Siding is a material for finishing walls, which allows you to protect them from precipitation and other adverse influences, as well as give the building an attractive appearance.

In the 19th century in the USA, they first began to sheathe the external walls of houses with boards, and in the mid-20th century, vinyl and metal finishing panels also began to be produced in the USA and Canada.

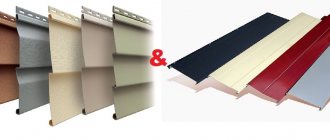

Today, all three of these siding options are widespread..

It is most often used for finishing walls outside the room, but the panels can also be used in interiors. The material has won such recognition due to its qualities - durability, strength, attractive and neat appearance .

What is a block house

Block house siding (other spellings are block house and block house) is one of the materials for wall decoration. A house covered with it looks like a log house, which is why a block house is also called log siding .

Like other types of siding, it can be used to decorate walls both outside and inside the building.

The main functions that such a coating performs :

- Giving the house a new attractive look;

- hiding defects in wall surfaces outside or inside the house;

- protection of external walls from adverse environmental influences;

- improving the thermal protection of the home.

At the same time, log siding has several undeniable advantages and:

- Good appearance;

- a wide variety of options for this finishing material.

The block house is either made of natural wood or imitates it using color and texture . Houses sheathed with this material look original and attractive, while buildings finished with conventional siding often look more like a hangar or warehouse building than a living space.

From a large number of possible options, you can choose the one that suits you. On sale you can find finishing panels for logs of various sizes and colors, a wide variety of possible patterns are available.

ATTENTION!

In addition to siding, manufacturers offer special additional elements. They can be used to decorate door and window openings of a house, as well as cornices . This allows you to complete the look of your home.

Photos of houses with block house siding:

House with block house siding

Block house

Description of material

Just a couple of decades ago, the block house was known only in Western countries , where it was actively used for finishing various objects. Not long ago, domestic consumers became acquainted with it.

Translated from English, this term means “block house”. In Western countries it refers to frame houses, and in our country it is one of the types of finishing materials. It means a board made from various types of trees, which is used for interior and exterior decoration. On one side the material has a flat surface, and on the other it has a convex surface. The block house is produced with imitation of various natural materials.

Specifications

Panel sizes may vary:

- Their length in most cases ranges from 2 to 6 m ;

- width - from 9 to 20 cm ;

- height - from 2 to 4 cm .

Vinyl siding is 80% PVC . Today, almost exclusively two-layer vinyl panels are used, which consist of a bottom durable layer, which provides a reliable base, and a top decorative one. The thickness of the latter is about 20-25% of the panel thickness.

The materials used to make metal log siding are galvanized steel and aluminum . During the production of such finishing panels, several layers of protective coatings are applied to the metal.

Wood siding is usually dried to a moisture content of 16-18% , this technology is used in the manufacture of panels from resistant wood species. Less resistant wood is subjected to heat treatment at a temperature of 170–220 °C. Also, during production, wooden siding can be impregnated with antiseptics under pressure .

Specifications

Brands and product prices

Since block house siding is a fairly popular facing material, you can easily find information about the ratings of its manufacturers. Thus, in the coming year, according to professional builders, the most popular manufacturer of acrylic siding is Tecos. The price of facing the most popular collection of this brand is 300 rubles per strip.

Among the manufacturers of metal siding, experts single out the domestic company Woodstock. Woodstock products are reliable materials with a service life of up to 30 years. Externally, it completely replicates a wooden beam. Costs about 500 rubles per square meter.

Vinyl siding is produced by many foreign and Russian manufacturers. Of these, the following companies have gained the most trust:

- Royal;

- Mitten;

- Deke Extrusion;

- American Siding;

- Nordseed.

The cost of vinyl siding varies from 150 to 250 rubles per square meter. The price depends on the brand of siding, the quality of the panels themselves, coating and other characteristics.

Vinyl block house

Vinyl panels require virtually no maintenance - they only need to be washed periodically, using non-abrasive cleaning products if necessary.

The main advantages of a vinyl block house:

- Not flammable;

- not subject to rotting;

- resistant to temperatures from -50°C to +60°C;

- does not lose its color, does not fade in the sun;

- does not require additional care.

Vinyl siding can be an excellent choice for lovers of natural materials, as it convincingly imitates their appearance, but does not require as much attention as natural wood .

However, it imitates a real log less naturally than a wooden block house, is very different from it in terms of tactile sensations and is therefore less suitable for interior walls.

Vinyl siding block house

Metal block house

Like vinyl siding, metal trim panels are very durable and will not rot or burn . Another advantage is their relatively low price.

The disadvantages include the fact that metal siding is very different from natural wood panels in appearance and tactile sensations.

Unlike wooden siding, it is not suitable for finishing interior walls , because few people would want to live or relax in a house that is lined with metal on the inside.

also heavy and creates a serious load on the walls of the building . Dents that appear on the surface of the metal remain forever.

Metal siding block house

Wooden siding block house

A wooden block house is a board for covering walls, one of the types of lining, its back surface is flat, and its front surface is convex. On the edges of the board there are connecting elements with which the block house is securely attached to the wall - grooves and tenons .

This finishing material appeared in the 90s, shortly after conventional lining. It quickly conquered the European market, and then appeared in Russia.

Wood siding is made from rounded logs . Its central part is used to make timber or boards, and the four remaining edges are used to make a block house.

Thus, this finishing material is produced on an industrial scale. Small batches are made from boards, processing them on a milling machine.

Features of log wood siding:

- wood is a natural, eco-friendly material that is pleasant to look and feel;

- siding made from it more naturalistically imitates real logs than siding made of vinyl or metal;

- a wooden block house is flammable and susceptible to rotting, so it is necessary to periodically treat it with special compounds or paint it.

This finishing material is made from both deciduous and coniferous wood . Most often, linden, oak, larch, pine, spruce and cedar are used for this.

IMPORTANT!

Panels made from coniferous trees have important advantages - due to the high resin content, such siding has good protection from moisture, so it rots less and is more durable.

Siberian larch is highly valued , the wood of which is superior to the wood of other coniferous species in hardness, resistance to moisture and resistance to decay.

Cedar is especially well suited for interior walls, as it controls humidity levels and creates a favorable indoor microclimate.

Wooden siding block house

Which block house type siding is better?

There is no clear answer to the question of which type of log siding is better - vinyl, metal or wood. Wood panels will be an excellent choice for connoisseurs of natural materials that are pleasant both to look at and to the touch .

This imitation of a log looks as naturalistic as possible, but you need to be prepared for the fact that it will need to be periodically applied with protective impregnations. If you paint it, wood siding significantly loses its appearance.

A metal block house gives the building an urban, industrial look . All this makes it not the best option for finishing a house, bathhouse or gazebo. This material is more suitable for covering the walls of factory workshops, warehouses and other similar structures.

A vinyl block house is a kind of golden mean between the previous two options. Just like metal, it is very durable and requires almost no maintenance, while vinyl is more similar to natural wood in appearance and tactile sensation .

Calculation tips

Siding panel sizes may vary. Average parameters – 3660*232*11 mm. There are from 15 to 20 panels in one box. Packing options are determined by the manufacturer. When purchasing finishing materials, you should follow a certain sequence:

- the calculation of the quantity must be done carefully: the perimeter of the building is multiplied by its height;

- the area of the openings is subtracted from the resulting figure;

- The area of the pediment is calculated separately;

- if the architecture of the building includes arches, a mezzanine, extensions, balconies, the area of each wall is calculated separately;

- the result obtained should be divided by the area of one panel, which can be subtracted by multiplying the length of the panel by its width;

- the resulting number of panels is divided by the number of pieces in the package declared by each specific manufacturer;

- when calculating, the amount of material should be rounded up; it is not recommended to buy siding individually;

- It is better to calculate the number of accessories in the store by turning to sales consultants for help.

Boxes with panels cannot be opened, this may negatively affect the quality of the material.

Siding installation

The block house can be mounted both horizontally and vertically. The first option for fastening the panels is most often used. In this case, thermal insulation material can be laid between the wall and the siding.

First you need to do the preparatory work:

- All wooden elements - house walls, sheathing, panels - must be impregnated or coated with compounds that will protect them from moisture, fire and parasites;

- it is necessary to caulk or putty the gaps and cracks (putty is less reliable);

- if necessary, electrical wiring and other communications must be installed, which should be located under the siding.

Having prepared all surfaces, you can begin installing the siding:

- It is necessary to make a sheathing made of wood or metal profiles;

- if you want to additionally insulate the building, you need to attach thermal insulation material to the wall;

- then you need to mount all the panels sequentially, starting from the bottom.

When making the sheathing, you can limit yourself to only vertical bars or a profile (with horizontal fastening of siding panels). If you want to give the structure additional strength, add horizontal guides to them .

ATTENTION!

In order to get a good result in the end, it is necessary to fix the sheathing evenly, so you must install it, checking the level and plumb line . If it is made of wood, it must be impregnated and covered with protective compounds, just like the walls of a house.

Wooden panels are installed using the tongue and groove method . In this case, it is better to point the spike upward, in which case the water will flow down better. The siding is attached to the sheathing using nails, self-tapping screws or clamps.

The latter are special strips, which, in addition to being attached to the sheathing, also provide a more reliable fixation of the panels to each other using a tongue-and-groove system.

When installing wooden siding on a wooden sheathing, the clamp must be inserted into the groove of the board and fastened with a self-tapping screw to the sheathing beam . The installation is reliable and very durable.

When fastening with nails or self-tapping screws, they must be driven into the tongues of the lining . Metal and vinyl siding block house is mounted using screws.

Siding installation

Correct installation

Installation technology

The siding installation process consists of several stages:

- installation of sheathing;

- laying thermal insulation and waterproofing material;

- installation of the starting bar;

- fastening ordinary planks;

- installation of corner internal strips;

- installation of corner external strips;

- laying the finishing strip.

Having basic construction skills, subject to strict adherence to the installation instructions, you can cover your house with siding yourself.