→ Materials

Knauf firmly holds its position as a leader in the modern building materials market. True German quality allows you to install durable and reliable plasterboard structures - ceilings, walls, partitions and arches. The assortment includes Knauf and GKL, and all the “consumables”: profiles, hangers, putties, primers. It is about profiles that will be discussed in the next material.

What is a profile for drywall from Knauf? This is an element made of high-quality galvanized steel intended for fastening gypsum boards in various types of structures. Their classification and technical characteristics are given in Table 1.

Table 1. Types of Knauf metal profiles

| Name | Features of application | Section, mm | Length, mm |

| Guide (PN) | Is a guide for rack profiles, necessary for creating jumpers | 50×40 65×40 75×40 100×40 | 3000 |

| Rack-mount (PS) | Used for the construction of vertical frame posts, connected to the corresponding Knauf guide profile for fastening drywall | 50×50 65×50 75×50 100×50 | 3000 3500 4000 |

| Ceiling (PP) | Has a C-shape, used to form a frame | 60×27 | 3000 |

| Ceiling guide (PN) | Serves as a guide for the PP; when installing ceilings, it is attached along the perimeter of the walls. | 28×27 | 3000 |

| Corner defensive | Protects corners from external damage | 25x25x0.4 31x31x0.4 31x31x0.4 | 3000 |

| Arched (PA) | Necessary for the formation of arches, domes and other curved structures | bending radius 500,1000 | 3000 6000 |

| Corner plasterer | Installed at the ends of walls for protection during operation | 35x35 | 3000 |

| Mayachkovy (PM) | It is the basis for the surface plastering process. | 22×6 23×10 62×6,6 | 3000 |

| Enhanced (UA) | Used as a rack element when forming doorways | 50x40 75x40 100x40 | 3000 |

Scope of application of the Knauf plasterboard profile

Sheathing work, as a rule, involves constructing a frame from Knauf components with a ventilation or technological gap for utilities, insulation for a summer house or sound insulation in an apartment. This approach also makes it possible to level the plane and create original structural forms in an accelerated manner without the use of water-containing building materials.

To implement such projects, it is first necessary to assemble the sheathing. It will serve as a supporting base for new walls, ceilings or floors. This frame is assembled from wooden beams or metal profiles. For interior work, the best option is a plasterboard metal profile made of galvanized steel. It is rarely used outside due to its thin anti-corrosion protection.

Important! Knauf aluminum products have better characteristics, have a longer service life and are less susceptible to changes in humidity, therefore they are allowed for finishing facades.

Peculiarities

Finishing sheets of plasterboard are attached to an iron sheathing, which consists of metal profiles. They are secured with galvanized screws. To create a supporting structure that will support the weight of the plasterboard, you will need various types of galvanized elements and connectors.

Steel structures from the German company Knauf are easy to install and last a long time. Assembling a frame from such metal components is not difficult for a professional.

Knauf's reputation is currently impeccable. Drywall profiles from this brand are recognized as ideal models in the field of building structures and interior cladding. Reviews from builders about working with profiles are extremely positive. The company's products are considered to be of high quality and reliable. Their production is strictly regulated; defects are eliminated during the production process.

By choosing Knauf profiles, you can be sure that in a few years you will not have to disassemble the ceiling or wall again to redo the structure. But still, before purchasing, you should familiarize yourself with the features and types of brand products.

Purpose

Any plasterboard covering has a solid base, which is a kind of “skeleton” for all other components and fastenings. Guides can be of different shapes, sizes and serve different purposes.

Load-bearing structures take on significant loads. If the material is of poor quality, then collapse of plasterboard structures or their deformation is possible. It is recommended to purchase such units made by well-known manufacturers who provide a guarantee for their products.

The master, before proceeding with the installation of drywall, asks a reasonable question: what material are the guides made of? This is a key point for the successful implementation of the project.

The profiles are made of durable metal treated with zinc. This material does not rust, the guides are durable and can serve for a long time.

The structure manufactured as a frame is simple and consists of two types of guides:

- vertical;

- horizontal.

Advantages of Knauf products

The company pays special attention to quality and uses 0.6 mm thick metal so that the element has sufficient rigidity. Compliance with the requirements for this parameter guarantees the strength of the gypsum board fastening to the frame, since the screws are firmly held in the metal. All steel is galvanized to prevent corrosion and increase service life.

Also distinctive features of the Knauf plasterboard profile are:

- stiffening rib;

- holes for fasteners, wires and other communications;

- markings for ease of installation;

- special geometry that facilitates the connection of elements.

Depending on the design of the frame, its thickness and power, the manufacturer’s catalog presents several types of profiles with different sizes. In order to build a wall or other structure, you will definitely need guides and rack types. The guides are attached to a solid base: the walls, floor or ceiling of the room being repaired. Rack-mounted ones are secured to the created frame with the help of grips using self-tapping screws with a press washer or other fasteners. For the construction of suspended ceilings, the Knauf company produces certain types of products. These elements have a different shape from the wall ones for greater strength.

Fastening and additional parts

To install facing slabs, you need not only steel products, but also a number of auxiliary fasteners. With their help, galvanized profiles are connected to each other, and the gypsum board is attached to a fixed frame.

- Part ES 60x125mm . This is a metal plate that can bend and take the shape of the letter “P”. It is perforated over the entire surface. Its main task is to connect surfaces with profile sheathing. In the middle of the product there are holes for mounting to the wall. The sides of the part are attached to the main galvanized element using self-tapping screws.

- The butterfly quick hanger performs the function of fastening where the ES part cannot cope (lack of the required length). It consists of several elements. This is a spoke with an eye and a hanger that is attached to the main CD profile. The length of the wire with the loop is 25 cm, 50 cm or 100 cm. A spring fixes the wire and the “butterfly” together. It can be adjusted by simply pressing your finger. However, such a system also has a drawback. The spring may weaken, and this will lead to the ceiling sagging after some time.

Butterfly hangers are not used when constructing walls. For this purpose, U-shaped brackets are used.

- An X-shaped coupling is popularly called a “crab” for connecting CD profiles. It is used for perpendicular joining of main profiles. The “crab” is snapped onto the element and then finally secured using screws and self-tapping screws. To install a jumper between the profiles, you need to select places with connecting couplings and place it between them. It is secured using metal screws.

- Connector for CD profile. It is used to build up the main profile. The element is located between two guides, connecting them. It is secured on each side with self-tapping screws.

- The fastening element for a two-level connection is not often used during installation due to its specificity. Its use is advisable in cases where the base is a wooden floor. The metal structure is double. The first level of galvanized elements is not attached to the wall (floating). The second layer of the structure is attached to the first using connectors. Installation of such complexity is required due to the fact that the wooden base is subject to deformation changes (moisture level, temperature conditions). The fastening element compensates for these vibrations.

All types of galvanized profiles and additional parts are fastened using expansion and driving dowels, wood and metal screws, and screws.

Gyprok

Gyprok profiles are superior to Knauf products in terms of price/quality ratio.

Their advantages:

- Strength is ensured by cold hardening using the unique UltraSteel® method.

- The corrugated surface of the element is covered with identical indentations. This allows you to screw the self-tapping screw into any point of the profile at the desired angle without slipping. In this case, a “harpoon” effect is observed: it is easy to screw in a screw, but much more difficult to remove.

Counterfeit profiles from this manufacturer are often found in hardware stores, but they are not difficult to recognize: branded elements are distinguished by clear and symmetrical corrugation across the entire width of the part.

The conditions under which the metal profile was stored are also important. Despite its resistance to corrosion, it is not allowed to be stored outdoors. Elements should not have burrs or scratches that violate the integrity of the galvanized layer. It is better to take products in original packaging.

Design and types of profiles

In cross section, profiles for gypsum boards are U-shaped.

Depending on the purpose, the edges can be rolled to give the products additional bending strength. All plasterboard profiles, with the exception of the corner-forming one, are divided into 2 groups:

- The rack profile is characterized by high rigidity with longitudinal edges rounded inward. The products are intended to create a basis for fastening cladding materials.

- The ceiling guide profile may not have additional fins. It serves to provide support for the sheathing. Products are attached directly to walls, floors and ceilings along the entire perimeter of the frame.

Racks and guides are made in pairs. The height of the first always corresponds to the width of the second profile element to ensure a tight nodal connection. The products are additionally fastened together with galvanized metal screws (bugs).

Separately, we consider a corner element with perforation or notch, which is designed to cover drywall cuts, form corners, and give them rigidity during plastering work. Made from steel, aluminum and plastic.

The beacon profile is used to pull the tie through the rule. Additionally, a fiberglass mesh can be attached to reinforce the leveling layer.

Guide type

The most commonly used kit is called a ceiling kit. The racks are marked as PP and have a width of 60 mm, a shelf height of 27-28 mm, a length from 2.5 to 4 m. Ceiling guides PPN, respectively: 27 mm, 28 mm and 3 m. The thickness is 0.5-0.6 mm . Also, as a counter rack profile, a strip with the following parameters can be used: 50-100 mm, 40 mm and 3-4 m. Unlike PP, there is no rolling of the longitudinal edge.

Septal

Such products, as a rule, have an additional notch for ease of installation of utilities, different widths of racks for laying Knauf mineral wool. They are intended for carrying out cladding work and erecting independent partitions. Guides (PN or UW) have the following dimensions:

- width from 42 to 150 mm;

- height from 37 to 40 mm;

- length from 2 to 4 m.

The width of the counter posts is selected in accordance with the guides. The height, depending on the manufacturer, is 40 mm (Giprok) or 50 mm (Knauf). The length of the mass-produced profile is within 3-4 m, but production of other products to order is allowed).

Partition profile

Arched types

In order to reduce the time for constructing structures of complex curved shapes, manufacturers suggest using a special arched or flexible profile. A distinctive feature of the products is the notch on the longitudinal edges. Thanks to this, the metal profile can be bent without breaking.

Depending on the internal or external deflection, the dimensions of the products differ (radius/length);

- convex: 1-5/0.4-2.6 m;

- concave: 0.5-5/2.6-4 m.

In addition to the side notches, the arched profile has perforations. Due to this, it is possible to change the shape along the main plane. In this case, the lines are also smooth, without corners. This eliminates the need to apply a large layer of leveling solution.

Arched type

Additional items

In order to strengthen the structure in certain areas, control the plane relative to the ceiling and organize multi-level structures, additional products are used. Often craftsmen cut racks or guides for this purpose, but often they cannot do without special fasteners. They are made of galvanized steel or aluminum. Dimensions typically correspond to popular post and rail kits.

More often, the following additional products are used to construct a frame for drywall:

- “Crab” or connector of posts at an angle of 90 degrees in one plane. With a load of up to 20 kg/sq. m. of lathing, it is not necessary to use self-tapping screws (the weight of drywall is 29 kg). The two-level clamp works in a similar way: its edges cling to the edges of the rolled edges, which ensures a tight fit of the CD profiles. The only difference is that the racks overlap each other, forming 2 planes.

- Straight hangers are perforated, making it easy to bend the plate anywhere. There is also no need to drill additional holes. This element is intended for the installation of suspended ceilings and inclined structures. They are also used in practice as an alternative to mounting brackets. The permissible load is 40 kg, the length ranges from 75 to 300 mm.

- The anchor suspension is used in conjunction with rods (steel rod). The products have a narrower focus - adjusting the height of the suspended ceiling, which is lowered relative to the base by more than 25 cm.

- The extension is used to splice racks. The element is inserted inside the profiles and fastens them through the side edges. This allows you to maintain a flat surface over long sections.

Extension - The corner clamp is designed to connect T-shaped posts at the same level. It provides a strong and reliable unit that can withstand a load of 20 kg/sq.m.

If the wall is sheathed at any height from the floor, then a plinth strip is used instead of a guide. It is also used to limit decor from the sides or top.

Important! The profile has perforations for better adhesion of the plaster mortar, hiding the outer edge of the product.

A hat profile is used less frequently. It is mounted without the participation of guides under Teploknauf. To enhance the rigidity of the structure, a metal profile with a cross section in the shape of Z is produced. To design open ends, the same parameter looks like G.

Table 1. Types of Knauf metal profiles

| Name | Features of application | Section, mm | Length, mm |

| Guide (PN) | Is a guide for rack profiles, necessary for creating jumpers | 50×40 65×40 75×40 100×40 | 3000 |

| Rack-mount (PS) | Used for the construction of vertical frame posts, connected to the corresponding Knauf guide profile for fastening drywall | 50×50 65×50 75×50 100×50 | 3000 3500 4000 |

| Ceiling (PP) | Has a C-shape, used to form a frame | 60×27 | 3000 |

| Ceiling guide (PN) | Serves as a guide for the PP; when installing ceilings, it is attached along the perimeter of the walls. | 28×27 | 3000 |

| Corner defensive | Protects corners from external damage | 25x25x0.4 31x31x0.4 31x31x0.4 | 3000 |

| Arched (PA) | Necessary for the formation of arches, domes and other curved structures | bending radius 500,1000 | 3000 6000 |

| Corner plasterer | Installed at the ends of walls for protection during operation | 35x35 | 3000 |

| Mayachkovy (PM) | It is the basis for the surface plastering process. | 22×6 23×10 62×6,6 | 3000 |

| Enhanced (UA) | Used as a rack element when forming doorways | 50x40 75x40 100x40 | 3000 |

Other types

The arched profile (APA) is designed for the formation of curved surfaces. It can be convex or concave. Created on the basis of the carrier, therefore it matches in size.

The price of an arched profile is higher than a regular rack. For this reason, many craftsmen make fragments of the arched frame themselves, making triangular cutouts in the side shelves of the guides or load-bearing elements. This step allows them to bend freely. The stronger the bend is needed, the more often the cutout petals are located.

The corner profile protects plasterboard corners from damage during operation. It is attached to a layer of putty, so it has perforations through which excess solution is squeezed out. The length of such elements is 3 meters; the width is available in corners with sides of 25 or 31 mm.

Angular

Corner finishing

The Omega profile owes its name to its internal section, reminiscent of the Greek letter of the same name. Its purpose is to fix laminated plasterboard panels on the wall, to which the usual methods of attaching gypsum boards are not suitable: they will violate the integrity of the decorative layer.

The sheets are inserted into the grooves formed by the shaped strips and are securely pressed against them.

The surface formed by laminated plasterboard using such fasteners is divided into separate squares or rectangles. This is often used in the overall design of the room, for example, as in the photo below.

What is needed to install Knauf profiles?

From the table above it can be seen that there are many options for manufacturing metal profiles, depending on the specific application as frame elements. Each type has its own installation features, so you can consider the whole process using the example of installing a suspended ceiling.

To begin with, you should familiarize yourself with a number of rules:

- carry out all repair work in a dry room;

- choose ceiling profiles for plasterboard from a well-known manufacturer (Knauf, for example);

- accurate marking is mandatory, as it will allow you to avoid gross mistakes and save material;

- Before installing the profile, you must additionally check the markings using a level;

- Before covering, you need to make sure that the entire frame is strong, as this will avoid “distortions”.

Once the design of the plasterboard ceiling has been chosen and the budget has been calculated, you can go to the construction supermarket. It is advisable to purchase there:

- laser level;

- measuring tool;

- drill or hammer drill;

- metal scissors;

- two types of profiles (guides and ceiling);

- pendants;

- dowels (anchors).

In addition, to create smooth lines, you need an auxiliary tool for bending gypsum boards and metal profiles. For example, an awl, a needle roller and special equipment for cutting metal. An arched profile will be the best solution for curly structures, since it is easier to bend than other types.

Adviсe

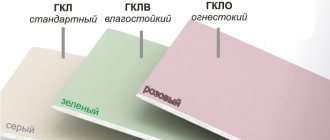

When finishing walls, the length of the sheets is calculated taking into account the height of the room. A minimum number of joints should be left. In our country, moisture-resistant gypsum plasterboard is most widely used, as well as standard gypsum plasterboard.

A wooden frame is used in extreme cases; the wood is deformed, so there is also a high probability that the coating will deform.

For successful installation, you must have a special Perflix-type glue in stock, as well as a special Fugenfuler putty. The internal guides should fit the marks as closely as possible, this will preserve the volume of the room as much as possible.

A gasket no thinner than eight millimeters must be placed between the floor and the gypsum board. After installation, the remaining gap is filled with moisture-resistant sealant.

Self-tapping screws are placed at a distance of at least 20 cm from each other, the distance from the edge is at least 10 cm. The joints are primed with a special primer (tif primer).

You can learn how to make a plasterboard ceiling with your own hands from the video below.

Installation procedure

There are several stages of installing a frame made from Knauf plasterboard profiles. First you need to determine the angle that is lower than all the others in level. To do this, you will need a simple measuring tool - a tape measure.

They retreat at least 5 cm from the selected point and place a mark along the perimeter of the room. All milestones are connected in a line using a painting cord. Using the applied markings, you can now attach the guides, then the hangers, the ends of which should be bent. After this, ceiling profiles are mounted using self-tapping screws and lintels are installed. That's it, the frame is ready. You can begin covering the gypsum boards and finishing work.

Installation of Knauf profiles will not be a problem for careful craftsmen, but the problem of choosing a manufacturer remains relevant. The fact is that building elements from well-known companies cost a lot of money, so the average person is always looking for an alternative. Finding it is not so easy, but it is quite possible to take correct measurements and installation. This approach will help save up to 10% of money. Are there any other ways to make reasonable savings without losing quality?

Partition C361

This partition is made of a single frame and sheathed on both sides with one layer of moisture-resistant plasterboard. This system includes moisture-resistant plasterboard - 12.5 cm, as well as filler - mineral wool.

Scheme with the dimensions of the partition c361

A moisture-resistant partition is placed in the bathroom and in rooms with high humidity. To install the partition, the temperature must be at least +10 degrees. The assembled partition weighs 18 kg. This is a big plus for apartments where load-bearing walls and other plasterboard structures cannot be weighed down.

Price

The table shows prices for steel profiles and Knauf components from Yandex Market, current for 2022.

| Product name, size, material | Cost (in rub.) |

| PP 3000*60*27 mm | 154-198 |

| PPN 3000*27*28 mm | 104-144 |

| PS 3000*50*50 mm | 224-253 |

| PN 3000*50*40 mm | 193-214 |

| PS 3000*75*50 mm | 262 |

| PN 3000*75*40 mm | 274 |

| PS 3000*100*50 mm | 301-319 |

| Direct suspension for PP 60*27 mm | from 7 |

| Anchor suspension/pull 1000 mm | from 34/7 |

| “Crab”/two-level/T-connector | from 14/17/36 |

| Extension | from 13 |

The technical characteristics of profiles produced by Knauf allow the use of products inside a building with any humidity. Outside, it is better to choose aluminum products. Connecting parts are used to control the level of the plane and enhance the rigidity of the frame. Hardware is determined according to density; these can be self-tapping screws with dowels or anchor bolts.