Putty is a special mixture that contains astringent components and additives. Its main function is to level the surface of walls and ceilings before performing decorative work. Using the mixture, deep and small cracks are eliminated, and a base layer is created for better adhesion to the finishing coating - wallpaper and other elements. Before starting repairs, you need to take into account the characteristics of the main building materials and the atmospheric parameters of the environment in order to determine the best putty for the job.

Types of putties

Putties can vary in their composition, that is, what kind of binder is used in their base:

Gypsum-based putties are the most common and the cheapest. They are used only for interior work and only in rooms with normal humidity levels. They do not shrink and are easy to handle, completely environmentally safe, since gypsum is a natural mineral.

In most cases, gypsum putties are the most justified choice.

Cement-based putties - used for outdoor work, as well as in those rooms where the humidity level is higher than usual - baths, bathrooms, swimming pools, kitchens and others. They are more expensive than gypsum, can shrink slightly, and have a longer drying time.

Polymer putties are the most modern, which are based on some kind of polymer: acrylic, vinyl or latex. In addition to the polymer, they contain various mineral fillers in the form of marble flour, fine-grained quartz sand, limestone, dolomite and others, as well as various plasticizers and modifiers, the name and percentage of which is carefully hidden by each manufacturer.

Polymer putties show their best qualities when working with plasterboard surfaces

The above-mentioned plasticizers and modifiers, various polymer components are included in the composition of both gypsum and cement putties, which are designed to improve their properties.

Putties come in two stages of readiness:

- Dry mixtures, which are most often packaged in paper bags and prepared at the point of use by adding a solvent. In the vast majority of cases, clean water is used for this. Obviously, such putties are easy to transport and store, they are cheaper, and they can be prepared in the required quantities right on the job site. However, if the preparation technology is not followed and the mixture preparation time is exceeded, the properties of such putties are sharply reduced.

- Ready-to-use putties, which are most often packaged in plastic jars or buckets. The advantages of such compositions are obvious - they do not need to be prepared, when the lid is closed they retain their properties throughout the entire guaranteed shelf life, they are easy to apply, and when using them there is a minimum of waste. Most often, ready-to-use putties are polymer. Their main disadvantages are the higher price and, unfortunately, the presence of a large number of counterfeit products on the market. Therefore, you should purchase them only from trusted sellers.

According to their purpose, putties are divided into:

- Starting or leveling putties. They can also be called first-layer putties. Their main task is to level the uneven base of the wall after plastering work, and the applied layer can be of variable thickness from 1-2 mm to 1.5-2 centimeters. Naturally, it is unlikely that it will be possible to apply a layer of 1.5-2 cm at a time, so puttying with the starting composition is carried out 2 and sometimes even 3 times. Such putties have a larger aggregate fraction. The thickness of the applied layer at a time is always indicated on the packaging of the putty.

- Finishing putties are intended for applying the first layer of putty and their main task is to obtain a perfectly flat and smooth wall surface, ready for final finishing: wallpapering, painting, cladding or decorative plaster. Before applying them, the starting putty must be thoroughly sanded and primed. The filler fraction size of such putties is significantly smaller, the layer thickness is from fractions of a millimeter to 1-3 mm. Trying to apply a thicker layer of finishing compound will almost always result in peeling.

- Universal putties combine the qualities of starting and finishing putties. They are used on fairly flat bases, for example, a wall in a concrete panel house, which will later be covered with wallpaper with a three-dimensional texture. This does not require a large layer to level and a surface that is too smooth for painting or thin wallpaper.

One of the best universal putties, but also expensive

Terms of Use

There are several basic rules for using Sheetrock Super Finish Putty.

- The product is intended for interior use only.

- A new application of putty is carried out only on a completely dry previous layer.

- The putty is sanded with 240-grit sandpaper.

- To successfully paint and apply decorative finishes, you must strictly follow the manufacturer's instructions. For the paint to adhere well, the coating must be dry, dust-free, matte, and not stick to your hands.

- Applying a thin leveling layer of putty to a sheet of drywall helps level out the water absorption of the material. In the future, this will help avoid stains on the surface being treated.

- During the dry sanding process, do not be too zealous. Do not treat the top of drywall or putty tape. In conjunction with Sheetrock putty, paper tapes, tapes with a metallized liner and protective corners are used.

Features of paper tape:

- makes the structure homogeneous and strong;

- has a fold in the middle for easy operation;

- does not require the use of adhesives;

- has good strength indicators;

Purpose of metallized paper tape:

- strengthening corners;

- strengthening structures when installing drywall.

Features of Paper Backed Metal Corner Guard (Paper Backed Anti-Corrosion Steel Tires):

- gives strength to corners;

- does not require additional fasteners;

- the adhesion of the finished composition to the paper base is higher, which ensures ideal surface smoothness.

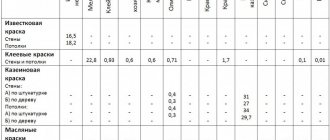

Consumption rates depending on the type of base

For puttying purposes, there are three types of surfaces:

- plastered;

- plasterboard;

- others.

Plaster

The consumption of putty on plaster is significantly influenced by the external environment.

Therefore, when puttying, it is important to comply with the actual working conditions and the recommendations from the manufacturer.

If the plastered surface does not have serious flaws and is processed in compliance with the temperature and humidity conditions, the normal consumption of putty corresponds to approximately one and a half kilograms of the mixture per square meter.

As already reported, the type of composition is of considerable importance: base mixtures are consumed in large quantities, and finishing mixtures are consumed in smaller quantities. So, with a millimeter thickness of the base coating, you will need 1-1.3 kg of mixture per square meter. But the finishing coating is thinner - only half a millimeter, and therefore the mixture only needs 500-600 grams per square meter. Moreover, in the calculations one must not forget that additional layers of putty will be needed.

As an example, we will give the calculation of putty when treating a wall. The wall area is 10 square meters. There are small cracks and unevenness on the surface. Below is a simplified calculation for two types of trains (starting and finishing):

- The average consumption of the base mixture per square meter of a millimeter layer is 1.15 kilograms. The planned layer thickness is 4 millimeters (4.6 kilograms per square meter). So, for 10 square meters with a 4-mm layer thickness, 4.6 × 10 = 46 kilograms of dry mixture are needed. However, this figure does not take into account the recommended error of 10%. Taking into account the error, the final result will be 50.6 kilograms per square meter (46+10%=50.6).

- The consumption rate of finishing putty is calculated based on the millimeter thickness of the layer. We calculate: 10 × 1.15 = 11.5 kilograms, and taking into account the error (11.5 + 10%) we determine the total consumption of 12.65 kilograms of dry mixture per square meter.

Note! The consumption of putty material is affected by the quality of priming. A well-primed surface will require less putty

Drywall

The consumption rate of putty for drywall (as, by the way, is the case with other materials) depends on the type of mixture chosen in terms of its components:

- Cement putties are consumed most abundantly - 1.2-1.4 kilograms per square meter.

- Gypsum mixtures are consumed less expensively - approximately 1 kilogram per square meter.

- Polymer compositions are the most economical in terms of physical consumption (but also cost more) - about 600 grams per square meter.

It should be noted that it is easier to work with plasterboard sheets than with plastered surfaces due to the initially smoother surface. The main task is to seal joint parts, cracks, and nail heads. A finishing coat must also be applied. One more point: it is easier to determine the required amount of putty in advance, taking into account the specific dimensions of the plasterboard sheet.

Other types of surfaces

Other types of surfaces include primarily concrete and wood. For concrete bases, the putty consumption per square meter is approximately the same as in the case of plastered surfaces. However, the layer thickness is much higher - about 10-12 millimeters for the base layer. For wooden surfaces, the thickness of the starting layer is much lower - up to 2 millimeters.

What else you need to know about the application technique

The consumption of Shitrok putty is almost always the same if you maintain the layer thickness. The material should only be worn indoors. Each layer must dry thoroughly before applying the next. The sealed seam must be dry before decorating or painting.

If you decide to use the dry sanding technique, then a paper grit of 240 units will do. For decorating and painting, follow the manufacturer's instructions. All surfaces must be clean, dry and matte before applying paint. Before decorating, paint materials must be completely dry. The surface of plasterboard sheets should be coated with a thin layer of putty to equalize suction before painting in areas where gypsum board walls and ceilings will be exposed to natural side lighting or artificial lighting, followed by painting with semi-gloss or gloss paint. When using dry sanding, sanding the outer paper layer of the gypsum board and the paper tape should be avoided.

Putty consumption per 1m2 on drywall

You can find out about density indicators on the packaging or ask the seller. Naturally, it varies and is in the range of 0.8-1.6 kg/dm2. It is quite clear that the higher the indicator, the more solution will be used per 1 m2.

The initial putty of walls under wallpaper is much lighter using a cement mixture, but it makes it possible to level the surface up to 60 mm in one go. At the same time, you can be confident in the quality of the work performed - it will never peel off or deform. This is what gypsum putty is. The finishing amount is even smaller - 0.4-0.5 kg per 1 m2 of surface to be treated. Gypsum putties have their own characteristics.

So, the finishing product cannot be used after its expiration date. It will immediately form lumps. But the starting one, on the contrary, is possible.

In order to determine the cost of puttying 1 m2 of wall, we divide the price by kilograms of putty mixture

Yes, by the way, on packaging bags or containers, manufacturers of this important building material always indicate the calculation of putty in the solution per 1 m2. After looking at them, you should understand that the volume of the finished mixture will be 3-4% less than the amount of dry mass

And one more thing - it’s never worth relying on a neighbor or friend who used, roughly speaking, one bag of putty mixture on one wall in his apartment.

Factors affecting material costs

In most cases, consumption rates are approximate. A professional planning the renovation will advise you on the approximate amount. However, in the future it is often necessary to purchase additional filler. To take the right amount of the mixture, you need to pay attention to the instructions for use.

The weight of the material indicated on the packaging reflects how much the composition will need to work. It is designed for perfectly smooth surfaces. In practice, it is always better to have a reserve, taking into account the characteristics of the walls of the room and other factors. The following reasons can be noted for the increased consumption of putty per 1 m2 of wall.

- The quality of building materials is the presence of unevenness and roughness, the depth of cracks on the surface.

- Partial mixture residue on the inner walls of the container for mixing mastic.

- Technique for thinning the mass with putty.

- Mastic application technique.

- Speed of distribution of the finished product.

The quality of mastic application requires the application of layers of a certain thickness. If the recommended volume is exceeded, the mass crumbles after drying. This will require adjustments to repairs and additional material costs. Usually the solution is applied twice. The first layer should not exceed 8 mm. The second time when calculating the putty, the thickness should be less - about 3 mm. The persistence of wall defects indicates poor quality plastering work.

For optimal consumption of putty, you must adhere to the rules for diluting the suspension.

- It is better to use small containers for preparing the mass, because the mixture hardens within an hour.

- There is no need to stir the solution until a homogeneous structure is obtained. Small lumps will acquire the required consistency as you work.

- The container should be washed thoroughly after each portion of putty. Remains of the previous putty accelerate the hardening of the working mass.

Attention! When repairing, experienced craftsmen do not recommend mixing more than 4 kilograms of dry matter.

Consumption rates depending on the type of base

- plastered;

- plasterboard;

- others.

Plaster

If the plastered surface does not have serious flaws and is processed in compliance with the temperature and humidity conditions, the normal consumption of putty corresponds to approximately one and a half kilograms of the mixture per square meter.

As already reported, the type of composition is of considerable importance: base mixtures are consumed in large quantities, and finishing mixtures are consumed in smaller quantities. So, with a millimeter thickness of the base coating, you will need 1-1.3 kg of mixture per square meter. But the finishing coating is thinner - only half a millimeter, and therefore the mixture only needs 500-600 grams per square meter. Moreover, in the calculations one must not forget that additional layers of putty will be needed.

As an example, we will give the calculation of putty when treating a wall. The wall area is 10 square meters. There are small cracks and unevenness on the surface. Below is a simplified calculation for two types of trains (starting and finishing):

- The average consumption of the base mixture per square meter of a millimeter layer is 1.15 kilograms. The planned layer thickness is 4 millimeters (4.6 kilograms per square meter). So, for 10 square meters with a 4-mm layer thickness, 4.6 × 10 = 46 kilograms of dry mixture are needed. However, this figure does not take into account the recommended error of 10%. Taking into account the error, the final result will be 50.6 kilograms per square meter (46 10% = 50.6).

- The consumption rate of finishing putty is calculated based on the millimeter thickness of the layer. We calculate: 10 × 1.15 = 11.5 kilograms, and taking into account the error (11.5 10%) we determine the total consumption of 12.65 kilograms of dry mixture per square meter.

The process of preparing the mixture takes into account the brand of putty and its composition

Important! For continuous adjustment, depending on the different options, between 900 and 2 kg of material is required.

First, the initial layer is applied. The dry mixture requires an average of 400 ml of cold water. The finished putty should be pasty. At first, it is necessary to apply a layer about 5 mm thick. In this case, the consumption ranges from 1 kg 200 g to 1 kg 800 g per square meter of surface. If surfaces are uneven, the basecoat will vary in size in different areas. The finishing layer is thinner. When diluted with water, one kilogram dissolves in 500-600 ml. Half of the leveling mixture is required.

Recently, universal solutions have been very popular, which can be used both as a base coat and for finishing work. The thickness of the layers applied to the surface does not exceed 4 mm.

Correct calculation and consumption of putty saves time and money when performing repairs of any complexity.

Ways to solve the problem

Most often, finishers use the time-tested method of laying a trial plot. Select one small part of the wall, which is conventionally taken as the standard. A full range of work is carried out on it. Primer, plaster and subsequent putty. The exact consumption of materials per 1 m2 is calculated and compared with the data provided by a standard calculator.

By drawing up a simple mathematical proportion, an error coefficient is derived, which is subsequently used to work on leveling all other walls. This method makes it possible not to exceed an error of 2-3% in further calculations. Thus, the consumption of plaster becomes more predictable when purchasing materials.

If the wall plastering is done efficiently, the calculation of putty consumption should practically not differ from the data provided by the calculator. Increased consumption of putty occurs mainly when the walls are not leveled enough and it is necessary to level this out with putty. In such cases, the consumption of putty per 1 m2 can reach the most unexpected levels.

The optimal option is when plastering and putty are carried out by one person or one team. Then responsibility for the final result cannot be shifted to the mistakes of the previous performer. This is another point, already organizational, but the consumption of plaster also depends on it.

High-quality leveling of walls and preparing them for further painting or wallpapering is the most important condition for performing all subsequent stages of construction or repair.

It is very difficult to stick wallpaper well to uneven walls: the edges of the sheets may not match due to the geometric curvature of the surface. The lighting in the room will be uneven, as the bumps and depressions will create shadows. Highlights and partial shadows form on the ceilings. Installation of furniture and wall equipment becomes more difficult.

In addition, the consumption of plaster is significantly affected by the selection and quality of materials used in the work, and their storage conditions.

For example, cement mixtures give, although small, but noticeable shrinkage, a greater number of roughnesses and cellular formations on the surface of the wall. This, in turn, leads to the fact that the consumption of putty per 1 m2 of plaster will be overestimated.

Such mixtures are used mainly for plastering the external walls of buildings, as well as in rooms with high humidity. There is absolutely no need to cover the walls of interior and living spaces with cement plaster.

Plasters based on gypsum, chalk or lime are smoother and do not shrink. They are produced in the form of dry mixtures and are convenient for transportation. They are well polished and processed to the required condition. In addition, many of the manufacturing companies add synthetic plasticizers to such mixtures, which makes these mixtures more elastic and resistant to mechanical damage.

Using tables or a calculator to calculate the consumption of plaster and putty when using such materials is more justified and appropriate.

And finally, the consumption of plaster directly depends on the professionalism of the craftsmen performing the work.

A scrupulous customer should always remember that a good master is more expensive than a beginner. But in the end, betting on skill always pays off handsomely. Confirmation of this will be the consumption of plaster.

Advantages

- Ease of use. I opened the bucket and off we went. No mess, no waste. The mixture holds firmly on the spatula, is easily leveled, and differences in layers are minimal.

- Relatively easy to grind. Of course, it doesn’t reach Vetonit, but it has a completely different quality.

- And the quality of the resulting surface is close to ideal. Under two layers of paint, no flaws can be seen at all (unless it was some Uncle Vasya who sanded, of course)

- Very long lifespan. Even if you putty with Shitrok all day, its remains in the bucket will not thicken. Close the lid, after six months you can start working again, the properties of the mixture will not change. The shelf life is twice as long as that of Vetonit bags.

- Very durable and comfortable buckets. Everything has already been said about them. The only negative is that a 17-liter bucket (weight 28 kg) may be a little heavy for you, and even too heavy for women.

How to calculate?

To calculate the exact amount of material that will be used during the repair process, do the following:

- find out the exact area of the room;

- measure the height and sum of the lengths of the walls;

- calculate the thickness of the walls, taking into account all surface defects;

- determine the thickness and number of putty layers (taking into account surface defects).

It is important to remember that the amount of mixture used also depends on other less important factors. It often happens that a fairly large amount of unclaimed material remains while working on tools; the composition hardens before it is used. It also happens the other way around: you have to redo some areas during the work process, which will require additional mixture

In general, inevitable losses can reach up to 10% of the total amount of material, so it is worth taking this point into account when preparing the mixture. In addition, the putty consumption rates also depend on the base of the mixture used.

It also happens the other way around: you have to redo some areas during the work, which will require additional mixture. In general, inevitable losses can reach up to 10% of the total amount of material, so it is worth taking this point into account when preparing the mixture. In addition, the putty consumption rates also depend on the base of the mixture used.

The basis can be:

- cement;

- plaster;

- adhesive.

Plaster

Before starting work, you need to understand how plaster differs from putty.

Both are used for finishing and serve for leveling, but there are important differences between them:

- Plaster, unlike putty, is used in much larger volumes. With the help of putty, as a rule, only small defects are masked, while plaster levels out larger damaged areas.

- The price of putty is significantly higher than the price of plaster due to differences in composition.

To calculate the required amount of putty for a plastered surface, you need to take into account climatic indicators and carry out work only in the range specified by the manufacturer.

Taking into account all the recommendations given by the manufacturer, per sq. m area usually requires one and a half kilograms of putty. However, the thickness of the applied layer and the quality of the wall, as well as the area to be puttied, should be taken into account.

For walls without significant defects, it is enough to apply a layer of 1 mm (the calculation is equal to a kilogram per 1 m2) of starting putty and 0.5 mm (0.6 kg/m2) of finishing putty. An increase in layer thickness entails a proportional increase in flow rate. Don’t forget about re-puttying, which is best included in the calculation before starting work. Consumption is approximately equal to one kilogram per square meter.

Drywall

Currently, drywall is one of the most common options for finishing a room. There is an opinion that there is no need to putty the coating if there is drywall, because it already has a flat surface. However, this opinion is wrong. Be sure to use a finishing putty to prevent paint or adhesive from soaking into the drywall.

The exact consumption directly depends on the surface area that needs to be treated. There is a little trick that allows you to reduce the amount of mixture: before puttying, the sheets of drywall need to be treated with a primer.

The amount of material for work depends on the composition.

The consumption table looks like this:

- When mixing cement-based putty, the calculation is 1.2 kg per square meter.

- The polymer-based mixture is consumed less than others - only 0.6 kg per 1 m2, however this type of composition is the most expensive.

- Gypsum mixture is the most economical option. Consumption is 1 kg per 1 m2.

Drywall is quite easy to work with. If the sheets were initially installed correctly, then you can do without careful alignment. Before the finishing coat, it will be necessary to properly seal the fastening joints and screw heads.

Other surfaces

When working on other types of surfaces, the walls must be coated with a layer of primer. In general, the amount of putty for concrete differs only slightly from the costs for the above types of surfaces. For a smooth concrete wall, you will need a first layer no thicker than 5 mm, and a second layer no thicker than 3 mm. Taking into account the thickness of the layer, the consumption per square meter is calculated.

You can also putty wood surfaces. But the layer of applied material should not exceed 2 mm.

Useful tips

Before applying almost all Weber Vetonit / Weber-Vetonit materials, the surface must be primed with a primer depending on the type of surface. Highly absorbent surfaces, such as foam block, gas block, old plaster, are best treated with a deep penetration primer, or a strengthening or universal primer. This is necessary in order to strengthen the base and increase adhesion (adhesion strength) with the applied material. For weakly absorbent surfaces, such as concrete, ceramic brick, a concrete contact primer is usually used, which creates an adhesive rough (due to quartz particles in its composition) film for the same purposes - increasing the adhesion strength of the material, i.e. in simple terms, so that the material has something to cling to.

When preparing solutions, be careful about the proportions of water and dry mixture. Strictly follow the manufacturer's recommendations for the amount of water per bag. This determines how the material will behave after application.

What are the consequences of not following instructions and why is it important? The most common reason for the appearance of cracks or severe cracking is failure to comply with the proportions of mixing the mortar. To find out how much water you need, use the manufacturer's instructions on the packaging or on the manufacturer's official website

Remember that guarantees of material quality are valid only if the manufacturer’s instructions on the technology of use and the requirements of SNiP and SP are strictly followed.

After applying dry mixtures, avoid drafts; the material should evaporate moisture evenly in a natural way, and drafts accelerate the process of moisture release. Also, after applying Weber Vetonit plasters, do not use heat guns, hair dryers and other heat devices to speed up drying, as this will also disrupt the process of natural moisture release.

And of course, take precautions. Keep away from children

During work, use personal protective equipment. Avoid ingestion. If Weber Vetonit plaster gets into your eyes or skin, rinse thoroughly with plenty of water and, if necessary, consult a doctor.

To summarize, let's summarize what has been said:

prime surfaces before applying materials; after application, avoid drafts; do not use heat devices to speed up drying; strictly follow the proportions of water according to the manufacturer’s instructions; Take precautions when applying plaster;

Starting putty - consumption per 1 m2.

For initial leveling of the base, starting putty is used. It is applied as an intermediate coating between plaster and finishing putty. At the same time, the starting putty contains a rather coarse fraction in its composition, since it is most often based on gypsum or lime. Therefore, its consumption will be the greatest. Starter putty is sold in paper packages of 25 and 30 kg.

Practice has proven that one standard 30 kg bag of any starting putty with minimal unevenness, and even under a painting mesh, is quite enough for 10-20 square meters. m walls.

But if the walls are in poor condition and not leveled, then the consumption of the putty mixture will increase. For example, if the layer of starting putty is planned to be 5 mm, then its consumption will increase to approximately 4-8 kg per square meter. m.

Features of starting putty consumption

An important point should be taken into account: it is not recommended to apply a starting putty composition thicker than 5-10 mm in one pass, otherwise it may crumble in the future. The description for any putty usually indicates the minimum and maximum allowable layer level at a time.

For example, for “Polimin ShG-11” putty, the calculated thickness at a time is taken to be no less than 3 mm, but not more than 10 mm. Composition yield: 1.05 kg per “square” with a layer of 1 mm.

But “SATYN PW-01” putty has a maximum permissible layer thickness of 8 mm, consumption per sq. m. is 1.3 kg.

The instructions for the starting polymer-cement putty “Ceresit CT 29” indicate that the thickness of application of one layer varies from 2 to 20 mm, and in fact, the consumption of this mixture per square meter. meter is 1.8 kg with a millimeter layer

By the way, as an initial leveling composition, you can also choose the popular “Knauf HP Start” starting mixture based on lime and gypsum. It is very convenient and is suitable both as plaster and as a starting putty. The stated limits of the coating are 1-3 cm. With a mortar thickness of 10 mm, a 30 kg packet of mixture is enough for 3.8-4.0 sq.m.

Specifications

Undoubtedly, Sheetrock lightweight polymer putty is one of the leaders in the finishing materials market.

The finished putty mixture of this brand is distinguished by the following technical characteristics:

- Convenient packaging. The volume of containers in which the finished mixture is produced varies from 3.5 to 28 liters, which allows you to select the required quantity individually for each finishing object. There are purchasing options for 7, 17, 18, 20 liters.

- Material color. The color of the putty in the container will be white. After drying on the surface, it acquires a pleasant ivory shade.

- Drying time of the material. Sheetrock putty mixture dries quickly - from three to five hours. This drying is influenced by the factors discussed above.

- The putty density is 1.65 kg/l.

- The vinyl included in the mixture allows it to treat any surface (the composition also includes talc powder, limestone and attapulgite).

- The mixture can be stored for up to one year and used more than once.

Calculation of consumption of DANOGIPS putty (11 l / 18 kg) (SHITROK)

Fast and inexpensive delivery, as well as unloading and lifting to the apartment on any floor.

Expert advice, assistance in selecting materials and calculating the required quantity.

Return within one month or extended return period until the end of the repair * for only 5% of the cost of materials.

All materials are stored in dry warehouses, have certificates and quality passports.

By clicking on the "Submit" button, you agree to the Privacy Policy

By clicking on the "Submit" button, you agree to the Privacy Policy

Cost of unloading and lifting

If there is a working freight elevator, the cost of unloading 1 ton of cargo, taking into account the lift to the apartment, is 1,200? regardless of floor.

In the absence of a freight elevator, the cost of lifting 1 ton of cargo to one floor is 1,200?.

The cost of simple unloading of vehicles without lifting to the floor is 1,200 rubles per ton.

The minimum cost for a loader is 300 rubles.

© M-Delivery, 2021

st. Mariupolskaya, 6, office 28. Moscow, 109382

We accept:

Source

Features of storage and care of tools

The composition can be stored for up to 1 year. It is optimal to create room temperature. Do not allow the container to be exposed to sunlight or near heating devices.

If the funds have been frozen, then defrosting is carried out naturally, without accelerating devices. The container must be hermetically sealed. Tools are washed from the composition using warm water and soap.

Do not allow the container to be exposed to sunlight or near heating devices.

Table describing some putties

| Brand | Place of use | Additional features |

| Shitrock | Interior work, can be used not only for sealing seams or cracks, but also as a topcoat | High adhesion and good elasticity due to the vinyl substances contained in the putty |

| Vetonit | Interior work carried out in dry rooms | Moisture resistance and environmental friendliness of the material, which contains cement, sand, limestone, various mineral additives and polymer-based glue. It is important to use the material when the room temperature is +10 degrees |

| Knauf | Interior work on dry surfaces | Environmentally friendly material, which has good adhesion and elasticity. The putty contains lime, gypsum and glue. |

Source