Frame house-building technology allows you to build comfortable housing quickly and inexpensively. The external walls of such a building are covered with OSB boards, which, unfortunately for all developers, do not have the aesthetic appeal required for the facade. Therefore, it is necessary to purchase material for cladding the house, which leads to higher construction costs.

Facade made of OSB boards

Manufacturers of paints and varnishes have taken into account the need of developers for finishing OSB boards and are offering their own solutions to this issue. Craftsmen who know how to create masterpieces from any material did not stand aside either. Thanks to these folk craftsmen, creative solutions for the exterior decoration of a frame house appeared.

Methods of decorative coating of OSB panels

Features of OSB boards

Production of OSB boards

Oriented strand boards (OSB) consist of several layers of chips and shavings pressed and glued together. A feature of the manufacturing technology of these types of panels is that the chips in the layers are located in different directions. This provides the material with high bending strength and allows it to securely hold the fastener. On the outer layers of the panel, the chips are located along the surface, on the inner layers - across.

Classification of OSB boards

But despite the longitudinal direction of the wood component, the front side of the panel does not have the smoothness necessary for high-quality painting. Both sides of the OSB board are uneven and rough. This feature has its pros and cons. The advantage is that the lack of smoothness allows you to get a surface with a spectacular texture. The disadvantage is the need for additional processing of the slab with various tools and materials.

The market offers several brands of oriented strand panels: OSB-1, OSB-2, OSB-3 and OSB-4. The latter are intended for front finishing and have a fairly smooth and effective surface. But in the construction of frame houses, OSB-3 is most often used, since it is cheaper and has all the necessary characteristics for constructing walls. However, the surface of OSB-3 boards needs to be improved.

OSB - oriented strand boards

Since this material is most popular among developers, all the finishing methods proposed below take into account the peculiarities of the surface of these panels and can be applied to products of other brands: OSB-1 and OSB-2.

Prices for OSB (oriented strand boards)

OSB (oriented strand board)

Consumer characteristics - weight, thickness, size

Trading companies offer OSB boards in a range of thicknesses and sizes. These products are not standardized and are therefore supplied in acceptable factory sizes. The available assortment and range of thicknesses allows you to choose the most suitable option, managing the budget for finishing work. Smaller sheets are suitable for independent fastening and cladding; they are supplied by American and European manufacturers. The weight of products with the same thickness and size parameters may vary slightly.

Table 2. Technical parameters of OSB boards from European manufacturers

| Options | Range |

| Available sizes (using Glunz as an example) | 2500*1250 mm, 2800*1250 mm, 3000*1250 mm, 6000*1200 mm. To order: 6300*2800 mm (6-30 mm) |

| Available thicknesses | 6, 8, 9, 10, 12, 15, 18, 22 mm. |

| Parameters of 1 sheet 2440*1220 with thicknesses from 6 to 18 mm (final parameters depend on the manufacturer) | Weight of 1 sheet: from 12 to 38 kg. Number of sheets on a pallet: from 55 to 140. Package weight: from 1.7 t to 2.1 t. |

The NordBord company produces products measuring 2550 * 590 mm with tongue and groove fastening on 4 sides, used primarily for laying floors. OSB boards are available for purchase individually and in packages; the quantity on a pallet depends on the thickness of the sheet. With a thickness of 10 mm, the package contains 90 pieces.

Table 3. Features of OSB boards made in Europe

| Name | Peculiarities |

| Ecological cleanliness | European-made boards can be used for interior and exterior decoration and are controlled by the E1 environmental safety standard. A hygiene certificate was received in the Russian Federation. |

| Moisture resistance | Swelling coefficient: OSB-1 – 25% OSB-2 – 20% OSB-3 – 10-12% OSB-4 – 7% |

| Deformation | It does not deform, so it can be used for load-bearing structures. The sheets do not have internal stress, such as, for example, remains during the manufacture of plywood. |

| Biostability | Not damaged by mold, mildew, or insects. Does not require additional processing. |

| Dimensions and thicknesses | Stable dimensions are ensured thanks to computerization of production. |

| Joinery processing | Easy sanding, the sheets have no defects, cracks, knots or voids. |

| Installation requirements | Fastening is done with nails using pneumatic tools, self-tapping screws, and staples. |

For external cladding of facades, OSB-3 and OSB-4 with a thickness of 15-25 mm are used. The cladding has low vapor permeability and does not require the installation of a vapor barrier. The spacing of the slabs during installation provides the necessary micro-ventilation.

Choosing a method for painting OSB boards

Choosing a method for painting OSB boards

Transparent coatings

Painting is the most inexpensive way to give panels an aesthetic appeal. Many developers like the texture of the slabs, which they would like to preserve. The unevenness of the surface of the panels when the sun's rays fall creates a certain play of light and shadow. It is this effect that is most attractive in untreated OSB.

In order to preserve and enhance it, use transparent paint with an ultraviolet filter. For example, Cetol Filter 7 Plus. This composition is intended for exterior wood finishing and is made on the basis of alkyd resins. The coating is transparent and has a semi-matte finish. The paint contains a UV stabilizer and water repellents, which provide reliable protection of wood from environmental influences.

Cetol Filter 7 Plus

If there is a need to preserve the natural texture of the slabs, you can use the following materials:

- clear varnishes;

- azure;

- transparent impregnations for wood.

Glazes are the most effective, as they have the ability to emphasize the grain of wood and give the painted surface a stylish shade and silky shine. A wide selection of these compositions is offered by the manufacturer BELINKA, whose assortment includes the “Toplazur” line, which includes 66 colors and shades.

Belinka Toplasur

Transparent wood varnishes will add gloss to the surface of the slab. You can use oil-based, water-based or organic-based formulations. Acrylic varnish will reliably protect the wood, and yacht varnish will give it a beautiful shade. An inexpensive and practical solution is semi-matte transparent “Drevolak”, designed for coating untreated wood and brick. This composition is easily applied to OSB and fills all its unevenness.

Drevolak - water-based acrylic varnish for wood protection

Prices for various types of construction varnishes

Construction varnishes

Tinting OSB boards

To emphasize the texture of OSB, you can use stain. To obtain the desired shade, it is diluted either with water, or with a solvent or acetone.

Shades of stains

The technique for painting OSB with stain is as follows:

- apply paint using a paint brush or spray gun;

- give time to dry (when diluting the stain with a solvent or acetone, the drying time is 5-7 minutes);

- Apply polyurethane primer to a dry painted surface and wait for it to dry.

Tools for applying stain to wood

In the photo - OSB board decorated with stain

To obtain the effect of artificial aging, use a patina of the desired color. After it dries, sand the slab with a soft foam sponge, which allows you to remove any remaining patina. After which the patinated panel is coated with transparent varnish.

Gold patina paint for wood

Prices for different types of stains

Stains

Covering enamels

In order to completely hide the protrusions of chips, thick covering enamels and water-soluble paints are used. The choice is wide:

- silicone;

- alkyd;

- pentaphthalic (forming a dense smooth film);

- acrylic (water soluble);

- latex.

Oil paint for wood

Oil paints have the highest viscosity. Their advantage is that they are practically not absorbed into the slab. Therefore, paint consumption is relatively low. The disadvantage of these compositions is the long drying time. But they have the main advantage: a durable covering layer and good adhesion to the surface, which is important when painting OSB. However, oil paints are not recommended for external use due to their instability to moisture and ultraviolet radiation.

Tikkurila Oil paint TECHO

Alkyd paints meet all requirements for painting facades. These compositions form a thin polymer film on the treated surfaces, which is moisture resistant and does not change its color when exposed to sunlight. Alkyd enamels can withstand significant temperature changes, therefore they are recommended for use in regions with any climate.

Range of alkyd coatings

Silicone paints are one of the most expensive. This is the main reason for their low popularity. This is despite the fact that silicone enamels fully comply with all the requirements for facade work. These paints have good resistance to mechanical stress, are crack-resistant and moisture-repellent. These compounds can be applied to OSB boards that have already been painted or whitewashed.

Facade silicone paint

Latex paints have high moisture resistance, so they are the best choice for regions with a maritime climate. Due to their excellent covering ability, they are not demanding on the quality of surfaces, which is especially important when finishing OSB boards. Facade latex paints can withstand a significant number of freeze-thaw cycles.

Latex water-based paint

The optimal choice for painting OSB is acrylic facade paints . They are inexpensive and have a lot of advantages: moisture resistant, withstand sudden temperature changes, vapor permeable, resistant to UV rays (do not fade in the sun). Acrylic paints can be applied at any time of the year. But in winter the air temperature should not be lower than -20°C.

Facade paint

Facade acrylic paint Ceresit CT 42

Prices for facade acrylic paints

Facade acrylic paints

Fire protection of OSB boards

The OSB board burns with the release of caustic substances, including toxic hydrocyanic acid. In the event of a fire, smoke is the decisive factor for survival. Using Soppka paints, you can solve two important problems at once: painting the panel and increasing its fire resistance several times.

Soppka - experts in OSB protection

Soppka compositions and paints are designed specifically for finishing oriented strand boards, so the manufacturer takes into account all the features of the surfaces of this material. The company's products have excellent adhesion to OSB, which cannot be said about other fire retardant compounds. The service life of Soppka coatings is more than 15 years. Paints can withstand any environmental influences.

Prices for various types of fire protection

Fire protection

Conclusion

OSB can be painted with any high-quality facade paint designed for fire protection of wooden surfaces. Good reviews about "Valtti Color Satin" from "Tikurilla". This enamel has excellent covering ability, does not change its color when exposed to sunlight, prevents wood from rotting, and has a noble matte finish.

Valtti Color Satin

Tikkurila Vallty Color Satin

If you decide to give the OSB surface an ideal smoothness, additional processing will be required, including grinding, priming, and impregnation with an antiseptic. All these points have many nuances that you need to know about to get the desired result. Therefore, it is better to consider painting OSB boards using specific examples of the use of various finishing options for these panels.

Plaster on OSB boards

An equally popular option for processing facade walls made of OSB boards. It's cheap, simple and effective. True, the entire structure and appearance of the OSB is hidden.

Features of plaster on slabs:

- Since the work is wet, the surface is additionally waterproofed with liquid rubber or roofing felt.

- To strengthen the layer, if it is more than 1 cm, a reinforcing mesh is used. It prevents the formation of cracks.

- The mesh needs to be plastered with a special compound for reinforcing work on the facade.

- The next layer is the finishing layer, which is also decorative. Performs two tasks: protects the walls of the house and gives them an original appearance.

The structure of the finishing layer is different and depends on the wishes of the owner. The most common options: fur coat, bark beetle, lamb.

The use of siding for exterior work is very justified, since this material was created precisely for such purposes. The cladding reliably protects the walls. At the same time, the cost of materials is affordable, and the appearance is decent.

There is vinyl siding, metal, wood and cement. Most often the first option is used. Its surface can imitate other materials, such as brick or wood. Siding is convenient to use for OSB, since to fix it it is not necessary to form a frame, as with conventional wall cladding. But, everyone chooses for themselves which option is better: with or without lathing.

Preparing OSB boards for painting

OSB requires preparation before painting

Before painting, the oriented strand panels are prepared. First of all, they need to be primed. This is not as simple a task as it might seem at first glance. The fact is that the front surface of the new slabs is smooth and quite slippery, so the primer will collect in drops and flow down. For this reason, experts recommend not to waste time and money on priming new slabs, but to immediately begin filling or painting them.

Panels that have stood in the open air for some time lose the smoothness of their front side. The surface becomes rough and able to absorb primer. The composition is applied with a roller on a long handle. The optimal choice is the Ceresit ST17 primer, the quality of which has been tested by time.

Primer ST 17

Prices for Ceresit primer

Primer Ceresit

How to choose OSB for external walls

The first oriented strand boards appeared in countries where the culture of frame construction had long been developed. Thanks to their excellent technical properties, they were immediately welcomed, and over time the material became even better.

Now OSB is used as a structural and cladding material almost on a par with plywood, but at a significantly lower cost. Such sheets are used in the construction of any type of building: creating roofs, filing ceilings, assembling floors...

However, covering the “pie” of light frame walls is, in fact, their real calling.

Technique for painting OSB boards

When applying paint with a brush or roller, you may notice that some chips swell from moisture and rise. This happens regardless of the type of composition chosen. If you need a budget solution for finishing the facade, you can ignore these small shortcomings.

But if you intend to complete all the work with the highest possible quality, you need to adhere to the following technique:

- priming the panel;

- installation of fiberglass mesh over the entire façade area;

- puttying with a moisture-resistant and frost-resistant composition;

- coloring.

When choosing elastic paints (for example, Descartes or Emarque), the puttying step can be skipped. These paints will fit perfectly on the mesh and cover it. After applying the second layer, the OSB will acquire a smooth, glossy surface.

Applying plaster to pox boards

The plaster coating extends the service life of the slabs and also prevents the walls from catching fire. High humidity causes oriented strand boards to change in size and can also become deformed due to temperature changes. Applying the plaster mixture directly to OSB is prohibited, as the coating may crack and chip after some time.

To prevent this from happening, builders use two application methods: • intermediate; • layer-by-layer.

Plaster is applied to OSB board

For intermediate application, polystyrene foam (gas-sprayed material) or glassine (cardboard impregnated with petroleum bitumen) is used. Expanded polystyrene helps to insulate wall floors from moisture and additionally provide thermal insulation. Glassine is not expensive and is available to everyone.

To prepare the base, the first step is to seal the joint gaps between the OSB panels. Then cover with an intermediate layer using polystyrene foam or glassine coating. A reinforced mesh sheet is fixed on top of it and covered with a plaster mixture.

When the plaster layer is applied directly to the oriented strand board, the work is performed in several passes. Initially, prepare the base, similar to the previous method. Afterwards, the first layer of plaster mixture is applied.

Without waiting for it to harden, a reinforcing mesh fabric is laid. As soon as the plaster mixture has dried, apply a second layer of plaster mixture. After the second layer has dried, the last leveling layer is applied. Without an intermediate layer, it is not reliable, because after three years of service, or even less, it begins to delaminate and fall off.

Installation of decorative stone on osb boards

Decorative stone of artificial origin looks aesthetically pleasing and rich, but it is difficult to install, and not everyone can afford its price. However, it is worth noting its durability and resistance to external factors, which will definitely pay for the exotic coating.

It is necessary to install a facade made of decorative artificial stone in several stages:

• filling the seams between OSB boards with a sealed mixture with a frost-resistant effect;

• priming the entire surface of the walls;

• putty with frost-resistant putty mixture;

• applying glue in 2 layers, embedding the reinforced mesh in the first;

• fastening of decorative facade stone to the second adhesive layer;

Type of finishing of OSB boards with decorative stone

It happens that the stone is fixed without an intermediate layer. This can lead to unreliability; after 3 years the coating may fall off.

Fastening siding to OSB boards

Facing the facade with siding sheets is a universal method. It is applicable to various surfaces. The material is affordable and has an aesthetic appearance. On uneven facade surfaces, siding is laid on a pre-installed sheathing. If the walls are smooth, then the siding can be attached directly to them.

In order to keep the OSB panels in unchanged condition, it is necessary to install a membrane between the siding sheets and the wall, which will prevent the penetration of water and drafts.

Decorative facade panels

Decorative panels for decorating the façade of a house are widely used. They are made from building materials such as metal, glass, plastic, wood.

Such panels are fastened in several ways:

Installation of decorative panels on the walls of an OSB house

All fastening options have their advantages and disadvantages. Everyone chooses what is more suitable and convenient for themselves. The most important thing is to strictly follow the technology and recommendations of professionals.

Methods for finishing osb outside

OSB painting with artificial aging effect

This method of processing OSB panels allows you to preserve the surface texture while smoothing out the most noticeable chip protrusions. The end result is a smooth slab, on which its natural pattern is clearly visible. Using multi-layer dyeing with compositions of different colors and purposes, they provide two stylish effects at once: colored dyeing and artificial aging.

Tools and materials that will be required to complete the work.

- Angle grinder (grinder).

- Abrasive grinding wheels of different grain sizes: P180 and P320. You can use modern abrasive Velcro tapes, one side of which is self-adhesive.

- Abrasive sponge P320.

Abrasive sponge fine grain P 280-P320

- Airbrush or spray gun.

- Primers: FI M194 and FL M042/CO2.

Primer FL-M042/C02 Renner

- Acrylic varnish “Mother of Pearl” JW M120.

- Tinted varnish JO 00M294.

- Patina GM M048/Black.

Stages of painting OSB boards

Step 1: Sanding the panel.

Smooth out uneven surfaces of the panel using a grinder and a P180 grinding wheel. To obtain the desired result, work with light pressure from the tool. The panels are passed over each section with an abrasive wheel no more than three times.

Sanding OSB

Step 2: Apply the first coat of primer.

OSB boards are made using a special adhesive impregnation, which includes various resins, wax and paraffin. These substances are necessary to prevent the panel from delaminating and the formation of rot and mold in it.

Primer for OSB

Applying primer

A primer on the sanded OSB surface is needed to ensure that the resins and paraffin continue to remain inside the slab. At this stage of work, barrier primer FI M194 is used. It is applied using an airbrush or spray gun. Material consumption is within 50-60 g/m2. Further work begins after 1.5-2 hours, after the soil has completely dried.

Step 3. Applying pigment primer.

At this stage of the work, the panel is covered with primer FL M042/CO2. This is a matte white composition that dries within 2.5-3 hours. The soil consumption should be at least 100 g/m2.

Step 4: Sanding the slab.

Use a grinder with a P320 abrasive wheel. Only the top layer of pigment primer is removed. The result should be a smooth whitish matte surface.

Primed surface

Step 5. Varnishing the slab.

Acrylic varnish “Pearl” JW M120 is applied to the OSB so that the weight of the wet layer is 100-120 g/m2. In order to achieve this result, each section of the panel must be covered with 2-3 layers of varnish. Then wait for the coating to dry completely for an hour.

Step 6. Patination.

At this stage of work, black patina GM M048 is applied to the panel. As before, an airbrush or spray gun is used for this purpose. The weight of the wet layer should be 60-80 g/m2. There should be no gaps in the panel from the previous white layer. The patina dries within 5-7 minutes.

Patina for wood Renner GM M048/C01

Step 7. Patina sanding.

Using light pressure, sand the panel with a P320 abrasive sponge. After such processing, you should get a surface with a clear chip pattern, the main part of which is white, and the spaces between the chips are black. This provides an artificial aging effect.

Remove excess patina with a sponge

Step 8. Tinting the OSB board.

Tinting is the stage as a result of which the slab acquires color. To perform this task, acrylic varnish is used. The color is chosen depending on how you want the facade of your house to look. Varnish consumption is within 100-120 g/m2. Drying time according to the manufacturer's instructions, but on average 1.5-2 hours.

Acrylic lacquer

It should be noted that as the varnish dries, its color will change due to the gradual acquisition of dullness. This example uses JO 00M294 zero gloss varnish. If you want to give the façade of your home a glossy look, you can opt for compounds that provide this effect.

Example of applying varnish with a brush

Decorative panels

The most difficult and expensive option is the installation of decorative panels. But, you can provide reliable and durable protection to your home. Everything pays off with interest.

- The surface seams are treated with sealant, the walls are primed to improve adhesion.

- PPS (insulation) is glued on top.

- It is puttied with façade putty.

- After applying the first layer, the surface is treated with glue, the mounting mesh is embedded in it and the second layer of glue is applied.

- A decorative stone is placed on the second layer.

Decorative panels are made from different materials, which determines their price. There are PVC panels on sale, which are cheap, but will not last as long. They have a high decorative component.

Here are some types of products:

- imitation brick;

- imitation stone;

- wooden panels;

- wood imitation;

- PVC panels;

- MDF panels.

Not all of them can be used for exterior decoration. It is important to take into account the property of the material to resist moisture, not fade and withstand temperature changes.

OSB boards are often used in frame construction to form walls. However, they cannot be left without proper protection. By choosing one of the above finishing methods, you can not only extend the service life of the structure as a whole, but also give the house an original appearance.

Technology of painting OSB with primer-paint

This method of painting oriented strand boards was developed by Holzer specifically for finishing the facades of frame buildings. Therefore, the instructions offered by the manufacturer use exclusively its products.

Tools and materials required to perform the work.

- A spatula with a narrow metal blade.

- Holzer Festspachtel Elastich putty.

Putty Holzer Festspachtel Elasticch

- Holzer primer color.

Holzer primer color

- Roller for applying paint (with a foam or faux fur coat).

- Container (tray) for paint.

If desired, you can use narrow decorative panels, with the help of which you can decorate the façade in the half-timbered style.

Finish example

Instead of plastic panels, you can attach thin wooden blocks, pre-treated with an antiseptic and painted in a color that harmonizes with the finish of the facade.

Stages of work

Step 1. Puttying the seams between OSB boards.

Holzer Festspachtel Elastisch putty is applied to the seams between OSB boards. Use a spatula to press the compound into the gaps and spread the putty at a distance of 5-7 cm from the seams. They strive to smooth out the composition in such a way as to obtain a smooth surface without visible cracks. Wait for the composition to harden.

Puttying

Step 2: Painting the panel.

Using a roller, Holzer primer is applied to the slab.

Application of primer

The soil dries in about 6 hours

You can choose any color from the manufacturer’s catalog (there are more than 7 thousand colors in stock). If a fur roller is used, it must first be kept in water for 1.5-2 hours. If a bucket is chosen as a container for paint, you need to prepare a small piece of plywood on which to roll out the roller, removing excess paint from its coat.

Coloring technique:

- paint is poured into the container;

- dip the roller in paint and roll it several times over a special part of the tray or plywood;

- Apply paint to the wall so that each next layer overlaps the previous one by 4-5 cm.

Holzer paints have good covering power, so even surfaces do not require a double coat. But in the case of OSB, it will be necessary to properly paint all the protrusions and recesses. Therefore, the manufacturer recommends painting with vertical strokes on the first day of work, and horizontal strokes on the second day. In this case, the coating will acquire the thickness and strength necessary for facades.

Video - Creative finishing of OSB boards

Finishing walls from OSB boards outside the house: how to finish OSB walls

Today, many methods have been developed for treating the surface of walls covered with oriented strand sheets on the outside. Each of them is focused on the characteristics of the cladding material (OSB), because it, like wood, is subject to deformation.

The main methods of external finishing of walls made of OSB sheets:

Painting a house made of OSB

Painting is considered the simplest and most affordable finishing method. For this, special wood paints are used: oil-based and water-based. For long service life of the coating, the surface must be prepared.

The first thing to do is to seal the seams between the panels. Afterwards, carefully treat the entire wall surface and prime it. The paint is applied in several layers, at least two, each of which must be dried.

Painting OSB boards with a roller

It is best to paint walls with a wide and thick brush or paint roller.

Pie wall based on OSB

As a result, the user came to such a “patty” of the wall. From inside to outside:

- drywall;

- wall;

- insulation – mineral wool, laid in 2 layers, with a total thickness of 100 mm;

- wind- and moisture-proof membrane;

- counter-lattice;

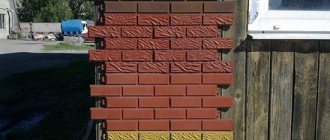

- OSB 3 boards with imitation of half-timbered layout.

Since total savings are at the forefront, the first thing our site user Victor Banev did was to virtually lay out the slabs on the walls to minimize their cutting and waste.

Moreover, the dimensions of the OSB sheet dictate the location of the decorative layout of boards (25x100 mm), which cover the joints of the slabs and imitate half-timbered timber.

After several intermediate layout options, we managed to come to a common denominator. A sheet measuring 224x122 cm, placed vertically, almost completely covers the wall, and overlays (boards) are needed only to protect the vertical joints of the slabs. We'll tell you how to estimate the layout (having taken all the necessary dimensions from the facade in advance) using the example of the left wall of the house.

If you look at the picture above, you will notice that 2 whole sheets of OSB are placed vertically on the left and right. Based on the results of wall measurements, it turned out that the distance (remaining gap) in the middle is wider than one sheet, but narrower than two. Those. - we need to sheathe the wall with two pieces laid horizontally, and then close the resulting horizontal seam. To maintain symmetry and the overall design of the layout, we add horizontal strips to the outermost OSB sheets and proceed in a similar manner along the entire perimeter of the building.

Finishing OSB walls outside the house

OSB boards or otherwise OSB sheets are widely used for the construction of walls in houses, in particular in frame construction. Therefore, the issue of their external decoration is very relevant today. Moreover, not only from an aesthetic point of view, but also in terms of protecting the material from the negative effects of external factors (high humidity, sudden temperature changes, solar radiation and others).

The issue of installing OSB boards on walls outside the house is discussed in the article: attaching OSB sheets to walls outside the house. Here we will consider the following issue: finishing walls from OSB boards outside the house.

The issue of finishing walls from OSB panels inside a house is discussed in the article: finishing OSB walls inside a room.

Ideal material for house facade

Everything we have learned about OSB material perfectly emphasizes the advantages of its use in facade work. Judge for yourself: workers can easily cut the slab sheet, lift it and hold it during installation.

You don’t have to worry that if it rains during construction, the material will deteriorate—the slab adheres moisture well. Again, easy to drill and holds tightly to the frame. When purchasing finishing material, you can select the required thickness in advance, and the price of USB panels for exterior finishing is quite affordable.

There is no need to worry about insects; we have not yet encountered bark beetles in slabs. It is worth noting that when installing panels on a facade, you don’t have to be afraid of myths about the toxicity of the material - in the open air the concentration of harmful substances is negligible, which means the finishing panels are safe for human health.

Durability of OSB

Usually, everyone who decides to do something like this is primarily concerned with the question - what will happen to the facade in 3-5 years if it is sheathed with OSB.

Some people think that the slabs will swell, because... OSB is not a finishing material intended for outdoor use. Some people believe that this cladding option is possible and, moreover, optimal from the point of view of reducing financial costs and the possibility of repeating it yourself.

Victor BanevFORUMHOUSE user

Whether or not to use OSB on the facade - opinions vary. I decided that the game was worth the candle in terms of speed, ease of installation and low cost of such a facade. I’ll just note that an OSB façade is an economical option for thrifty summer residents. To decorate a permanent structure - a cottage - more weather-resistant materials should be used.

Looking ahead, let's say that the service life of the facade made of OSB boards has already entered its third year, and what it looks like is clearly demonstrated in the following photo.

Pie wall with OSB

The result is impressive, and now let's move on to practice. There is an old uninsulated dacha measuring 6x8 meters. The outer cladding is inch board. On top of the boards is painted hardboard. The place of alteration is the Leningrad region, i.e. an area with higher humidity than Moscow, with frequent rains, fogs and short summers.

What is required is to insulate the building from the outside and make a beautiful façade. The budget is minimal. This means: work without hired workers, using relatively inexpensive materials and technology that can be done by two people. The user’s train of thought when choosing methods for finishing the facade is also interesting.

Victor Banev

I don't like finishing the facade with siding. It's boring. Block house is too expensive. The well-proven option of using CSP (cement particle board) for further painting and imitation of half-timbering is also eliminated. Expensive and, due to their heavy weight, difficult to lift the sheets, much less mount them at a height. Sheathing it with clapboard is also not the same. But I, as they say, fell in love with half-timbered wood and began to think about how to bring this idea to life.

After going through several options, the user decided to make the façade he liked so much as a half-timbered structure based on OSB boards. This, according to the user, is much cheaper and easier than fiddling with the DSP.

Façade mounting technology

In construction, installing an OSB panel on a facade is considered a non-labor-intensive job that can be done by yourself. You just need to cut the sheets yourself before attaching them to the façade. It is advisable to do the work with a friend, one holds the sheet and the other screws it on.

The plate is easy to drill, so a screwdriver with charged batteries and wood screws are enough. Although the slab does not absorb moisture well, it needs to be painted. Be sure to putty and plaster first - these three protective layers will provide protection from water and cold for many years. Designers recommend additional finishing with slats, the so-called contrasting “half-timbered” style.