What kind of plasterboard profiles can there be?

In 1980, a paper mill owner named Ostug Sackett had the idea of creating a new building material from gypsum. At first, plasterboard sheets replaced plywood and chipboard in small houses. It was then that the interesting properties of this material were discovered. The joints of smooth and even cardboard are very easy to seal so that when painting or other types of finishing, they will be completely invisible. Breaking a marked sheet instead of sawing it is much easier. Constancy of dimensions eliminates cracks in joints... Drywall has proven itself in the construction market for a long time and has remained an integral part of repairs to this day.

This or that plasterboard structure must be supported by a frame made of strong and stable parts. These are guides and profiles of various shapes, which are connected to each other using special fasteners. They differ in purpose and application, as well as in size and quality. It is very important to make the right choice when purchasing, the result of the work will depend on it. After all, if you take a bad or simply unsuitable profile for a certain type of work, the design will eventually have to be redone. For example, a sheet on a partition will bend or “move” to the side, gaps at the joints will become visible, or a noticeable “wave” will appear on the wall itself. In order to avoid mistakes during repair and construction, you need to thoroughly study the types and sizes of drywall profiles. Find out exactly what material is needed to build a particular structure.

Interior design and architecture

Metal profiles are products of considerable length. made by rolling a metal sheet. The profile can have different shapes and cross-sectional dimensions. For the manufacture of profiles, various grades of steel and aluminum alloys are used. The width of metal profiles can reach sizes of 1 - 10 cm, while the wall thickness is 0.1 - 1.2 cm.

When erecting high-rise structures, it is necessary to make an accurate calculation of the power load in order to avoid deformation of the buildings. Most often, two types of deformation may occur—elastic and plastic. It is plastic deformation that can cause the destruction of the entire structure.

Profile advantages.

The undeniable advantages of this type of building material include the following properties:

- product strength;

- lightness of the metal profile, which allows you to create lightweight structures;

- ease of installation and high speed of manufacturing metal structures;

- low cost of material;

- long service life of metal profile structures.

It is all these obvious advantages of the metal profile that allow it to be used during the construction of high-rise buildings and finishing of various levels of complexity.

Types of metal profiles.

Today there are a large number of profiles with different cross-sectional shapes. Also, profiles may differ in the manufacturing method. To protect them from oxidation and rust. products are coated with galvanization or other protective compounds.

There are several main types of profile products:

- Profile pipe;

- Profiles for drywall;

- Profile components;

- Metal profiles for roofs;

- Thermoprofile.

Let's look at each of these types of metal profiles in more detail.

Profile pipe.

This type of profile product is a long product that is empty inside and has a cross section in the form of a certain geometric figure:

- square;

- rectangle;

- oval;

- polygon.

The profile pipe is intended for use in external finishing or construction work. This type of profile products is intended for the construction of various metal structures, the manufacture of rafters and floor beams, as well as doorways.

In terms of its purpose, the profile pipe fully corresponds to a reinforced concrete or wooden beam. The production process uses hot or cold working and special deformation of sheet metal. The thicker the metal sheet, the more difficult it is to make a profile pipe from it - but the more durable the product will be.

There are a huge number of different types of profile pipes, but among them, products with a rectangular or square cross-section are characterized by the highest strength. Installation of profiles of this type is carried out by electric welding, but it is also possible to connect them using clamps.

Metal structures made from profile pipes are characterized by strength. but at the same time they are light in weight. For domestic purposes, metal profiles are used that are simple in shape and relatively small in size.

For the construction of large facilities and in industry, almost all existing types of metal profiles are used. Steel profile pipes are used for the construction of trade modules, tents and pavilions, for sports fields, as well as during the installation of advertising boards.

Profile pipes of the smallest size are used in the production of sports equipment, furniture manufacturing, and also as finishing elements in interior design. And for the manufacture of powerful and strong structures that carry a large load, profile products with a cross-section of 10 x 10 x 6 cm and larger are used.

Aluminum profile pipes are used for the manufacture of lightweight structures that must be resistant to metal oxidation and rust. To make the aluminum alloy stronger, but at the same time not lose its ductility, copper, manganese and magnesium are added to it.

Profiles for drywall.

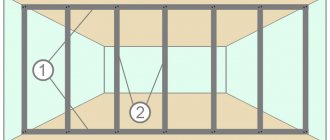

To create interior partitions indoors, special types of metal profiles are used, which also differ in size and shape. They are often used to make frames for suspended ceilings and partitions, and are also used to cover wall surfaces.

There are several types of metal profiles for installing drywall, among which are the following:

- Rack profile (PS) - in appearance it is a strip of tin, bent in the form of a channel. This type of profile is easily subject to deformation and, if necessary, can be made using simple equipment, or even manually. To provide additional rigidity, the products have longitudinal corrugations.

The main purpose of the rack profile is the installation of partitions, various vertical racks and wall cladding. During installation of structures, the rack profile is mounted with a guide profile of a suitable size. The peculiarities of their shape allow for maximum joining of products with each other.

There are special holes in the walls of the rack profile through which the cable can be pulled during installation of electrical wiring.

- Guide profile (PN) - performs the functions of a horizontal guide, shaped like the letter "P", into which vertical posts are inserted. The guide profile is also used as a guide when installing a ceiling profile selected to size.

- Ceiling profile (PP) - used for covering the surface of walls and during the manufacture of a frame for a suspended ceiling. It is attached to the base using special hangers. The ceiling profile must be purchased complete with connecting elements of the required sizes to facilitate and speed up the installation of the ceiling.

- Corner profile (PU) - designed to protect the outer corners of plasterboard sheathing from various types of mechanical damage. The special shape and acute angle of the cross-section allow this type of profile product to fit as closely as possible to the cladding.

Also, this type of metal profile has perforations, through the holes of which putty penetrates, helping to tightly bond the metal to the plasterboard sheet.

- Bent profile (PG) - there are two types - concave and convex. This type of profile products is used for the installation of multi-level ceiling structures and for creating arched openings.

Roof profile.

Metal profiles are widely used during the construction of one-story residential buildings. Today, it is much more profitable and convenient to replace the rafter system with a steel profile, because profile products can withstand a much greater load compared to wooden beams. The profile has fire-fighting properties and also has a long service life.

Metal profiles for the manufacture of load-bearing structures can be made by hot rolling or bent. At the same time, the consumption of hot-rolled profiles will be significantly higher compared to bent ones. The metal surface is protected from corrosion by zinc coating or treatment with special compounds.

Thermoprofile.

This type of profile product has an external resemblance to a metal profile for installing drywall. However, the main distinguishing feature of a thermal profile is that its surface has a special perforation, which helps reduce heat loss.

The perforations are arranged in a checkerboard pattern. Such a perforation of the sheet allows you to lengthen the heat flow through the metal, which significantly reduces heat loss. This improves the noise insulation and vibration resistance of the product. Thermal profiles are most often used in the construction of external beams of a house, as well as in the process of cladding the facade for the installation of insulating material.

Ceiling profile for plasterboard. Sizes and types.

Rack profile (designated as: CD or PP).

Perhaps one of the most popular profiles for installing plasterboard on the ceiling. This type provides reliable fastening of the sheets. And if you choose the dimensions correctly, the work space will be used as economically as possible, leaving almost no waste.

CD or PP sizes:

- Profile length - from 2.5 to 4 meters

- Width – 60 millimeters

- Shelf height – 27-28 millimeters

Guide (UD or PPN).

Profiles are used for the construction of suspended ceilings. These elements are mounted over the entire area of the work, because when securing sheets of cardboard, the drill passes directly through them. It is advisable to purchase guides that already have cut holes (perforated profiles). Then it will be much easier to carry out installation.

Dimensions:

- Thickness – 0.55 millimeters

- Length – 3 meters

- Width – 27 millimeters

- Height – 28 millimeters

Profile (UW).

This type is very similar to the UD described above. It is used in the same way, but has different dimensions:

- Length – from 3 to 4 meters

- Width from 5 to 10 centimeters

- Shelf height – 40 millimeters

- Metal thickness – from 0.4 to 0.6 millimeters

How to choose sizes

The modern market is overflowing with various types of metal strips designed for installation of gypsum boards. Depending on what kind of structure is being built, a certain type is used.

Metal strips are:

- Guide for the ceiling structure PNP (UD).

- Ceiling – PP (CD).

- Rack-mount - PS (CW).

- Guide – PN (UW).

- Corner PU.

- Lighthouse view.

- Arched - PA.

The first 4 types are the main materials in creating a plasterboard structure. The rest are additional elements that create rigidity.

Each type has dimensions. The main ones:

| No. | product name | Its markings | Dimensions |

| 1 | Ceiling guide | PNP – UD | 27x28 |

| 2 | Ceiling | PP – CD | 27x60 |

| 3 | Guide | Mon – UW | 50.65.75.100x40 |

| 4 | Rack-mounted | PS – CW | 50.65.77.100x50 |

To create sheathing for wall alignment, the following materials are needed: guide PN, rack PS.

Ceiling and rack guides are not used in the same design. They are designed to create different lathing.

Arched profile (PA) for drywall. Sizes and types.

This profile has cuts along the edges, thanks to which the metal product can be evenly bent and adapted to the construction of almost any complex structure. For example, make an arch or shelf in the wall of an unusual shape. There are both concave and curved types of arched profiles.

Dimensions of concave arched profiles:

- Radius from 500 to 5000 millimeters

- Length from 2600 to 4000 millimeters

Convex profiles can be:

- Radius from 1000 to 5000 millimeters

- Length from 400 to 2600 millimeters

Is it possible to adjust the sizes

Factories produce standard product lengths of 3-4 meters. However, in creating an even partition or wall with figured elements, different lengths of the product are needed. To do this, the metal elements are either extended or cut to the length required for the structure.

Profile cutting methods:

- Scissors for cutting metal. You can cut the product evenly only along the marked lines. The disadvantage is the slightly curved edges after cutting. The cut strip is placed on a flat surface and leveled by tapping with a hammer.

- A hacksaw is not a very convenient method. There are small shavings from cutting the product. However, the cut will be smooth.

- Bulgarian. When working with an electrical appliance, sparks fly in all directions.

Craftsmen do not recommend cutting the profile with a grinder - the protective layer on the edges of the cut metal strip is damaged. As a result, the edges may become covered with rust.

- Cutting machine. A large electrical appliance used in large rooms with large volumes of work.

You can cut the profile without any problems using Soviet-made scissors.

Elongation of a metal element. In order to increase the product, 2 methods are used:

- The use of an extension cord is a durable metal part coated with a protective layer against corrosion. It is applied to the edges of two planks and fixed with self-tapping screws.

- Homemade extension cord from the PN guide. It is necessary to cut 10 cm from the product and attach it to the edges of the profiles. Fixation is done with self-tapping screws.

It is easy to adjust the length of the metal frame element. You just need to make accurate measurements and marks. You should not lose sight of millimeters, as they can play an important role in the evenness of the structure.

Profiles for creating a frame structure on the wall have certain dimensions and material thickness. They are coated with an anti-corrosion agent (galvanized) - moisture does not affect metal products. Before purchasing profiles, you need to know their number from the measured dimensions of the room.

Aluminum and galvanized profile for plasterboard. Sizes and types.

Profiles for drywall are made from different metals; let’s look at the most common types: aluminum and galvanized, as well as their characteristics.

Aluminum profile and its features.

This profile is not cheap, but it has excellent characteristics, so the high price is justified. Such profiles are good for constructing window frames or finishing household appliances. For example, if you need to make a niche for a washing machine in the bathroom. This product is distinguished by its long service life, durability and lightness. It does not weigh down the entire structure and is very easy to install. Plastic and resistant even to low temperatures. Builders recommend buying aluminum profiles for wall and ceiling cladding.

Profiles of this type are available in both cold and warm aluminum. Cold-formed is made of metal 4 millimeters thick, and bends without heating. It varies in shape (P, W, T, H - shaped). Withstands loads of up to 1.5 kN per 1 meter of wall.

Galvanized profile.

A galvanized profile is not inferior in price to an aluminum one. It is used to construct the base of the frame in rooms with high humidity - in the kitchen or bathroom. This is because it is resistant to rust and does not require additional treatment with anti-corrosion agents. Like aluminum, the profile is light and soft; screwing self-tapping screws into it will not be difficult. Galvanization is also used to create additional stiffeners if the plasterboard sheets are thicker than 12.5 millimeters.

There is also a plastic profile. Its purpose is to cover the joints of plasterboard sheets at the outer corners, giving a beautiful finish. And also, they cover the transition of drywall and other materials, for example, wood.

pros

RECOMMENDED ON THE TOPIC

- Types of wrenches

- Types of sliding gates

Why are metal profiles so popular? This is due to their positive technical and operational characteristics, which include:

- Resistance to sudden temperature changes and high air humidity;

- High strength and reliability - these parameters are due to the presence of stiffeners in metal profiles and sufficient thickness of the metal;

- Corrosion resistance. Most models have a protective, anti-corrosion coating (a layer of zinc or polymer coating), which allows them to retain their original appearance for a long time even in conditions of high humidity;

- Environmental friendliness of this building material. Do not emit harmful chemicals into the atmosphere;

- Easy to install. To use metal profiles in repair and construction work, you do not need to purchase expensive tools. Cutting or bending is carried out using standard devices: metal scissors, grinders, hacksaws;

- Long service life. If installed correctly, metal profiles can serve you for a long time;

- A unique combination of price and quality. Their low cost makes them stand out in the building materials market. The use of metal profiles in repair and construction work will not greatly affect the final budget and will not entail unexpected material costs.

Additional accessories for fixing drywall.

In order to assemble the sheathing, you will need auxiliary parts:

- Two-level connector for CD profile. This part is sold in an unfolded, flat form and before starting work it needs to be bent in the shape of the letter P. It is used to connect rack-mount parts perpendicular to each other.

- Single-level connector for CD profile or “Crab”. They connect perpendicular CD profiles in exactly the same way. If the load is more than 20 kilograms, then you will need two self-tapping screws for fastening. Otherwise, the seals are simply bent.

- Direct suspension for a rack (supporting) profile. This is a bracket, the standard length of which is 12.5 cm. It looks like a strip of aluminum or galvanized steel with holes. Withstands loads up to 40 kilograms. It is attached to the wall with two dowel nails, then the edges are bent and the frame parts are already attached to them.

- Anchor suspension for ceiling carriers. Often called suspension with traction. Replaces the part described above if it is not long enough. Used on horizontal surfaces, for ceilings, for example.

- Extension. Needed to connect two carriers to each other. It has tubercles on the sides, this indicates where the profile joins. There are also two holes for screwing in self-tapping screws.

- Corner connector. It connects elements that do not form a cross. You can do without a connector. Cut the flanges of the profile that needs to be connected so that a tongue is formed, and screw it in place with self-tapping screws.

What is a metal profile

Frame profiles are thin metal products made from galvanized sheet, cold rolled, aluminum or plastic.

They usually have a T-, L- or U-shape with cavities. There are profiles for drywall:

- Angular;

- Flat;

- In the form of a channel.

They are used as load-bearing elements for gypsum plasterboards when:

- Creation of level ceilings;

- strengthening plasterboard edges;

- formation of the “skeleton” of curved structures, arches;

- installation of partitions;

- covering walls and ceilings with significant differences in the surface;

- internal wall or ceiling insulation, sound insulation

The quality of all types of profiles for plasterboard is established by GOST and TU standards.

A huge number of companies are engaged in the production of long lengths, in particular such well-known ones as Knauf and Giprok.

There are many varieties of metal profiles, which are very important to understand and be able to choose them correctly, otherwise, when installing “from whatever,” you end up with an uneven, fragile surface, or, on the contrary, an unreasonably hard and excessively expensive surface.

Accessories for fastening plasterboard.

Self-tapping screws are needed to connect all the frame parts and to install drywall. They also come in different types.

- Self-tapping screws LB9 (11, 16) and LN9 (11, 16). The numbers after the name indicate the length of the screw. Type LB is drilling, and LN is piercing. Builders call this type of product “bugs.” These “bugs” have a convex cap, and this prevents the drywall from fitting tightly to the frame.

- Self-tapping screws TN25. These screws are used to attach the sheets to the profiles. They have a flat cap so that when priming the wall, it can be easily hidden. There are also long self-tapping screws of this type; they are needed if, to increase strength, you need to screw two sheets at once.

- Self-tapping screws with press washer. Suitable for working with any materials. They can be either drilling or piercing types. Length from 9 millimeters to 10 centimeters.

- Self-tapping screws with dowels. The guides are attached to the enclosing structures. The range of these elements is large; which one to choose depends on the material of the ceiling or wall and the size of the profile.

- Ceiling wedge anchor. This fittings are used to attach anchor suspensions to the ceiling.

- Dowel nail. Product lengths range from 40 to 60 millimeters. Used to secure the frame to a brick or concrete wall. To make this easier, you can hammer the screws in instead of screwing them in.

Corner

The corner profile has an L-shaped section. Its shelves come with the same or different lengths. They are called equal-flange and unequal-flange corner profiles. Products are made by hot rolling or bending sheet steel. Corners are used as elements subject to axial loads - tension and compression. To obtain a combined section, you can connect several corners together.

The parameters of metal corners are regulated by state standards:

- GOST 8509-93 - equal-flange hot-rolled profile;

- GOST 8510-93 - unequal flange hot-smooth profile;

- GOST 19771-93 - equal flange bent profile;

- GOST 19772-93 - unequal bent profile.

Available with shelf widths from 20 to 250 mm. They are used to strengthen window and door openings during masonry, for the manufacture of wickets, gates, in the construction of stairs, etc.

Tips on how to choose a profile and components for drywall.

- Please inspect the profile carefully before purchasing. If you notice rust, you should refuse to buy such material. Once corrosion has already begun, it is impossible to stop it!

- Check the thickness using a caliper. If it turns out to be insufficient, then during operation the screws will scroll.

- Do not take a profile with burrs. In the process of work, injure your hands.

- Take a closer look at the product from the end. If it was not stored correctly in the store, it may be bent. With such a profile, you will no longer be able to create a perfectly flat surface of the structure.

- Keep in mind that it will be difficult to screw self-tapping screws into a profile with a weak notch.

- Experienced builders advise double-checking whether the dimensions correspond to those stated in the instructions and in reality. Some manufacturers deceive buyers, especially regarding the length; it may be less than expected, by 2 centimeters.

- The quality of fastening fittings should also be checked. Very often you come across self-tapping screws with a broken tip or with screwdriver notches clogged with metal.

- Carefully inspect the plastic plugs of the dowels so that there are no sagging, otherwise it will be difficult to drive them into the hole, and sometimes even impossible.

- Give preference, however, to a profile with dot perforations along the strip - it is more rigid and resistant to loads. This structure prevents the screws from slipping and makes it possible to screw them in at any angle.

- Trust already proven manufacturing companies such as Knauf and Gyprok. But there are also our domestic manufacturers who produce profiles for drywall no worse.

- Some cunning sellers try to hide defects by painting the profile and adding shine to it. Take a closer look at these options; you may not be able to buy them at all.

- The product should not be flimsy and bend when pressed lightly.

And one last piece of advice at the end of the article. Do not skimp on high-quality profiles and components for them. As the famous saying goes: “The miser pays twice.” If you purchase a low-quality or damaged profile, then eventually, sooner or later, you will have to redo all the work. Somewhere the sheet will become a “bump”, somewhere the joints will become visible, and somewhere the structure will bend inward. Therefore, choose the material carefully; pickiness will not be superfluous here. Good luck and easy work!

I-beam

An I-beam is a steel beam with an H-shaped section. GOST 8239-89 defines the dimensions and properties of hot-rolled I-beams. I-beams are distinguished by their rigidity and strength. If we compare it with a square profile beam of the same cross-sectional area, then the strength of the products is 7 times higher, and the rigidity is 30 times higher. The only significant disadvantage of the I-beam profile is its low resistance to torsion.

Steel I-beams are classified:

- in terms of manufacturing accuracy - high (A), increased (B), normal (C);

- geometric parameters - profile height, width, thickness of shelves;

- size ratio - normal (B), wide-flange (W), column-mounted (K), special (S);

- length - ranges from 6 to 24 m.

It is used in long spans of frames of buildings and structures, in the construction of bridges, and as part of columns.

Mounting parts

Fastening fittings are used to securely fix profiles to reinforced concrete surfaces. With their help, individual elements of frame structures are firmly connected and sheets of plasterboard are attached to the profiles. Fastening parts are classified as follows: rods, brackets and hangers.

Advantages of galvanized steel

The main advantage of galvanizing is considered to be a long service life, even in a humid environment, since the zinc coating of the steel surface reliably protects the product from possible corrosion. As a result, it is perfectly used as a roofing covering.

Unlike a wooden frame, a galvanized frame is not susceptible to various insects and stably retains its original shape even after a long time.

Adviсe

To avoid problems in the future, it is necessary to responsibly approach the choice of metal profiles for the frame and be guided by the following rules:

Basic standards regarding the construction of structures from gypsum plasterboard and gypsum fiber boards are enshrined in SP 163.1325800.2014

It is this document that you need to focus on so that everything is safe. The production of galvanized steel profiles must take place in accordance with GOST 14918. A serious manufacturer must provide the products with all certificates. To choose the appropriate option, you need to pay attention to the thickness of the metal. The optimal value is 0.6 mm or more. The presence of grooves on the profile ribs does not guarantee rigidity, because bending occurs in a different area. It is better to abandon the rack profile with hooks for the guide, except in situations where the fragments fit tightly together without bending

The fact is that when joining, the PN rib changes plane, and this leads to deformation of the drywall surface.

It is recommended to purchase products from well-known and trusted brands.