Nowadays, drywall has become a very popular building material. Looking at the photo of drywall fasteners, you can note that it is very easy to work with, having all the necessary accompanying tools and materials for fastening.

The most popular and fastest way to assemble building structures is fastening. By choosing the right screws, the assembly will remain strong for a long time and will not change the given shape.

Dowel-nails

Installation of a frame for plasterboard begins with fastening the hangers, and then the guide profile to the floor and ceiling. Most often, hangers and profiles are attached to a concrete or brick wall. Less often - to a wooden base, even less often - to plaster. For wood and plaster you need self-tapping screws, we will return to them a little later; for concrete and brick you need dowel-nails. They come in two types and both are suitable for fastening frame parts to a solid base.

Dowel-nails with thread. The simplest and most common option for fastening profiles. To use it, it is enough to have a hammer drill with different modes; in some cases, you can get by with a simple drill or even a screwdriver. Externally, the nails look like a self-tapping screw, but they are exactly a nail; you need to hammer it into the dowel with a hammer and only at the end can you tighten it with a screwdriver. Pay attention to the thread, it is not symmetrical and is shifted towards the head, so it is driven in easily. If necessary, the nail can be unscrewed.

Dowel-nails with thread for fastening plasterboard profiles to walls

Dowel-nails are needed with a size of 6x40mm or 6x60mm, this is quite enough for strong fastening of the guide profiles. It is better to use only on walls and floors. If the holes in the ceiling are loose and the dowel-nails dangle in them, then it would be safer to choose another fastener for the ceiling - a wedge anchor or a dowel-nail for a pneumatic gun.

Dowel nails for a mounting gun. Expensive, but very durable fastening option. For the ceiling, you can use short 18mm dowel nails. Despite the small size, the connection strength is very high.

Cassette with dowel-nails for construction and assembly gun

When driving a nail, it is practically soldered to the concrete due to the high temperature. Such dowel-nails are driven in with a special pneumatic gun. Not every home has such a tool, but the speed of operation and durability are at a high level.

Considering the high cost of the air gun and the dowel-nails for it, the popularity of such fasteners, even among construction crews, is low. Efficiency is excellent, but too expensive.

Fastening additional elements to the drywall surface

If you need to hang a lamp on a plasterboard ceiling, attach a TV, a mirror or something else to a plasterboard wall, then you cannot do without special fasteners. You should not hope that a regular self-tapping screw screwed into the gypsum board will be able to provide reliable fastening.

To solve this problem, you can use the following fasteners:

- "Butterfly". A plastic, or less often metal, dowel inserted into a drilled hole. When the screw is screwed in, its wings, which are located behind the surface of the drywall, open and securely fix the fastener.

- Driva type dowels. They do not require pre-drilling, since this part has small drills at the end. A dowel made of plastic or metal is screwed into the gypsum board, where it is held in place by a special thread with a rare pitch. The screw screwed into it serves to fix the attached element.

- The “Molly” type dowel is somewhat reminiscent of a “butterfly”, but has a more complex structure and is capable of supporting more significant weight. It is also inserted into a pre-drilled hole, after which the special “hangers” that provide fixation are opened by screwing in the bolt. Subsequently, the bolt is unscrewed, and in its place you can place an eye, hook or screw necessary for mounting the attached product.

Self-tapping screws

To assemble a frame from profiles, you will definitely need self-tapping screws - for wood, if the frame guides are attached to a wooden surface, and for metal, to fasten different types of profiles together.

Self-tapping screws for fastening the profile frame. Two types of self-tapping screws are excellent for fastening the profile to each other - with a cylindrical head and with a press washer. All threads are small, for metal.

Self-tapping screws with cylindrical head

Self-tapping screws with press washer

These screws can have different coatings, tips, and sizes. Which one you choose is up to you, the difference between them is not fundamental. To assemble the frame, metal screws with a diameter of 3.5 mm and a length of 9.5 mm are used.

Self-tapping screws for fastening plasterboard sheets. To install gypsum board sheets to the frame, you will need self-tapping screws, always with a countersunk head. For a metal frame - fine thread, for a wooden frame - large.

Self-tapping screws for fastening drywall to the frame

The tip can be sharp or with a drill. A self-tapping screw with a drill is used for metal frames with a thickness of more than 0.7 mm. This way the profile does not deform and it is easier to screw in the self-tapping screw.

List of necessary components for drywall

There are many names of such components, and some have rather narrow specific uses. To avoid mistakes, it is worth understanding certain types of fittings or profiles. Anchor hangers are produced with various long rods of 250, 500, or 1 thousand mm. The safety factor allows you to withstand a load of up to 25 kg. “Crab” connector Two-level connectors for CD profile.

Such fittings are designed to connect the frame slats crosswise, in two planes, when one profile lies on the second, and at a right angle (perpendicular). During installation, the connector is bent into the shape of the letter “P” and secured with fleas. Components for assembling walls and partitions also come in two types: rack-mount and guides. Their purpose is the same as the previous types of profiles, the former serve as frame racks, and the latter as the base for their fastening. They are marked CW and UW respectively.

Like other metal elements, straight hangers are zinc coated. The length can be different: 75, 125 or 300 mm. For use, the plates are bent, giving them the shape of the letter “P”.

The top, which is attached to the load-bearing surface with dowel-nails, and the frame posts are fixed to the free ends.

Rivets

An alternative to self-tapping screws when installing a frame from profiles can be rivets.

Rivets and riveter

The method is excellent, the rivets hold well, nothing falls off, the head has minimal convexity. But this connection method is used much less frequently; it requires additional tools and more time.

Advantages of components for Primet galvanized profiles

All Primet drywall components are made from high quality galvanized steel.

Which is better: heated floors or radiators?

Warm floorBatteries

The advantages of Primet components for gypsum boards include:

- high anti-corrosion properties;

- the ability to withstand significant loads in various directions;

- resistance to temperature and humidity changes;

- high fire safety;

- simplified installation due to the presence of grooves and corrugation;

- long service life.

Delivery of galvanized profiles and Primet components

We will deliver galvanized profiles and components for gypsum boards to wholesale buyers in the following cities of Russia: Aksai, Alexandrov, Arkadak, Armavir, Astrakhan, Barnaul, Belgorod, Biysk, Birobidzhan, Bryansk, Veliky Novgorod, Vladikavkaz, Vladimir, Vologda, Voronezh, Volgograd, Vsevolozhsk, Gatchina, Gelendzhik, Gorno-Altaisk, Donetsk, Evpatoria, Yekaterinburg, Izhevsk, Iskitim, Ivanovo, Yoshkar-Ola, Kaliningrad, Kazan, Kaluga, Kemerovo, Kimry, Kirov, Kislovodsk, Kovrov, Kolomna, Kopeisk, Krasnodar, Krasnoyarsk, Crimea, Kumertau, Kurgan, Kursk, Lensk, Lipetsk, Lomonosov, Moscow, Magnitogorsk, Makhachkala, Millerovo, Mineralnye Vody, Murom, Naberezhnye Chelny, Nakhodka, Nevinnomyssk, Nizhny Novgorod, Novorossiysk, Novosibirsk, Oktyabrsky, Omsk, Orenburg, Orel, Orlovsky, Orsk , Pavlovo, Penza, Perm, Petrozavodsk, Primorsko-Akhtarsk, Pskov, Pushkin, Pyatigorsk, Rostov-on-Don, Ryazan, St. Petersburg, Samara, Saransk, Saratov, Sevastopol, Serov, Simferopol, Smolensk, Stavropol, Stary Oskol, Sudak, Sysert, Tambov, Tver, Tomsk, Tuymazy, Tula, Tyumen, Ulyanovsk, Ufa, Khabarovsk, Cheboksary, Chelyabinsk, Shakhty, Shadrinsk, Engels, Yuzhno-Sakhalinsk, Yakutsk, Yalta

Galvanized profiles and components for gypsum boards have a favorable price-quality ratio. The use of galvanized Primet profiles and Primet components significantly reduces costs when installing plasterboard structures.

Cutter

A profile cutter is not a fastener, it is a tool. The fastener in this case is the profile itself. The cutter pierces both profiles at the junction, cutting out the retaining whiskers on the reverse side.

Profile cutter for drywall

The cutter has a lot of advantages over self-tapping screws and rivets - there are no costs for fasteners, there are no convex surfaces, the connection occurs instantly, and its strength is fully consistent with the design.

68 tools for working with drywall

Read

Construction of a metal frame for partitions

Installation of the frame begins with markings on the floor, walls and ceiling. The boundaries of the partition are outlined with a pencil and the fastening of PN profiles of the appropriate size begins along the marked marks - 50, 75 or 100 mm. The size depends on the thickness of the wall, and markings on the walls are made vertically according to the level.

First, soundproofing tape is glued to the profiles on the side of the outer shelf. Its function is as its name suggests. The profiles are fastened with 6 mm x 40 mm dowels, if in concrete, or with 3.5 mm x 60 mm wood screws, if in a wooden surface. First, the PN profile is attached to the floor, ceiling and walls.

The next operation is attaching the PS profiles. The PS profile is inserted vertically into the PN profile and adjusted to the level. Installation pitch 400 mm or 600 mm. Metal-to-metal fastening is done with a cutter (a tool that pierces holes through the double metal of profiles). If there is no such thing, then you can tighten it with hardware called fleas in the construction environment.

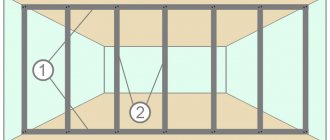

Installation diagram of the frame for the partition.

If the length of the profiles is shorter than the height of the ceiling, then it is necessary to lengthen the racks. To do this, an overlap is used and an additional piece of profile at least 50 cm long is placed at the joint. Knauf technology has special connectors between profiles. The connection is made in the same way as with racks - a cutter or hardware.

The additional part is done in a checkerboard pattern, that is, one rack on the bottom, another on top, and so on.

To fasten gypsum boards 2400 mm long, you have to install jumpers at the joints of the sheets. The jumper is made of PN and attached to the PS. The lintels are also installed in a checkerboard pattern - one lintel 1200 mm long (this is the width of the gypsum board) at the bottom, the other 1200 mm long at the top in the next span. The frame is ready, and we’ll talk about installing the doorway below.

Anchors

A variety of anchors will come to your aid when the walls lack strength, they crumble and crumble when drilled. Or when you need to hang something very heavy on the wall.

Wedge anchor. Not to be confused with a wedge anchor, this is a different type of fastener and is not suitable for a profile. And the wedge anchor, which is shown in the photo, is well suited for attaching pendants to the ceiling.

Wedge anchor for fastening plasterboard guide profile

Most often, threaded dowel-nails are used for ceilings, but they may not be reliable in a vertical position due to the poor strength of the ceiling. The dowel-nail can dangle, and with it the entire frame.

The wedge anchor holds up perfectly even in loose concrete; its design tightly wedges the mechanism so that pulling it back will be a difficult task. In addition, the wedge anchor meets fire safety requirements, since it has no plastic components and is made entirely of metal. For this type of fastener you will need a hammer and hammer.

Anchor bolt. Or a wedge anchor. Anchor bolts are not needed to fasten the frame and plasterboard sheets, but they are perfect for hanging very heavy objects on a plasterboard wall. Boiler, bracket for a large TV, wall cabinet.

Anchor bolt for heavy objects

The anchor bolt is not mounted into the drywall or frame, but into the main wall. It is important to understand that the length of the anchor bolt must be chosen so that most of it is in the main wall and only a small piece of it sticks out from the plasterboard wall. This is the only way it will withstand heavy loads and not break.

The anchor is foldable. Attaches directly to a sheet of drywall rather than to a concrete wall. Folding supports increase the strength of the fastener.

Folding Drywall Anchors

A folding anchor can have different types of pins - a hook, a ring or a screw. The supports can be either folding or tilting. Folding supports are equipped with springs, tilting ones are not.

Folding anchors are useful for not very heavy interior items - shelves, clocks, paintings, mirrors. You can use them to hang a chandelier on the ceiling.

Sliding mounting option

This example of a floating fastener installation is used primarily in timber-framed areas. This is due to the fact that wood tends to dry out and become slightly deformed. Therefore, for high-quality finishing of internal walls with plasterboard, floating structures are used.

The frame of this design can be in various versions - from wooden blocks, from a metal profile, sliding supports on the ceiling.

Dowels

Dowel butterfly. Simple and convenient fasteners for small interior items hung on a plasterboard wall. It got its name because of its shape. Originally sold flat. During installation, the self-tapping screw is screwed in and folds the dowel, increasing the support area and forming a butterfly shape.

Drywall fasteners butterfly dowel

It is mounted in a sheet of plasterboard in a vertical position. To prevent turning, it has special ribs. Requires sufficient space inside the wall. I wrote detailed instructions in an article about the correct installation of a butterfly dowel.

Dowel Molly. Structurally similar to the butterfly dowel, but made of metal. The dowel itself is always the same, but the pin can have different options - a ring, a hook, an angle and a screw.

Types of Molly dowels

When the threaded element is tightened, the body of the dowel turns into a kind of umbrella, resting against the sheet of drywall on the back side.

An example of fastening with a Molly dowel

This increases the support area of the fastener and its reliability. To prevent rotation, the dowel is equipped with spikes.

Dowel Driva. It has both an external conical thread and an internal self-tapping thread. It comes in both metal and plastic.

Types of Driva dowels

Using a sharp drill, it bites into a sheet of drywall and is fixed in it using an external thread. The dowel is screwed in using a screwdriver.

An example of fastening with a Driva dowel

After this, you can screw in the self-tapping screw and hang light objects.

Doubel Hartmut. Knauf fasteners. The threaded element is only a screw.

Doubel Hartmut

The metal support is folded along the plastic guides, inserted into the hole in the drywall, aligned parallel to the wall and secured with a plastic clamp. The extra mustache just breaks off.

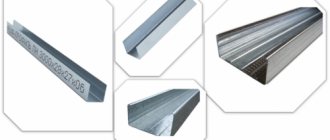

Metal profiles for installation of drywall

Metal profiles for installing drywall are something without which the finishing material itself means nothing. Profiles are an integral part of any frame design for finishing surfaces with plasterboard: be it a suspended ceiling, walls, partitions, door or window slopes. Auxiliary elements for installation are made from thin metal strip by cold rolling on profile bending machines.

Six main types (markings) of metal profiles

To protect products from aggressive environmental influences, they are manufactured with a galvanized coating, which forms a reliable protective layer. Mechanical processing of metal profiles for installation of drywall is carried out using various devices, including cutters, electric scissors, hand scissors, etc.

According to their purpose, mounting profiles are divided into the following types:

- Rack profile (PS).

- Guide profile (PN).

- Ceiling profile (PP).

- Ceiling guide profile (PNP).

- Angular profile (PU).

- Arched profile (PA).

Rack profile (PS)

The appearance of the profile resembles the letter “C” and is intended for metal structures of plasterboard partitions. It is designated as follows: PS 50/50, PS 65/50, etc., and the first designation is slightly different from what is indicated. For example, in PS 50/50 the first size will actually be 48.5, which allows it to be joined to the guide profile without deformation.

Rack profile for making a frame when installing a plasterboard ceiling

It is worth noting that the dimensions are given for the Knauf joint venture, which differ from the Russian counterpart in that the Russian profile has a flange of 50 mm, not 35 mm. A 50 mm wide edge is the most practical and facilitates the installation of plasterboard sheets, since it is easier to get into a wider shelf with a self-tapping screw when attaching them. In addition, the Knauf profile has longitudinal recesses on the shelf, making it easier to center the screws when attaching gypsum boards. The size of the PS is selected depending on the dimensions of the partition and possible thermal insulation.

Guide profile (PN)

The guide profile also has a C-shaped configuration, but differs from PS in that it is unequal, that is, it has the following dimensions: PN 50/40, PN 65/40, etc.

Profile KNAUF PN 28\27 3 m

NP "Knauf" are used as guide parts for PS and have ready-made holes Ø 8 mm in the shelf, which advantageously facilitates the process of constructing the frame. But if necessary, you can drill additional holes.

Ceiling profile (PP)

While not original in shape, the ceiling profile also has a C-shaped appearance and is used to construct a frame for plasterboard ceilings, as well as for finishing gypsum board walls. The profile dimensions are 60 x 27 mm; the shelves have three grooves for centering the screws and for imparting additional rigidity to the profile.

Ceiling profile and ceiling guide profile

The PP is mounted to the ceiling using special brackets (suspensions), which are fastened to the profile with self-tapping screws. The 60 mm shelf is very convenient when attaching plasterboard sheets to it.

Ceiling guide profile (PNP)

The ceiling guide profile is made in size 28/27 (in mm) and is used to place a PP profile in it when equipping a frame for a plasterboard ceiling. PNP is installed around the perimeter of the room under the ceiling along pre-marked lines, and in the case of constructing a frame for finishing the walls with plasterboard - at the top under the ceiling and at the bottom near the floor. In the PNP shelf there are holes Ø 8 mm at a distance of 250 mm from each other for fixing the profile to the PNP with self-tapping screws.

Angular profile (PU)

The corner profile (PU) is used to protect the joints of two plasterboard sheets from damage. For a tight fit, the PU has an angle of not 90 º, but 85 º, which creates tight contact with the gypsum board corner.

The corner profile is designed to protect the outer corners of plasterboard partitions and cladding from mechanical damage

The corner profile has holes (perforations) in both flanges Ø 5 mm so that during puttying, putty can enter the holes, which promotes reliable adhesion to the drywall. The profile size is 31 x 31 mm.

Arched profile (PA)

The arched profile (PA) serves as the base for all curved structures made of plasterboard and is made from PP by bending.

Arched profile for drywall

The minimum possible radius is 500 mm. It bends both with shelves inward and shelves outward, depending on the shape of the ceiling.

Liquid Nails

The strange name hides ordinary construction adhesive. Glue has little in common with nails and screws, but, nevertheless, it is also present in our selection of fasteners for a reason.

Liquid Nails

Liquid nails can be used to glue various materials, including drywall. To do this, you do not need to build a frame from a profile; the sheets are glued directly to the wall.

Liquid nails are supplied in tubes and are applied using a special gun.

Type of fastenings used during construction

Plasterboard assemblies usually have the following composition:

- Gkl (plasterboard sheet)

- Metallic profile

- Wooden spacers

The variety of materials used subsequently leads to the need to consume different hardware.

Profile connectors

In addition to self-tapping screws, rivets, dowel-nails, profiles are joined together using special connectors.

Crabs. Create X-shaped or T-shaped connections of profiles.

Crab profile connector

The crabs have special latches for the profile size. For greater reliability of the connection, it is better to fasten the crab and profiles with self-tapping screws; the crabs also have holes for them.

Extension cords. If you need to increase the profile, this can be easily done using an extension cord.

Profile extension

You join two profiles through an extension and secure them with four self-tapping screws. The connection is ready.

Two-level connector. You will need it if you are planning a two-level frame made of profiles. Its function is to create X-shaped connections at a 90 degree angle.

Two-level profile connector

It goes on sale in unfolded form and, when assembled, is bent into a U-shaped element.

Side connector. Forms a T-shaped profile connection.

Side profile connector

If a side connector is not available for sale, you can use a crab by cutting off one extra side.

Corner connector. Fixes the ends of the profile at an angle of 90 degrees.

Corner profile connector

Supplied flat. Before assembling the frame, the corner is bent at the perforations. Attached to the profile using self-tapping screws.

Additional views

Mayachkovy (PM)

This type of profile is installed to level surfaces. For example, before plastering them, finishing them with materials that are glued to the base.

22 x (6, 10); 23 x 10

Price – from 20 to 45 rubles/piece.

Corner (PU)

It is used after laying drywall, when it is necessary to align the corners and give them a more aesthetic appearance.

35 x 35, 25 x 25

Price – from 32 to 36 and from 21 to 49 rubles/piece. respectively.

Practical recommendations

In some cases, it is possible not to mount the supporting frame:

- if the differences in height on the surface are insignificant and it is possible to attach drywall to it using the gluing method.

- when “weighting” after installation of the metal profile is unacceptable or undesirable. The weight of one rail (depending on the parameters) can average from 400 to 950 g.

A base defect such as unevenness in certain areas can be eliminated using putty compounds - read about it here.

In practice, the width of the metal profile designated by the Manufacturer and the actual width are somewhat different. The difference is about 1.5 mm, and this must be taken into account.

Basic principles for selecting fasteners for working with metal profiles

To ensure a strong connection, high-quality fasteners are needed. When choosing them, it is recommended to take into account the following criteria:

- Color. All products in one box must be the same color. This ensures that the batch is made from the same raw material and has a uniform coating, resulting in the same strength and corrosion resistance.

- For a rod, the head diameter and thread pitch must be the same for one batch.

- Sharp and drill ends must not have nicks or other defects.

- The cap should have a symmetrical slot; asymmetry indicates a defect.

- Factory-manufactured products are marked.