High-quality floor repair depends on the correct choice of base. The choice of modern materials is so wide that it is often difficult for the average person to decide what exactly he needs. For flooring on a wooden base, particle board materials are most often used. But what should you choose, chipboard or MDF? How do OSB boards differ from plywood and what will be better for flooring?

How much does one sheet of chipboard cost?

Depending on the type, brand and surface of the material, the price for a sheet of chipboard can start from 650 rubles. The price of a laminated chipboard sheet with a size and thickness of 2800x2070x16 mm will be about 1,420 rubles. While sanded chipboard of the same size will cost 880 rubles.

Interesting materials:

When does university studies start in 2022? When does spring conscription 2022 Kazakhstan begin? When does the zodiac sign Sagittarius begin? When do Brahma chickens start laying eggs? When do quails start laying eggs? When do Bashkir ducks start laying eggs? When do chickens start laying eggs? When do domestic ducks start laying eggs? When do pullets start laying eggs? When do mulards begin to lay eggs?

What is a prefabricated screed

The very definition, prefabricated screed, assumes that the screed structure is assembled from individual structural elements. Unlike solid (poured) screeds, prefabricated screeds are assembled without the use of “wet” construction technologies, from individual elements of the frame or underlying layer and layers of sheet building materials.

The bottom (supporting) layer of the prefabricated screed can be:

- The underlying backfill layer is made of special bulk fine-grained building materials (sand, backfill for gypsum plasterboard);

- The structure is made of logs - sheathing. This is a special wooden frame, made of timber, on a subfloor.

The top layer of the prefabricated screed can be made from:

- Fiberboard (Fiberboard);

- Chipboard (chipboard);

- Moisture-resistant tongue-and-groove chipboard (VDSPSh);

- Oriented strand board (OSB, OSP);

- Gypsum fiber board (GVL);

- Plywood.

According to the technology, sheet material is laid in two layers with offsets in rows and layers, avoiding the coincidence of seams of different layers.

Content

The construction market today is extremely large and represents a large number of materials that serve as wood substitutes. Among them are fiberboard, chipboard, OSB (OSB) and plywood. These products are significantly cheaper than conventional lumber and are therefore increasingly used as an alternative. But it is worth considering that each type has its own characteristics, as well as functional and structural differences, which makes them suitable for certain tasks. Therefore, let's look at the features of each material, their differences and decide which coating should be used and when.

Gypsum fiber boards (GVL)

Gypsum fiber boards (GVL boards) are specially created for flooring, called dry screed. GVL are laid only on a backfill layer of special backfill. It is impossible to use GVL in a structure made of logs, due to their fragility to fracture.

The strength of the GVL surface is given by locks along the edges of the sheets, made in the form of a tongue and groove. The lock is coated with a special mastic and fastened with self-tapping screws. The seam between the sheets is taped. Any finishing material, with the exception of parquet, can be laid on a dry GVL screed.

Note: The package refers to “capricious” finishing materials, which need to be laid only on a layer (layers) of plywood, moreover, cut into squares of 500 by 500 mm.

Which material is better

Let's figure out what is better: plywood or chipboard. First, let's decide what's best for furniture. In furniture production, laminated chipboard is more often used to reduce the cost of finished products. The lamination layer provides the sheets with additional protection from moisture. Therefore, they can even be used for kitchen sets.

What's best for the floor? Evenness and durability are especially important for the floor. Since chipboard wears out, does not hold fasteners well and is more susceptible to moisture, it is rarely used to level floors. It can be used to lay a floor under linoleum, but under parquet you will need plywood: chipboard is not suitable for sanding. It is also better to line the finishing floor with FC plywood. It is more durable and more attractive.

You can inexpensively buy all types of plywood and tongue-and-groove chipboard from us. Our warehouse always has as much material as you need. We guarantee fast delivery of orders in Moscow and Moscow Region.

Size

Wood boards are produced in different sizes, which allows you to choose the right option. The larger the dimensions of the slab, the fewer joints, and this in turn increases the reliability of the structure.

Standard dimensions (LxW):

- OSB –2440x1220 mm, 2500x1250 mm, 915x1830, 3660x1220 mm;

- Fiberboard – 2440x1220 mm, 2140x1220 mm, 2745x1700 mm, 2745x1220 mm;

- plywood – 1525x1525 mm (FK), 2440x1220mm, 2500x1250 mm (FSF, FOF).

The thickness of the wood board is determined based on the distance between the supports, the type of load and the load-bearing characteristics of the board. To correctly calculate the required thickness, it is better to contact specialists.

Standard thickness:

- OSB – 6-40 mm;

- Fibreboard – 8-25 mm (soft), 6-12 mm (semi-hard), 3.2-6 mm (hard and extra-hard);

- plywood – 3-40 mm.

Oriented strand board (OSB, OSB)

Oriented strand boards are similar to chipboards, but have a number of significant differences:

- OSB types OSB3 and OSB4 are not afraid of moisture;

- The slabs of these modifications can withstand heavy loads, which allows them to be used even in load-bearing structures.

OSB panels are produced with tongue-and-groove end locks. They create stronger joints and stronger floor and wall surfaces.

conclusions

When choosing a material for installing a floor, it is difficult to immediately answer the question of which is better: OSB or plywood. There are many factors that determine the characteristics of sheets. Both varieties have similar properties, are durable, tolerate contact with moisture, but can behave differently under the same conditions.

When installing plywood, the coating does not bend, because this material fits well and does not “play” under pressure. It better withstands mechanical loads, but does not have sound insulation, and therefore requires the use of substrates. OSB is a sheet that is distinguished by its versatility, which is due to its low content of harmful components and affordable price.

oak country white door minister ros photo

Source

Areas of application

The areas of use of wood-based panels are varied. Chipboard and fiberboard have long found their use in furniture manufacturing. Manufacturers use this product because of its easy processing and affordable price. Some are attracted by the neat and aesthetic appearance of the material. Despite these advantages, chipboard and fiberboard are significantly inferior in strength to natural wood. Budget furniture is made from pressed material.

To give furniture a more expressive and attractive appearance, experts use coloring compounds and synthetic coatings. Models made from sheets that imitate natural raw materials are very popular. Fiberboard and chipboard have also found their application in the production of acoustics, including subwoofers. The sheets have the necessary strength and low weight. The result is practical music equipment that is lightweight.

Some types of chipboard are actively used in construction. They make reliable interior partitions that you can make with your own hands and install without the help of specialists. We noted above that the slabs have also found their use as an additional floor covering. Fiberboard is often used to make the back walls of furniture and drawers. The use of slabs reduces the cost of the finished product and its life. Fiber sheets are used for finishing loggias and balconies. With their help, you can insulate a location or close it from prying eyes.

Owners of private houses also paid attention to wood building material. It is used as additional thermal insulation. The sheets make light and practical temporary buildings, which will definitely come in handy in the garden or garden.

In this case, it is recommended to use moisture-resistant chipboard panels.

Plywood

Plywood is the last sheet building material of this review. Plywood can be used for any construction of prefabricated screeds, and also as an underlying layer for poured screeds.

The widespread use of plywood is limited by its high cost, which is not reasonable for installing a cheap floor, say, from linoleum. However, for parquet floors, plywood is indispensable. It creates a smooth, durable base with performance characteristics as close as possible to parquet.

Laying plywood

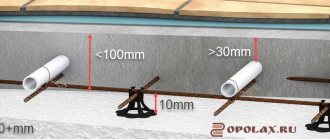

Plywood is laid in two layers, pre-cut into sheets measuring about 50 by 50 cm. The rows of plywood are shifted, the layers of plywood are shifted to avoid the seams matching along the horizon and layers. A gap is left between the sheets.

Plywood is laid on a 1 mm layer of mastic applied to concrete or cement bases. Additionally, the plywood is secured with screws on dowels. Plywood is laid on the joists without the use of mastics, only with the use of self-tapping screws.

Features of materials

Chipboard (chipboard) is a pressed board material consisting of sawdust and shavings mixed with synthetic glue and hot-pressed into sheets. This durable and comfortable material is actively used in the production of furniture and interior decoration.

Chipboard has a number of advantages:

- high strength;

- heat and sound insulation;

- various sizes;

- ease of processing;

- price.

- Floor and roof sheathing is an ideal layer for parquet and linoleum flooring, and is excellent for sheathing roofs under tiles.

- Manufacturing of wall partitions - when remodeling premises, it is actively used as a rough material.

- Furniture manufacturing - racks, shelves, cabinets in offices are made of chipboard.

- Door production – budget interior doors are made from chipboard.

Plywood is a sheet material consisting of several layers of wood veneer glued together perpendicularly. This durable material is used in construction, renovation, and furniture production.

Advantages of plywood sheet:

- increased moisture resistance;

- strength and wear resistance;

- resistance to temperature changes;

- non-toxic;

- aesthetics.

- Furniture production - the texture of plywood itself is original, and is often used in the production of chests of drawers, tables, cabinets, shelves, and children's beds;

- Covering floors and walls - plywood is often used as the basis for parquet, and for walls the beautiful texture of the material is used as a decorative detail;

- Mechanical engineering - plywood is used as flooring in buses, trailers, and trucks.

Let's compare the characteristics

Based on the basic characteristics of the materials, you can decide on the choice of base floor:

- Environmental friendliness is one of the key factors. The performance of the materials under consideration varies. Thus, plywood is considered the safest, while chipboard causes the most controversy.

- Strength. When choosing a material for this parameter, it is worth considering the density and structure of the material. So, the most durable ones are plywood and OSB, and in last place are hardboard and MDF.

- Dimensions. For installing a subfloor in small rooms, this indicator is also important, however, the length and width of all slabs are approximately the same, which cannot be said about the thickness. So, the densest material is OSB and chipboard, and the thinnest is hardboard.

- The cost of materials is variable and this parameter depends on many factors, such as the production method, class of material, raw materials used, additional processing, etc. OSB is in first place in terms of budget, and plywood is in last place.

Fiberboard (Fibreboard)

Fibreboards are the main sheet material used in a wide variety of floor designs. Fiberboard is made practically from wood waste using the hot pressing method. Fiberboard is not afraid of moisture, adheres well and partially absorbs sound.

If you look at the technological maps and regulatory documents on the construction of floors, fiberboard remains the main sheet material used in the construction of screeds.

However, the small thickness of the sheets limits their use in prefabricated screeds on joists, leaving them a niche for prefabricated screeds on the backfill or use as a substrate.

Fibreboard laying

- Fibreboard is laid on hot or cold mastic with 40% of the surface coated in two layers. The seams between fiberboard sheets (without a lock) must be glued with paper or tape 50±10 mm wide.

- Rolled finishing materials (linoleum, carpet) are laid on super-hard fiberboard sheets. Fiberboard strips serve as a layer between the floor joists and the concrete.