A wooden facade is environmentally friendly, fashionable, stylish... and very inconvenient. Despite the fact that wood remains a timeless classic of finishing, it is also the standard “material you would never want to work with.”

There are more than enough reasons for this opinion, wooden facade:

- Requires special treatment, which needs to be updated regularly. Without impregnation, wood quickly loses its attractiveness, begins to rot and dry out.

- Subject to combustion, not fireproof. Moreover: impregnated wood in the event of fire can release toxic substances (depending on the impregnation used).

- Afraid of rodents, insects, mechanical damage - and almost all negative factors. This problem is partially solved by processing, but there is still no complete protection.

- It's quite expensive. Even budget pine or spruce will cost a pretty penny, but something more interesting - for example, red cedar - may completely go beyond a reasonable budget.

So it turns out that, with all its advantages, a wooden facade is a very capricious and not at all cheap option. So is it worth it?

Many designers and architects believe not. Moreover, now on the market there is a large selection of modern facade materials that perfectly imitate the texture and surface of wood - you can preserve the visual appearance of the house, while avoiding the problems associated with wood.

Which specific material is better to choose? We talk about the most popular solutions, their advantages and disadvantages, in this article.

About façade finishing

Any owner is not indifferent to the appearance of his home. A stylish, neat façade is a subject of special concern. At the same time, facades made of different materials manifest their properties differently: if the brick finish gives the building features of monumentality and durability, then the trump cards of a wooden house are comfort and warmth. Wood also has other positive qualities (for example, it is environmentally friendly and easy to process); At the same time, wood finishing also has significant disadvantages:

- Low resistance to humidity . The main disadvantage of wooden finishing, dependence on the intensity of precipitation and temperature fluctuations, results in the appearance of mold, rotting and destruction. To protect the surface of the facade, it is necessary to carry out periodic treatment with impregnations and paints and varnishes.

- Fire hazard . It is almost impossible to increase the fire resistance of a wooden facade. Even careful and timely treatment with a fire retardant can only slow down the combustion process.

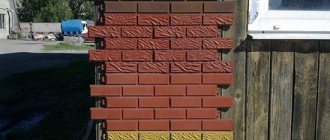

Combined facade finishing Source es.decorexpro.com

- Price . High-quality wood paneling made from valuable wood species can cost a decent amount of money (not counting the cost of subsequent maintenance).

If you still really want the house to have a pristine, natural look, facade panels made of other materials with an imitation of a wooden surface will come to the rescue. The construction market offers a significant selection of similar facade products, different in composition, structure and properties.

Which printers are suitable for printing with wood filament?

Naturally, when we talk about WOOD, we mean FDM printers. By and large, any devices that can operate in the above temperature and speed conditions are suitable. There are no special requirements. The main thing is to have a high-quality extruder. It's also a good idea to have a heated platform. Some types of plastic will require a larger nozzle diameter. For example, for the LAYWOO-D3 brand.

Important! If you are going to produce large products, you should pay attention to printers with a larger print area.

Facade panels: features of use

Cladding panels, regardless of composition, have an appearance that imitates natural wood (pine, oak, larch or cedar) with amazing accuracy. With the help of such cladding, you can decorate the house in any chosen style - classic, modern, Provence or half-timbered. The facade of the house under the tree is characterized by the following features:

- The material is resistant to atmospheric humidity (the main enemy of wood) and therefore more durable.

- The panels are distinguished by a variety of textures and a wide range of colors ; your choice will be much wider than when considering wood cladding options.

Modern style project with wood finish Source pinterest.com

- In most cases, panel finishing is done using the technology of hinged ventilated facade systems .

The basis of the ventilation system is a wooden or metal frame. The system serves not only as a decoration method, but also performs other functions (for example, it is able to hide defects in the facade wall). Under the facing panels, as a rule, insulation is laid and enough space remains for free air circulation and removal of excess moisture. In general, the design reduces the thermal conductivity of the house and protects load-bearing walls.

See also: Catalog of companies that specialize in facade and finishing materials.

Why imitate wood?

Imitation allows you to create a variety of wood textures, cuts in longitudinal and transverse sections, the structure of old petrified rock or eaten away by insects, as well as make spectacular stylistic variations. After all, the use of natural wood varieties is in many cases impractical and unjustified.

Patterning tools

You can apply the selected material to the wall using a spatula or trowel. To develop a drawing, the following tools are required:

- palette knife;

- textured roller;

- video with the image of a wood cut;

- rubber spatula with a pattern;

- various models of spatulas;

- stencil.

How to make a wood-look spatula with your own hands

There is no need to buy an expensive spatula. It can be cut from ordinary plastic packaging from construction or other materials. First they draw a shape, and then cut it out with well-sharpened scissors and form notches. The following types of spatulas will be needed:

- wide with large teeth;

- medium with sparse serrations;

- small smooth.

Advantages of wood panels

Despite the fact that the traditional wooden decoration of the facade looks stylish and respectable, it is increasingly being replaced by panels made of modern finishing materials. Their popularity is explained by important advantages inherent to one degree or another in all varieties:

- Significant operating time . The period during which the cladding of a house retains its strength and attractive appearance reaches 25-40 years.

Scheme of a ventilated facade Source 4homes.ru

- Versatility . Wood-effect panels can be used to cover buildings built using any technology: brick, blocks, timber, SIP panels, logs and frame technology. The cladding can be combined with any facade materials - from brick, stone and concrete to metal and glass.

- Resistance to natural influences . Most materials boast excellent resistance to frost (which is valuable in many Russian regions) and solar ultraviolet radiation.

- Improving the thermal insulation of premises . A wood-look facade allows you to reduce heating costs in winter and air conditioning in summer.

- Technologically simple installation .

- Minimal maintenance during operation. As a rule, dirt can be easily washed off with water from a hose.

See also: Catalog of wooden house projects presented at the Low-Rise Country exhibition.

Types of facade panels

The growing popularity of cladding with facade panels leads to an increase in the range; Manufacturers offer products from a wide variety of materials, each with its own advantages and disadvantages.

Panel cladding is designed for a wide temperature range Source womanadvice.ru

Metal panels for facade

Metal siding with an imitation of a wooden surface is made in the form of both traditional lining and block house; There are also other imitations of wooden texture. Metal siding for the facade of a private house has the following characteristics:

- Material . The panels are produced by molding from thin sheets of aluminum, stainless or galvanized steel 0.5 mm thick. Imitation of a wooden surface is achieved by applying a decorative polymer coating.

- Device . The panels are equipped with a perforated edge and a latch lock. This system facilitates reliable fastening of the elements. When installed correctly, the finished facade can withstand significant wind loads, and thermal deformation does not change the appearance of the facade.

Metal siding for logs Source 2gis.ru

- Physical parameters . The wood-look façade made from metal siding is durable, fire-resistant and has a service life of up to 35-45 years. The material is easy to install and practical to maintain; Despite its relatively low weight, it is resistant to mechanical damage.

- Feature that needs to be taken into account. The metal surface has high thermal conductivity , so you will need to lay a layer of thermal insulation (for example, polyurethane foam or mineral wool) underneath it.

- Flaws . Metal panels are not the cheapest option available, and aluminum siding will cost more than steel.

Wood imitation paints

Many designers and artists practice the use of paints and varnishes. The most popular method is to sequentially overlay contrasting shades on top of each other and then process them with special brushes . This method is more realistic.

Tools for work

To work you will need:

- tools for applying the first layer - brush, sponge or paint roller.

- brush with artificial bristles for glazing;

- rocker to create a pattern;

- soft brush made of natural fibers;

- pencil, ruler, tape;

- piece of fabric;

- thickener for acrylic;

- finishing coating.

Shades for the first layer

For the base, regular white acrylic paint is suitable. In stores you can find special tinting compounds and by mixing to achieve the desired shade. The easiest way is to use gouache paints. It is better to conduct color experiments on sheets of plywood or MDF. It is important that the initial layer is a couple of shades lighter than the glaze. Manufacturers offer a wide range of shades for the base layer:

- iron oxide is red;

- burnt umber or sienna;

- natural sienna;

- milky beige.

Shades as glaze

The final color will depend on the compatibility of the first layer with the color of the glaze. The composition should include two parts acrylic or latex paint and one part thickener. The following shades can be used as glaze:

- burnt umber and sienna;

- black;

- red iron oxide.

Work order

Many people note that the method of simulating texture using paint is the most familiar and understandable. To properly make the coating, follow these steps:

- First you need to apply a light color using a brush or sponge.

- Wait for the paint to dry.

- Next, mix the glaze to apply a decorative coating.

- An even layer of glaze is applied on top of the first layer. It is better to work with a small area of the area.

- Then slowly run a rocker over the wet icing, creating rows.

- To achieve the best effect, periodically remove dirt from the instrument.

- Occasionally, you can move along the surface not with the tool itself, but with a comb or grooves.

- Before drying, the layer is treated with a soft brush along the direction of the wood fibers.

- Wait until the surface is completely dry and use it for its intended purpose.

It is advisable to try the technique on a cardboard sheet of medium configuration. Only after achieving the desired effect can you begin to work on the real surface. It’s also worth trying the topcoat so that unexpected nuances do not arise in the future.

Thus, there are proven ways to create realistic wood imitations. Using the recommendations proposed in this article, you can make a unique wood-look material with your own hands and without the help of specialists. The main thing is to prepare the necessary tools in advance and choose a more understandable method.

Video description

About log siding in the following video:

Fiber cement

Despite the fact that fiber cement panels with wood texture appeared on the construction market relatively recently, they have already been appreciated - both by users for their good performance characteristics and by installers for the ease of working with this material. Since, in addition to the quality of the material, one of the most important criteria for its selection is service support, in order to reveal the full range of advantages, we will consider fiber cement facade panels of the Cedral brand.

Fiber cement siding has received well-deserved positive reviews from customers, thanks to its following positive qualities:

- Environmental friendliness

When fiber cement was first invented, asbestos was one of its main components. But its use was abandoned in 1976 because researchers were concerned that asbestos dust was harmful to health. Today, in the production of fiber cement siding, cement, sand, water and natural reinforcing fibers from cellulose are used, that is, fiber cement has become completely natural.

Eco-friendly fiber cement panels are even used for terraces and gazebos Source cedral.world

Features of wood filament

In appearance, WOOD (LayWood) filament resembles a regular PLA or ABS rod, only painted. The material with wood dust is slightly rough. When they print with it, there is a pleasant smell of burnt sawdust in the room.

Main features when printing:

- printing temperature: 195–220 °C;

- printing speed: 40–100 mm/sec;

- working platform temperature: 50–60 °C (optional).

It should be noted that filament from different manufacturers requires individual adjustment of the printer. For example, some sellers recommend setting the operating temperature as for PLA, and the printing speed as for ABA. In some cases, the plastic may change color, so it is better to run the test model several times to calculate the temperature and speed conditions.

Plastic BfWood Bestfilament 1.75 mm 0.5 kg

- Color Natural

- Plastic type for BFWood 3D printer

- Thread diameter, mm 1.75

- Weight, kg 0.5

- Price 2,000 rub.

Go to product

Video description

About the facade made of fiber cement siding in the following video:

- What's the result?

Unlike wood, fiber cement siding does not dry out over time. Fiber cement is noticeably stronger than plastic panels, and metal “outperforms” in such indicators as lack of corrosion, minimal thermal expansion, plus it does not “rattle” when it rains. The six-layer paint coating significantly increases the already considerable resistance to UV radiation and atmospheric conditions. “Dry” processes are used for installation, which can be carried out all year round. Finally, the right fiber cement siding is beautiful.

As for service support, there is no need to take everyone's word for it. You can contact the manufacturer directly for advice.

When working with clients, Etex adheres to the principle “it is better to see once than to hear a hundred times.” Potential buyers have the opportunity to order free product samples to clearly evaluate the quality of fiber cement siding.

The Cedral website has an intuitive visualizer, thanks to which even a beginner in construction can independently design the architecture of the house and calculate the approximate amount of materials on the facade finishing calculator. If you are planning to save on labor, then here are the step-by-step installation instructions, which are available on the manufacturer’s website with visual video examples.

Vinyl siding

Polymer material occupies a high position in the finishing materials market due to its combination of practicality and affordable price. The basis for production is polyvinyl chloride (PVC), from which panels are formed that successfully imitate the structure of wood. Products on sale are 0.8-3.6 m long and 0.2-0.6 m wide; They are equipped with a locking connection, ensuring a high-quality, gap-free fit. The features of the material include the following characteristics:

- Good imitation of natural wood . The line of wood-look PVC panels is presented in a wide selection of color shades, allowing you to choose an imitation of a wide variety of wood species. Horizontal siding replicates several types of wood siding; finishing can be done in a variety of ways: overlapping (herringbone), block house (under a log), in the edge (ship plank).

Facade cladding with vinyl Source ro.decorexpro.com

- Light weight . Lightweight panels ensure quick installation because they do not require reinforcement of the foundation and façade walls.

- Restrictions . During severe frost, the material becomes more fragile, which slightly increases the risk of mechanical damage.

Video description

About the facade composite board in the following video:

Veneer cladding Source eternit.ru

Wood-polymer composite (WPC) panels

Production from WPC has become possible thanks to new technological developments. The structure (cellular structure) of the material reminds everyone of the familiar polycarbonate; it consists of crushed wood compressed with polymer resins. WPC siding for external wall decoration appeared relatively recently, but has already managed to displace wooden and metal counterparts due to its characteristics:

- Long service life . Products made from WPC retain their original appearance for a long time. Paint pigments are added to the mixture rather than applied to the surface, as a result the skin is not afraid of ultraviolet radiation.

- Appearance . WPC siding looks like natural wood; the facade of any house will look elegant and presentable.

- Saving settings . The panel finish has no external linear expansion, does not deform and is characterized by high mechanical and atmospheric resistance.

- Easy care . Special care (additional treatment with protective compounds) is not required.

Wood-polymer composite Source eternit.ru