Updated: 04/23/2021 12:51:21

Expert: Konstantin Borisovich Polyakov

The main problem with modern furniture is its price. Interior items made from natural materials that are environmentally friendly and safe are too expensive. And after buying an apartment, there is often simply no money left for solid wood furniture.

Therefore, we have to choose less expensive materials. And in the lower price segment, options such as MDF and PVC are leading. These are plates made from wood chips or polyvinyl chloride, which are distinguished by their low price, visual appeal and good price characteristics for their cost. But which of the two materials should you prefer?

In this material we will figure out what the difference is between MDF and PVC - and which is better.

Difference between MDF and PVC

At the turn of the 20th and 21st centuries, a large number of diverse materials entered our everyday life. And it is sometimes difficult for an inexperienced person to figure out in which cases one should be used and in which another. Moreover, many of them appear mainly in the form of abbreviations, which makes it even more difficult to understand their purpose. Let's figure out how MDF differs from PVC - these are, perhaps, one of the most common materials in construction and some other types of human activity.

Deciphering abbreviations

MDF is an English abbreviation, that is, in the original it will be MDF. Having deciphered it, we get MediumDensityFibreboard, which translated into Russian means “medium density fiberboard”. It is made by pressing wood chips in a dry environment at high pressure and temperature. Urea resins are used as a binding material, which reduces the emission of harmful formaldehyde to natural. The USA was the first to establish industrial production of MDF boards (this happened in 1966), and Russia joined their production only 31 years later. Well, the leader in production today is (as expected) China.

The difference between MDF and PVC is that the second material is a product not of the woodworking industry, but of the chemical industry. PVC stands for polyvinyl chloride. This clear plastic is a thermoplastic polymer of vinyl chloride (a colorless gas with a sweet odor). PVC is highly resistant to many aggressive substances - acids, alkalis, mineral oils. It does not burn in air, but has poor resistance to frost, poorly tolerating temperatures below -15 degrees Celsius.

Comparison

Knowing the differences in the composition of these materials, it is easy to determine the scope of application of both. MDF is indispensable for finishing. For example, a wide range of wall panels are made from it, as well as flooring (laminate). In addition, MDF is an ideal material for the manufacture of furniture cladding, as it can be milled well, which is important when turning curved holes; It is also used for the production of containers. A special segment of its application is the production of speaker enclosures, because MDF perfectly absorbs sound due to the homogeneity of its composition.

PVC is used for insulating wires, producing pipes for various purposes, and a wide variety of films that are used everywhere - from the manufacture of some parts of clothing to the material of suspended ceilings. PVC is used to make profiles for plastic windows and doors, furniture decorative elements and car mats. It is used as a sealant in refrigeration technology, a material for the manufacture of souvenirs and parts of promotional items, and for applying a relief pattern to work knitted gloves. This list can be continued for a long time, because thanks to its qualities, PVC is widely used.

Which is better: PVC panels or MDF panels?

Let's start with PVC, also known as Polyvinyl Chloride, a material known to many.

This colorless, transparent plastic does not burn in air and has low frost resistance. Panels made from this material are not afraid of water and high humidity. The moisture resistance of wall panels allows them to be used in rooms with high humidity, such as a bathroom. PVC is produced in such a way that pores and cracks do not form on the surface of the panels, in which unfriendly bacteria, mold and fungi can grow, and harmful insects cannot create nests for themselves.

Differences

Distinctive features:

- You cannot create relief on plastic. Milling is often done on the film.

- Plastic products have a wider range of colors and can be created to order.

- MDF film is less practical.

- Plastic is stronger.

- MDF products with a protective film layer have a lower price.

- Plastic coatings are more resistant to the negative effects of water, humidity and high temperature.

- The film is easily applied to surfaces of any shape (straight, curved, corner). Plastic is not suitable for the design of shaped parts; it can lose strength parameters when making complex elements.

- Film coating is less durable. Its service life is limited to six years. Plastic products can retain their original properties for about 25 years.

- Plastic products have more positive reviews.

- Plastic is more wear-resistant.

- The color gamut is wider for film coating.

- Plastic facades look more stylish and bright.

- Facades lined with plastic can be restored if defects appear.

Which MDF panels are better?

MDF panels for wall decoration are medium-density fiberboards. They are made by dry pressing wood chips under high temperature and pressure. Urea resins are used as a binding material for sawdust.

Features of MDF panels

MDF panels are very easy to install, are inexpensive and perform well during operation. In addition, the variety of panel designs allows you to give any room an excellent appearance.

Installation of the panels does not require special preparation of the walls, and the condition of the walls does not in any way affect the complexity of installation and subsequent use. They can be installed both vertically and horizontally and even diagonally.

Plastic

This is a material of organic origin. It is based on synthetic and natural high-molecular compounds. The facades are made of chipboard covered with a 2-4 mm layer of plastic.

Advantages:

- Non-susceptibility to the negative effects of direct sunlight (the surface does not fade).

- Water resistance.

- Hygiene.

- You can create curved contours.

- Resistance to the destructive effects of acids and alkalis.

- Low price.

- Fire resistance.

- Safety.

- Combination of performance qualities of enamel and film.

- Possibility of imitation of wood, granite, marble.

- Softness and flexibility.

- Using the postforming technique, you can create an original design.

- Reliability.

- Practicality.

- Wear resistance.

- Wide choice of colors.

- Possibility of restoration.

- Ease of use for façade cladding.

- Possibility of applying photographs or drawings to the surface.

- Visual expansion of space.

- Frost resistance.

- Durability.

- Easy to clean from dirt, grease stains and dust.

Flaws:

- Over time, small scratches form that spoil the appearance of the glossy surface.

- The matte type of product is difficult to clean.

- The gloss shows fingerprints.

- Low strength.

- Exposure to temperature changes.

- Incorrect installation may result in deformation.

Types of MDF panels

There are several types of MDF panels that differ in characteristics, production method and color variations. Depending on the production method, the following types of panels are distinguished.

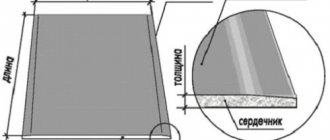

Solid pressed panels

Smooth boards on both sides, which are made by pressing chips under high pressure and using high temperatures.

Laminated panels

They are produced in the same way as solid-pressed ones, but at the final stage of production the front side of the slabs is also covered with a polymer film. Thanks to this coating, the slab receives additional protection from mechanical damage and other influences. Film with any design, any color can be used.

Moisture-resistant panels

MDF panels, resistant to moisture, are made from denser material. High-quality wood is used for their production. These panels can be used to cover a bathroom or balcony.

According to the method of designing the front part, all MDF panels are divided into:

veneer panels, which in their texture and appearance are similar to natural wood. To achieve this effect, natural wood veneer up to 3 mm thick is applied to the surface of the slab;

laminated panels, the shiny and smooth surface of which is achieved by laminating the sheet with a polymer glossy or matte film;

painted panels onto which a special paint is applied, covering all texture irregularities and creating an ideal matte or glossy finish.

Chipboard boards (laminated)

Another economical and, perhaps, the most affordable option is laminated chipboard. Unlike classic chipboard, laminated products can be thoroughly washed and cleaned without fear of deformation and damage. The fact is that the top layer (the lamination itself) is both decoration and protection of the material.

Advantages of chipboard panels:

- budget, because their cost is the lowest among wall panels;

- strength;

- ease of maintenance of the panels.

This type of panels is an ideal ratio of price and quality. Look at the photo below and see for yourself that finishing with such wall panels looks very good.

Chipboard panels in the kitchen

But what if there are no drawbacks:

- Chipboard does not tolerate constant temperature fluctuations (not critical for an apartment building, but important for the private sector);

- fragility due to possible deformation under the influence of moisture and steam, which cannot be avoided in the kitchen.

But still, chipboard panels are also widely used for finishing work in the kitchen.

High quality MDF panels in stock

At Remycom you can order high-quality MDF panels from popular domestic manufacturers: Kronostar, Eurostar and other brands. You can choose MDF boards of any type and color on our website, including those stylized to look like natural wood.

We offer you favorable prices for the entire range - from only 129 rubles per piece and convenient delivery conditions. We work directly with first-category manufacturers and dealers, so we guarantee the high quality of all products.

How do laminated PVC panels differ from other types of panels?

Laminated PVC panels are made entirely of polyvinyl chloride. Polyvinyl chloride - PVC for short - is a synthetic polymer that is made from natural materials: table salt and petroleum products. PVC is the most common type of plastic, which is characterized by a given strength, as well as being versatile and economical to use. The main consumer properties of PVC are:

- Strength;

- Durability;

- Resistant to water;

- Resistant to most chemicals, including many acids and solvents;

- Weather resistance;

- UV resistance.

Combined facades

Front decorative panels covered with veneer and enamel at the same time are an option for those who are looking for non-standard design solutions. Typically, such facades are used when decorating a kitchen in the Art Nouveau style.

Advantages

- Low price compared to kitchen sets made from natural wood

- Increased moisture resistance and strength

- Possibility of manufacturing radius facades

Flaws

- The veneer may peel off from the substrate

- UV Exposure

- Fingerprints and dirt are visible on glossy areas

Kitchen fronts are not cheap. It is necessary to approach their choice with full responsibility; the final decision is made only after weighing all the pros and cons.