Updated: 04/23/2021 12:51:21

Expert: Konstantin Borisovich Polyakov

Drywall and OSB are boards made of gypsum and wood, respectively. They have a similar scope of application and are intended for cladding walls, forming floors, leveling floors, creating ceilings and similar construction operations. However, despite their general similarity, OSB and drywall are intended for different purposes.

To compare OSB and drywall, let's take a closer look at these materials.

Tandem cardboard and gypsum

Drywall is particularly popular today, as it has a number of advantages that its structure gives it. Plasterboard consists of three layers:

- core - it consists of gypsum and additional additives, which give the sheets certain properties;

- two layers of cardboard. They cover the core on both sides.

Structure of the slab

The composition of the material in percentage terms includes: 91.1% - gypsum, 5.78% - cardboard, and the rest - water. Thanks to this device, drywall has the following advantages:

- it is a completely environmentally friendly material;

- a light weight. The stove weighs relatively little so that one person can move it without any problems;

- easy installation;

- strength;

- durability;

- the slab is an excellent basis for various finishing materials - paint, wallpaper, decorative stucco, ceramic tiles, artificial stone, etc. Plasterboard walls and ceilings can be decorated in the most unimaginable ways;

- You can create a wide variety of structures from it: suspended ceilings, wall cladding, formation of partitions, arches, niches and columns;

- safety. The material is completely safe for human health. Only when cutting it you need to cover your eyes and mouth so that dust does not get there;

- price. The material is available and costs less than some other types of finishing, especially if drywall is used to renovate the entire house.

With a material such as drywall, you can give your apartment a unique appearance, making it original and very beautiful. In addition, drywall has certain specific properties that are given to it by special core additives. Among the special properties of the material are the following:

- moisture resistance. Sheets with such properties can be installed in rooms where there is a humid microclimate. Such slabs are used in the renovation of attics, kitchens, bathrooms and toilets;

Moisture resistant sheets

- fire resistance. This type of slab is used in rooms with a dry microclimate, as well as where there are increased fire safety requirements. Thanks to special additives, such material can withstand exposure to open fire for about 40 minutes;

Fireproof sheets Fireproof sheets

- fire and moisture resistance. There are sheets of plasterboard that can combine both fire resistance and moisture resistance. They are installed in rooms with dry and humid microclimates;

- ordinary. Such sheets are used for finishing walls and ceilings in rooms with a normal microclimate.

In general, drywall can be used in almost any room: bathroom, kitchen, living room, toilet, bedroom, etc. Balconies, loggias and attics are also finished with this material.

Why is plaster still relevant?

It would seem that this finishing material should have long ago and hopelessly lost its position as morally obsolete. However, it continues to be used, and in the age-old rivalry of which is more reliable and better: plaster or drywall, it confidently holds its own on a par with its competitor. And all because he has some qualities that are inaccessible to him.

- If the plastering work is carried out at the proper level, you won’t have to return to it again for about 30 years. Yes, you will change the wallpaper, re-paint or re-tile the tiles, but there will be no need to restore the base.

- The high cost of plastering work is the main argument when choosing between plaster and plasterboard sheets. However, this is a myth, blown out of proportion. The work of a professional, naturally, is not cheap. However, drywall experts will also cost you a pretty penny. But in terms of consumables, plaster is simply incomparable to gypsum board. If we consider impartially, it will cost 2-2.5 times cheaper than the famous designs.

- When choosing between plaster or gypsum board, first of all you should think about the reliability of the resulting surfaces. The first one is shock resistant and absolutely indifferent to water. The second one can be broken by hitting it well with your elbow, but moisture causes it to swell and become deformed.

- The main advantage of plaster is that you can safely attach any heavy objects to it, from air conditioners and water heaters to heavy bookshelves and cupboards.

Disadvantages of plaster mixture

However, nothing is perfect in the world. Drywall strengthens its position due to the inherent disadvantages of plaster.

- Plastering is a dirty process that requires cleaning, and not only in the room where the work is being done: traces of it somehow spread unnoticed throughout the apartment.

- An important argument against plastering is the delay in time. Before you begin the final finishing, you need to wait until it dries.

- With large defects in the walls, it is extremely difficult to achieve their smoothness with a layer of plaster.

- And the main thing: without being a professional builder, you are unlikely to be able to accurately determine how well the plasterer did his job. All the troubles will appear when painting or wallpapering, when it will be too late to make a claim.

Let's talk about the shortcomings

Despite the huge number of advantages, plasterboard as a material used for interior decoration also has some disadvantages:

- It is impossible to hang heavy objects on walls made of plasterboard sheets without prior preparation and compliance with installation rules - paintings, wall cabinets, TV, mirror, shelves; Sheet cutting

Note! Each individual situation has its own step-by-step instructions that will help you cope with the task of hanging heavy objects on plasterboard walls without any problems.

- deformation of the slabs when trying to fasten heavy objects to the walls;

- When cutting sheets into pieces, small construction debris appears. Therefore, all work on cutting plasterboard should be carried out with special safety glasses, and also cover your mouth with a mask;

- reducing room space by assembling the frame.

If desired, all these negative aspects of working with the material, in addition to reducing space, can be leveled out. To do this, you must strictly follow the appropriate step-by-step instructions.

What is the difference

There are some differences and features of using plasterboard sheets and OSB boards:

- All types of OSB boards are not recommended for use near an open fire, as this is dangerous according to safety regulations.

- To fasten heavy objects to plasterboard sheets, special fastening is required.

- The resins used to produce OSB boards can emit formaldehyde compounds that are harmful to health.

- When cutting plasterboard sheets, a lot of dust is generated, penetrating into the human lungs.

- OSB boards are more difficult to install in some rooms.

- If damaged during transportation, plasterboard sheets are more susceptible to breakage.

- Various decorative elements with small inserts are best made from plasterboard sheets (they are easier to trim and form the desired bend).

- For certain types of shelves and partitions, OSB board is better suited in terms of strength.

- If the plasterboard sheets are stored incorrectly and have sagging, it is easier to correct the unevenness while maintaining the properties.

Purpose of the material

Any of the above types of plasterboard sheets are used for the following types of work:

- leveling walls in the bathroom, kitchen, living room and other rooms. They are even suitable for finishing the attic;

- installation of complex ceiling structures;

- assembly of furniture of the parameters that are necessary;

- creation of shelves, niches and columns, both functional and decorative;

- creation of stands;

- installation of complex figured elements. They can be installed on walls or ceilings.

The material is excellent for finishing walls and ceilings in residential and non-residential premises. It is plasterboard that is most often used for finishing the attic, kitchen, loggia and bathroom.

So what should you choose?

All other things being equal, a person decides to sheathe or plaster based on his own considerations. However, there are situations in which a certain finishing material becomes indispensable.

- In small rooms it is worth abandoning the gypsum board: it will steal your already insufficient space.

- Where there is no need for perfectly smooth walls - closets, basements - preference should again be given to plastering.

- Plaster becomes the only solution even in unheated rooms. For example, in a summer kitchen or cottage.

- If there is a need to hide pipes, meters or wiring, drywall is the best choice.

- If deadlines are pressing, plasterboard structures will allow you to move into a renovated apartment faster.

- In a cold room, it would be wise to choose frame sheathing with insulation.

- Where heavy objects will hang, or in rooms with high constant humidity, we again return to plaster.

Finally, I would like to note that if you have settled on the sheathing option, you should not rack your brains over what is better: OSB or plasterboard?

Which is better: heated floors or radiators?

Warm floorBatteries

GKL will cost you less and will give you a much smoother surface. And OSB is only suitable for non-residential premises - it produces not very useful formaldehyde fumes.

Let's move on to the opponent - OSB

OSB structure

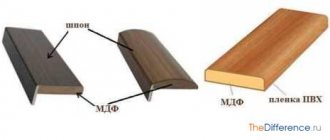

Recently, there has been a trend towards increasing popularity of OSB boards. Very often, such a slab comes in tandem with three-layer panels and insulation, which increases the thermal insulation properties of the entire structure. Oriented Strand Board (OSB) or Oriented Strand Board (OSB) is a multilayer sheet. Usually it consists of 3-4 layers. Its layers include the following materials:

- wood shavings. It can have a longitudinal or internal transverse orientation;

- various resins;

- boric acid;

- synthetic wax.

OSB consists of 95% sawdust, the remaining 5% comes from a small amount of impregnation, paraffins and glue. The properties of the slab directly depend on the type and quality of sawdust. Sometimes the top of the slab is additionally treated with wax to increase its moisture-resistant qualities. This structure of the material determines its following advantages:

- availability;

- reliability;

- external resemblance to a tree. Great for wall decoration;

- high quality;

- low weight;

- high rate of fracture deformation.

In addition, the material has the following properties:

- relatively high strength. It is higher than that of chipboard;

- has some moisture-resistant properties;

- ease of processing;

- excellent sound absorption;

- high rigidity.

As you can see, OSB boards have quite good advantages, allowing them to be widely used for interior decoration.

Which is better - OSB or plasterboard: comparison of gypsum and particle boards

The category of structural finishing materials includes sheet gypsum and wood products, with which you can build dividing partitions, cover walls, ceilings, etc. with your own hands.

There are several types of oriented strand boards on sale, of which laminated or varnished OSB-2 boards can be used for interior decoration. OSB-4 is used for the construction of external walls in frame houses and for laying floors. OSB-3 boards are recommended for finishing rooms with high humidity.

Average price of OSB-3: 200-300 rubles. for 1m².

Let's try to draw a conclusion. Both gypsum and wood boards will find their buyers, as both materials are irreplaceable when used correctly. If you choose a material for interior decoration, taking into account the pros and cons of drywall, I still recommend gypsum plasterboard.

Why? Are you choosing structural finishing materials and don’t know what is cheaper and better? I bring to your attention an overview of the characteristics of gypsum and particle boards, which are indispensable when performing home renovations. After reading the review, you can decide which of the listed materials is suitable and which is not.

The use of sheet plasterboard is possible only in the interior, subject to normal humidity and normal air temperature.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials

Flaws

Sawdust for production

Among the disadvantages of OSB boards, the main place is occupied by the possibility of the material releasing toxic substances. Formaldehyde and toxic resins can be released here. During the production of OSB boards, large sawdust is used, which are connected to each other with glue during the process. The result is a solid slab. It is the presence of glue in OSB that is the reason that such a board can be toxic and release dangerous compounds into the air.

Note! Much less glue is used to create OSB boards than when producing chipboards. Therefore it is less toxic.

The disadvantages of OSB include:

- low fire-resistant properties;

- low strength indicators. To increase it, two plates are installed;

- more difficult to install on walls. Installation is more labor-intensive compared to drywall;

- cutting creates a lot of construction waste;

- low vapor permeability properties.

This material is not very suitable for renovation work in the kitchen, bathroom and attic.

Pros in favor of drywall

In addition to the advantages already listed, it is worth noting that according to all the criteria for arrangement, experts single out drywall. The following positive aspects of its use can be highlighted:

- Ease of processing and installation. This does not require special tools; installation for any surface can be done with your own hands;

- Due to the fact that it is not treated with impregnations on top, it is possible to create any decor;

- It is possible to create flexible structures compared to plywood, it is possible to create incredible shapes.

Choosing a material for leveling the walls of a room is quite a difficult task even for a professional. Well, then what can we say about a beginner whose questions are “Which is better - plywood or drywall?” or “What should be the optimal thickness of gypsum board for sheathing?” will inevitably lead to a dead end. Below we will try to understand the intricacies of choosing the appropriate type of gypsum plasterboard, and also consider the pros and cons of plasterboard sheathing in comparison with the use of other building materials.

Moisture resistance. Moisture-resistant plasterboard slabs with such characteristics are installed in damp rooms, for example, when finishing an attic floor, kitchen, or bathroom. GKVL sheets

There are a lot of finishing materials on the market. And among such abundance, the most popular are plasterboard and OSB boards. Finishing in which drywall is mounted on OSB is often used. How justified is this? Each of these materials has positive characteristics and disadvantages, which are worth considering in detail in order to understand which of these materials is preferable in construction. OSB in the attic OSB on the walls Gypsum board finishing Room finished with plasterboard

Comparative analysis of materials

It is impossible to understand which is better than plasterboard or OSB without examining these materials in detail. Each material is unique. It has positive and negative properties, as well as its own installation nuances.

Drywall

GCR is by far the most in demand and popular among builders. And this is not surprising; the structure of this material gives it a lot of advantages. The gypsum board sheet consists of:

- cores – a compressed gypsum mixture, the special properties of which are achieved by adding special additives to the gypsum;

- thick cardboard - 2 layers, which is located on both sides of the core.

This device gives drywall a lot of advantages:

- it is an absolutely harmless environmentally friendly material;

- small specific gravity. It will not be difficult for even one person to carry out the installation;

- simplicity in arrangement of structures;

- lasting;

- durable;

- plasterboard slabs are an excellent basis for further finishing with any materials; in addition, you can create any curved structure;

- possibility of use in the installation of partitions and walls with insulation, arches, figured ceilings, columns and niches;

- price - if you are renovating a house or apartment, then it is easier and cheaper to use plasterboard to decorate the walls than any other building material.

With the help of plasterboard slabs, you can transform the interior of an apartment, making it exclusive and unusual. Interior arch Ceiling made of gypsum plasterboard Niche for a TV made of gypsum plasterboard Drywall has features due to the additives that are present in the core of a certain brand of material:

- Moisture resistance. Moisture-resistant plasterboard slabs with such characteristics are installed in damp rooms, for example, when finishing an attic floor, kitchen, or bathroom. GKVL sheets

Fireproof plasterboard. Sheets are red in color, which, thanks to certain additives, can withstand exposure to fire for 40 minutes. They are used in dry apartments with elevated temperatures. Sheets of fire-resistant plasterboard GKLOFinishing of premises with fire-resistant sheets

- Fire and moisture resistance. This is a universal material that is installed in rooms where, along with high humidity, there is high temperature.

- A simple material that is used for cladding rooms with normal humidity.

- Before hanging a heavy object on a plasterboard wall, you need to install mortgages while installing the frame;

- if a heavy object is incorrectly fastened to the wall, the slab may become deformed from the weight;

- when processing and cutting the material, fine dust is formed, which can cause allergic reactions if inhaled, so you need to use protective clothing;

- the frame, which is assembled for attaching drywall, takes up useful space.

KNAUFS sheet size Comparative table of KNAUF size and weight To summarize: GKL can be used in almost any room, be it a bathroom, attic or loggia.

Flaws

The material has many advantages, which is why it is popular among developers, but despite this, it is worth talking about the disadvantages:

Frame on the wall for plasterboard Arrangement of the frame on the ceiling Frame for a gypsum plasterboard partition with a door These are non-critical indicators. By adhering to strict assembly rules, they can be minimized; the only negative that remains is the reduction in space.

Purpose of the material

Drywall can be used in the following cases: Design of a room with a decorative partition made of gypsum board Plasterboard structure on the wall This material has many more advantages than disadvantages, which is why it is so popular. Important. Before you start installing this material, you need to determine what you want to get in the end; this is the only way to complete high-quality interior design.

OSB panels

Increasingly, OSB boards are used in construction, which are usually used in conjunction with insulation for the construction of frame buildings. The material has proven itself so well that it is often used for cladding indoor and outdoor surfaces. What are the slabs made from?

- wood shavings;

- resin;

- boric acid;

- synthetic wax.

This material consists of 95% chips, 5% resins and adhesive. The quality of the slabs depends on the type of wood from which it is made. For moisture resistance, the board is coated with a wax composition. Properties of OSB board Due to its texture, the material has many advantages:

- reliability;

- affordability;

- resemblance to a tree;

- low specific gravity;

- high quality;

- durable when used correctly.

Characteristics of OSB boardsOSB has certain properties:

- High strength indicators.

- Moisture resistance when properly processed.

- Easy to use.

- Rigidity.

- Sound absorption.

OSB is an excellent material that can be used for interior decoration, and it is used without a frame on the walls.

What is OSB used for?

In construction, slabs are used:

- external cladding of buildings, subject to further cladding with decorative coatings;

- roofing sheathing during the construction of an attic;

- arrangement of a rough ceiling and floor; Scheme for installing a floor using OSB

- wall pasting;

- production of vulture panels for the construction of buildings.

The material appeared on the market not so long ago, but thanks to its positive characteristics it has become widely used in construction. Of course, its low cost also plays an important role. These materials are often used in tandem, since OSB boards are very difficult to decorate with decorative coatings, sheets of plasterboard are often glued onto it, which is much easier to cover. At the same time, the structure turns out to be durable. This is the answer to the question: is it possible to attach drywall to OSB for interior decoration. The video describes the use of OSB boards.

In custody

If we talk about cost, then OSB boards and plasterboard are located in almost the same price range, so the choice is made according to other parameters. It is worth noting that drywall is much more environmentally friendly than OSB, which contains resins and glue. GCR is made from biological material. OSB is flammable. If the material is cladding in a residential building with stove heating, then you should opt for plasterboard - it is safer. In damp rooms, it is better to use moisture-resistant gypsum boards for finishing; they are much more reliable. Although if you buy OSB treated with special wax, then there will be no problem. An OSB board is perfect if you need to level the walls without constructing a frame, and also make the floor warmer. This video shows the decorative finishing of an OSB board. This is impossible with plasterboard , as it may warp from moisture. OSB or drywall? Before making a decision, you need to weigh all the positive and negative aspects of these materials, and only then decide. In any case, the choice remains with the owner of the house or apartment - more precisely, on the preferences and wishes for finishing.

A selection of photos of interior design with plasterboard and OSB boards

Purpose of the material

OSB boards are used in the following situations:

- for external cladding while using some cladding coatings;

- continuous roof lathing;

- installation of subfloors;

- for the production of structural SIP panels;

- wall covering.

Wall finishing

In addition, the material is used for finishing and structural work. This material is almost completely unsuitable for wall decoration in some rooms (as already mentioned - in the bathroom, kitchen, etc.).

Let's sum it up

Now you know which construction materials are ideal for cladding walls, ceilings and for laying screeds in the interior. If you have any questions, I recommend watching the video in this article.

Did you like the article? Subscribe to our Yandex.Zen channel

June 22, 2022

Plasterboard systems, Wood

If you want to express gratitude, add a clarification or objection, or ask the author something, add a comment or say thank you!

Verdict

It is worth noting that the price of OSB board is approximately on the same level as drywall. Therefore, based on the price parameter, it is difficult to make a choice which is better - gypsum board or OSB. Therefore, the choice should be made based on other parameters. In terms of environmental friendliness and harmlessness, drywall wins. It contains only biological materials, and glue and resins are used to make OSB boards. Also, OSB board cannot withstand exposure to direct fire. As you can see, it’s already 2:0 in the GCL. In general, having studied in detail the advantages and disadvantages of materials, we can conclude that it is still better to use drywall for renovations in the bathroom, kitchen, wall decoration for the attic and other rooms. The choice should be based both on personal preference and on the merits of the material, as well as the location of its further installation: in the bathroom, kitchen, attic walls, etc.

Instructions for laying lining on drywall

How to properly glue fiberglass to plasterboard covering

Interior decoration of a frame house

Without appropriate cladding, any house is just a box, unsuitable for living. The quality of the interior finishing of a frame house will determine the comfort and style of your future home. Today we will look in detail at options for every taste and budget.

Paradoxical as it may seem, recently it has become fashionable to choose the “C” variety. This lining has a low cost and perfectly imitates the “vintage” style.

- removal of old coatings;

- ceiling screed;

- laying a layer of insulation for walls;

- wall cladding;

- creation of a subfloor;

- leveling all surfaces that are planned to be covered;

- installation of slopes.

- “Extra is a grade without any defects, with a perfectly flat and smooth surface.

- “A – small chips and darkening in the lamellas are acceptable.

- “B – cracks and knots may be present.

- “C – the presence of dark spots, resin bags, cracks, knots over the entire surface is allowed.

- Cover the slats with special bioprotective compounds against fungus and mold.

- If color is fundamentally important, you want to make the coating darker or lighter, then cover it with stain or other special substances to create the desired tone for wooden materials.

- The lining can be mounted on OSB boards, that is, directly on the finished wall.

- There are many options for fastening this material - with nails, staples, clamps, etc. The best of them will be the one that causes less damage to the material.

GVL or SML

Let's consider another option for replacing GVL with SML. SML is a glass-magnesium sheet; the material also has many other names, but they are all the same thing. It is a building material that is created on the basis of magnesium binder. Do not worry about its composition, it is safe for humans and is widely used for finishing residential and public premises. Magnesium glass sheets have a main advantage over other finishing materials - resistance to fire.

LSU is used for covering walls, floors and ceilings, and creating partitions. The same can be said for GVL. However, often with the composition of these building materials. Therefore, experts recommend buying only if there is detailed labeling and a verified supplier. Each of the materials is practically not afraid of fire; GVL and SML are often used for cladding elevators, for example.

The price also varies, GVL is much more expensive. LSU is characterized by high fragility; when working with it, a lot of debris is generated. Difficulties may arise when laying the finishing layers of tiles and wallpaper.

GVL or plywood

Plywood is multilayer sheets based on a special veneer that is glued together. The number of layers may vary. There are painted moisture-resistant sheets. Used in residential premises and frequent use.

The sound insulation properties are much lower than GVL, but at the same time they are several times stronger. When producing plywood, there is no strict monitoring of the ideal sheet thickness along the entire perimeter. When working with it, a lot of chips fly away. Not bad for leveling the floor; professionals even prefer plywood over gypsum fiber board. The price of gypsum fiber is much higher due to the composition and production method.

Chipboard (chipboard)

Chipboard is a sheet building material pressed from “chopped” wood based on resin binders. The thickness and strength of chipboard are superior to fiberboard, which is why chipboard is used not only as an underlying material (rarely due to its high cost), but as a top layer in floor structures on joists.

However, chipboard is afraid of moisture and, due to its resins, emits substances that are not entirely environmentally friendly. This limited the use of chipboard in flooring until the advent of VDSPS.

Moisture-resistant chipboard, tongue-and-groove (VDSPSH)

Moisture-resistant particle board with tongue and groove along the perimeter (VDSPSH) is specially created as the upper surface of the prefabricated screed. VDSPSh is used not only in floor structures on joists, but also on backfill materials.

A tongue and groove lock around the perimeter of the VDSPSh slabs allows you to firmly connect them into a single, durable floor base, ready for laying finishing materials.

The tongue and groove lock is coated with a special mastic and connected with threaded connections. Gluing the seams with moisture-resistant chipboard and its moisture resistance allow them to be used even for tile work.