Gypsum decor is varied, which allows it to be used in interiors of any style, size and purpose. To decorate your home with relief decor, it is not necessary to purchase ready-made elements or order them from workshops. Working with alabaster is not difficult, just study the technology and features of the material. From the article you will learn how to make stucco molding from plaster with your own hands.

When we see intricate relief decorations, it’s hard to believe that we can do it ourselves at home. The secret is that such decor is not sculpted, but cast in special patterns. Sculpting an elegant figure from alabaster is possible for people with artistic skills. For the rest, additional devices help create plaster products with their own hands at home. They greatly facilitate the process of obtaining decor.

How to choose material?

The appearance and durability of the decoration depend on the correctly selected raw materials. Experts recommend using alabaster grades from G5 to G25. For large works, grades from G4 to G7 are suitable. The powder is sold dry in paper bags ranging from 5 to 30 kg. To make your own gypsum products white and durable, it is recommended to purchase raw materials from large construction stores or specialized markets.

Alabaster packaging

Advice! When purchasing gypsum by weight, make sure that there are no sand impurities or caked lumps. The color should be uniform and the grind should be fine.

Some manufacturers produce raw materials marked “for artistic stucco.” Products made from it are distinguished by increased whiteness. It is fine-grained, durable, and has a high solidification rate.

In craft departments or construction stores, special plaster casts are sold - containers for pouring the mixture into the model. Previously, they used rubber balls cut in half. By squeezing one edge of the plaster, it is convenient to fill the template details with the contents.

Preparatory activities

Do-it-yourself plaster stucco molding at home is created in stages:

- Determine the size and model of future jewelry. It is necessary to plan in which part of the room the elements will be located. Dimensions and decor design should harmoniously complement the style of the room.

- Make a full-size paper sketch. Based on the drawing, sculpt a model of relief decoration from construction or art plasticine.

- You can order a prototype of a future work in the workshop, buy a polyurethane analogue.

- Make an impression based on the obtained sample.

- Cast the product and process it.

Advice! Large complex stucco decorations should not be installed in small rooms. It will look out of place and weigh down the space. It is better to give preference to laconic images of small sizes.

Before starting production, it is necessary to prepare the site. It would be good if it was a separate room - a garage or a workshop. If there is no such room, when work will be carried out in a living room, nearby surfaces must be covered with film to protect them from dirt and dust.

For work you will need a table or other surface corresponding to the size of the elements. It is important that the tabletop is absolutely flat and horizontal. This can be achieved using a level.

During the creation process you will need tools and materials:

- construction plasticine;

- beaker;

- plaster;

- spatulas of different sizes;

- stationery knife;

- narrow brush;

- silicone;

- release liquid, silicone oil, ordinary soap or soap solution;

- painting mesh or gauze.

Tools

In addition to materials, when creating wall bas-reliefs you will also need the appropriate tools. The most basic is a metal trowel made of stainless steel. With its help, the solution is applied, leveled and small relief surfaces are formed. The trowel is usually used when large areas of the wall need to be decorated. To form an extended relief, you will need to additionally purchase a plastic trowel. In addition, for the work you will need a set of such tools

Putty knife. It is a technical tool designed for applying mortar to a trowel and for picking up its excess and stripping it. Using a spatula, they also create a base layer on the walls.

- Palette knife. These are small spatulas of different shapes that allow you to apply the solution, remove it and create the desired relief.

- Sculptural grid. It is a professional double-sided tool with spatulas and blades. This mesh is needed for precise drawing, detailing the design and creating fine relief.

- Medical scalpel. You can’t do without such a tool, as it allows you to make precise cuts. The set should have several scalpels of different shapes and sizes.

In addition to the above, you will also need such auxiliary tools as a chisel for wood carving (fresh plaster cuts well, like wood), and a pastry syringe (they are convenient for adding small portions of material).

Mold making

To make gypsum stucco molding look beautiful with your own hands, you need to choose or make the right matrix for casting yourself. You should not save either money or time on this. Cheap templates stretch, have inaccuracies, and may break. Metal patterns are of high quality and durability. They cost several times more, and they are usually made to order.

Silicone is suitable for creating a template at home. When handling it, you need to take into account the following features:

- less durable than metal ones;

- the composition does not spread well over the workpiece.

These problems can be solved. For greater strength, a frame is made of alabaster or other hard material (plastic, wood) under the silicone template. To make the gypsum solution easier to distribute over the impression, the latter is lubricated with a liquid that improves sliding.

The finished model is coated with silicone using a brush. At this stage, it is important to prevent bubbles, which will lead to unevenness in the plaster decor. After applying the first layer, reinforcement is done - gauze is laid, then repeated 2-3 more times. The thickness of the silicone should be 3-5 mm. The gauze should not be stretched so that when compressed it does not deform the product. Each layer of silicone takes 2-3 hours to dry.

After final drying, the silicone blank is removed from the model. For greater stability, a frame or base is constructed. The first one is made from boards according to the dimensions of the workpiece. The second is cast from alabaster. It follows the contours of the silicone template and does not allow it to change when pouring plaster.

Removing the silicone mold from the model

Advice! For small molded units, ready-made silicone blanks are suitable, intended for creating soap, candles, and confectionery. They are presented in a wide range in the creativity departments.

Checking the quality of plaster

Sometimes knowledge of how to properly plaster walls with gypsum plaster is not enough. Plasterers must also know some of the subtleties of work and have some skills.

There should be no question: is it possible to plaster walls with gypsum plaster, which forms any defects on the surface. It should be even, smooth, without stains, cracks, or bubbles.

The quality of the plaster can be fully appreciated in good lighting. Let's say the quality of a plastered ceiling is checked with a special directional light.

I would also like to note that professionals who have been involved in interior decoration for many years work primarily with gypsum materials.

After reading this article, you will know how to quickly plaster a wall with gypsum plaster, and you will no longer have doubts about whether it is possible to plaster walls with gypsum plaster. It is great for leveling walls. However, it can only be used in rooms with humidity above normal. You will be able to carry out all the finishing work yourself if you carefully study and use one of the options described by you.

Preparation of the solution

To make your own gypsum stucco molding beautiful and durable, you should choose high-quality dry raw materials. They differ in composition. Some manufacturers add additional components that make working with the mixture more convenient and the final product highly durable.

Cooking rules:

- The solution is prepared in small portions in order to have time to distribute the entire amount among the containers.

- First, water is poured in, then powder is poured in, but not vice versa. Otherwise, lumps will form and the mixture will not work.

- The ratio of parts of water and alabaster is 10 to 7.

- The liquid is used cold.

- The consistency of the solution resembles liquid sour cream.

- First, the gypsum is poured into water and allowed to settle. Then mix thoroughly. A small volume is stirred with a spatula; for a significant amount, a drill with a mixer attachment is used.

- To improve the plasticity of the composition and to prevent the finished product from cracking, PVA glue is mixed into the mixture.

- Cement is added to increase strength.

Preparation of the solution

Beginners in handling gypsum should know the features of the material:

- liquid solution is plastic;

- hardens quickly;

- when drying, alabaster expands;

- the final product is fragile, especially small parts.

The solution hardens within 5 minutes. During this time, it is necessary to fill out all the blanks. For those who are faced with such work for the first time, the task will be impossible. The hardening mixture will not penetrate into all recesses, especially small and narrow ones.

Advice! To slow down the hardening of the gypsum mixture, add gelatin or hide adhesive solution, borax, slaked or quicklime. They allow you to delay hardening by 30-35 minutes.

In some cases, hardening needs to be accelerated, for example, if a figure is formed on a wall. The easiest way is to pour in hot water. And also for this purpose, add alum, sodium sulfate or regular table salt.

How to do stucco on the wall with your own hands

For this purpose, it is worth having plasticine, Vaseline, plywood, plastic or plaster, silicone sealant, putty and glue. If desired, the bas-relief can be left without painting, but painted it will look more advantageous. The first priority is to determine what plot will be presented in the stucco. After this, you need to sculpt the chosen figure from plasticine on a piece of plywood. For a large-scale plot, it is recommended to use a sheet of plasterboard. It is worth constructing a foundation from it. After the figure is formed, it should be lubricated with Vaseline. The top of the sculpted figure is covered with silicone sealant and dried. Usually the figure dries within 24 hours, sometimes a little longer - it all depends on its size. The part is strengthened using glue. However, if its size is significant, it is preferable to use wire as reinforcement. Hanging a plaster figure with suggestible weight is done using metal bolts or rods. However, it is considered more appropriate to make a less huge figure, or it is necessary to divide it into parts. It is also possible to attach the part to a metal plate and then screw it to the required place

It is worth taking into account that before placing the bas-relief, it is imperative to reproduce the alignment of the walls. After placing the stucco on the wall, all existing seams must be covered with putty.

It is also recommended to coat the finished bas-relief with varnish or primer.

Creation technology

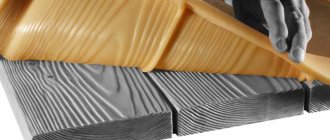

First, prepare the silicone pattern - clean it from dust and small particles. To make it easier to remove the plaster figure, a release silicone grease is applied to the template. To do this, use a brush to treat the entire surface, leaving no uncovered areas. In untreated areas, the composition will set tightly; removing the hardened product without damage will be problematic.

The prepared solution is poured into lubricated matrices. It is recommended to do this in two steps:

- Apply the first layer of gypsum mixture with a brush. In this case, you need to make sure that there are no air bubbles left. When they burst, depressions and cavities will form on the figure, and the surface will not be uniform and smooth.

- Fill the container to the brim.

Advice! Large-sized works or works with thin parts are recommended to be reinforced with reinforcement. To do this, after applying the first layer of gypsum, a painting mesh is placed in the mold. Then fill the remaining space.

Afterwards, the structure must be gently shaken to release air bubbles. The back part needs to be leveled with a spatula. If it turns out to be lumpy, then fixing it to the wall or ceiling will be unreliable. There will also be noticeable gaps between the figure and the wall. Additional effort will be required to seal the cracks and level them.

The gypsum solution is kept for 20 minutes, after which it is carefully removed. If you do this earlier, the alabaster that has not completely set will be damaged. If left for a longer period of time, the plaster will harden greatly and adhere to the silicone template. Deformations may occur during removal.

The finished part is left to dry for a day. The air temperature should not be lower than +16℃.

Drying finished parts

Renaissance and Romanticism

Renaissance and Romanticism are somewhat similar to each other, as they allow multi-level ceilings and walls with numerous niches. If the Renaissance also needs figurines, then romanticism is distinguished by the lightness and individuality of its owner.

Finishing work

If all the steps are completed according to the instructions described, then the DIY stucco molding should turn white after 24 hours of drying. At this stage, the part is polished, defects are removed, and brought to the desired appearance. For leveling, use fine sandpaper. You must act carefully so as not to damage the fragile part. Then the parts are coated with a primer.

Sanding of finished products

The plaster figure has a matte white color. Having covered it with colorless varnish, we get a decoration ready for installation. Alabaster stucco in a natural shade is used in many interiors. But if, according to the idea, the figure should have a different color, then it is painted with water-based paint or patinated. It is more convenient to do painting before attaching the parts.

Drawing

To complete the work you will need the following tools: wallpaper glue, putty, high quality primer. First you need to remove all old coatings from the wall on which you plan to apply the image. Next we perform drying and priming. First we make a pencil sketch on the wall. Beginners are not recommended to immediately start drawing complex pictures.

Tropical vegetation and birds of paradise are suitable for practicing skills. You can use the cell enlargement technique if you have little to no skills. We draw squares both on the wall section itself and on the drawing. We transfer all the lines gradually, one by one. The main thing is to remember what image scale is chosen, even when it comes to small details.

Installation features

Three days after low tide, the figures are ready for installation. Small gypsum units are fixed with an adhesive composition. It consists of PVA glue and water in a ratio of 1 to 1.5. Notches are previously made on the back side for better adhesion to the surface. The glue is applied to the wall or ceiling, to the element. Then they are connected using rubbing movements. In this case, excess glue will protrude around the edges. They are removed with a spatula before they harden.

Large figures are heavy. They are additionally fixed with dowels. To do this, holes are drilled in the product and screws are screwed into the wall or ceiling. The resulting depressions are covered with gypsum mixture and sanded. The same composition is used to rub the cracks and correct the figure if necessary.

Tips and a description of the technology on how to make plaster products with your own hands will help you create a unique decor for your apartment or house. A tastefully selected volumetric composition will create a harmonious space with a special mood.

Decorative finishing using stucco

The main advantage of decorative stucco on the walls is its combination with various trends and styles, ranging from timeless classics to modern minimalism.

Thanks to a special molding technique and an asymmetrical order of elements, stucco can hide many surface defects, cover communications, and also add elegance to the most ordinary niche in the wall.

Today, such decorations include stucco borders, pedestals and pilasters, brackets, as well as domes, bar counters and bookshelves. At the same time, instead of a border for the ceiling, gourmets prefer to use decorative cornices, which add solemnity and sophistication to the interior.

Materials for making stucco molding

Stucco can consist of wood, artificial polymers and gypsum. As for the first type, this is an environmentally friendly and quite expensive building material. The latter is also good, but it is difficult to install. Thus, modern types of plastic remain - polystyrene and polyurethane.

So which is better? Polyurethane is much cheaper than polystyrene and lasts up to 30 years, while the latter quickly loses its appearance. If you care about your own health, then the polyurethane stucco option will meet all the requirements and be hypoallergenic. Moreover, such products are known for their clear drawing; they can be laminated and primed with water-based emulsion.

Gypsum is a material that, when hardened, expands and, under pressure, penetrates into the smallest relief depressions, which adds special advantages to it. Thanks to this property, designers can realize the most sophisticated fantasies and transform the existing interior into an exclusive place to relax.

Tips for use in the interior

Who said that stucco has no place in a modern interior? It's all about the quantity and design of the elements. Relief decor decorates walls, ceilings, niches, fireplace facades, window and doorways. The shape of the stucco is also different. Let's look at some types.

Socket

Gypsum rosettes are used as a base for a central chandelier. In classic interiors it has a round shape with various ornaments. The options are extensive; in modern style rooms they are found in the form of geometric patterns and abstract shapes.

Plaster rosette on the ceiling

Panel

They decorate part of the wall indoors or outdoors. The variety of drawing subjects allows you to organically fit three-dimensional images into the interior, highlighting a certain wall. If there are defects on the surface, then thanks to the panel they can be hidden.

Plaster panel

Plaster panel

Skirting

One of the most popular stucco forms in interiors of any style. They are used to decorate the junctions between walls and ceilings or floors. By varying the width of the plinth, you visually increase or decrease the height of the ceiling. They are often painted in a color contrasting with the walls, which gives the room solidity.

Ceiling plinth in the interior

Molding

Another popular stucco decor. Smooth moldings without a pattern are suitable for rooms in a minimalist, hi-tech, and modern classic style. Products with various ornaments will look good in Baroque, Art Deco, and Classic styles.

Plaster molding in the interior

Plaster molding in the interior

Cornice

Cornices are most often found in the exterior decoration of buildings, but they are also popular for interior decoration. They emphasize the junction of the wall and the ceiling. In modern apartments, this type of stucco is installed as part of the lighting solution. A space is left between the cornice and the ceiling in which an LED strip or other light sources are placed.

Plaster cornice in the interior

Pediments

We came to interior design from classical architecture. In rooms, pediments are installed above door and window openings, arches, and built-in wardrobes. Traditionally they have the shape of a triangular vault, which is not always appropriate in living rooms. The clear geometry makes the space uncomfortable, and the size of the element allows it to be used only in spacious rooms. In this case, use the option with a gap at the top. The figure becomes less elongated and takes on an interesting shape.

Pediments in the interior

Pediments in the interior

3D panels

Decorative gypsum panels are a trend in modern interiors. They are used to decorate walls, giving them expressiveness and an interesting texture. They are painted and tinted. Thanks to the backlight, the convex parts of the structure emphasize the three-dimensionality.

3D plaster panel

3D plaster panel

Arch

This element is used to decorate door and window openings, to divide space and design niches. Classic ones look like a regular arc. Modern options are presented in a wide variety: square, irregularly shaped, with niches and lighting.

Plaster arch in the interior

Art Deco

Art Deco is the option when a combination of something completely incompatible at first glance is acceptable. Creative execution can include all possible chic items.

It is not necessary to adhere to any single type of plaster elements; you can combine classic designs on vases and niches with modern figurines.

Typically, this style is preferred by people with an active lifestyle who value comfort and luxury in one set.

How to restore

Over time or due to mechanical damage, the gypsum decor is destroyed. In this case, restoration of worn parts or their complete replacement will be required.

Renovation Tips

When carrying out restoration activities, the following recommendations are taken into account:

- Before starting reconstruction, you should study the scale and type of damage, and then choose the appropriate method of exposure or camouflage.

- If a small fragment is destroyed, replacement is not required. Existing damage is repaired directly on the element.

- If the stucco molding has changed color due to getting wet or dirty, the entire product is painted in a color that matches the interior. Water-based paint is suitable.

- Artistic painting will help hide minor scratches. Oil paints are used for this.

- In case of loss of a significant part, restoration work is carried out by checking the photograph, if available.

- If there is no photograph of the lost part, then a new one is made taking into account the general style of the room.

- During restoration, cracks and seams are opened and re-sealed with fresh mortar.

- Weakly fixed parts are removed, the surfaces are leveled and fixed again. In this case, double fastening is recommended - with glue and dowels.

- If paint comes off on an area of a figure, the entire element is painted over. Otherwise, the color of the freshly coated area will be different. To do this, the old layer is cleaned off the part, the surface is sanded, primed and a coating of the desired color is applied.

Relevance

There are many materials from which volumetric surfaces are made. They all differ in their properties and have disadvantages. Materials from which the panels are made:

- Gypsum and additives.

- Polymers with additional components.

- Paint for coloring.

One wall in the room is given a plaster finish. If all the walls are covered with material, then the room will become smaller and will “crush” with its convex pattern. Basically, this is a blank wall in the living room, a partition with a TV, and the head of the bed.