When building a house, as well as finishing it, it is very important to decide on the materials that will be used. So, which is better, plywood or drywall, those who encounter types of finishing for the first time ask themselves. Both of these materials are quite economical and are used almost always.

Drywall and plywood are widely used in home construction and decoration. They are almost in the same price range.

Of course, plywood is a more environmentally friendly product, it is made of natural material, and drywall is nothing more than ordinary cardboard impregnated with a special composition.

Plywood is great for laying on laminate floors, and plasterboard is used for leveling walls or creating various design solutions inside the house.

The ideal material for creating interior partitions is plasterboard.

It should be taken into account that drywall is resistant to moisture. Therefore, it is often used in the kitchen, bathroom or other places associated with dampness.

For the interior decoration of a house made of timber, plasterboard would be better, because when the temperature changes, condensation occurs, and plywood does not like moisture and can warp.

When creating interior partitions, a better material than plasterboard has not yet been invented, so it remains to be recognized as the first choice. However, such walls are quite thin, with little sound insulation.

It does not withstand heavy loads and, naturally, is inferior to natural wood, but it has a very even and smooth surface and does not depend on the vagaries of the weather.

Drywall, its advantages and disadvantages

Drywall is currently used in almost all finishing works. It is necessary when creating figured structures, designing window and door slopes, ceilings and walls. With the help of drywall, you can embody all sorts of creative ideas from designers.

Advantages of drywall:

- Environmental friendliness

- Good thermal insulation properties

- Ability to hide communications

- Fire safety

- Flexibility and lightness

Disadvantages of gypsum boards:

- Fragility, low strength

- Instability to moisture (but there is moisture-resistant drywall)

Data-lazy-type=”image” data-src=”https://remontcap.ru/wp-content/uploads/2017/11/2b-1024×684..png 1024w, https://remontcap.ru/ wp-content/uploads/2017/11/2b-300×200..png 1086w» sizes=»(max-width: 620px) 100vw, 620px»>

Chipboard, its advantages and disadvantages

Chipboard is one of the most popular materials in construction. Because of its strength, it is used in the manufacture of doors, installation of partitions between rooms, or in the manufacture of various furniture.

Advantages of chipboard:

- High strength and rigidity

- Easy to process

- Wide range of applications

- Nails and screws are firmly attached

- Homogeneity of material structure

- Possibility of manufacturing parts of various shapes

Disadvantages of chipboard:

- Twice as expensive as a gypsum board sheet of similar size

- Swells from moisture

- Flammability

- Toxicity (contains formaldehyde resins)

Data-lazy-type=”image” data-src=”https://remontcap.ru/wp-content/uploads/2017/11/1-1..jpg 640w, https://remontcap.ru/wp- content/uploads/2017/11/1-1-300×199.jpg 300w» sizes=»(max-width: 640px) 100vw, 640px»>

Fiberboard, its advantages and disadvantages

This material consists of wood fibers, special additives and synthetic polymers. It is made in two ways: either drying the wood fiber carpet or hot pressing.

Advantages of fiberboard

- Long service life

- Water resistance

- Low cost

- Variety of shapes and sizes

- Good thermal and sound insulation properties

- Ease of handling due to low weight

Disadvantages of fiberboard

- Quite limited scope of application of certain types of fiberboard

- Some types of fiberboard are toxic because they contain formaldehyde

Data-lazy-type=”image” data-src=”https://remontcap.ru/wp-content/uploads/2017/11/e-zVbZ9-..jpg 400w, https://remontcap.ru/wp -content/uploads/2017/11/e-zVbZ9—150×150..jpg 300w, https://remontcap.ru/wp-content/uploads/2017/11/e-zVbZ9—200×200.jpg 200w" sizes=”(max-width: 400px) 100vw, 400px”>

Characteristics of OSB

Of all the materials, it is most similar to OSB plywood.

The fundamental difference between them is that in plywood the veneer sheets are solid and are located perpendicular to each other in terms of the structure of the wood fibers. In OSB sheets, created from the same raw materials, the chips are located chaotically. It is difficult to compare the strength of plywood and OSB - it depends on the type of wood used, the quality of the glue and, of course, the thickness of the product. OSB is characterized by the following advantages:

- high shear strength achieved due to a more uniform structure;

- less weight with the same sheet thickness;

- low manufacturing costs and, therefore, lower prices;

- minimal susceptibility to component delamination;

- possibility of facing with veneer or film;

- waste-free production and recyclability.

In what cases should I use gypsum plasterboard for interior decoration, in what cases should I use chipboard, and in what cases should I use fiberboard?

Chipboard

More often used where strength, rigidity, a strong base and solid support for structures are required. They are perfect for the construction of floors, as well as for the manufacture of window sills, doors, and shelving. Chipboard is also used to create decorations (niches, facade interiors, etc.), to cover partitions between rooms on which paintings, shelves, etc. are hung.

Drywall

Excellent for covering fairly large surfaces that will not be subject to mechanical stress during operation. It can be used to install suspended ceilings. Pre-primed HAs can be painted and wallpapered well.

Fiberboard

is in great demand today. All kinds of furniture elements are made from this material. Some old furniture and walls are covered with fiberboard. In addition to furniture production, fiberboard is used in construction and decorative work.

Thus, it is impossible to unambiguously answer the question “which is better, chipboard, fiberboard or plasterboard,” since the choice of material will depend on the type of work and construction purposes.

Sheathing can be done using either plasterboard or plywood. It's up to you to decide what's best. Before choosing which material is better to use for the job: drywall or plywood, you need to decide what you want.

Plywood is a more natural material, since it itself consists of birch veneer and glue that holds all the layers of plywood together. There are many varieties of plywood, some are more stable and durable, others are more flexible. But overall the material is quite useful and practical. Plywood can be five-layer, three-layer or simply multi-layer. In general, plywood is used to provide insulation in industries such as: aviation, shipbuilding. In addition, it serves as a material for bushings for bearings.

As for drywall, its materials cannot be called environmentally friendly, because... its surface is a cardboard sheet, and the inside is filled with gypsum dough with various chemical additives.

Lining

As already mentioned, the traditional solution is to sheath and insulate a wooden house with wooden materials. Lining is ordinary boards equipped with special grooves to fit them tightly together.

Previously, this material was used to line the inner surface of the walls of the carriages of the Tsar's trains - hence this unusual name.

The main disadvantage of clapboard cladding is that this option is somewhat formulaic. Indeed, many people are now resorting to this method of interior design. Therefore, for champions of individuality, lining is not the best choice. At the same time, with its help you can get:

- environmentally friendly coating in wooden design;

- large selection of wood species and quality categories;

- various types of external surface treatment;

- the unique aroma of fresh wood for many years.

It is best to install the lining on a pre-assembled frame made of metal or wooden bars. In this way, any existing wall irregularities can be easily eliminated.

A metal profile, which is used for working with drywall, is excellent for these purposes. To fasten the board to the sheathing, special hidden elements are usually used - clamps. If the frame is wooden, you can use the old method of fastening with nails.

Features of both types of materials

Also, when determining: drywall or plywood, take into account other features of these materials. The only and main drawback of plywood is deformation due to any type of moisture. Therefore, using this material it is better to check the humidity of the room. Although plywood is well suited for flooring as well as extensive installations. Drywall, of course, has more advantages: it is resistant to moisture, suitable for the construction of partitions or ceiling cladding, in addition, it is excellent for quick installation.

Debates regarding which is better: plywood or plasterboard are ongoing among builders. Some say that you simply cannot find a better material than drywall. It is moisture-resistant, difficult to ignite, and in addition, profiles for it can be easily found. It is easy to use and quite cheap.

Those who fight for environmentally friendly building materials come to the defense of plywood. Perhaps plywood is a little more expensive than drywall, but it is made from natural materials. In addition, the strength of plywood has not been in doubt for many years, and drywall, in turn, is a rather fragile material in this sense.

In general, what is better: drywall or plywood is up to you to decide. For those who are more concerned about the environmental friendliness of their premises and the strength of materials, plywood is suitable, but for those who prefer cheap and easy-to-handle material, drywall is more suitable.

9409 0 5

Are you choosing structural finishing materials and don’t know which is cheaper and better? I bring to your attention an overview of the characteristics of gypsum and particle boards, which are indispensable when performing home renovations. After reading the review, you can decide which of the listed materials is suitable and which is not.

Briefly about the main thing

Using a cold attic space and creating a warm, cozy living room in it is possible today. We offer a choice of 6 options for covering the interior space of the attic.

Classic lining will help create a cozy “rustic” interior. Drywall will make it possible to create modern forms. A block house or imitation timber will immerse you in the atmosphere of a rich village mansion. Plywood will allow you to create a warm room with maximum savings. OSB boards will solve the finishing issue in the shortest possible time.

Knowing the characteristics of materials and their capabilities in installation and operation, you can make the final choice. After all, one of the attic cladding options will fit perfectly into your interior.

Read later

Review of structural finishing materials

The category of structural finishing materials includes sheet gypsum and wood products, with which you can build dividing partitions, cover walls, ceilings, etc. with your own hands.

| Illustrations | Description of construction materials |

| Drywall . This environmentally friendly material consists of a gypsum plate covered with thick cardboard on both sides. Depending on the composition of the gypsum layer and the processing of the cardboard, gypsum fiber sheets (GVL), plasterboard sheets (GKL), etc. are distinguished. | |

| Oriented Strand Board (OSB or OSB) . OSB board consists of medium- and large-sized chips, pressed in a resinous binder into rectangular sheets. There are three classes of OSB with differences in structure density and, as a consequence, strength. | |

| Chipboard (chipboard) . Chipboard is sheets pressed from small shavings and sawdust in a resinous binder. Due to the small size of the chips, the finished product is characterized by high density and greater weight compared to OSB. | |

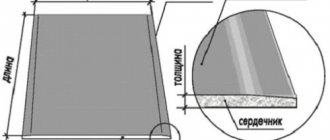

| Multilayer plywood sheets . This is the most environmentally friendly and visually attractive material of all the listed wood products. Plywood is made from natural wood veneer glued together with a resin-based binder.

|

Characteristics of gypsum sheets

The prices in the article are current in the summer of 2022.

Gypsum sheets on the market are presented in three standard sizes: 2000×1200 mm, 2500×1200 mm and 3000×1200 mm. The material is also divided into ordinary (GKL), moisture-resistant (GKLV) and fire-resistant plasterboard (GKLO).

| Illustrations | Application |

| Laying dry screed . Special gypsum sheets with a thickness of 15-20 mm are laid, as in the photo, on expanded clay backfill. This technology was developed by Knauf and is used in many countries around the world when arranging residential premises. Price: from 300 rub. per sheet 1200×600 mm. | |

| Cladding of walls and slopes . When finishing walls and assembling partitions, the thickest sheets are used: 12.5 mm. The cladding is carried out on a supporting frame, which traditionally contains heat and sound insulation. Price: from 230 rub. per sheet 2500×1200 mm. | |

| Ceiling cladding . For such purposes, a plasterboard sheet with a thickness of 9.5 mm is used. Installation is carried out on a suspended lathing. Price: from 250 rub. per sheet 2500×1200 mm. | |

| Arch trim . For such purposes, the thinnest sheet with a thickness of 6.5 mm is used. The small thickness of the sheet is due to the fact that the strip of drywall has to be bent. Price: from 300 rub. per sheet 2500×1200 mm. | |

| Installation of partitions . For the construction of partitions in residential premises, it is recommended to use tongue-and-groove slabs or plasterboard. In the case of plasterboard, installation is carried out on a frame; in the case of tongue-and-groove slabs, you can do without a frame. |

The use of sheet plasterboard is possible only in the interior, subject to normal humidity and normal air temperature.

Characteristics of particle boards

There are several types of oriented strand boards on sale, of which laminated or varnished OSB-2 boards can be used for interior decoration. OSB-4 is used for the construction of external walls in frame houses and for laying floors. OSB-3 boards are recommended for finishing rooms with high humidity. Average price of OSB-3: 200-300 rubles. for 1m².

| Illustrations | Application |

| Floor covering . When laying a floor, tongue-and-groove particle board is used in much the same way as plasterboard is used when installing a dry screed. To connect the floor fragments, a fastening recess is made along their perimeter. | |

| Wall covering . For these purposes, only laminated OSB with a low degree of toxic substance emission are used. The use of such cladding is advisable in utility rooms and temporary residence facilities (cabins, resort houses, workshops, etc.). | |

| Floor covering . Using OSB, you can not only sheathe the ceiling, but also clad the ceiling in a frame house. | |

| Construction of partitions and load-bearing walls . Load-bearing walls are sheathed with OSB in frame houses, and interior partitions are built using the same principle. The walls covered with OSB are covered with lining. |

Comparing both materials

- Scope of application

. Both plasterboard and particleboard products are used in a similar way, but OSB can be used for exterior cladding of a house, subject to subsequent finishing with DSP or similar mixtures. - Compatibility with finishing materials

. Both drywall and OSB can be painted and wallpapered only after preliminary puttying. Unlike preparing gypsum boards, puttying OSB is a more labor-intensive process. - Environmental Safety

. Drywall is environmentally friendly as it does not contain toxins or carcinogens. OSB contains resins that release phenol vapor into the environment. In order to reduce phenol emissions, the surface of particle boards is laminated, varnished or painted. That is, you can use gypsum plasterboard and OSB, but only with additional finishing. - Moisture resistance

. Both materials are not initially designed for contact with moist air. But the range of manufacturers includes gypsum and particle boards that are resistant to moisture.

Let's try to draw a conclusion. Both gypsum and wood boards will find their buyers, as both materials are irreplaceable when used correctly. If you choose a material for interior decoration, taking into account the pros and cons of drywall, I still recommend plasterboard. Why?

- Firstly, the price of drywall, even taking into account the purchase of related materials, is lower.

- Secondly, the instructions for working with gypsum plasterboard are simpler than using particle board.

- Thirdly, using gypsum plasterboard, you can create complex architectural forms, which, in principle, is impossible using OSB.

Let's sum it up

Now you know which construction materials are ideal for cladding walls, ceilings and for laying screeds in the interior. If you have any questions, I recommend watching the video in this article.

June 22, 2022

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Is there any alternative to drywall? Of course, this material has excellent technical characteristics, but sometimes there is a desire to decorate the room with something else. Therefore, how much better would it be to use other materials? This definitely needs to be dealt with.

What can replace drywall?

The following materials are mainly used:

- These slabs are considered excellent finishing materials. In this case, OSB is an excellent replacement for drywall. This material appeared on the construction market relatively recently. At the same time, many people began to use OSB boards in a short time. Typically, with improved technical characteristics, OSB boards are much cheaper than plasterboard.

- SMG.

Glass-magnesite boards can also be used as an alternative substitute for drywall. They are used to sheathe roofs, ceilings, attics, level the surfaces of walls, make multi-level floors, etc. Although in this case drywall will be cheaper. - Chipboard.

Chipboards are needed to build internal partitions. - GGP.

Tongue-and-groove boards are considered much stronger than drywall. They are used to build walls. Tongue-and-groove tiles are made from gypsum, to which various necessary substances are added. Tongue-and-groove tiles are also divided into hollow and solid. They are distinguished by high strength and excellent sound insulation.

How to sheathe the inside of an attic inexpensively: 6 sheathing options to choose from

March 08, 2020

Read later

We will send the material by email

Recently, in country houses and dachas, the attic as a living space has been steadily gaining popularity. Previously uninhabited, cold spaces under the roof are being transformed into exquisite, warm, furnished rooms, gyms, bedrooms and even libraries. Let's consider how and with what to sheathe the inside of an attic inexpensively and efficiently, turning a previously non-residential space into a cozy room, comfortable for permanent residence.

Cladding of the attic floor Source sktvoydom.ru

Drywall and plywood: which is better to use?

Plywood or drywall? This question comes up all the time. To understand whether plywood can be considered as a substitute for drywall, you need to learn about the advantages and disadvantages of both materials in more detail.

- Fire resistance and moisture resistance

. In this regard, drywall has a significant advantage, since plywood does not tolerate moisture and burns easily. - Material price.

Plywood costs much less than drywall, which is its significant advantage. - Installation of flexible structures.

If the design of the room is very complex, then the use of plywood comes to naught. Drywall can be bent as required. - Finishing.

It is very difficult to stick wallpaper or paint on plywood, while this can be done easily with drywall. - Tools and skills

. Drywall is easy to work with and does not require any additional skills or tools. This will not work with plywood.

It is worth remembering that most often these materials are used in completely different areas, so a full comparison of them is very difficult. However, on construction forums they will still ask the question “Is it worth exchanging drywall for plywood?”

MDF panels

Panels similar in appearance and shape, which are made from a material that is more environmentally friendly than plastic. If the surface of the walls is sufficiently flat, such panels can be installed directly on the wall; otherwise, installation of a frame is necessary, in the same way as is done for lining or drywall.

It should be noted that the design of MDF panels is not limited to the traditional wood-look coating. Currently, you can buy such panels in a wide variety of colors and textures. Some examples are shown in the photo below.

Tongue-and-groove tiles

Tongue and tongue tiles have a number of advantages, which is why many people consider this material to be better than drywall.

So this is:

- Easy installation

. PGPs are designed in such a way that their installation is carried out in a short time. - Excellent thermal insulation

. If you choose full-bodied PGP, then your apartment will always be warm. - Small thickness

. GGP is much thinner than drywall, which allows you to use precious centimeters correctly.

Installation of a partition made of tongue-and-groove slabs (video instructions)

Headlining

Of the entire technological process of renovation in an apartment, the ceiling surface requires the most attention. Often in houses built before the nineties of the last century, the slabs are laid in such a way that a gap is formed between them, and the joint of the slabs cracks due to shrinkage.

There are several methods for solving the problem: covering the ceiling with plasterboard, installing a suspended or stretch ceiling, as well as covering it with timber or plastic. Each option has its own advantages that distinguish it from others.

SMG

Glass-magnesite sheets have the following technical characteristics:

- excellent sound insulation,

- moisture resistance,

- high resistance to adverse weather conditions,

- light weight,

- long service life.

If we talk about the differences between SMG and drywall, they are as follows:

- used for both internal and external work,

- withstands high humidity and high temperatures,

- ease of installation.

Of course, drywall is much cheaper than SMG. But the scope of its use is quite limited. Therefore, SMG can be used in places where drywall would be useless.

Chipboard

Chipboard panels are most often used as ordinary interior partitions.

The main advantages of this material are:

- Chipboard is much cheaper than plasterboard,

- Chipboard is easy to install.

But there are also disadvantages:

- Chipboard must be very carefully prepared for finishing,

- Chipboard does not tolerate moisture even more than drywall. Accordingly, this material can only be installed in very dry rooms.

OSB

Oriented strand board also has a number of its own features. Let's look at them in detail:

- Made from natural wood materials

. Because of this, deformation of the slabs sometimes occurs. - The material is not flexible

. If the slabs are thin, then it is still possible to bend them. But this cannot be done with thick slabs. - Complex processing

. This material is not as easy to process as drywall. - Price

. It will be much cheaper to level walls with plasterboard than to perform a similar action using oriented strand boards.

In this case, the advantage of drywall is quite obvious. And the fact that it costs less, and its quality is much better, makes it even more competitive.

Block house

A block house is a type of wooden lining, which differs in the shape of the front surface - it is a material that imitates a rounded log in its appearance. In view of this, all characteristics, as well as methods of its fastening, are similar to lining. Read more about the characteristics of a block house here, and about methods of working with it here.