The use of façade panels as exterior finishing began relatively recently. The development of construction technologies and the emergence of new materials has made it possible to radically change the entire methodology for external finishing of residential industrial and office buildings. The variety of shapes and colors, accurate imitation of natural materials, combined with an affordable price, have ensured wide popularity of facade panels.

Simplicity of installation, low weight and high performance characteristics allow the use of these materials for any type of building. Installation of panels can be done independently, since it does not require special skills or special tools. This review will examine in detail various types of facade cladding panels, highlighting their advantages and disadvantages.

Types of panels by imitation

Under the stone

Under the stone - this type of material allows you to protect the facade from aggressive climatic manifestations.

With imitation stone

Under the brick

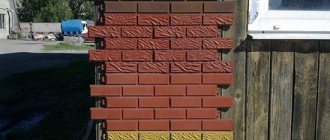

For brick – can be made of fiber cement or clinker brick. It has excellent sealing/ventilation/thermal insulation properties, as well as good decorative characteristics.

With imitation brick

Under tiles

Under the tiles - a two-layer finishing material based on polyurethane foam and clinker tiles.

Under tiles

Under the tree

Wood-like - can be made from vinyl, fiber cement, wood fiber. Japanese façade panels also look very attractive under wood:

Imitation of Japanese wood panel

The essence of premature renovation and how to avoid it

Premature renovation is a consequence of ill-conceived savings - a concept whose essence is far from new, but it will be better if you do not have to learn it from your own experience.

Renovation is usually called the timely reconstruction of an object, which is carried out without violating the integrity of its structure and underlying structures (walls, foundation, etc.). If the owner is forced to change the finishing coating after 5 years, or even after 2 years of permanent residence in the house, such renovation is considered premature and unjustified from a financial point of view. It is not at all difficult to calculate how many times during the entire period of operation the home owner will have to pay money for work and for building materials, doing, in fact, the same thing.

For comparison: renovation can be called timely if the walls of the house are designed to last 100 years, and the renovation of the facade took place, say, 20 years (or even more) after the facility was put into operation.

There are many people who are forced to engage in premature renovation of the facade, but only one reason pushes them to take this step: an ill-considered choice of finishing material.

Installation of facade panels

Fiber cement panels for the facade are mounted with self-tapping screws.

Installation of fiber cement panels

The metal version of the material is installed on a special sheathing of the house, after preliminary insulation of the facade. Plastic facade panels do not require special preparatory work before installation. They are attached to the frame using special fasteners.

Photo of installation of PVC panels

Clinker panels for facade cladding are mounted using self-tapping screws, a screwdriver and diamond discs.

Plastic siding and its features

Plastic siding is unusually cheap and widespread.

But for all its popularity, it has very significant disadvantages:

Firstly, plastic siding resists mechanical stress very poorly: it bends, scratches and breaks quite easily. And even if you are not bothered by the deep scratches that appear on the surface of the plastic siding after just a couple of years of use, chips, dents, and breaks that form over time will not let you sleep peacefully. It is these defects that force premature renovation of the facade, investing time, effort and money in its appearance.

Secondly, plastic is very “afraid” of low temperatures; in severe frosts, its mechanical strength drops to critical values, which makes it impractical to use the material in harsh climatic conditions.

Thirdly, installing plastic siding does not contribute to fire safety at all.

Features of metal siding

Metal siding is strong and, according to the developers, durable. But here’s the problem: we all know that “water wears away stones.” As it turned out, water “sharpens” not only stone, but also iron, which is open to any atmospheric influences. A clear demonstration of this is corrosion, the appearance of which the owner of metal siding becomes aware of at the most inopportune moment.

And even if water does not reach the metal thanks to a high-quality protective coating, the noise produced by precipitation will force everyone to reconsider their views on the practicality of metal siding.

Grand Line

In many ways, the Grand Line brand is known for vinyl siding, as this is one of its first areas of activity. As a result, the brand’s products have successfully passed certification in the USA. Let's find out a little more about the manufacturing technology of the material.

PVC panels are façade finishing. Vinyl products have low weight and good strength characteristics. The durability of such panels is practically not inferior to their counterparts made of polypropylene or fiber cement.

The Grand Line collection, called Tundra and characterized by good color fastness, deserves special mention. One of the disadvantages of the product is the price, but on the other hand, you have to pay for quality, and a lot.

Natural stone: for which houses can it be used?

Natural stone: for which houses can it be used? (photo No. 3)

Stone for exterior decoration does not fade, is not afraid of humidity and temperature changes, and is environmentally friendly. Attached with special glue. The service life of the cladding largely depends on the quality of this glue. Over the years, stones may fall off the façade.

The overall appearance of the facade depends on the location of the finishing elements. It is important to take into account the size of the stones, make uniform seams, and combine the pattern correctly. The work can only be trusted to professionals: there is no room for savings, the quality of the facade depends 100% on the skill of the mason.

Strengths:

- Status: expensive facade for expensive houses

- Durability: This is the most durable finish available today when installed by a professional.

- Investment in real estate as an asset: such a house will be in demand on the market for permanent residence.

Weak sides:

- It is heavy, so it is not suitable for any facade.

- Only a highly professional mason should install natural stone

- Work can only be carried out in warm, dry weather, otherwise the glue may lose its properties and the stones will quickly begin to fall off.

- To make the facade look beautiful, you need to find a good professional.

- Stone finishing is expensive considering the work.

Main selection criteria

Facade facing stones and panels, which are used to decorate building facades, lose their original appearance and strength over a long period of time. There are times when the finishing cladding material can fall off and cause harm to both the structure itself and its appearance. The reason for this phenomenon may be the incorrect selection of building cladding material. In order to choose the right facing stone or panel tiles, you must be guided by the following criteria:

- Manufacturer. It is better to choose a domestic manufacturer of facade stones and panels. Since products from Russia are more adapted to the climatic conditions of our country and are more durable in relation to foreign ones. Although facade stones and panels from foreign manufacturers have a more beautiful appearance and design.

- Price. This criterion applies to both the purchase of facade panels, artificial stone, and natural stone. The price of the facade stone and panel may indicate whether the facing material has additional additives, such as dyes, plasticizers and other components. The addition of such components leads to a deterioration in the quality and reliability of the façade material.

- Date of manufacture. In order for facade stones or panels to have all the declared characteristics, it is necessary to pass more than one month from the date of manufacture, so to speak, to obtain strength.

- The structure of the surface of a stone or panel. The surface of the façade stone or panel must be completely free from stains, cracks, and chips of significant size. The stone and panel must be uniform.

- From one batch. Purchasing and purchasing façade material from different batches does not exclude the possibility of obtaining goods of different colors. Also, production dates for different batches may vary significantly.

Siding based on natural wood and its derivatives

The advantages of siding made from natural materials are very ambiguous. On the one hand, the presence of a natural texture is a plus, on the other hand, it gives wooden siding the most minimal advantages. This is explained by the inability of natural wood to resist fungal infections, as well as the effects of mold and fire. We have already mentioned the dubious durability of paints and varnishes with which wood is necessarily coated.

If we consider the features of siding made from OSB-4 facade boards, then the story will turn out to be prosaic. Thus, OSB-4 siding quickly cracks in the cold and is completely unsuitable for northern regions; this material loses its aesthetics for no apparent reason, which very quickly necessitates additional painting of the facade. In addition, OSB-4 siding boards, distributed in the Russian Federation, are often substandard goods with an inexpressive texture, which at the same time have an unreasonably inflated cost.

Porcelain tiles for facade

Porcelain tiles are one of the best for finishing. The range of porcelain stoneware tiles is huge. There are many varieties of this material on sale based on color and texture.

The iridescent surface of the product looks impressive. There are also materials with imitation wood and natural stone. Like all materials made from fired clay, porcelain tiles are distinguished by their strength, moisture resistance, resistance to temperature changes, and fire. It does not change color over time.

Bright colors of porcelain tiles

The low hygroscopicity of the material is the reason for installing the tiles on a ventilated frame. The surface of porcelain stoneware can be:

- matte;

- polished (with a slight shine);

- glazed;

- polished;

- partially polished (with matte and shiny areas);

- structured (with a pattern, relief, imitation of the texture of natural materials).

Matte surface of porcelain stoneware

Tiles are produced mainly in two sizes: 30x30 cm and 80x120 cm.

For facade walls, it is better to use large-sized porcelain tiles to avoid the unsightly appearance of a large number of joint lines and to make them less noticeable.

An option when porcelain tiles look much better

If you want to visually increase the size of the building, use products with a polished surface to decorate its facade.

Design nuances

A weather- and mechanically resistant material that provides thermal insulation and protects the walls of the house from wear and tear is not all that is usually needed to enjoy looking at the house. Otherwise, everyone would live in houses covered with simple sandwich panels. Aesthetics are important.

Brick finish

It is affected by the location of the panels:

- Vertical. It will make the house visually taller, which is useful for small, squat houses.

- Horizontal. Will make the house appear lower and wider, which is useful for tall houses that look too narrow.

- Brick. It is used for base planks - they are not laid exactly on top of each other, but with an indentation, just like bricks are laid. It looks good and does not bring any special visual changes to the shape.

Vertical products will make the house visually taller

It is influenced by colors:

Bright white looks good, but it needs to be washed constantly, otherwise it will fade and turn gray very quickly. Bright black is usually not used for houses unless it is a Gothic style house.

The exception is a black background with a bright pattern or accessories that attract attention. But still, it is generally considered that the effect is too dark. Shades of yellow

The sunny color will attract attention to the house, making it visually cozier and more pleasant. A common color that looks good in a garden setting. Shades of green. They are rarely used for summer cottages, since a green house surrounded by greenery will look a little strange. But for a country cottage surrounded by other buildings, a garage and a neat garden, soft shades of mint or light green are well suited.

Bright white looks good but needs constant washing

- Shades of red. They are usually considered too bright and therefore undesirable, but muted options, such as brick, fully correspond to the classic ideas of a country house.

- Shades of brown. They look good and remind you of village houses. But it is not recommended to take cold or too dark ones.

- Delicate shades. Beige, pink, peach. They will make the house a little larger and more comfortable in appearance. Well suited for small houses where coziness is the main idea of the design.

- Cool shades. They will also make the house look larger, but at the same time more austere and darker. Pairs well with glass or metal inserts.

This is affected by the finish:

- Clean plastic. It does not look very aesthetically pleasing, because at one glance it seems that the house was cheap for the owners. But for a small house, which should not be too sophisticated, it is adequate.

- Pure wood or stone. Natural materials are always beautiful. The tree looks warm, cozy, reminiscent of villages and pleasant childhood memories. Stone is more austere, but if combined with wood, it will look softer.

- Pure metal. It goes well with glass, perfect for decorating a home in a high-tech style. Gives a special shine and severity of style. Reminds me of skyscrapers and industrial buildings.

- Clean glass. It goes well with metal, it really depends on the specific glass. Transparent looks extravagant, rich, a little strange. Matte is reminiscent of the sea, tall buildings, and the centers of large cities. It is good for frosted glass to be colored, this gives it additional charm.

Stylish country house

- Under the brick. It is made using PVC panels, the plastic for which is poured in several layers into a mold that replicates natural brickwork. From a distance it looks indistinguishable from real brick, is well suited for a house in a classic style, plus it allows you to save money - PVC is cheaper than real brick and much lighter.

- Under the tree. Made using fiber cement or PVC, it allows you to enjoy the aesthetic appearance, forgetting about all the shortcomings of wood and the fact that it needs to be renewed so that it does not rot. From a distance, again, it is indistinguishable, but up close it reveals nuances of color. The uniqueness of natural wood is missing.

- Under a stone. Natural stone is heavy and expensive, it is better to buy fiber cement or PVC for it. They, of course, wear out faster, but if you want to change the exterior of the house, replacing them will be much easier.

Horizontal products will make the house lower and wider in appearance

Tip It's a good idea to combine different materials. Lay stone-like panels in two rows, and finish the top with wood or wood-like panels. Include glass inserts between metal panels. The main thing is that the result is combined.

Cozy house in Provence style

Fiber cement siding and its characteristics

Siding can also be fiber cement. By the way, he deserves special attention.

Let’s consider, for example, fiber cement siding “KEDRAL” - although the material is not new (that is, already time-tested), many have not yet heard of it. In fact, this is a facade board, which is designed for quick and not very labor-intensive finishing of low-rise premises of various functional purposes.

This siding is based on a fiber cement board, which has the texture of natural cedar and a wide range of colors (30 different colors and shades). Fiber cement siding is perfectly combined with any building materials (brick, natural stone, glass, etc.), giving a stylish and laconic look to residential and auxiliary buildings.

It is easiest to talk about the advantages of fiber cement facade boards based on the disadvantages of more familiar finishing coatings (which have already been discussed above).

The manufacturer of fiber cement siding KEDRAL decided to deal with the main disadvantages of traditional facade materials in its own way. The mixture of cement and cellulose gives the material the strength of concrete, low temperatures, however, like heat, it is not at all afraid of, while cement does not burn and is absolutely immune to the effects of open flames (unlike, for example, plastic). By the way, in order to damage the fiber cement board, the “attacker” will have to make quite serious efforts. A cement mixture with a thickness of 10...12 mm, reinforced with cellulose fibers, is hardly amenable to even targeted mechanical influences.

Now, as for corrosion and the destructive effects of atmospheric moisture to which metal facade materials are susceptible: the material does not need protection from the first negative factor, because it does not contain metal inclusions. At the same time, it is protected from moisture thanks to a special coating, as well as due to its cement base.

Now, briefly about the additional advantages of KEDRAL fiber cement siding:

- the aesthetics of the texture and variety of colors allows you to organically combine CEDRAL siding with a wide variety of building materials (stone, wood, brick, etc.);

- durability (if installed correctly, the service life of the finishing coating is 50 years);

- increased frost resistance is a quality that allows the material to withstand even very sharp temperature changes without damage.

Considering that fiber cement siding is a fairly new material, we will talk about its main technical characteristics:

- the frost resistance of the material is characterized by 150 cycles of thawing and freezing, after which the residual strength of the siding is at least 90% of the original strength;

- the level of water absorption of façade material CEDRAL does not exceed 20%, which indicates its absolute immunity to the effects of atmospheric moisture and intense precipitation;

- Currently, KEDRAL façade siding is assigned flammability group G1, which indicates its complete fire safety.

Environmental friendliness, ease of installation and stability of the color palette make the presented material a promising and reasonable solution for finishing any modern facade.

Caring for fiber cement siding comes down to periodic cleaning of dust, which is done without the use of special cleaning agents. Agree, it is very tempting to invest once in installing a high-quality facade and, for 50 years, without worries and hassle, enjoy the results of an informed choice. The owners of plastered, wooden and metal facades never even dreamed of this.

Here the emphasis should be on a “reasonable” choice. An error in the choice of material leads either to the cost of premature renovation or to numerous inconveniences during the operation of the facade (noise during rain, labor-intensive maintenance, etc.).

Important! You should be extremely careful when choosing facade materials for a wooden house. Sometimes mistakes turn out to be fatal and lead to the fact that the walls of a wooden house “die” from rot and mold literally before our eyes.

The same can be said about mistakes when choosing installation specialists. Any façade material has its own characteristic features, and no matter how responsible the installer may be, he may not take them into account due to simple ignorance of the technology.

A simple example: fiber cement siding was installed neatly and flawlessly (in terms of size matching and correct installation of fasteners). At the same time, the installers did not take into account one point that was insignificant at first glance: waste in the form of chips and dust generated during the cutting process of the material remained lying on the front surface of the siding. As a result, cement dust ingrained itself into the surface after the first precipitation, and the façade had to be repainted. This is not critical, but quite unpleasant.

It is best to look for specialized installers on the websites of official product dealers. This significantly expands the supplier’s guarantees, allows you to save on the purchase of material (after all, an experienced installer always knows how to minimize the amount of surplus and waste), and also gives confidence in the correct and flawless installation of the facade.

The result will look something like this:

Dock

The Russian company produces several product lines at once:

- Fels - the collection will appeal to fans of the Scandinavian style, as the façade panels quite accurately imitate the structure of smooth rock;

- Stein - imitation of natural stone made in the best traditions of country houses in Victorian England;

- Berg collection - represented by classic European brickwork.

- Burg - stones of different shapes stacked in a chaotic manner.

- Stern is traditional stonework from northern Europe.

- Klinker - thin, long bricks stacked in neat masonry.

The brand’s technical specifications are also pretty good – the service life of façade panels is about 50 years. They are created on German equipment that supports 3D printing technology. All cladding is certified and very realistically conveys the texture of natural materials. The disadvantages of the product are the price and possible fading of materials placed on the sunny side of the house.