional skills of a mason to create an even seam or prepare a solution of the required consistency and optimal composition.

In terms of external indicators, siding is not only not inferior to brick or stone, but is also significantly superior to the material (especially brick) in terms of maintaining aesthetics: for example, it does not show a whitish coating, like on red brick, or small traces of chipping, like on white silicate.

And the price of brick siding is lower than the cost of stone material. And the ability to install the panels yourself makes the cladding process doubly more cost-effective. The air gap that appears between the wall of the house and the panels provides ventilation to the outside of the building and also helps to retain heat in the rooms.

It is most often possible to determine that a house is sheathed with siding and not bricked only after careful examination. Therefore, there is no reason to fear that the appearance of the house will be “reduced” when facing with panels.

It is very difficult to determine that a house is covered with siding and not covered with brick.

Types of metal siding for brick

Metal siding for brick, first of all, has several varieties according to the type of material:

- Steel. The most durable type of panels has proven to work well as a base covering;

- Aluminum. The most expensive type of all. It is light in weight, which makes it suitable for use on large surfaces or entire walls as a base covering;

- Metal-plastic. A material that successfully combines a low price with a high-quality imitation of texture.

Among the samples of metal siding for brick, there are various relief options:

- Smooth;

- Relief imitating masonry;

- Imitation of facing brick (clinker), with a smooth surface;

- Imitation of ordinary brick with a rough surface.

There are different color solutions to match the natural colors of certain brands of brick.

The surface turns out to be quite realistic; it is not easy to distinguish it from natural material even at close range.

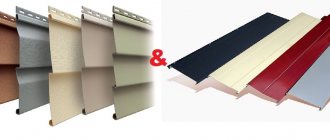

Metal siding is divided into the following types:

- Under the tree;

- Under the beam;

- Ship plank;

- Under a stone;

- Under a log.

Some manufacturers supply models with imitation of aged masonry with an abundance of cracks, small chips, etc.

This surface replicates the appearance of ancient buildings; lovers of vintage styles will love it.

In addition, various methods are widely used to imitate different degrees of brick firing - from even to burnt, with black spots. Lovers of naturalness in cladding will appreciate the quality of the surface, which creates the effect of completely natural materials.

Brick facing panels: features, prices

The desire for naturalness most of all explains the popularity of using brick siding. A brick house is perceived as a solid structure with straight lines of window openings, corners, balconies and other architectural elements.

There are a large number of varieties of brick siding on the market:

- classic red brick masonry;

- soft pastel options, panels with pink and even peach shades;

- gray and brown “brick” for connoisseurs of visually heavy buildings;

- panels with combined “masonry”.

Brick siding for the exterior of a home can be made from vinyl, metal, and fiber cement. Depending on the material and manufacturer, panel sizes vary. It is possible to highlight only the general dimensional indicators of the thickness of products. Vinyl panels have a thickness of 0.7-1.3 mm, fiber cement panels - 6-35 mm; metal – 0.4-0.6 mm.

To decorate your home, you can choose inexpensive domestically produced panels, for example, Keramite. Outwardly, they resemble ceramic bricks. Sold in packs of 10, in the following sizes:

The price of brick siding is much lower than the cost of stone material.

- height (useful) – 45 cm;

- width (useful) – 105 cm;

- area (usable) – 0.427 m².

Among the imported options, it is worth highlighting the panels of the Canadian company Novik:

- height (useful) – 47 cm;

- width (usable) – 122 cm;

- area (usable) – 0.516 sq. m.

The price of one domestically produced brick siding panel is 300-400 rubles. Imported products cost an average of 550-750 rubles per piece.

Materials used in the production of siding

Various polymer and natural materials are used to produce panels. The characteristics of the building sheet depend on the combination of raw materials from which the blocks are made.

- PVC boards (80%) are used for brick-like vinyl siding. The remaining 20%? auxiliary and binding materials. Suitable for wood and brick. The service life is 25–50 years. A very popular material.

- Aluminum and galvanized steel sheets To protect against corrosion they are treated with special compounds. Metal is used for finishing industrial and warehouse premises.

- cement is actively used in the production of siding. The raw material is not used in its pure form, but mixed with cellulose. This combination reduces the weight of natural raw materials, imparts strength, durability, and resistance to moisture, mold, and fungi. The material retains heat well and is a sound insulator.

- Polypropylene is a strong and durable synthetic material used for the production of basement siding.

Some facade blocks are covered on the back side with additional materials that help retain heat in the room and provide sound insulation.

The cost of blocks with insulation is not much different from simple ones, but they help to significantly save on heating. These are sandwich panels that are slightly thicker. To install this type of slab, additional wall insulation is not required.

Features of choice

The choice of “brick” or “stone” siding is based on an analysis of the main criteria listed below.

- Impact on the load-bearing structures of the structure. Based on this parameter, siding can be divided into two categories. Lightweight - metal and vinyl. Does not have a significant impact on the supporting structures of the building. It is recommended to use it if it is necessary to finish large areas of the façade of a building. Heavy - fiber cement siding, usually used for finishing small buildings made of concrete and brick. And also for cladding foundations and basement floors of any structures.

- Design combined with cost. Uniform color is a budget siding option. As a rule, it imitates brick. At the same time, the image of masonry joints, as well as the texture of the material, is applied to the surface without any relief. With highlighted seams - mid-price range. The joints of the “masonry elements” are embossed and highlighted in a more intense color. Relief cladding is the most expensive. Typically made from thick-walled, high-quality acrylic or fiber cement. Completely imitates the texture of natural materials. Additionally, it is painted in several colors.

Metal and wooden lathing for fastening siding are very similar in appearance, but are very different in their load-bearing capabilities

Important! Vinyl siding has one more, important, criterion for selection. It is decorated.

Decoration can be done in several ways:

- Application to the surface - such a decorative coating can be easily damaged, after which the finishing element needs to be replaced;

- Bulk coloring - pigments are added to raw materials during the production process and the color of the siding is the same throughout its entire thickness.

Advantages and disadvantages of use

Each type of panel imitating brick has its pros and cons. The significant advantages of siding compared to brick are:

- low weight - polymers and metal are several times lighter than ordinary brick, this significantly reduces the load on the walls;

- accessibility - sheets made from synthetic raw materials are much cheaper;

- ease of installation - siding is mounted using special locks;

- easy repair - if the plate is damaged, it can be easily replaced with a new one.

The positive qualities include the fact that siding is not inferior to natural material in strength, and some types, for example, metal, are superior to it. It is durable and moisture resistant. Builders also consider ease of maintenance to be an advantage of the panels.

Important! When buying brick façade siding, you should correctly calculate the amount of material and purchase the product from one batch. If you have to purchase missing sheets, they may differ from the previous ones in shade.

Installation nuances

Installation of brick siding differs from the technology of installing conventional facade siding in other panel sizes. This does not complicate the work, it just requires a slightly different approach.

At the same time, the need to use H-planks disappears, since the longitudinal joining is incorporated into the form of the panels at the structural level and does not require additional elements .

Installation procedure:

- The beginning of work is the inspection and elimination of wall surface defects.

- Installation of sheathing. The load-bearing layer is always vertical; if you plan to insulate the walls, then the first layer is horizontal.

- Installation of corner profiles, starting strips, lining of window openings.

- Installation of siding panels.

The screws are not screwed in tightly; they should be loosened by 1.5-2 turns.

Installation photo:

Types of brick siding

There are several types of siding that look approximately the same in appearance and differ from each other only in the material from which the base is made:

Vinyl

There are many reasons for the popularity of the material:

- is light in weight - finishing with siding does not weigh down the building;

- cheap;

- durable;

- does not fade in the sun;

- easy to install;

- resistant to mold, fungi, rodents;

- visually completely imitates brick.

Vinyl panels have a porous structure and retain heat well.

The disadvantages of builders include the relatively low strength of the material. In terms of resistance to mechanical damage, it is inferior to other types of siding.

Metal

One of the types of finishes that are most resistant to mechanical damage is brick-like metal siding. The advantages of this material also include durability, a large selection of colors, and availability.

Flaws:

- in comparison with vinyl, it weighs more (but lighter than natural brick);

- after mechanical damage, the sheets are practically unsuitable for restoration;

- moisture resistance requires special anti-corrosion treatment;

- installed on a special frame.

Fiber cement siding

The mixture of cement and cellulose resulted in increased strength of the building material. The large weight and high cost of the panels are considered to be significant disadvantages, which is why they are used mainly for basement finishing.

Important! To install cement siding, reinforcement of the foundation is required, since the load on the walls and foundation after lining with such material increases significantly.

Basement siding

The blocks are installed in the basement of buildings. Special material (polypropylene) gives it increased strength.

The industry offers a large selection of basement siding with imitation brick.

This is a complete reproduction of brickwork or three-dimensional panels that resemble masonry only conditionally. The color range of brick panels is close to natural - various shades of brown, white, as well as gray and black.

Leading manufacturers and characteristics of their products

There are many domestic and foreign manufacturers of siding that imitates stone or brick. Typically these ventures are joint ventures. Their products are not inferior in quality to European ones. The cost of domestic products may be 15-20% lower.

Nailite International renamed Exteria Building Products (USA) in 2009

It produces vinyl panels of large format 0.47 × 1.13 m. The main differences between the products are: coloring in the mass, expressive relief of the seams and front surface. The most popular collections in Russia include the following:

- Stacked Stone - natural stone;

- Hand-Laid Brick - brickwork;

- Hand-Cut Stone - imitates Roman masonry.

Collection "Stacked Stone Premium"

ROYAL EUROPA

A Polish-Canadian company producing vinyl siding used for finishing walls and basements. It is a subsidiary of Royal Building Products, the largest manufacturer of polyvinyl chloride building materials. Available in two versions: “stone-like” – 0.51×1.265 m, “brick-like” – 0.395×1.14 m. The color range is limited to white and red shades. The main difference is the color scheme of the masonry joints.

Decorating the facade of a house using color options from the “Stone” collection

KMEW (Japan)

The KMEW company is one of the leaders in the Asian market for the production of fiber cement panels. The finishing material is coated with several layers of protective substances, after which a protective ceramic coating is applied that imitates the texture of natural materials. Positioned as an elite finishing material with unique performance characteristics, durability and strength. The company offers more than 30 collections of stone and brick siding with different textures:

- rubble;

- Roman masonry;

- polylithic;

- noodles;

- polygonal;

- torn stone;

- wild masonry, etc.

Each of the collections has a wide range of colors.

Finishing the facade with fiber cement boards KMEW collection “NH4713”

Konoshima Chemical Co., Ltd (Japan)

The company produces façade and plinth panels made of fiber cement that imitate stone and brick. The main difference of this product is the use of nanoceramic spraying, which gives the finishing coating additional resistance to abrasion, scratches and other mechanical damage. Siding produced by Konoshima has improved sound insulation characteristics.

Internal structure of siding elements produced by Konoshima

Wandstein (Russian-German enterprise)

Produces façade and plinth panels from PVC. The products are distinguished by high quality and dimensional accuracy. Thanks to special additives, the coefficient of linear thermal expansion is significantly reduced (ZugFest technology). Multiple dyeing technology and high-quality BRILLUX dyes are used, which guarantees rich color and prevents fading in the sun.

Finishing the facade of a building using Wandstein basement and facade siding

Alta-Plastic

It produces construction and finishing materials from PVC, including basement and facade siding. The most popular collections are:

- Granite - imitates large-format stone blocks. Has a natural color and texture;

- Rubble stone - has a characteristic rounded shape of relief elements;

- Bassoon - the design is designed to resemble stone blocks with an aged texture;

- Canyon - imitates layered stone masonry with a relief texture.

Facade panels from the “Bassoon” collection

How to choose the right siding?

The choice of material is determined, first of all, by the tasks assigned to it. To finish the base, you should choose the thickest samples of material that ensure the strength and reliability of the coating of the lower part of the house.

If you plan to completely finish the entire wall, or part of it over a fairly large area, the best solution would be to use aluminum panels, since they are lighter and will not create unnecessary load on the walls.

In addition, they are more convenient to use and are easier to lift to the installation point.

The combination of panels of two or more colors, forming a certain ornament or contrasting transition, looks very aesthetically pleasing. Such wall decoration options are also common on natural brickwork, so using different tones will help enhance the effect of the imitation.

Types of siding by material

Finishing the facade with siding of a private house or country cottage requires careful attention to the choice of material. The abundance of offers on the construction market complicates the task, so it is necessary to study all the varieties and features of facade slabs.

All types of siding are presented in various color variations and can have different sizes. The most popular are cement, metal and polymer varieties.

Vinyl

Vinyl

Plastic siding made from PVC is characterized by color fastness and reasonable price. It is very easy for them to cover the outside of a house. It looks as natural as possible and such brick siding is almost impossible to distinguish from natural material. At the same time, it is fragile, especially in the cold season, so you should be careful when using it and avoid mechanical stress.

Manufacturers also produce thicker and more durable polypropylene brick siding. It is mainly used for finishing the basement, but complete exterior finishing of the house is also possible using this option.

Also very popular are innovative sandwich panels, which are a multi-layer insulated structure, which eliminates the need for additional thermal insulation and significantly reduces the time for cladding.

Metal

Metal

Brick panels made of metal have increased strength. The variety of metal facade materials is very large, which allows you to choose a color that perfectly harmonizes with other elements of the building: white, gray, shades of burnt or clinker brick.

A special feature of iron siding is its high weight, so a special frame is required that can withstand the current loads.

In addition, the metal material is susceptible to corrosion, so you should find out in advance about the availability of a special protective coating.

Despite the higher price, metal brick panels are an excellent option for exterior decoration, since they are durable, reliable, strong and retain their original appearance for a long time even when influenced by negative factors.

Cement

Fiber cement

Fiber cement brick siding belongs to the premium category and has the highest strength, frost and moisture resistance.

In addition, it belongs to a low flammability class, which makes it possible to use it for cladding houses where high fire safety requirements are imposed.

This material perfectly tolerates any type of external influences and does not lose its characteristics.

The use of fiber cement siding allows you to give any building a presentable appearance.

Preparing the sheathing

To install the panels, a support system is required, since the material cannot be attached directly to the wall. Firstly, it is necessary to provide a ventilation gap, and secondly, the presence of insulation on the walls will not allow installing siding directly on their surface.

Wooden or metal strips are used to create a supporting system that provides ventilation and can hold the material.

Requirements for them:

- Straight, without curvature, lines;

- The thickness of the planks must correspond to the thickness of the insulation (this especially applies to wooden parts);

- The pitch of the planks (the distance between the rows) should ensure the strength and reliability of the installation of the panels.

When choosing a material, you should take into account all the features and properties of wood and metal.

Experts recommend using metal guides for gypsum boards; they have a straight surface, are securely attached to the walls and can be reconfigured many times (if errors are detected), which is much more difficult for wooden planks.

At the same time, the thermal conductivity of the metal should be taken into account and it should be insulated so as not to form cold bridges with the inevitable appearance of condensation.

Installation of the load-bearing sheathing is carried out in the direction perpendicular to the location of the panels. If a double layer is used - the main one and the counter-lattice, then the first is installed in the direction of installation of the panels, then the counter-lattice is installed in a perpendicular orientation.

Features of installation work

Installing siding requires some skill. However, if you strictly follow the instructions provided by the manufacturer, it is quite possible to do it yourself. No specialized or expensive tools are required for installation. You definitely need: a screwdriver, a level, and for metal siding - metal scissors. The installation process includes the following steps:

- Preparing the base surface. As a rule, siding is used in ventilated facades to protect thermal insulation. Therefore, the surface of the walls is predominantly flat. If significant excavation is necessary, the defects are filled with repair mortar.

- Installation of sheathing. The material used is wooden blocks or profiles for drywall. The load-bearing elements are installed vertically, with a step corresponding to the dimensions of the finishing panels.

- Installation of insulation, water and wind insulation;

- Installation of counter-lattice, which consists of pressure strips 1.5-2 cm thick, installed on top of the supporting beam to fix the waterproofing membrane.

- Installation of the starting bar. The quality of the entire finish depends on how correctly the starting level is set. Therefore, its installation should be approached with particular care.

- Decoration of window openings - corner strips of window frames are installed.

- Installation of panels. Fastening the panel starts from the corner of the wall. The panels of the first row are cut at right angles and tucked under the corner profiles. The first panel of the next row is cut in half so that the siding elements are installed with offset vertical seams.

Related article:

Insulation for the walls of the house outside under the siding. How to choose high-quality insulation and what types exist? Read more in a separate publication on our portal.

Installation diagram of siding panels

Important! Regardless of what material the panels are made of, you cannot tighten the screws all the way, and you cannot install siding elements right next to each other. They must have a certain mobility and a small temperature gap.

Related article:

Do-it-yourself siding installation : instructions for dummies with photos, advantages of using panels and their varieties, tips and tricks - in our publication.

Calculator for calculating the quantity and cost of siding per house

Video: installation of facade panels

How is the fastening done?

- Siding is fastened from bottom to top. The lower part of the panel has a lock - a longitudinal profile designed to attach and secure the lower edge either to the starting strip or to the bottom row panel.

- The upper edge is equipped with a nail strip - a flat strip with a row of oblong holes into which self-tapping screws are screwed. The sides of the panels correspond to each other or to special corner additional elements, also designed in the form of brickwork.

- In the set, the entire surface completely replicates the appearance of a brick wall; joints and joints are completely invisible. If you need to use panels of several colors, no problems arise, since the material is completely interchangeable and allows you to combine several color options for greater expressiveness.

Installation features

Installation of panels for the facade can be done using two methods. This is installation with glue and on the lathing. The panels themselves are sometimes additionally connected to each other using special fasteners, similar to a puzzle.

How to install façade panels correctly

You can use the adhesive method only if the walls of the house are perfectly smooth, without serious defects. Otherwise, the material simply will not stick to the wall surface. Special adhesives or solutions are used as adhesive components.

Installation on lathing is used most often, since there are almost no perfectly smooth walls in houses. In this case, the sheathing itself is first mounted on top of the walls, and then the panels are fixed onto it. Between them and the wall there remains free space, which allows you to lay a fairly impressive layer of insulation.

On a note! There is also a hinged option for installing panels, when brackets and profiles are attached to the wall using anchors, and slabs (thermal plates) are mounted on top of them. Only in this case there is free space between the wall and the panels for air circulation.

The nuances of installing siding on corners and window openings

The corners are decorated with appropriate additional elements - corner strips, which have an appropriate profile for attaching panels and are made in the same manner as the main panels.

The installation of corner strips is carried out before the installation of the main elements, simultaneously with the design of window and door openings. The panels are inserted into a special longitudinal socket, which is equipped with corner strips.

- When preparing the panel for installation in a corner profile, it is necessary to take into account the temperature gap, designed to compensate for the expansion of the material from heating by the sun's rays. Metal panels are less susceptible to such expansion, but, nevertheless, tight installation is unacceptable; it is necessary to provide a length margin of about 5 mm.

- Window openings are decorated in several ways, depending on how deep the window blocks are recessed into the wall. If the openings are shallow, then a regular additional element is used - a platband.

- For deeper openings, you can use a J-bar (at a depth of up to 20 cm), or install a set of panels cut to length, one side of which is connected to the wall plane using a corner strip, and the other is connected to the window frame through a finishing strip. This option is used for slope depths greater than 20 cm.

Fiber cement facade panels

Fiber cement panels

The most reliable materials for cladding facades are cement and stone. They are traditionally used for external work, as they have maximum resistance to environmental influences. The use of cement involves a number of labor-intensive and “wet” processes. Therefore, people have always looked for ways to minimize the hassle of plastering the facade.

The Japanese were the first to find a way out. They have developed a way to produce cement-based panels that are not only strong and durable, but also aesthetically pleasing. These are fiber cement products. They contain components that provide relative flexibility of the material. Therefore, fiber cement facade panels have sufficient bending and compressive strength.

Japanese facade panels

The production technology is based on a conveyor process. Products sequentially go through several stages:

- preparing the mixture;

- molding;

- drying;

- applying finishing and protective coatings.

The special characteristics of fiber cement panels are provided by the cellulose they contain. This component gives the material moisture resistance and strength. In production, they are guided by two types of standards: the domestic GOST 8747-88 and the European one accepted in the international classification: DIN EN 12467.

Fiber cement panels

Prices for popular finishing fiber cement panels

Fiber cement panels

Characteristics of fiber cement products

| Linear deformation | Density | Frost resistance | Flexural strength | Flammability class | Water absorption |

| Within 2% | 1.5 kg/m3 | At least 10 freeze-thaw cycles | 21.5 MPa | NG (non-flammable material) | Within 7-20% |

Schematic diagram of the structure of a fiber cement facade panel

Scheme of the structure of a fiber cement panel

Features of installation of fiber cement facade panels

There are two possible installation methods.

- Directly on the walls.

- On the frame (sheathing).

Panels can be mounted without lathing

The choice of installation technology depends on how smooth and strong the facade walls are. For finishing houses made of foam and gas blocks, only the second method can be used, despite the fact that the walls of such buildings are even and relatively smooth. The fact is that these porous materials actively absorb moisture. Therefore, the outer layer of the blocks may be loose. For this reason, reinforcement is necessary: lathing.

Wall made of aerated concrete blocks

However, the frame acts not only as a foundation that provides strength. It is necessary for the installation of a ventilated façade required for foam and aerated concrete. With the help of a ventilation gap between the wall and the facing layer, moisture coming from both inside the house and from the external environment is removed.

Lathing for installation of ventilation façade

For frame houses, including those built from sandwich panels, it is possible to mount directly to the walls. As a rule, the façade cladding of the frames is 9-12 mm OSB, a board that is sufficiently protected from moisture. When choosing this installation method, you should also take into account the fact that the panels will not completely adhere to the wall. In any case, there will be a minimum gap sufficient for steam to escape. Therefore, you should not be afraid of the occurrence of a thermal effect.

OSB boards, facade

Prices for OSB (oriented strand boards)

OSB (oriented strand board)

Rules for installing fiber cement panels

Fiber cement siding - installation diagram

To construct the frame, you can choose the most convenient material in this case: metal profiles or wooden blocks. Brick panels are used not only for cladding walls, but also for plinths. Therefore, installation of the sheathing can be carried out both from the beginning of the wall and from the blind area.

Metal profiles

The design of a ventilated facade requires the presence of upper and lower openings for moisture removal. Therefore, there is no need to install additional finishing profiles under the cornice and at the base of the facade. When performing work, the architectural features of the building and the presence (absence) of a ventilation utility network are taken into account.

Before you begin installing the panels, it is recommended that you familiarize yourself with the list of rules that must be followed. This will make it possible to complete the façade cladding in full accordance with the technology for installing fiber cement panels.

- It is not permissible to install the panel close to the base or starting strip. Otherwise, moisture will accumulate in these areas, which can lead to the formation of mold or mildew.

- It is necessary to exclude the possibility of gaps appearing when joining two panels. Moisture can penetrate into the cracks, which will lead to the gradual destruction of adjacent materials.

- The panels are secured only through special fasteners.

- There should be at least 10-15 mm between the bottom edge of the first panel and the starting strip. This gap will act as a lower ventilation gap.

- It is extremely important to install the panels in a strictly vertical position. If you allow the finishing material to slope, this can cause distortion of the facing structure with its subsequent destruction.

- Experts recommend installing fiber cement panels starting from the central vertical axis of the wall, and symmetrically in both directions from it (from the axis).

- Installation of panels on roof slopes is prohibited. For this purpose, special roofing materials are used.

Features of panel installation

Components and tools, calculation of quantities of materials

To install fiber cement panels under brick, you will need the following components:

- starting bar;

- strike plate (aluminum);

- finishing strip;

- docking strip;

- corner element.

An example of fiber cement panels and additional elements for them

To correctly calculate the required amount of materials, it is recommended to pre-lay out the panels on a piece of paper. The following parameters must be indicated on the drawing:

- dimensions of the wall and openings (windows and doors);

- distances from wall corners to openings;

- distances between openings;

- distances from the base to the bottom edge of the openings;

- distances from the top edge of the openings to the cornice.

Calculation of façade area

Panel Layout

Next, you need to determine and indicate the location of each sheathing post. To install the panels, you need a frame that tightly surrounds all window and door openings. Vertical profiles (or wooden blocks) are installed in increments of 100-120 cm. The first and last posts should be located along the line of the wall corners.

Frame diagram

Having a ready-made drawing of the sheathing in hand, it is easy to calculate the required length of the material that will be used to construct the frame. The calculation is made in linear meters. The length of one unit is taken as the base (for a metal profile this is 280 cm, 300 cm, 305 cm, 600 cm).

Next, the “layout” of the panels is performed. First of all, find out the length and width of one unit. Then they calculate how much finishing material will be needed to cover a given wall.

The most convenient metal profile for constructing the frame is PP 60/27. In addition, you will need hangers for working with drywall and galvanized screws.

Profile and suspension diagram

Required tools:

- screwdriver;

- hammer drill (or drill with hammer drill mode);

- jigsaw;

- construction bubble level at least 80 cm long;

- metal scissors;

- hammer;

- screwdrivers.

Sample set of tools for panel installation

The panels are cut using a jigsaw or grinder with a stone disc. When using the second tool, you need to take into account that before starting work you must turn on the low speed mode. In this case, there will be no formation of sparks that could damage the facing layer of the panel.

Prices for angle grinders (grinders)

Angle grinders (grinders)

Cutting and processing of fiber cement panels

To attach the panels to the frame, you will need special metal brackets, which are called “clasps”. These connecting elements are equipped with several holes; it is recommended to fasten through the central one. For this, screws or self-tapping screws are used.

Stainless steel clip and screw

Additional elements

Accessories

Stages of installation of fiber cement panels under brick using insulation

If the wall requires insulation, the first step is to install a heat insulator. It is recommended to choose dense materials of the correct geometric shape. These include sheet foam and mineral wool slabs. Any of them is attached to the wall using plastic dowel-nails with a wide round cap, which is otherwise called an “umbrella”. If the load-bearing surface is flat and strong, you can stick polystyrene foam. But even in this case, you will need a duplicate fastening using dowel-nails.

Stages of installation of thermal insulation materials

Step 1. Perform a visual inspection of the load-bearing surface. If places that require strengthening are found, cement-sand mortar is mixed (for walls made of brick and concrete) and work is done to seal the cracks. If the walls are wooden, replace the lumber that has become unusable with new one.

Step 2. Mount the brackets.

Bracket installation

Glue is applied to the foam sheet at 5 points: in the middle and in the corners.

Application of the solution

Step 3. Glue the canvas to the wall. Allow the glue to set for the time specified in the manufacturer's instructions.

Step 4. Install a drill with a pobedit tip into the drill. Drill holes where the glue is applied.

Step 5. Install a hollow rod and dowel nail into each drilled hole. If necessary, use a hammer.

Styrofoam fastening

Step 6. Drive the second part of the nail dowel into the rod: a fastening element with a wide round head.

Attaching the insulation

Step 7. Cover the insulation with a vapor barrier film using a construction stapler and galvanized staples.

Step 8 . They continue to work using the technology described below: install the frame and attach the fiber cement panels.

First of all, the base drip is installed

Horizontal profile

Vertical profiles are attached to the horizontal profile with self-tapping screws

Installation of fiber cement panels

If the walls are insulated not with foam plastic, but with mineral wool, the installation process is similar, with the exception of the stage of gluing the heat insulator.

Prices for thermal insulation materials

Thermal insulation materials

Installation of panels

- The panels are installed using self-tapping screws. The first row is fixed on the starting strip, which is pre-installed at the required height simultaneously with the installation of corner strips and the design of window openings.

- The starter bar is a strip equipped with a lock similar to the one on the bottom of the panel. Installation involves snapping the lock and fixing the top of the panel using self-tapping screws.

- The next panel is joined to the first along the line of lateral contact, repeating the contours of the brickwork in discord. The entire row is installed in this way, after which the entire procedure is repeated on the next row.

Important! Self-tapping screws should not be tightened tightly. The material must be able to move freely during thermal expansion, so all fasteners are slightly loosened. This condition is met when installing all siding elements.

Panel selection

Selecting panels is quite simple, but you need to know what is important to consider in order to avoid mistakes. So, first of all, it is worth taking into account the features of the building itself - what and how it is made of, what foundation it stands on, etc. If the house is located in a region where severe weather can be expected in winter, then it is better to immediately take the option of panels that has additional layer of insulation.

The process of installing panels with insulation

Prices for popular finishing wall thermal panels

Thermal panels

It is also worth paying attention to the strength class of the coating. In order to save money, you should not take an incomprehensible and fragile material - repairs and replacement of the coating can cost more than installing normal material right away.

It is also important to pay attention to the cost - you should take into account all expenses, focusing on your own budget. There are a great variety of panels on the market, and everyone can choose the best ones at the cost. True, you should choose those whose quality you can be sure of - these are materials from trusted manufacturers.

Berg brick-look facade panels

Important! The features of the landscape and design of the house should be taken into account, but here we are talking more about the external decorative characteristics of the panels than about their performance indicators.

If we talk about manufacturers, brands such as ABC, Roben, Stroeher and Feldhaus Klinker received good reviews. Materials from Kmew and Docke-R are also praised.

Facade panels DÖCke-R

Tips for decorative facade finishing

In order not to overpay for extra slabs, and not to buy missing ones, you should correctly calculate the required number of sheets. When purchasing blocks, ask the seller for a certificate - you cannot trust dubious companies.

Decorating a house is an expensive task and involves long-term use of materials. It is important that it is of good quality.

On a note! Any type of siding can be installed not only on the entire wall, but also on individual fragments: areas under the roof, corners, windows, and along the perimeter. It is possible to combine several types of panels.

A combination of the same type of panels, but in different colors, looks good - this will preserve heat and sound insulation and give the house an elegant look. Such a house will not only become more comfortable to live in, but will also acquire a new, original design.

A combination of several types of finishes (expensive and cheap siding) will help save money.

A plastered house with siding located in the basement of the same shade looks beautiful.

Designers do not recommend combining brick finishes with wooden materials. Such a building will have an unsightly appearance.

The use of slabs imitating brick is not limited only to residential buildings. They can be installed on gazebos, outbuildings, and finish the foundation of permanent fences.

When choosing the type of sheets, you should take into account the operating conditions: humidity, the possibility of mechanical damage, temperature changes.

Modern types of siding for exterior home decoration

Initially, siding was made from natural wood. The boards were laid from bottom to top, sometimes end to end, and paint or varnish was applied to them as a protective layer. This coating is expensive and short-lived. In conditions of high humidity, the boards still lose their appearance and integrity after a certain amount of time.

In the demonstration photos, the finishing of houses with brick siding (or imitating other materials) is made of the following compositions:

- wood pulp;

- vinyl;

- fiber cement;

- metal

The wood-cellulose mixture is made like MDF. The crushed wood is pressed under high pressure and temperature, and resins are added to it for strength and moisture resistance. Externally, the coating has a pleasant appearance, it is inexpensive, but is not durable.

The most popular is vinyl siding. The advantages of this material include:

- resistance to temperature changes, ultraviolet radiation, humidity;

- variety of colors, high aesthetic qualities;

- light weight, ease of installation;

- non-toxic and does not support combustion.

Due to its affordable price, vinyl siding is the most popular.

It is very important that vinyl siding drains condensation along the outside. Disadvantages include the possibility of mechanical damage due to a significant impact, as well as high thermal conductivity, which is why the use of insulation is required during installation. Many people prefer to cover their houses with brick-like vinyl siding: it is affordable and labor-intensive, and the building becomes neat and presentable.

Note! Dark types of plastic siding panels are somewhat more expensive, since color stabilizers and a large number of coloring pigments are added to them during production.

Metal siding is a more expensive facing material. It is made of zinc, steel or aluminum and is a metal that is coated with a primer and a polymer coating. The top layer usually has decorative embossing.

Fiber cement plastic is made from cellulose compressed with cement. The facing material is heavy. It is with the help of this composition that natural stone is most often imitated.

The top layer of metal siding usually has decorative embossing.

Siding Care

Manufacturers take into account the location of use of siding for a brick house, so they manufacture it with specific operating conditions in mind. It does not require special care; it is enough to periodically clean the panels from settling dust - the blocks should be wiped or washed with ordinary household products.

Do not scrape the panels or wash them under strong water pressure. In the first case, there is a risk of damage to the protective coating, in the second - moisture entering the interior, which will lead to loss of heat and sound insulation.

Comparing these materials with each other and choosing the best

It is very difficult to compare different materials, since the properties and specific features of a particular material are taken into account initially; material unsuitable for certain purposes will not be used.

However, based on the practical results of using siding, we can identify some general, purely operational parameters for which such a comparison will be quite correct:

- Durability . This value is in most cases calculated and has not been verified in practice. The 50 years declared for most materials have not yet passed, so it is impossible to say unambiguously how much a particular material can withstand these values. At the same time, it should be taken into account that metal begins to corrode over time, vinyl panels are prone to changes in structure under the influence of UV rays, and fiber cement samples, when the protective coating is destroyed, will become saturated with water and will collapse . However, according to this position, experts unanimously give primacy to metal siding.

- Coating stability . This is an important parameter that determines how much the material is able to maintain its presentation (external qualities, not the condition of the material itself). Since some types of siding are completely dependent on the condition of the coating (metal siding completely loses its imitation qualities in the absence of a coating), vinyl siding should be singled out as the winner on this basis.

- Price . Often this is a determining value that influences the choice of a particular material. In this regard, the clear leader is vinyl siding, which is almost half the price of metal or fiber cement.

NOTE!

Based on these parameters, vinyl siding can be identified as the most successful choice in terms of technical and price criteria .

Reviews

Today, metal siding is rightfully recognized as one of the most popular facing materials, as it is characterized by a long service life, unpretentiousness and an uncomplicated installation method.

The lion's share of owners of private houses note that such facade finishing material seems to them more practical than real wood coverings.

It does not need to be regularly looked after and treated with antiseptic compounds. The same cannot be said about walls made of timber or logs - they must be periodically coated with special compounds, without which they will begin to crack, fade and rot.

However, metal siding is inferior to natural wood in its strength characteristics. For example, many buyers note that dents easily remain on the material from the Grand Line company. Moreover, some users rudely nicknamed it “tin can.”

Of course, if you protect the metal siding of this company from mechanical damage, it will last for a very long time. The only defect to which it will be susceptible is color fading.

Consumers leave good reviews about the products of JSC Metalkomplekt. Metal siding from this manufacturer not only lasts a long time, but is also quite dense and reliable. Many consumers have chosen Metallokomplekt products, as they are represented by a rich assortment. You can choose the right siding to suit every taste and budget.

Consumers leave not the best reviews about products. Its product range is quite rich, but many people have encountered defective metal siding from the company, which, moreover, was not delivered within the time period specified in the contract.

Consumers leave good reviews about the products and “Krona”. These manufacturers boast a large range of products that meet all existing standards and GOSTs.

Metal siding for brick: advantages and disadvantages

You can decorate the facade as a brick using any type of siding, including metal. Should I give preference to this option? As mentioned above, such siding is made of sheet metal with an external polymer coating applied to it. This facing material has many advantages:

- variety of textures, shapes, shades;

- light weight;

- accessibility of installation;

- resistance to ultraviolet radiation and temperature changes;

- ease of care.

Using metal siding, you can clad the most complex architectural elements, since there is no need to leave gaps for the expansion of the material.

Metal siding also has some disadvantages. And this is, first of all, the price. Catalogs of metal siding for exterior home decoration offer samples of facing material that imitate:

- clinker brick;

- smooth;

- "old" masonry.

Metal siding panels can be used to finish the most complex architectural elements.

Almost all existing types of brick can be seen on metal cladding panels. Manufacturing technology, namely the quality of the coating, most affects the price. The cheapest metal panels made of steel with a polyester coating have a price of 490 rubles per 1 m², which is twice as expensive as similar vinyl products.

Disadvantages of metal siding also include susceptibility to rough mechanical stress - the appearance of dents. Deformed panels cannot be restored.

Note! The above disadvantage is often used when it is necessary to clad parts of a building with complex architecture: you can bend the panel and obtain the required configuration.

Summarizing

Siding made to look like brick has almost complete visual similarity to brick, but at the same time it is free from many of the disadvantages of natural masonry, and in some respects it is superior.

Using this material, you can make a beautiful facade that will add austerity and comfort to your home for many years with minimal investment of money and time.

A varied range of colors will allow you to combine and bring to life any design ideas, and the texture of the brick will determine the sophisticated style of other decorative elements of the house and the surrounding landscape.

Stone siding for exterior decoration: photos and prices

Among modern residential buildings, there are many buildings that are perceived as mansions. If you look at it, these are sometimes the most typical structures in architectural terms, to which the finishing gives a certain charm: the houses are lined with stone-like siding. Photos on the Internet show an imitation of facing with white rubble stone, rather voluminous boulders, flat fragments, etc.

Fiber cement panels can most accurately reproduce the appearance of natural stone.

In general, there are several main types of stone imitation:

- granite;

- burnt stone;

- rubble;

- canyon.

It should be noted that more and more new design developments are appearing, so the list proposed above may soon become incomplete.

The “stone” panel can be made of vinyl, metal and fiber cement. Products made of metal and vinyl have many characteristics similar to panels that imitate brick, and repetition would be inappropriate. But it’s worth taking a closer look at the fiber cement finishing. It is this material that is more capable of visually reproducing natural stone. It is also worth noting the extreme strength of the panels - they can only be damaged by targeted actions using heavy tools.

As disadvantages, it is worth noting the high price, which is largely justified by good performance characteristics:

Exterior stone siding can be made from vinyl, fiber cement, and metal.

- durability;

- resistance to temperatures and humidity;

- ensuring thermal insulation of the building;

- high aesthetic qualities.

It would be useful to highlight another distinctive feature of siding with “bricks”, visually similar to fragments of natural stone - the large weight of the panels: 1 m² can weigh from 16 to 40 kg.

On a note! Before using fiber cement panels for cladding, be sure to ensure that the structure is resistant to additional load.

As for the price, a panel of standard sizes 100x45x12 mm will cost (depending on the manufacturer) 1440-2000 rubles. A fairly common size is 3000x455x16 mm. Cladding with such panels is much faster, but requires the participation of at least two people.

Before finishing a house with fiber cement panels, you should definitely make sure that the walls are resistant to additional load.

What is more expensive: metal siding or brick?

This question interests many country property owners. Before finishing the facade of a building or other construction work, people try to calculate all the costs. If we compare the average price range of metal siding and facing bricks, then their cost will be approximately the same. This is only one material cost line.

Metal siding panels are lightweight and can be quickly mounted on the surface of the facade, even with your own hands. Facing bricks are much heavier; to install such finishing you will need a reliable and durable foundation that can withstand additional loads. In addition, not every owner of a country property will be able to install a brick wall. This kind of work is quite complicated and costs money. Thus, covering the facade of a residential building with metal siding will cost much less than finishing the walls with decorative bricks.

Features of application and installation

In the modern construction market you can find several options for making metal siding. The first type of product is used for finishing the facades of residential, industrial and administrative buildings. The second type of material is used for cladding the base of buildings. Next, we will get acquainted with the features of installation work.

Preparing the sheathing

Before carrying out the main work, it is necessary to make a lathing to securely fix the panels to the surface. The frame guides can be made of wooden slats or metal profiles. When using wooden structures, it is necessary to soak them in an antiseptic solution, which will prevent the appearance of fungus or mold on the surface. In addition, such products are coated with fire retardants that prevent the material from burning.

The sheathing guides are installed perpendicular to the laying of the sheathing panels, usually in the vertical direction. Before carrying out such work, it is necessary to clean the base surface from debris and dust, tighten the cord in the upper and lower parts of the building facade. The guides are installed level in one plane, the distance between adjacent elements should be equal to the length of the panels (for ease of fastening). The sheathing elements are fixed to the base surface using dowels or self-tapping screws. The last type of fasteners is used for wooden walls of buildings.

Facade siding

The installation of façade siding panels begins with fixing a special profile and platbands on window and door openings. Next, we proceed to secure the starting bar. This element is fixed at the bottom of the profile along the perimeter of the entire building. The position of the guide bar must be aligned according to the readings of the building level.

After the preparatory operations, they begin to secure the first panel. The lower part of the stylized product is installed in the guide bar, the top is fixed to the sheathing using self-tapping screws. Work begins from the corner part of the building, the panels are securely fastened together using special locking connections. A good effect can be achieved by covering a brick house with metal siding with insulation. When using such products, you can significantly save on coolants.

When securing the material to the frame, it is necessary to slightly under-tighten the fasteners to avoid deformation of the coating during the expansion of the metal in the summer.

Installation of basement siding

There are certain differences in the technology of fastening facade and plinth panels to the sheathing. During installation of the material in question, the following rules must be observed:

- the first panel is fixed a few centimeters below the main profile;

- when installing panels, move from the corner, from left to right;

- the first element from the edge is moved all the way. A layer of sealant is applied at the junction of the products at the corner of the building.

Base panels have a slightly different design than façade panels. At the back of such products there are mounting pins that protect the siding from possible deformation during sudden changes in temperature and humidity.

Stiffening ribs are not used to fix the panels. The products are securely fastened together thanks to a special locking system; they are inserted into the guide bar in the upper part and fixed to the sheathing with self-tapping screws. A sealant is used to prevent moisture from entering the coating.

If it is necessary to bend the profile at the corners of the building, it must be heated.

Metal

One of the types of finishes that are most resistant to mechanical damage is brick-like metal siding. The advantages of this material also include durability, a large selection of colors, and availability.

This is how metal siding looks like brick on the facade of a house Source 2gis.ru

Flaws:

- in comparison with vinyl, it weighs more (but lighter than natural brick);

- after mechanical damage, the sheets are practically unsuitable for restoration;

- moisture resistance requires special anti-corrosion treatment;

- installed on a special frame.

See also: Catalog of companies that specialize in insulation and finishing of houses.

Brick imitation

Brick siding is a building material that is the ideal embodiment of high performance characteristics, aesthetic appeal and affordable cost. The advantages and benefits of exterior brick siding force it to attract the attention of buyers and bring it to a leading position among facade materials in the construction market. It is this that will give the building a prestigious appearance, without requiring any additional maintenance. Dobrostroy LLC offers to buy brick siding for all clients in Moscow and the region . We have a huge assortment that will bring even the most intricate design solutions into reality with a relatively small financial investment.

Advantages and benefits of brick siding:

- — reliability, practicality and durability;

- — resistant to natural factors (frost, moisture, high and low temperatures, fungus, etc.), as well as mechanical damage;

- — easy to care for;

- — the aesthetic appeal of the material gives an elite appearance to any building;

- — significantly reduces the heat loss of the building if additional insulation is used during installation;

- — environmentally friendly building material;

- - economically beneficial - brick siding has an affordable price.

External brick siding price

- Pricing policy for this finishing material

depends on three main criteria:

- - manufacturer's company;

- — quality of the material;

- - appearance of the product.

Brick siding, the price of which is affordable for the client, as well as the widest range, will allow everyone to make the right choice. The Domremstroy LLC catalog presents facade materials from the world's leading manufacturers. A variety of textures, color shades, as well as geometric parameters of the material will allow you to create a unique elite facade. When purchasing this facing material, you should also take into account the costs of its installation. After all, the service life of the facade largely depends on the quality of the installation. To ensure the durability and reliability of the facing material, it is recommended to turn to professionals. It is also worth considering that additional insulation of the building will also affect the cost of siding installation .

Buy brick siding in Moscow

Inexpensive facade material, brick siding is an ideal option for creating an attractive appearance of a building without huge financial investments. Dobrostroy LLC offers all residents of Moscow and the region a huge range of this facing material at an affordable price. Our managers will provide detailed information about the product both online and by contact phone numbers, and will also place your order. Prompt delivery will not keep you waiting long, we cooperate with leading transport companies - this is a huge selection of high-quality goods, pleasant service and fast delivery.