Many owners of dachas and other suburban real estate try to make the façade of their house look like wood to imitate the finishing of a natural material. To perform such work, you need to choose a suitable product for this on the construction market. From our article we will learn what materials can be used to decorate a façade to look like wood, get acquainted with the advantages of such products and the most suitable options.

About façade finishing

Any owner is not indifferent to the appearance of his home. A stylish, neat façade is a subject of special concern. At the same time, facades made of different materials manifest their properties differently: if the brick finish gives the building features of monumentality and durability, then the trump cards of a wooden house are comfort and warmth. Wood also has other positive qualities (for example, it is environmentally friendly and easy to process); At the same time, wood finishing also has significant disadvantages:

- Low resistance to humidity . The main disadvantage of wooden finishing, dependence on the intensity of precipitation and temperature fluctuations, results in the appearance of mold, rotting and destruction. To protect the surface of the facade, it is necessary to carry out periodic treatment with impregnations and paints and varnishes.

- Fire hazard . It is almost impossible to increase the fire resistance of a wooden facade. Even careful and timely treatment with a fire retardant can only slow down the combustion process.

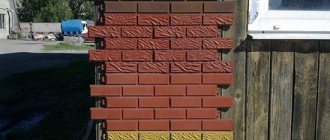

Combined facade finishing Source es.decorexpro.com

- Price . High-quality wood paneling made from valuable wood species can cost a decent amount of money (not counting the cost of subsequent maintenance).

If you still really want the house to have a pristine, natural look, facade panels made of other materials with an imitation of a wooden surface will come to the rescue. The construction market offers a significant selection of similar facade products, different in composition, structure and properties.

Thermodecking material

Wood siding appealed to many buyers, but there was still a demand for something natural, but also durable . And such material appeared. This is Thermodecking material. The process of its production is simple and complex at the same time:

- preliminary drying of wood in special chambers at a temperature of 130-180 degrees;

- an increase in temperature and pressure in the chamber, saturating it with water vapor, and sometimes with chemicals. The result is the decomposition of hemicellulose, a change in the structure of wood, the splitting of its fibers and the bonds between them. The material becomes less porous, and therefore more resistant to moisture, rot, decomposition and fungus, i.e. the biostability of wood increases significantly;

- stabilization of the resulting state by lowering the temperature or through the action of certain chemicals.

The nuances of the technology may differ from manufacturer to manufacturer, but the general advantages of Thermodecking remain the same:

- safety and environmental cleanliness. This is a natural material that is not capable of releasing harmful substances. If only steam and temperature were used during production, the resulting product is absolutely safe;

- wonderful appearance. Wood not only retains its natural beauty, but also receives a more pronounced pattern. Even the simplest and cheapest species begin to resemble expensive types of wood;

- resistance to moisture, so the material is not afraid of rotting, swelling and mold;

- resistance to temperature changes;

- higher strength and durability than conventional wood;

- practically does not dry out or shrink.

There is only one significant disadvantage - the high price, which is explained by the complexity of the technology. If we take into account that the facade will be decorated with durable natural wood, which is not afraid of moisture and sun, then the high cost can be considered an investment.

WestWood production technology

The final quality of the wood will depend on the technology and equipment used. Technologies such as VacuumPlus, PLATO, Bikos-TMT, Thermowood and others are used. As an example, let’s take a closer look at WestWood technology , which is characterized by the use of fairly high temperatures and the complete abandonment of “chemistry”.

WestWood technology was developed and patented by Thermodecking. All the nuances of production and assortment can be found on the website https://trmd.ru. The company provides a 20-year guarantee for all products, and the chosen production technology allows it to be confident in the quality:

- careful control over the quality of raw materials at our own procurement bases;

- use of modern equipment for sawing solid wood;

- high-quality drying, organized thanks to the uninterrupted operation of the equipment;

- nuances of heat treatment. The wood is heated in chambers at a temperature of 185-205 degrees at elevated pressure and in the presence of water vapor. The latter prevents fire and participates in chemical processes occurring in wood. Drying lasts several hours, and the entire cycle takes 30-36 hours. No chemicals are used, which means maximum environmental friendliness;

- finished products are stored in modern warehouses.

Ash, birch, alder, pine and linden are used in production. In addition to wall panels, this technology is used to produce decking boards, furniture panels, timber and other products. The company's specialists can help with the choice of material, as well as with delivery and installation. In addition to high quality products, customers with regular orders receive a discount of up to 9%.

Facade panels: features of use

Cladding panels, regardless of composition, have an appearance that imitates natural wood (pine, oak, larch or cedar) with amazing accuracy. With the help of such cladding, you can decorate the house in any chosen style - classic, modern, Provence or half-timbered. The facade of the house under the tree is characterized by the following features:

- The material is resistant to atmospheric humidity (the main enemy of wood) and therefore more durable.

- The panels are distinguished by a variety of textures and a wide range of colors ; your choice will be much wider than when considering wood cladding options.

Modern style project with wood finish Source pinterest.com

- In most cases, panel finishing is done using the technology of hinged ventilated facade systems .

The basis of the ventilation system is a wooden or metal frame. The system serves not only as a decoration method, but also performs other functions (for example, it is able to hide defects in the facade wall). Under the facing panels, as a rule, insulation is laid and enough space remains for free air circulation and removal of excess moisture. In general, the design reduces the thermal conductivity of the house and protects load-bearing walls.

See also: Catalog of companies that specialize in facade and finishing materials.

Gallery

Finishing with block house siding:

Finishing with shiplap and herringbone siding:

Finishing with ceramic siding and fiber cement siding:

Advantages of wood panels

Despite the fact that the traditional wooden decoration of the facade looks stylish and respectable, it is increasingly being replaced by panels made of modern finishing materials. Their popularity is explained by important advantages inherent to one degree or another in all varieties:

- Significant operating time . The period during which the cladding of a house retains its strength and attractive appearance reaches 25-40 years.

Scheme of a ventilated facade Source 4homes.ru

- Versatility . Wood-effect panels can be used to cover buildings built using any technology: brick, blocks, timber, SIP panels, logs and frame technology. The cladding can be combined with any facade materials - from brick, stone and concrete to metal and glass.

- Resistance to natural influences . Most materials boast excellent resistance to frost (which is valuable in many Russian regions) and solar ultraviolet radiation.

- Improving the thermal insulation of premises . A wood-look facade allows you to reduce heating costs in winter and air conditioning in summer.

- Technologically simple installation .

- Minimal maintenance during operation. As a rule, dirt can be easily washed off with water from a hose.

See also: Catalog of wooden house projects presented at the Low-Rise Country exhibition.

Sheathing

The process of covering a house with thermal panels made of wood is not much different from working with similar materials. For example, plastic panels for the exterior of a house are installed using exactly the same principle. First, the sheathing is installed, where, if necessary, heat and waterproofing materials are laid.

Then the panel is inserted into the guides and fixed. All fasteners must be strictly perpendicular to the surface. Then install the next one.

First they assemble one wall, then only move on to the next. And so on. The last panels are trimmed if necessary.

as well as Modern materials for facade finishing

Types of facade panels

The growing popularity of cladding with facade panels leads to an increase in the range; Manufacturers offer products from a wide variety of materials, each with its own advantages and disadvantages.

Panel cladding is designed for a wide temperature range Source womanadvice.ru

Metal panels for facade

Metal siding with an imitation of a wooden surface is made in the form of both traditional lining and block house; There are also other imitations of wooden texture. Metal siding for the facade of a private house has the following characteristics:

- Material . The panels are produced by molding from thin sheets of aluminum, stainless or galvanized steel 0.5 mm thick. Imitation of a wooden surface is achieved by applying a decorative polymer coating.

- Device . The panels are equipped with a perforated edge and a latch lock. This system facilitates reliable fastening of the elements. When installed correctly, the finished facade can withstand significant wind loads, and thermal deformation does not change the appearance of the facade.

Metal siding for logs Source 2gis.ru

- Physical parameters . The wood-look façade made from metal siding is durable, fire-resistant and has a service life of up to 35-45 years. The material is easy to install and practical to maintain; Despite its relatively low weight, it is resistant to mechanical damage.

- Feature that needs to be taken into account. The metal surface has high thermal conductivity , so you will need to lay a layer of thermal insulation (for example, polyurethane foam or mineral wool) underneath it.

- Flaws . Metal panels are not the cheapest option available, and aluminum siding will cost more than steel.

Flaws

Disadvantages include high maintenance requirements. This includes the following points:

- wood requires pre-treatment. If the production technology has been violated, then such panels will not last long;

- you need to take care of the wood: process it regularly, clean it, tint it, etc.;

- Before installation (or immediately after), it is important to properly protect the slats from external conditions: weather, mechanical damage, insects and rodents. Without impregnation, there is a high risk that the material will quickly become unusable.

Video description

About log siding in the following video:

Fiber cement

Despite the fact that fiber cement panels with wood texture appeared on the construction market relatively recently, they have already been appreciated - both by users for their good performance characteristics and by installers for the ease of working with this material. Since, in addition to the quality of the material, one of the most important criteria for its selection is service support, in order to reveal the full range of advantages, we will consider fiber cement facade panels of the Cedral brand.

Fiber cement siding has received well-deserved positive reviews from customers, thanks to its following positive qualities:

- Environmental friendliness

When fiber cement was first invented, asbestos was one of its main components. But its use was abandoned in 1976 because researchers were concerned that asbestos dust was harmful to health. Today, in the production of fiber cement siding, cement, sand, water and natural reinforcing fibers from cellulose are used, that is, fiber cement has become completely natural.

Eco-friendly fiber cement panels are even used for terraces and gazebos Source cedral.world

Installation technology

For installation work on installing siding you will need the following tools:

- level;

- roulette;

- metal scissors;

- hacksaw;

- screwdriver with attachments;

- drill (hammer);

- Bulgarian.

Depending on the type of siding, ordinary screws are used as consumables, alone or in combination with special fasteners.

Important! It is not recommended to cut polymer or metal siding with a grinder. When cutting metal, the cutting wheel heats it up, damaging the outer anti-corrosion coating. And polymers can deform under the influence of temperature.

Siding installation begins with the installation of a starting strip. It is mounted at a height of 30-40 cm from the lowest point of the house in relation to the ground level. It is necessary to set the starting bar absolutely horizontally; the quality of all work depends on this.

Installing the starting bar

If the finishing of the foundation or basement floor protrudes beyond the siding, it is imperative to install a drainage strip above the basement.

If complex additional elements are used during the installation process, they are installed in the appropriate places immediately after the starting strip is secured.

Complex additional elements

Complex additional elements and features of their installation:

- The H-connector is complex.

- The outer corner is complex.

- The internal angle is complex.

- Slope plank or platband.

- Low tide bar.

Installation of row strips can be carried out around the structure or each wall can be finished separately. An ordinary strip of siding is inserted into the vertical grooves of the additional elements and lowered onto the starting strip. It is necessary to insert it into the locking connection until it clicks. Do not use a hammer or use any other mechanical means on the siding. With the starting strip and additional elements correctly set, the row strip will fit into the locking joint quite easily.

Installation of the first row strip on the starting strip

The horizontal position is checked. Next, the strip is secured with a screw strictly in the center of the mounting holes. The sequence of fastening is from the center to the edges to prevent the formation of waves. All subsequent strips are installed in the same way.

Related article:

Do-it-yourself siding installation : instructions for dummies with photos, advantages of using panels and their varieties, tips and tricks - in our publication.

Calculator for calculating the quantity and cost of siding per house

Video description

About the facade made of fiber cement siding in the following video:

- What's the result?

Unlike wood, fiber cement siding does not dry out over time. Fiber cement is noticeably stronger than plastic panels, and metal “outperforms” in such indicators as lack of corrosion, minimal thermal expansion, plus it does not “rattle” when it rains. The six-layer paint coating significantly increases the already considerable resistance to UV radiation and atmospheric conditions. “Dry” processes are used for installation, which can be carried out all year round. Finally, the right fiber cement siding is beautiful.

As for service support, there is no need to take everyone's word for it. You can contact the manufacturer directly for advice.

When working with clients, Etex adheres to the principle “it is better to see once than to hear a hundred times.” Potential buyers have the opportunity to order free product samples to clearly evaluate the quality of fiber cement siding.

The Cedral website has an intuitive visualizer, thanks to which even a beginner in construction can independently design the architecture of the house and calculate the approximate amount of materials on the facade finishing calculator. If you are planning to save on labor, then here are the step-by-step installation instructions, which are available on the manufacturer’s website with visual video examples.

Vinyl siding

Polymer material occupies a high position in the finishing materials market due to its combination of practicality and affordable price. The basis for production is polyvinyl chloride (PVC), from which panels are formed that successfully imitate the structure of wood. Products on sale are 0.8-3.6 m long and 0.2-0.6 m wide; They are equipped with a locking connection, ensuring a high-quality, gap-free fit. The features of the material include the following characteristics:

- Good imitation of natural wood . The line of wood-look PVC panels is presented in a wide selection of color shades, allowing you to choose an imitation of a wide variety of wood species. Horizontal siding replicates several types of wood siding; finishing can be done in a variety of ways: overlapping (herringbone), block house (under a log), in the edge (ship plank).

Facade cladding with vinyl Source ro.decorexpro.com

- Light weight . Lightweight panels ensure quick installation because they do not require reinforcement of the foundation and façade walls.

- Restrictions . During severe frost, the material becomes more fragile, which slightly increases the risk of mechanical damage.

What it is

Wooden panels are a relatively new type of building material. At the moment it is actively used in Europe and North America; in Russia this finishing option is little known. Previously, only wooden siding was used for façade cladding. Panels serve as an alternative.

These panels for the exterior decoration of a wooden house are wood glued together in layers. The connections occur not in length, but in width. The result is fairly thick sheets of regular geometric shape. Thanks to this, it seems that the lamellas are monolithic wood. The pattern and texture of the material are also completely preserved. Each thermal panel completely preserves all the properties of wood.

Video description

About the facade composite board in the following video:

Veneer cladding Source eternit.ru

Wood-polymer composite (WPC) panels

Production from WPC has become possible thanks to new technological developments. The structure (cellular structure) of the material reminds everyone of the familiar polycarbonate; it consists of crushed wood compressed with polymer resins. WPC siding for external wall decoration appeared relatively recently, but has already managed to displace wooden and metal counterparts due to its characteristics:

- Long service life . Products made from WPC retain their original appearance for a long time. Paint pigments are added to the mixture rather than applied to the surface, as a result the skin is not afraid of ultraviolet radiation.

- Appearance . WPC siding looks like natural wood; the facade of any house will look elegant and presentable.

- Saving settings . The panel finish has no external linear expansion, does not deform and is characterized by high mechanical and atmospheric resistance.

- Easy care . Special care (additional treatment with protective compounds) is not required.

Wood-polymer composite Source eternit.ru

Burnt board

Having talked about the main types of cladding for facades, let's move on to technology. As mentioned above, when working outdoors, the board must be painted or coated with protective preparations. But you can do without “chemistry”. To make wood impervious to moisture, ultraviolet radiation, rot, insects, etc. need... to burn it.

Firing options

Surprisingly, a regular gas burner turns wood into an almost invulnerable material. The melted resin closes the pores like glue. Under the influence of high temperatures, the sugars contained in the juice decompose - food for harmful microorganisms. And the soot settling on the surface makes the board difficult to ignite.

Resinous woods such as cedar, pine, spruce, etc. perform best when fired. However, other breeds can be treated in a similar way. But you need to work with a gas torch or a blowtorch. On a regular open fire, the material chars too much and loses its strength.

Burnt wood does not require painting or impregnation with protective agents. Moreover, its lifespan is calculated in decades