Lining is a universal material, used mainly for interior work. The cost of this building material varies depending on its quality. Before you begin installing the lining, you should make the necessary calculations of its quantity, for which you can use an online calculator, or know how to calculate the lining yourself.

A convenient and simple calculator for calculating the amount of lining: https://otdelkaexp.ru/kalkulyatory-rascheta/kalkulyator-rascheta-vagonki-dlya-sten-po-ploshhadi.html.

We calculate the lining per m2

If it is not possible to use an online calculator, then you should use basic knowledge of geometry and spend a little time. For example, we use a standard room with the following dimensions:

- Length – 8 m.

- Width – 5 m.

- Height – 2.35 m.

The sequence for calculating the amount of wood paneling is as follows:

- Find out the area of all the walls in the room. First, you should calculate the longest wall and multiply by 2. To do this: 8 m must be multiplied by 2.35 m and multiplied by 2. Answer: 37.6 m2 is the total area of \u200b\u200bthe two walls.

- Next, we find the area of the smaller walls: multiply 5 m by 2.35 m and multiply by 2. Answer: 23.5 m2.

- The total area of the walls of the room will be: 37.6 m2 plus 23.5 m2. Answer: 61.1 m2. But we should not forget about such an important parameter as the surface area of the ceiling, which is equal to the area of the floor. Calculation: multiply 8 m by 5 m, answer – 40 m2. This means that the total area that needs to be covered with clapboard will be 101.1 m2.

Video on Youtube:

For greater accuracy, you should make a small margin, for example, a couple of square meters on top. And the final answer will be 103-105 m2. This amount of wood paneling is quite enough to cover a room with the above parameters.

Of course, the data obtained is quite enough to purchase the required amount of lining. But the lining is sold in the form of separate boards, with certain dimensions, and a situation may arise when a hardware store needs to name the exact number of these same strips, and not the total square footage. To calculate the number of lining strips, you should find out the size of one, which is 6 m by 0.15 m. The standard thickness of one board is 2.5 cm, but this parameter is most often not used, because the area is calculated, not the volume.

The surface area of one board is 0.9 m2. It remains only 105 m2 divided by 0.9 m2, which will be equal to 117 (rounding up 116.6) pieces of wood paneling.

Intermediate approach: adjustment for finishing

It is important to understand here that the actual square footage of the final cladding surfaces will be noticeably smaller than that obtained if the lining is calculated based on the areas from the general plan of the load-bearing structures in Scheme 1. The size values will especially decrease if the bathhouse is completely insulated from the inside. But in any case, the steam room will require additional internal lining with a thermal and vapor barrier cake.

Calculate the final dimensions

Let's assume that this is exactly the case - our building already has sufficient thermal efficiency. We only insulate the steam room using an auxiliary layer of thermal insulation 50 mm thick. The result of changing the final dimensions of the premises is indicated in Diagram 2.

Scheme 2

How did these numbers come about? In this case, the calculation of the lining for the bathhouse takes into account the following values:

- thermal insulation with lathing – 50 mm;

- cranial block for fastening the lining and creating a ventilated space behind it - 30 mm;

- facing lamellas - 12.5 mm (one of the popular sizes).

Naturally, the adjustment of dimensions in the washroom and rest room is influenced only by the cranial sheathing and the padded decorative strips. Additionally, the example given is for a horizontally oriented board. If the arrangement of the elements is planned vertically, then the installation of a counter-lattice batten will also be required, the thickness of which should also be taken into account.

Next, we calculate using a simplified method

Using the simplified method already given above, you can calculate the lining according to the adjusted final dimensions and find out that now the area of all ceilings is 19.79 m2 (was 21.6 m2).

To calculate the area of the walls, you must first find the reduction in the height of the premises due to the installation of floor coverings (the lathing frame will be mounted on top of the finished floor), as well as the thickness of the ceiling cladding. How much the floor will rise will depend on its structure included in the detailed design of the bathhouse. You may just need a leveling screed, a tile or plank covering, or a full multi-layer structure with heat and waterproofing materials. Therefore, to make it easier to understand how to calculate the lining, for the sake of clarity of the example, let’s assume that we have already assembled the finished floor. All that remains is to take into account the structures of the ceilings, which we assemble in the steam room, like the walls, with additional insulation, and in the remaining rooms without internal insulation. Then the height in the steam room is 2407.5 mm, and in the washing room and rest room 2557.5 mm.

The perimeter of the steam room walls is now 9.06 m, therefore their area is:

9.06*2.4075=21.81 m2.

The total perimeter of the walls of the washing room and rest room is 21.72 m, area:

21.72*2.5575=55.55 m2.

Quadrature of the surface of all walls of the building:

21.81+55.55=77.36 m2.

Let's summarize the amount of cladding, including ceilings, excluding infill openings and keeping in mind the safety factor:

(77,36+19,79-9)*1,15=101.37 m2.

If we compare with the previous result, which showed the calculation of the lining using a simplified method - 107.065 m2, then their difference is obvious.

Calculation of lining for the attic

For such a room in a house as an attic, you should use a fairly simple and practical formula:

S = 2AB + 2b (4A2-b2)/4

The components of this formula are as follows:

- S – total area.

- A is not the total length of the room, but the distance from the ridge to the beginning of the roof slope.

- B is the width of the room.

- b – door width.

Calculation of lining for the attic

But we should not forget that the attic can be built with additional bulkheads, the parameters of which should also be included in the formula:

S = 2AB + 2b (4A2-b2)/4 + Ph

This formula is practically no different from the previous one, with the exception of two components:

- P is the perimeter of the bulkheads, which can be found by multiplying the width by the length of the bulkhead.

- h is the height of the bulkhead.

Accurate calculator for calculating lining: https://bouw.ru/calculator/raschet-vagonki.

We calculate the amount of lining for the balcony

Calculating the material for the lining is practically no different from calculating a standard room, with the exception that the area of the balcony should be divided into separate components, which will greatly simplify the process. For example, a balcony consists of a space under a window facing outside (length - 4 m, height - 1 m), a ceiling (length - 4 m, width - 2 m), a lower part on the side of the balcony door (length - 3.6 m, height - 1 m) and two side walls (length – 2 m, height – 2.5 m). We carry out calculations separately:

- The sheathing area of the space under the window facing outside: 4 m multiplied by 1 m, the answer is 4 m2.

- Ceiling area: 4 m multiplied by 2 m, answer – 8 m2.

- The area of the lower part on the side of the balcony door: 3.6 m multiplied by 1 m, the answer is 3.6 m2.

- Sheathing area of two side walls: 2 m multiplied by 2.5 m and by 2, answer – 10 m2.

- All that remains is to add up the resulting numbers: 4 m2 plus 8 m2, plus 3.6 m2 and plus 10 m2, the answer is 25.6 m2.

Accurate calculation of lining for a balcony

We round the result up and add a couple of meters of material for unforeseen expenses. The final answer: covering a balcony with clapboard will require 28 m2 of building material. As stated earlier, the area of one board is 0.9 m2. 28 m2 must be divided by 0.9 m2, which will be equal to 32 (rounding up 31.1) pieces of lining.

Determining the sheathing area

In order to cover a country house with clapboard, you must first calculate the clapboard, calculate how much material you will need for all types of work, how much it will cost and try to save money correctly. Costs can be reduced by making correct calculations.

You also need to be able to save correctly, because ardent savings can lead to poor-quality finishing, and this is no longer the ultimate goal for everyone who decided to create coziness and comfort in their home, and of high quality. This is precisely what wooden lining can provide.

Determining the area of one floor

To make it clearer to you how to correctly calculate building materials, we will give an example. Today it will be a room 3 x 4 meters, we will cover the entire room including the ceiling.

So, our room has a length and width of 3x4, and a height (h-height) of 2.5 meters:

- In order to determine the area of the wall, you need to make a very simple calculation - the height must be multiplied by the length, the total we get is 10 (2.5 * 4);

- The area of the opposite side will be similar, that is, equal to the first calculation, which means that in total we will get - 20 (10 * 2). The next calculation will concern an already short wall;

- To find out the square footage of another (short) wall, you need to multiply the height by the width. We get 7.5 (2.5*3);

- We double the result obtained in the previous paragraph, because there are two such walls. Total: 15 (7.5*2);

- To determine the surface area of the ceiling, you need to multiply the width by the length = 12 (4*3);

- All the data we obtained in previous calculations are added together, resulting in 20+15+12=47. This result will be the area of all surfaces of the room that we are going to cover with clapboard;

- Since we have two such rooms on the ground floor, the total sheathing area will be 94 square meters. The calculations are very simple, you just need to be careful.

Lining calculation calculator

The popularity of using lining is increasing every day. And there are good reasons for this:

- lining is a universal material that is suitable for finishing both external and internal walls;

- the cost makes it accessible to the general public;

- The wide range of materials used in production allows it to be used in a wide variety of design projects.

But no matter what lining is chosen, errors in calculating the required amount of material can not only disrupt the current repair process, but also significantly change the expected finishing result.

What else do you need to know about lining boards?

The board, called lining, differs not only in its size, it can be made from different types of wood. Thus, larch perfectly withstands high temperatures and high humidity, which is why lining made from this wood is used in steam rooms and saunas.

Good oak is used for interior cladding of a private house. This material will not rot or lose color over time. Spruce and other coniferous wood can “take root” in dressing rooms and other auxiliary rooms. This material is cheaper, but less resistant to external influences compared to the above options.

Wood selection

Today, the construction market is filled with a variety of options for finishing materials, so for a beginner in repair and construction, choosing lining can be a serious challenge.

The main thing that a buyer must go to the market with is the concept of the exact value of the required amount of material. This approach will help prevent some uncomfortable situations. After all, buying extra materials leads not only to a loss of money, but also time for its possible return.

Important! When choosing wooden lining, special attention should be paid to the type of wood from which it is made. The most common options are deciduous and coniferous wood.

Let's look at the types of trees most commonly used in lining production:

- Pine. It is distinguished by high strength indicators, which attracts consumers. However, you need to know that pine lining quickly loses its original color if it is not treated with protective varnish or stain.

- Oak. The beautiful structure of the wood, which practically does not rot, makes this lining a leader in the ranking of the popularity of finishing materials. Its only drawback is the high price, which is not affordable for everyone.

- Ash. It is not used very often because processing such wood is quite labor-intensive and costly. But at the same time, ash wood is very durable and does not change its structure and shape when dried.

- Linden is an ideal option for arranging steam rooms in a bathhouse or sauna. It retains heat perfectly without emitting resin oils that are harmful to human health.

Choosing wood

Today's construction market is represented by various manufacturers of finishing materials, so the choice of lining should be approached with maximum responsibility, focusing on previously performed calculations.

Important! Each type of wood has its own characteristics. For the manufacture of lining, as a rule, hardwood and coniferous wood are used, but the latter are categorically not suitable for rooms with high temperature load, for example, for saunas and baths.

Let's look at the main rocks used for the production of panels:

- Pine. It has good strength, but is prone to darkening if not covered with varnish or other means. When painting, the color is not distributed evenly.

- Oak. It is resistant to decay processes, has a beautiful texture, but is one of the most expensive materials.

- Ash. Its characteristics are similar to oak, it does not crack during drying, has a long service life and exceptional aesthetic parameters. Panels made of this material have a yellowish-brown tint.

- Linden. It is resistant to high temperatures, so it is perfect for a bath. It is not cheap.

Types of wood

The quality of the lumber and, as a consequence, the final appearance of the product, significantly affects the price of the lining.

There are four main types of wood that can affect the cost:

- category "Extra". This is the highest class of wood, which has no knots, cracks or other defects on its surface;

- class “A” is assigned to wood that can have one or two knots per linear meter of board;

- class “B” assumes that there are dark-colored defects on the surface of the wood, up to 1 cm in diameter;

- class “C” is assigned to the lowest quality wood from which lining of the appropriate price and quality is produced.

It is not difficult to calculate the required amount of material. If any difficulties arise, the seller of the product will always come to the rescue. The main thing is to make all calculations on time, before the transaction is completed. This will help save money and prevent a situation where a very large amount of trim remains after repairs.

Of course, there should be a supply of lining, but within reasonable limits. As a rule, experts recommend adding 10-15% of the reserve to the calculated value of the required amount of material.

Important! When choosing a forcing, take into account the functional purpose of the room where the finishing work will take place.

How much does a linear meter of lining cost?

Price of lining

| Lining calm | ||

| Lining calm grade A 16x115x3000 | 2080 rub. | 740 rub. |

| Lining calm grade A 16x115x6000 | 3698 rub. | 740 rub. |

| Lining calm grade C 12.5x96x3000 | 1679 rub. | 530 rub. |

| Lining calm grade C 16x115x3000 | 1863 rub. | 660 rub. |

What units are the lining sold in?

Lining is mainly sold by cubic meters, which can create some inconvenience when calculating the required amount of material. For greater convenience, it is worth remembering approximately how much area a lining of a certain size can cover:

- a panel whose dimensions are 6000*200*8 mm will occupy an area of 1.2 m2;

- if the lining parameters are 6000*250*5, then the area size will be 1.5 m2;

- a panel with dimensions 2600*148*6 will cover an area of 7.07 m2.

As you can see, the dimensions of the material take into account the thickness indicator. If the lining is sold individually, then the thickness indicator has no meaning and is not used when performing the calculation.

However, in the case of selling material in units of volume, the thickness parameter has a significant impact on the final result when calculating the required amount of lining.

Briefly about the main thing

Lining is a material for finishing work, made of wood and having a special design with “locks” that facilitate its installation.

Calculating the lining with a calculator helps to find out how many packages of this building material need to be purchased for the intended purpose.

When calculating the amount of lining boards for cladding, you need to take into account the parameters of the lining, the room (premises), as well as the presence and size of openings.

Lining can be sold per piece or per square or cubic meter.

To find out how much lining there is in 1 m2, you need to make simple calculations or enter the required values into the appropriate columns of a special calculator.

Ratings 0

Calculation of the amount of lining

The amount of lining is calculated using the following algorithm:

Determine the total area for cladding:

S = (2AN + 2VN) – ( ahn + bh 1 n 1) , where A is the length of the room; H – room height; B is the width of the room; a – window width; b – door width; h, h1 – window and door height; n, n1 – number of windows and doors.

If the ceiling area is taken into account, the calculation formula is as follows:

S= (2AH + 2BH +AB) – (ahn + bh1n1).

We determine the area of the lining for the attic, the ceiling of which is represented by two surfaces and a vertical front without bulkheads:

S = 2 AB + 2 b (4 A 2- b 2)/4 , where A is the distance from the ridge to the base of the slope.

If you need to calculate the amount of lining for an attic with bulkheads, the formula is as follows:

Area = 2AB + 2b (4A2-b2)/4 + Ph, where P is the perimeter of the bulkheads, h is the height of the wall.

You can calculate the area of one panel using simple mathematical calculations. To determine the area of one panel, you need to multiply the length of this panel by the width. In the result obtained, it is necessary to subtract the area of the groove, which is not an element of the skin surface.

To calculate the required amount of material in pieces, you need to divide the total area of the cladding by the area of one panel.

Calculations can be carried out manually, but this process, as a rule, takes a fairly large amount of time and effort. Special computer programs for online calculators will help speed it up and make it easier. As practice shows, the final values when using this method will not differ significantly from those that would be obtained by manual calculation.

How to find out how much wall covering material is needed?

The complexity of the calculations lies in the way the panels are implemented. Intermediaries and manufacturers offer material in cubic meters, which implies the content of a certain number of panels, taking into account their thickness, the width of the board and the length of the lamella. For cladding, you need to know the area to be covered, which does not take into account the thickness of the material profile and its shape.

The calculation result depends on the type, type and size of the lamellas. Each product has its own methods of converting from volumetric units to area and vice versa. Below is a table for common standardized sizes of 12 cm wide canvases:

| Thickness, cm | Area, m2 | In m2, pcs. | Volume, m3 | In m3, pcs. | Covered area 1 m3, m |

| Length 2 m | |||||

| 1,2 | 0,24 | 4 | 0,003 | 357 | 85 |

| 1,5 | 0,36 | 3 | 0,004 | 233 | 83 |

| 2 | 0,72 | 1 | 0,009 | 116 | 83 |

| Length 3 m | |||||

| 1,2 | 0,24 | 4 | 0,004 | 278 | 66 |

| 1,5 | 0,36 | 3 | 0,005 | 185 | 66 |

| 2 | 0,72 | 1 | 0,011 | 91 | 65 |

| Length 6 m | |||||

| 1,2 | 0,24 | 4 | 0,005 | 208 | 50 |

| 1,5 | 0,36 | 3 | 0,007 | 138 | 49 |

| 2 | 0,72 | 1 | 0,014 | 71 | 51 |

According to the table, one cubic meter of different profile sections for lamellas of different lengths can contain a certain number of whole panels. You can determine how many sq. meters will cover 1 m3 of material of the selected standard size.

Attention

All calculations given were performed for lamellas with a standardized width of 12 cm.

This is necessary to facilitate ordering the quantity of material if the surface area for finishing is being calculated.

Panels in units of measurement

Wood sellers sell lumber in different units: packages, square or cubic measures. It is necessary to understand what is indicated on one package or only sq.

meters, or cubes of material, its main dimensions. Therefore, a transition will be required from different values in which finishing panels are calculated. Sometimes a certain number of pieces is required, for example, only a certain length of blade may be on sale, and the buyer wants to make a continuous cladding with 10-15% shorter lamellas than there are. Therefore, he needs to count the number of slats. They will cover the desired length of the wall, and the excess paintings will go to waste.

Many varieties and types of lining differ in the length of the panels, the thickness and shape of the profile, and the width of the strip. These values will be needed to determine the volume or area of coverage. GOST 8242-88 standard dimensions of lumber should be taken into account. Variations are made with the length and thickness of the plank.

Types of standard lining sizes:

- Thickness – 1.2-2.5 mm.

- Width – up to 15 cm.

- Length – up to 6 m.

Dimensional parameters of eurolining:

- Thickness – up to 1.5 mm.

- Width – 8-12 cm.

- Length – up to 4 m.

How many linings per m2? How to correctly calculate the number of boards per square wall

In our daily life, we very often face the issue of choosing building materials and components for them. Many people simply upholster their feet in the hope of finding a quality product at a low price.

So that you do not torment your feet, we have created for you the website Lesobirzha.ru, where the entire range of our products is displayed. Here you will find everything you need for finishing both interior and exterior from the best manufacturers in our country.

To begin with, let’s imagine what lining is and what types of wood it is made from. Lining is a special type of finishing board made of high-quality natural wood and it is made from such wood species as: larch, pine-spruce, Angara pine, cedar.

In this article you will learn several important points:

- how to correctly calculate the amount of lining per square wall;

- how to choose a clamp number for lining;

- What formula is used to calculate the bars for the sheathing?

How to calculate how much lining is needed for installation on a wall or ceiling?

Our consultants constantly have to answer these questions: how to calculate the square footage of the lining and the number of boards for installation?

Photo 1. Installation of cedar lining

To calculate how much lining is required for installation on the wall, we need:

- know the square footage of the wall or ceiling;

- multiply the length by the width of the paneling, so we will find the working area of the board;

- Next, we take the square meters of our wall or ceiling (the square footage may be different) and divide it by the resulting working area, so we will get the amount of lining for installation.

How to choose the right clamp for lining?

First, let's tell you what a cleimer is. This is a metal perforated plate (clip) for fastening lining, wall panels and block houses.

Photo 2. Claymer for lining

When choosing a plate as a fastener for lining, we choose reliability and confidence in the design. Not all carpenters like to work with a clamp, but this is because it is faster to fasten it with self-tapping screws, but the trouble is, no, no, the tenon will break off when mounted on screws, and some of the products will be damaged, but with a plate it is reliable and without breakages.

Photo 3. Claymer No. 6

How to choose the right clipper is very simple. It is marked with numbers from 1 to 10, which reflect the distance of the clamp tongue from its base.

Photo 4. Reinforced clamp

The clamp can be fastened with a nail, self-tapping screw, or construction stapler. There is also a reinforced clamp, it holds heavier wooden structures. So, how to choose the right clamp for lining? It is necessary to measure the thickness of the rear groove of the lining, onto which the mount will be placed.

If it is 5 mm, then we choose a clamp with the number 5, if it is 3 we choose with the number 3, etc. We do the same with the reinforced one.

How to calculate how many bars are needed for sheathing?

For lathing, the most optimal size of the bar is 40/20 - 30/40 (we attach the lining). For street sheathing we will need a bar measuring 50/40 - 60/40 (we attach the plank). The length of the bar can be from 2 to 3 meters in both the first and second cases. Let's return to the question of how to calculate how many bars are needed for the sheathing?

- you need to know the square footage where the sheathing will be attached;

- multiply the number of square meters by 2.5 and then divide by the length of the bar.

So, we received the number of bars for our sheathing.

Photo 5. Lathing made of timber

The products of our company will satisfy any client with any requests. You can also make a request and place an order on the website. Learn a lot of information from our articles and come to the right decisions. You will find a lot that will surprise you on our website Lesobirzha.ru (for example, a wood painting service with convenient color selection calculators for each product). The highest quality wood from elite wood species will exceed all your expectations. Call us, we are happy to help.

How to correctly calculate how much canvas is needed?

Calculations do not always include the size of the canvas or other dimensions. When entering any data in calculator software environments, the required amount of lining is approximately determined in the required units of measurement, giving an insignificant error.

Even with an ideal software or manual method, it is impossible to obtain the exact number of panels, taking into account their damage or improper processing (how to process lining?). Therefore, you need to purchase cladding with a small (10-15%) margin .

To calculate the number of canvases, the basis is the definition in a unit of volume:

Attention

N (pcs.) = 1 / (L x W x T) , where:

- N – number of whole lamellas;

- L, W, T – their length, width and thickness, respectively.

If you need this value in square meters.

meters, then the parameters are used without taking into account the thickness of the profile: N (pcs.) = 1 / (L x W)

For example, let’s take a canvas 20 x 120 x 6000 mm, which needs to cover a room area of 40 m2 along the walls.

For all calculations to coincide, they must be performed in a single system.

For example, convert all parameters of the dimensions of one lamella into meters:

20 x 120 x 6000 mm = 0.02 x 0.12 x 6 m.

In 1 m2: 1 / (6 x 0.12) = 1 / 0.72 = 1.4 pcs.

In 1 m3: 1 / (6 x 0.12 x 0.02) = 1 / 0.0144 = 69.5 pcs.

Therefore, the number of lamellas for an area of 40 m2 will be:

40 x 1.4 = 56 pcs. Or translated into volumetric units: 56 / 69.5 = 0.81 m3.

When shipping material, the seller rounds the required volume to the nearest whole number of sheets.

How to determine square meter?

If the finishing will be done by calculating the total finishing area, then the easiest way to calculate the number of panels is to determine the number of whole panels in one square meter.

For calculations you need:

- Find out the parameters of the element - the length and width of the lamella. For example, let’s take a lining 2 m long and 12 cm wide (this is 0.12 m in terms of meters).

- Determine the area of one canvas by multiplying its length by width: 2 x 0.12 = 0.24 m2.

- To determine the number of whole lamellas in 1 m2 of lining, you need to divide this area by the found value for a unit of material: 1 / 0.24 ≈ 4.17 (pieces).

Attention

In practice, a fractional value is often indicated, but in fact no one buys several whole boards and the specified trim. The amount of material is rounded up to a larger whole number, in our example it will be 5 planks.

When calculating for a large area, you can leave a fractional value, since for 40 m2 of surface the area of “cuts” of each square meter will be almost 7 m2. But rounding up is irrational, since there will be a huge overrun of up to 12 m2. This is only relevant in the case of a general calculation of the area.

After the material has been calculated, you need to know how to handle it. We suggest reading about how to store the material, line the inside of the premises with clapboard, cladding the walls of a bathhouse, balcony and loggia, what methods of fastening are available, how to properly varnish the clapboard for a long time, as well as how to update old panels and decorate the clapboard.

How to find out the area?

When making calculations for a room, you should take into account its dimensions - height, width, length.

To make things easier to understand, let’s choose the following room parameters:

- height – 2.45 m;

- width – 4.5 m;

- length – 5.35 m.

Calculation algorithm:

- The area of parallel walls is determined: their length or width is multiplied by height, which gives 4.5 x 2.45 = 11 m2 and 5.35 x 2.45 = 13 m2, respectively.

- The total area of all walls is determined as double the sum of two adjacent ones. It is equal to (11 + 13) x 2 = 48 m2.

- If you also need to finish the ceiling, then its area is found as the product of the length of the room and the width: 4.5 x 5.35 = 24 m2.

- Summing up the area of the walls and ceiling, we get the total value: 48 + 24 = 72 m2.

- Considering the presence in the room of a window with a size of 3.5 m and a height of 2 m, one door with opening dimensions of 1 m by 2 m, it is necessary to subtract the area of the openings from the obtained result, which is determined by multiplying their heights by the corresponding width: 72 - (3.5 x 2) – (1 x 2) = 63 m2.

- The optimal margin is usually 10-15% of the required finishing area; let’s determine the ratio of the incoming areas of the window and door opening as a percentage: 100% - (63 / 72) x 100% = 12.5%.

Important

From the above calculations it is clear: if the room has one window and one door, then the calculation is allowed without deducting these objects, since they approximately constitute the required supply of lining. This greatly simplifies the calculations.

In-depth (element-by-element) calculation taking into account the dimensions of the lining

It makes sense to start this design method only if you have a good understanding of the range of existing material, the features of its installation, including the assembly of the frame, laying insulation, installing a vapor barrier and ventilated space, and fastening the lining.

An in-depth calculation of forcing for a bathhouse will be a continuation of the intermediate method, where we have already calculated the final dimensions of the premises after finishing the finishing work, Scheme 2. Using these data, as well as the characteristics of the products that will be installed, it is necessary to practically give an element-by-element layout for each surface to be tiled .

What width should I choose for the lining?

The first step is to find out how many rows of boards will lie on the walls and ceilings. Despite the fact that vertical assembly of wall panels is more economical, horizontal installation is more often chosen for baths. It is carried out from top to bottom, not reaching the finished floor covering at least 20 mm to ventilate the cladding. That is, our set height will be 2387.5 mm (in the steam room) and 2537.5 mm (in the washing room and rest room).

We select options to calculate the amount of lining, taking into account that the last lamella should have minimal trimming, Table 1.

Table 1.

| Width of the lining, mm. | Number of rows of whole boards, pcs/width of the last lamella after cutting, mm. | |

| Steam room | Washing room, rest room | |

| 88 | 27/11 | 28/73 |

| 110 | 21/77 | 23/7 |

| 130 | 18/47 | 19/68 |

| 135 | 17/92 | 18/107 |

| 190 | 12/107 | 13/67 |

A similar table must be compiled for ceilings. In this case, you can be guided by the principles of aesthetics or only by efficiency, mounting the lamella always parallel to a short wall, regardless of the placement of entrances and windows. After all, the retail price of short lining is lower than similar products with a longer overall length. Let's consider an economical option, table 2.

Table 2.

| Width of the lining, mm. | Number of rows of whole boards, pcs/width of the last lamella after cutting, mm. | ||

| Steam room | Washing | Restroom | |

| 88 | 28/50 | 39/82 | 29/62 |

| 110 | 22/95 | 31/104 | 23/85 |

| 130 | 19/44 | 27/5 | 20/14 |

| 135 | 18/85 | 26/5 | 19/50 |

| 190 | 13/46 | 18/95 | 13/144 |

It should be clarified that in order to calculate the lining correctly, you should take into account only the useful width of the lamellas, the one that will remain along the front part after aligning the lock joint. For example, planks with a useful width of 88 mm have an absolute size of 96 mm when measured at the extreme points of the tongue and groove.

How to use the results of the tables in practice?

One of the installation rules recommends designing a set of lamellas in such a way that a minimum strip is cut from the last board. From the tables it can be seen that if you do not use products of different widths, then the universal options are 135 mm or 190 mm slats (green font). They fit equally well on walls and ceilings, since their finishing strip is wide enough for convenient, reliable assembly. We do not place the last plank (135 mm from the lamella) 5 mm on the ceiling in the washing room, since the resulting gap will be closed by the corner finishing strip. From Table 2 it is also clear that the calculation of the lining reveals products (their dimensions are highlighted in red), the use of which in certain cases will be problematic. The narrow strips of the last planks are both inconvenient to cut and their strength leaves much to be desired.

If one strives to use the narrowest strip everywhere, since it warps less in damp rooms, then in some cases it will be necessary to use products with different dimensional parameters. For example, the width of the lining:

- for walls/ceiling in a steam room – 110 mm/88 mm or 110 mm;

- for walls/ceilings in the washing room and rest room - 88 mm/88 mm.

Individual approach for each surface

At the next stage, the element-by-element calculation of the lining for a bathhouse will largely be based on the assortment of local retail outlets that interests us. Although in theory lining is produced with board lengths of 200-6000 mm, it is unlikely to be possible to purchase them with a clear layout on the walls and ceilings. Most likely, you will have to choose products of the same profile with several lamella length options.

In this case, it is necessary to draw a complete development of the planes of all walls and ceilings. It will clearly show possible options for using cuts of long boards in short areas. For example, from a blank wall of a washing room (3515 mm), if the order includes a lining 4000 mm long, you can transfer the cut parts to the opposite surface for finishing around the doors. Calculation of the amount of lining for such installation may include a connecting strip above the doorway, as well as wherever required. This helps to significantly save material by reducing the amount of substandard trim..

It is possible to obtain even more waste-free cutting of lumber if you make it to order for each surface to be faced. It makes sense to do this if there are carpentry production nearby that guarantee the final quality of their products, that is, they must have a humidity of 12% (±3%) and also meet all other standards for their class.

What do we get in the end?

Having drawn the layout of the rooms on a plane and knowing the number of slats on them, it remains to calculate the lining, taking into account the minimum margin. With this approach it will be no more than 5%. We also take into account that now, instead of the height and length of any of the rooms, to find the quadrature of the surfaces, we take the value summed up from a set of lamellas. In this case, the width of the finishing board is considered without trimming.

For ease of calculation, we use a 135 mm bar everywhere. Then the sizes of the sets take the following values:

- steam room walls – 18*135=2430 mm;

- walls of the sink and rest room – 19*135=2565 mm;

- steam room ceiling – 19*135=2565 mm;

- washing room ceiling – 26*135=3510 mm;

- rest room ceiling – 20*135=2700 mm.

Surface areas:

- steam room walls – 2.43*9.09=22.09 m2;

- walls of the sink and rest room - 2.565 * 21.72 = 55.71 m2;

- steam room ceiling – 2.565*2.015=5.1 m2;

- washing room ceiling – 3.51*2.615=9.18 m2;

- rest room ceiling – 2.7*2.115=5.7 m2.

General quadrature for surface layouts:

22.09+55.71+5.1+9.18+5.7=97.78 m2;

It remains to calculate the amount of lining for purchase, subtracting the area of the door and window openings, and also taking into account the margin for trimming:

(97,78-9)*1,05=93.2m2.

Note. In all three calculation methods, the material for designing the slopes of the openings was not taken into account. Sometimes trimmings from the finishing strips of ceilings or walls may be sufficient for narrow slopes. The need to purchase additional lining must be considered separately in each specific case.

Features of calculation without a calculator

If you don’t have a special calculator at hand, in which you simply need to enter the required values in special fields, then you can use all the above rules for calculating the amount of required lining. It is necessary to correctly calculate the following parameters:

- Total area , which is calculated as twice the sum of the areas of adjacent walls of the room (read about covering the walls of rooms and houses with clapboard here).

- Ceiling area , which is equal to the same value for the floor, is calculated by multiplying the length by the width of the room.

- The total area of door and window openings , which is determined by the separate sum of the area of each window and door, and these parameters are taken as the product of the height and the width of the corresponding opening.

- The finishing area that will be required to cover the walls and ceiling of the room can be determined as the sum of the required material for the walls and ceiling, calculated from the resulting value of the opening area.

If it is necessary to calculate a geometrically complex surface, then it is divided into several sections of a simple shape and calculations are made. This formula easily combines all the calculations made, which greatly simplifies the process, since you will need to make the necessary measurements and substitute them in their corresponding places.

It is easy to calculate the number of wooden panels or the required volume of finishing material for a room. You must follow all the recommendations outlined or simply use formulas with substitution of your values and parameters.

The easiest way to calculate is online calculators that perform calculations without human intervention. You need to be careful with the specifics of these applications, as some may take into account a certain % of the margin, while others do not, which causes discrepancies.

How to calculate the area of the first floor

It is better to consider the algorithm for calculating the area of a room using the example of a 5x8 house, where we will cover the walls and ceiling with clapboard.

Next you need to calculate the square footage of one of the rooms. Let its length (a) be 5m, width (b) 4m, and height (c) 2.5m. And then everything was as we were taught in the school geometry course.

Using the same principle, we find the parameters of the remaining rooms and summarize. In this case, the second room had the same dimensions, so the area of the entire first floor is: 65+65=130 square meters.

Calculator for calculating lining for walls by area

Lining is a universal material for covering walls outside and inside a building. The material is made from natural wood, has low cost and attractive appearance.

Below is a calculator for calculating lining for wall cladding and home decoration. With its help, you can carry out all computational operations online.

[CP_CALCULATED_FIELDS id=”27"]

To operate the calculator, a formula was used based on the sheathed area and the area of the lining itself. To get the result you need to enter data about the surface and board parameters.

If all four walls are sheathed, then you need to fill in the fields: length, width, height. If there are windows and doorways, their number is selected. Next, enter their parameters in the drop-down field.

We made several drop-down fields so that you can set parameters for openings of different sizes. For identical openings, it is enough to duplicate the values.

| Size, mm | Area, m2 | volume, m3 | In m3, pcs. |

| 12x120x2000 | 0,24 | 0,0028 | 357 |

| 15x120x2000 | 0,24 | 0,0036 | 277 |

| 20x120x2000 | 0,24 | 0,0048 | 208 |

| 12x120x3000 | 0,36 | 0,0043 | 232 |

| 15x120x3000 | 0,36 | 0,0054 | 185 |

| 20x120x3000 | 0,36 | 0,00723 | 138 |

| 12x120x6000 | 0,72 | 0,0086 | 116 |

| 15x120x6000 | 0,72 | 0,011 | 90 |

| 20x120x6000 | 0,72 | 0,014 | 71 |

Afterwards, you need to select the board parameters from the proposed options. The calculator already contains the length and width of the board for regular lining. For eurolining, you need to select “Custom sizes” and manually enter the dimensions you need.

As a result, the online calculator will quickly calculate and display the working area, which is the sum of the difference between the total area and the area of the openings. In the “Wood panel consumption” field, the minimum number of boards in pieces will be indicated.

To the obtained value we recommend adding 10-15% of the material that will be used for trimming or scrap. If the calculations did not take into account the area of various openings, niches, doors, gates, then their parameters can be taken into account as an extra charge.

Main dimensions and parameters

The lining is sold in cubic meters, square meters and packages. It all depends on the selling party and volumes. In some construction stores, due to small sales volumes, they may be sold in pieces.

The calculator for calculating the amount of lining gives the result in pieces. To convert these values into cubic meters, use the table located under the calculator. Additionally, the area of one board is indicated for manual calculations.

The standard formula for calculating the number of boards per cubic meter: 1 m3 / (L*H*B) = N pieces, where L is length, H is height, B is width.

The length of the board for wall cladding varies from 2 to 6 meters

For example, let's take a 15x120x3000 lining. The size is indicated in millimeters, so we substitute the parameters in meters into the formula. You need to calculate the number of boards in one cubic meter. 1 m3 / (3*0.015*0.12) = 185 pieces.

The length and width of the lining is regulated by GOST 8242-88, but some sawmills make boards taking into account only two parameters. Basically this only applies to thickness and length.

The standard dimensions of the lining are as follows:

- length – no more than 6 m;

- width – no more than 15 cm;

- thickness – from 12 to 25 mm.

Eurolining has a length of no more than 4 m, width from 8 to 12 cm, thickness up to 15 mm. Other types of lining can have excellent dimensions in all three respects.

For the calculation, size does not play a special role. The calculation calculator allows you to enter any data for the edged board. The output will be an approximate result with a minimum error.

How to calculate without a calculator

In addition to special programs, the calculation can be done manually. This is especially important when you need to estimate the amount of material at the work site. Simple arithmetic formulas are used for this.

Rooms and surfaces of complex shapes can be divided into simpler sections

Manual calculation of lining for walls and houses is performed in the following order:

- Total area, S = (2AL + 2BL), where A is the length of the room or building, B is the width of the room or building, L is the height of the room or wall.

- Ceiling area, S2 = CD, where C is the length of the ceiling, D is the width of the ceiling.

- Area of window and door, S3 = ab + cd, where a is the height of the window opening, b is the width of the window opening, c is the length of the doorway, d is the width of the doorway.

- Covered area, S4 = (S – S3) + S2. If necessary, all calculations can be combined into one formula: S = (2AL + 2BL + CD) – (ab + cd).

If there are several windows in the room, then you need to put the corresponding number in the third formula. For example, for three windows – S3 = 3ab + cd. As a result, to calculate the amount of lining, you need to divide the result obtained by the area of one board.

Type of wood and type of board

Larch is the optimal wood for use in baths and saunas

Lining refers to lumber quality, which is determined by the concept of class or grade. This parameter is adjusted depending on the type of wood used. Coniferous lumber is regulated according to GOST 8486-86, and pine and larch lumber according to GOST 26002-83.

To determine quality, it is customary to use classes such as:

- Extra – lining of the highest quality without knots, cracks or other defects.

- A – a board that can contain up to 2 knots per 1 linear meter.

- B – on the surface of the lining there are dark veins and shallow scratches, up to 1 cm in diameter.

- C – low grade with all the above problems.

“Extra” and “A” class lining is used for cladding interior walls and houses. Other varieties act as boards for finishing technical rooms. For the production of lining, the wood used is pine, oak, larch, ash, aspen and linden.

Larch and linden boards are optimal for use in steam rooms, bathhouses, and rooms with high humidity. Such wood is not subject to loss of color, does not crack, and does not twist when drying.

Oak is used for finishing inside the house. It has an excellent structure, does not rot, does not lose color. The only negative is the high cost of lumber.

Boards made of spruce and coniferous species, as a rule, have many knots, therefore they are used for cladding walls in dressing rooms. After installation, the surface must be covered with a protective composition, since spruce wood quickly loses its original appearance.

When purchasing lumber, it is advisable to go to the warehouse or go straight to the hardware store. Once on site, you should carefully check the material and make sure that you are offered the appropriate type of board.

Try not to order facing materials without checking, as cases of substitution or sale of low-quality products are becoming more common. If, nevertheless, the material was delivered to the work site without an initial inspection, then ask to unpack the pallet or take out 2-3 sheets for visual inspection.

If the quality of the board differs from the parameters dictated by GOST, then you can safely refuse the purchase or demand an advance payment back. Usually, if there are 2-3 bad boards in a pack, then the selling party simply slips in a low-quality or defective board.

Lining calculator: calculate quantity, area, volume

Hide

1. Lining calculator

2. How to calculate the number of linings by area?

With this online calculator you can:

- calculate the amount of lining;

- lining area in square meters;

- find out the volume of the lining in m3.

To do this, select one of the 2 calculation options in the drop-down list and insert the appropriate values into the fields.

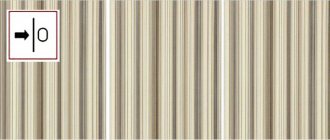

For calculations, it is necessary to take into account the working width of the lining. The diagram above shows how it stands out visually.