When we build our home, we strive to use high-quality, attractive and affordable building materials. The appearance of natural wood for facade decoration will always be popular. But many people are not able to handle natural boards due to their high cost. Therefore, they are more often inclined towards alternative and inexpensive solutions, one of them is to use imitation timber as a finishing material.

What is imitation timber and why is it better than other materials?

Imitation timber (false timber) is factory-made wooden panels made from materials of various types of wood.

What does imitation timber look like? In appearance, this material is similar to wooden lining, cut into specific sizes.

The false beam panel looks like a trapezoid in cross-section, and the surface decorated with imitation timber is smooth, with triangular grooves for the seams.

The material is several times cheaper than natural timber and exactly copies the texture of natural wood.

A block house in cross-section is a segment of a circle. The surface formed by the panels of the block house imitates a log house.

In terms of appearance, what is best to use is a matter of aesthetics.

Raised timber can be used both for exterior decoration of houses and to create a unique interior design. Everyone knows about the advantages and beauty of natural wood - the unique structure and environmentally friendly material, combined with an affordable price, immediately gained popularity among analogues on the construction market.

Advantages and disadvantages

This type of cladding is made entirely from natural wood. Breeds are used that are able to withstand negative environmental factors for a long time. At the same time, there is additional processing that improves technical characteristics. Therefore, imitation timber has all the advantages of ordinary wood:

- Pleasant and natural look.

- Ecological cleanliness.

- Additionally, it insulates the building from heat loss and noise penetration, so you can use a thinner thermal insulator when arranging the facade.

- Versatility - they are sheathed with imitation timber on buildings built from different materials (brick, concrete, gas block).

- Affordable price.

- Good selection of sizes and textures. The variety of patterns is achieved due to the number of wood species (spruce, pine, oak, larch and others).

- Simple and quick installation.

- The service life reaches 30 years, subject to proper installation and further maintenance of the cladding.

But, of course, this material also has all the disadvantages of wood. Therefore, when choosing facade cladding with imitation timber, you should prepare for the following disadvantages:

- Before installation, the material must rest for a couple of days in order to “get used” to the environmental conditions;

- panels require regular treatment with protective agents (varnish or paint). If obvious flaws appear on the surface, you will have to completely remove the paint and varnish material, eliminate the flaw and apply several layers of protection;

- high price of additional elements, for example, external and external corners, ebbs, slopes and others;

- Despite serious processing in production, wood is highly flammable.

There are many pros and cons of cladding the façade with imitation timber, but the cons can always be overcome if you approach these problems wisely. Therefore, if you decide to choose just such a finish, immediately think about how to protect the material from possible discrepancies.

Comparison with other types of cladding

The building materials market offers a large selection of options that are similar in appearance to wood. The most popular are vinyl and metal wood siding. This finish actually has a wood grain pattern on the front side. But up close, the artificial substitute is very different from its natural counterpart.

Vinyl siding melts easily, releasing caustic substances, is not durable and does not retain heat well, so you will have to use thicker insulation under the cladding. The price of such panels is much lower, the service life is almost the same as that of imitation timber.

The metal brother does not have soundproofing properties at all, which means that even small drops of rain will be heard in the rooms. The cost of metal cladding is identical, but the service life is much higher and can reach up to 50 years.

Design solutions

To make the house truly original and beautiful, before starting tiling work, you need to consider a couple of ready-made projects and choose an option to your taste. Wood finishes are often combined with other materials. Thus, designers propose finishing the basement of the house with stone (natural or artificial), and covering the facade walls with imitation timber.

A good option would be to use several shades of wood, that is, choose varnishes or impregnations of different saturations. Paints for wood are also suitable, then the flight of fancy is limited only by the palette offered by the manufacturer.

If you are unsure of your capabilities, there are many companies that will help you choose a facade design in accordance with the customer’s requirements and the general concept of the site where the house is located.

How to choose false timber

It is necessary to choose a false beam based on many components - the specific surface for its installation, external or internal purpose, size of the material, preferences for the type of wood.

Regardless of what grade of imitation timber you choose for interior or exterior decoration, you must choose a material without fallen knots and carefully inspect it when purchasing.

Modern technologies make it possible to significantly save money and perform façade cladding or interior finishing with this beautiful, durable and safe material.

Dimensions

Standard material dimensions are:

- length from 2 to 6 meters;

- board thickness -1.6 -3.6 mm;

- width - from 100 to 200 mm.

Manufacturers produce the most popular product dimensions in construction, which allow finishing any façade and interior surfaces.

Which tree species are better

To produce this natural finishing material, larch, linden, spruce or pine are most often used as raw materials.

You can order factory-painted false larch timber

The type of wood affects the final cost of the false beams. Products made from pine are most in demand due to their low price. Spruce is also in demand in the production of such products. This tree is more resistant to moisture.

Premium wood includes Angara pine and cedar. Linden and oak are also used for manufacturing - but their intended use is more often saunas and baths. Houses made from imitation timber do not lose their original appearance for a long time, provided that all wood selection criteria are met.

Imitation cedar timber has a minimum of knots

In addition to size, the choice of high-quality false timber is influenced by its humidity and drying methods - with chamber drying, imitation timber is lighter in weight than with atmospheric drying, it is good for indoor use.

Variety

Differences in the quality of false beams are determined in the process of sorting the produced wooden panels. There are four types of grades of imitation timber:

- Extra – (0)—the highest quality and selected material;

- A (1) – small chips on wooden products are acceptable;

- In (2) - unevenness and size fluctuations are acceptable within the normal limits;

- C (3) - the most budget option of the material - the presence of knots, cracks and chips is acceptable.

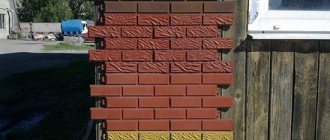

Wood-look composite panels are an ideal option for exterior decoration

Faux wood boards are formed from a mixture of cellulose fibers and plastics, such as polyvinyl chloride, polypropylene or rigid polyethylene. The content of natural material is 30-70%. The addition of plastic provides durability, moisture resistance and the ability to be dyed in many colors. The composite material will not deform under the influence of moisture, it does not rot in contact with water. The surface of the boards has a texture that imitates wood grain. The timber intended for terraces is covered with brush, which ensures slip resistance.

How to calculate the amount of material

When finishing houses and imitating timber, it is important to carefully calculate the amount of material required. To decorate a room internally with false timber, it is necessary to calculate the finishing area - calculate the area of each wall, floor and ceiling minus the openings. Each individual area must be divided by the area of one board. Adding all the indicators will give the total number of boards required for a specific room or facade. It is better to buy false beams with a 10% margin in case of damage or defects.

We attach the calculation using the example of lining, since it is the same.

In addition to wooden decorative panels, you will also need moldings for finishing—plinths, corners, and cornices.

Installation methods

When covering walls, both internal and facade, you can choose horizontal or vertical methods for installing imitation timber.

Horizontally

When installing the imitation timber horizontally, place the starting board with the ridge up, then the next parts of the “lock” should be at the bottom during assembly so that no water gets into the groove.

Vertical

When vertically finishing cottages, private houses or summer cottages with imitation timber, the installation of the first board begins from the side edge of the windows to the door. The material sheathed in a vertical direction creates a smooth, ideal surface and visually expands the space in small rooms.

Care instructions after installation

In order for the finished cladding to serve for a long time, it requires care. For this, there are specialized tools that will protect the panels. Primers or wax are often used. After coating, the boards will need to be cleaned from dust from time to time; wet cleaning is allowed, but without abrasive compounds and detergents.

Additional protection and individual shade can be achieved with stain, paint or varnish. Due to the latter composition, the service life is significantly increased, but the coating must be renewed periodically. Stain helps improve the texture of the wood and adds shine. Imitation timber is an excellent option for decorating internal and external spaces, which will suit any interior and architectural style. To obtain a high-quality finish, you will need not only to provide periodic maintenance, but also to comply with installation work.

Attaching imitation timber to the wall

The material can be attached to any walls of houses - frame construction, block, wood or aerated concrete. Whether it is a permanent suburban house or a small country house does not matter either.

Preparing the base

Installation of imitation timber is easy to do with your own hands - installation of the material is simple and does not require the help of professionals. You also need to prepare fastening elements, insulation (in the case of facade insulation) and slats for the sheathing in advance.

Important: the imitation timber must be primed and painted before installation, so that there are no cracks during operation.

Before installing the imitation timber from the inside, the packages of the panels must be opened to allow the wood to acclimatize to environmental conditions. Thus, after lying for a couple of days, the moisture content of the material will become the same as the environment. Subsequently, when it is secured, there will be no gaps. The surface of the walls must be cleaned of dirt and dust and treated with an antiseptic.

Lathing

For lathing on the facade, a planed beam of 50*40 mm or 50*50 mm is chosen under the false beam frame. It must also be treated with an antiseptic composition. In addition to bars, you can use galvanized metal profiles, which are used when installing plasterboard partitions. Installation of the sheathing is carried out from the corner of the house during facade finishing and attached to the surface using self-tapping screws; the recommended frame sheathing pitch is about 70 cm.

How to properly secure imitation timber

When finishing facades with imitation timber, it is also better to treat the panels with an antiseptic in order to extend the life of this material. The installation of panels and their fastening is carried out moving from bottom to top.

One of the fastening elements is used:

- self-tapping screws - attached so that the head is twisted in the same plane with the front side of the false beam and does not protrude;

- galvanized nails, which are driven into the ridge at an angle of 45 degrees;

- special clamps, but they are recommended to be used for panels of small thickness.

Material calculation

Before starting to carry out cladding work for the walls of a house using imitation timber, you will need to calculate the actual volume of the material itself, as well as the components (corners, extensions, etc.) that will be required during the work process.

To do this, you will need to take measurements of each wall that you plan to cover with finishing. The length and width of window openings, as well as door frames, are measured separately. Since these areas will not be covered with cladding, their area must be subtracted from the total area of the facade. This means that you will need to purchase fewer finishing materials.

Facade protection

The facades of houses made of imitation timber are treated with insecticides to increase their service life and preserve the characteristics and texture of wood. This way, the wood remains protected longer from dangerous pests - bugs, as well as fungus and mold.

For safe living in a house finished with imitation timber, wood panels must be treated with a façade fire retardant compound. Additionally, wax-based oils will help protect wood from adverse weather conditions.

Do-it-yourself selection and installation of lathing

For a house made of wood, it is advisable to use wooden blocks with a cross-section of 40 - 50 mm . The wood should be thoroughly dried and treated with antiseptic and moisture-resistant agents. Metal profiles are used for installation of cladding in concrete or brick walls.

Installation of the sheathing is carried out by attaching the guides in a vertical position in increments of 600 to 800 mm.

Corner guides should be mounted in such a way that there are two bars at each corner.

IMPORTANT!

When installing the sheathing, you should check the uniformity of installation using a level.

In addition to double corner strips, you should additionally install bars in places where shelves or other hanging elements are attached that can weigh down the structure.

The wiring should be pulled between the sheathing, insulated with a special corrugated tube.

Having completed the sheathing over the entire area, you should begin installing the facing panels.

How to attach imitation timber to the ceiling

Finishing the ceiling of a room with such material is a rather complicated procedure, since when installing a ceiling with wooden panels you have to constantly work above your head and keep the material suspended.

For the ceiling cladding, choose a thin-width material made from dry wood. The stages of attaching panels to the ceiling are the same as for walls - lathing, protecting communications running along the ceiling, filing boards, varnishing.

Thermal insulation and vapor barrier

A vapor barrier film should be attached to the prepared surface to prevent the formation of condensation moisture inside the skin . To do this, the film is attached using a stapler (to a wooden surface) or using sheathing beams (to a brick or concrete surface) so that the smooth side of the vapor barrier is in contact with the wall.

Cover the entire surface for cladding with film. The seams of the film should be overlapped by 100 - 150 mm and secured with tape.

CAREFULLY!

The location of the vapor barrier film should be free, without tension.

Otherwise, the membrane may break through during the installation of sheathing or thermal insulation, as well as during the natural shrinkage of the walls of the house.

In some cases (in the absence of external thermal insulation of the house), the installation of thermal insulation materials is required. In this case, when calculating the sheathing pitch, not only the length of the cladding board under the timber is taken into account, but also the width of the insulation. Roll or block insulating material is placed tightly between the sheathing guides without gaps or joining holes.

Important nuances

In order to qualitatively sheathe a house with imitation timber, you need to take into account a number of features when choosing and installing the material:

- pay attention to the quality of wood when purchasing it;

- when choosing imitation timber, it is necessary to take into account the type of premises - external or internal decoration, grade and species of wood for certain purposes;

- strictly follow all technology and stages of panel installation;

- in rooms with high humidity it is better to use metal profiles as lathing;

- when laying false beams on the wall, it is better and easier to install, starting from the floor and moving upwards;

- strictly follow the rules for placing the panel “lock” - groove up, tenon down;

- Be sure to treat the material with antiseptics and protective compounds.

Video description

An example of interior decoration of a house using imitation timber in the video:

And then a few more options for interesting solutions:

Combination of timber and plaster finishing

As practice shows, facade cladding can be done with different types of finishing. For example, imitation timber and plaster. The appearance of the house is distinguished by smooth lines, severity and elegance, and the resulting “striped” pattern will visually increase the height of the building.

Combined finishing of a two-story house Source betonicum-stroy.ru

Full exterior cladding of the house with imitation timber

Anyone can become the owner of such a wooden tower. The layout of the house is suitable for both active recreation and year-round living. Finishing with false beams can be done not only outside, but also inside, then your guests will definitely be able to find themselves in an old Russian fairy tale. The main thing is that the interior design matches this.

Finishing a 9x9 house with imitation timber Source www.hmkmos.ru

Timber and stone

Wood and stone go well together in decoration. This can be seen in the following project. Moreover, if in the first option the ratio “wooden covering - plaster” is approximately 1:1, and they are equally responsible for the appearance of the building, then in this case the “stone” decorations are minimal and are designed to emphasize the naturalness and superiority of wooden compositions.

Timber and stone in home decoration Source zillow.com

House with attic

Wood always remains the most environmentally friendly material. Many people strive to make it a cozy home or cottage. Here is an option for a small cottage with an attic floor. It looks like an ordinary house, but to add color, the imitation timber is painted with stain, wrought iron railings give it an intriguing look, and finishing the foundation with a stone finish completes this ensemble. This is how even an ordinary house can be turned into a small miracle of design by adding a couple of highlights.

A combination of false timber, stone and forged elements Source woodeco.org

Imitation of log walls

At first glance, it seems that the house is made of rounded logs, but, as in previous versions, this is just finishing with imitation timber. A simple way to replace expensive rounded wood, while maintaining the naturalness of the materials used, without compromising the quality of the construction project.

House project with rounded wood trim Source profibrus.ru

The cost of finishing with imitation logs depends primarily on the price of the lining that will be used for the cladding, plus the geometry of the house - the simpler it is, the less labor costs.