Putties under the Knauf brand: starting, finishing and universal - are an integral part of any construction. This German company has been producing finishing materials for a long time and has managed to gain recognition throughout the world. Major renovations in an apartment inevitably involve leveling the walls. To do this you will need starting and finishing putty. The first is necessary for preliminary (rough) preparation of the base, the second - for the final stage. Let's figure out why you should give preference to Knauf, because putties are presented in a fairly wide range on the construction market.

Peculiarities

All putties from Knauf are ready-made mixtures that can be used by absolutely anyone. For convenience, all products are packaged in paper bags of 25-30 kilograms. Putties are divided according to method of application and composition. The following categories can be distinguished:

- Putty start. It is made on the basis of gypsum or cement. Can be used for finishing walls and ceilings in residential premises. Thanks to its composition, it has a good margin of safety and provides additional sound insulation.

- Finishing mixtures. The composition does not require additional grouting after application. In essence, this is a finished surface finishing.

- Universal compositions. They are characterized by fast setting. For the universal putty to adhere to the base, it is enough to wait only 30 minutes. It is worth noting that this mixture fully lives up to its name. It can be used to level walls and ceilings and eliminate joints. In addition, these compounds can be used on any surface. They contain astringent polymer additives that ensure reliable adhesion.

Classification of Knauf putty by purpose

Knauf putties are dry and ready-made substances with a specific purpose:

- Sealing gaps, cracks, joints: “Uniflot”, “Safeboard Spachtel”, “Fugen”, “Fugen Hydro”;

- Continuous or basic puttying, the thickness of which is more than 1 mm: “Knauf-Fugen”, “HP Finish”, “Basis”;

- Continuous finishing putty (more than 0.2 mm): “Polymer Finish”, “Rotband Profi Paste”, “Rotband Finish”, “MP Paste”, “Satengips”, “Aisspachtel”.

Knauf Rotband

The best option for finishing interior spaces. The mixture can be called universal. It is suitable for leveling concrete, brick and polystyrene foam bases, and can be applied to walls and ceilings. In addition, the putty is impervious to damp environments, making it suitable for use in bathrooms and kitchens.

USEFUL INFORMATION: Advantages and disadvantages of walls made of aerated concrete blocks

Putty Start Rotband has a number of undeniable advantages:

- Good moisture conductivity. After using this putty, moisture does not remain in the room, and therefore there will be no dampness in the apartment.

- Environmentally friendly. There are no harmful chemical elements in the composition. The putty is based on gypsum, which does not cause allergic reactions in the body. Such mixtures can be used to decorate a children's room.

- Reliability. Rotband does not crack even when applied in a thick layer.

If the instructions for use are strictly followed, the result is an absolutely flat surface on which the finishing can be applied. Rotband putties can be of three shades: white, pink and gray. It is worth noting that the recommended application thickness can vary from 5 to 30 mm. About 8 kilograms of material will be required per square meter of area. Complete drying time is 6 days.

Buy Knauf Rotband online

Buying online is very convenient and safe: you can purchase the mixture without leaving home or visiting a store. All purchases will be delivered to your home.

In addition, in the online store, on each product page you can see the exact characteristics and real customer reviews.

Packaged in 30, 10 and 5 kg.

Knauf starting putty characteristics. Composition and technical characteristics

Both the base (starting) and finishing putty have a similar composition.

The main differences are the viscosity of the consistency and the size of the filler fraction. Differences in composition:

- cement;

- plaster;

- polymer.

Cement starting putty contains different types of cement. They are characterized by different colors, with different saturations. A distinctive feature of cement putty is its resistance to moisture. If a large layer is applied, damage may occur due to drying. They are best used for finishing buildings, facades, bathhouses, kitchens and other concrete surfaces.

Gypsum putty for walls – white. This is due to the presence of gypsum as the main structural element. Distinctive features are elasticity and shrinkage when drying. Due to the presence of gypsum in the composition, drying time is much shorter than other types.

Polymer – based on polymer compounds. Colors are light brown and white. The main feature of this type is its long service life and ease of use. It is easy to use and has unique construction properties.

Consumption per 1 m2

Material consumption primarily depends on the type of surface.

What affects material consumption:

- surface;

- type of soil.

Depending on the components used in the putty, the consumption may also depend. For example, gypsum starting soil requires less consumption and dries quickly.

On a flat surface, soil consumption is 800-900 g/m3. If the surface is as uneven as possible, with large protrusions, then the consumption increases significantly, and reaches 8 kg per m3.

Important. The layer density should not be more than 10 mm, otherwise the efficiency will be reduced. There is a possibility of destruction of the structure, since the layer will not support the weight and will collapse.

Knauf Goldband

In essence, this is a variation of the previous plaster, but there are significant differences between the two mixtures. For example: Goldband is for walls only. There are no adhesive components in the composition. Therefore, after complete drying, the putty may simply fall off the ceiling. But it is ideal for processing brick and concrete bases with deep relief. It is worth noting that Goldband can be applied in a fairly thick layer - up to 50 mm. The remaining characteristics of the putty are identical to Rotband Knauf.

What is starting putty

The starting and final putty perform the same function - they smooth the surface of the walls. But then what is the difference between the starting and final putty?

The fact is that the starting (basic) putty contains a large fraction of filler. This will allow you to eliminate bulges with differences of up to 1 centimeter, as well as deep chips and cracks.

If you need to remove the most severe bulges, i.e. more than 1 centimeter, the walls will have to be plastered according to the beacons. True, the plaster also has a thickness limit - its layer should not exceed 7 cm.

After application, the base putty is sanded with P80-P120 abrasive. This allows you to get a relatively smooth surface, which is suitable for applying decorative plaster and almost all other final coatings.

Newbies are often interested in whether it is possible to glue wallpaper using starter putty? Wallpaper does not require a completely smooth base surface, so final puttying is not required.

The final putty is intended not so much to smooth the base, but to ensure a smooth surface. Its small thickness is less than mm, and its greatest thickness usually does not exceed 3-4 mm. This allows you to remove sanding marks and other small imperfections on the surface.

Final puttying allows you to create a completely smooth surface of the walls.

Gypsum plaster Knauf Iceberg

Knauf Eisberg gypsum plaster is used for leveling walls and ceilings in dry rooms, repair and restoration work. The material is universal and does not require subsequent puttying. The main component of the building mixture is high-quality gypsum, which is an environmentally friendly and lightweight material. Package weight - 30 kg.

USEFUL INFORMATION: Installation of ventilation in an apartment with your own hands

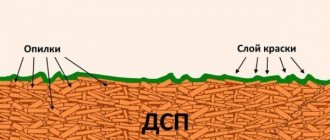

Gypsum plaster cannot be used in conditions of high humidity, otherwise it is universal and can be used for different substrates:

- concrete of different structures (dense and cellular);

- cement plaster;

- stone and brick;

- expanded polystyrene and DSP.

Advantages of gypsum plaster

The material “breathes”, regulates the amount of moisture in the air, absorbing it when there is excess and releasing it when there is a deficiency. Creates a favorable indoor microclimate.

The mixture is plastic and easy to apply; it is easier to work with than other types of plaster. The coating provides good heat and sound insulation. The consumption of gypsum mixture is significantly lower compared to cement.

Packaged 30 kg

Dry and ready-made Knauf putties

The previously mentioned finishing materials are produced in dry form. Their cost is much lower than ready-made ones. Also has a longer shelf life under proper storage conditions.

An important disadvantage is exposure to moisture. Dry mixtures must be stored in dry rooms.

The ingress of moisture will lead to their rapid hardening and deterioration. When storing finished putties, special care is not required.

- It is only important to remember that you should not prepare putty “for future use” long before carrying out repair work, without calculating the maximum possible amount of material per coverage area.

- Putty that has expired should not be used. There is no need to store materials remaining after repairs. Having completed the finishing of the room as quickly as possible, the unpacked dishes with ready-made putty can be handed over.

- Many stores allow this possibility when performing finishing work promptly. With dry it is more difficult - there is no guarantee that it was stored without moisture. But, you can try.

The main thing is not to delay using this material, thanks to which you get beautiful, smooth surfaces for painting or gluing wallpaper.

Finished Knauf products are presented in the following finishing types:

- Vinyl paste Rotband Pro;

- MP Paste, intended for application with a special device (for example, a spray gun).

Knauf materials for interior and exterior decoration, including special high-strength products for hiding seams and joints, starting and finishing putties, etc.

Primers and other building materials necessary to create beautiful, smooth walls in any room are suitable for complex use.

You won’t have to waste energy and time looking for additional funds. As they say: “A sharp friend is better than two new ones.”

Putty Start Knauf HP

This putty is available in two variations: for manual or machine use. This information is usually indicated on the packaging. For example: the MP 75 marking indicates that the mixture is intended for machine finishing of premises.

Important! Mixtures for machine use can be used manually, but vice versa is strictly prohibited! Putties for manual use can ruin expensive finishing equipment.

Knauf HP Start is suitable for any hard surface. The maximum thickness of the applied layer should not exceed 30 millimeters. The composition dries in about 7 days; for one square meter of area you will need about 10 kilograms of material.

It is worth noting that this gypsum putty can be combined with other types of plasters.

Knauf gypsum plaster characteristics. Description and properties of Knauf gypsum plaster

Knauf gypsum plaster is made from a natural mineral of sedimentary origin. The stone settles to the bottom of lagoons and lakes, compressed under the water column from particles of bones of dead animals.

Sulfur is taken from the same organic residues or thermal springs. All that remains is to add water to the gypsum formula, the presence of which is natural in lagoons. So we get the chemical notation: - CaSO4 * 2H2O. There are no harmful elements in it.

"Knauf" is a plaster consisting of more than 95% gypsum. This makes the product environmentally friendly. The remaining 5% are polymer impurities. They correct the natural properties of aqueous calcium sulfate.

The water from it is evaporated at the powder stage. Finishers re-mix the liquid before leveling the walls and ceilings, restoring the plasticity of the plaster. The resulting mass evaporates moisture again, hardening within 20 minutes.

This limits the finishing crews' actions. You have to mix the plaster in small volumes, rushing to apply them to the walls before they lose their plasticity. Polymer additives in plaster increase the working life of some types of plaster to 40-45 minutes.

Also, additives to the gypsum mass can reduce its fluidity. This is relevant when working with fine-grained minerals. When ground, it breaks down into particles less than a millimeter in diameter.

Mixing them with water gives an excessively fluid mass. When applied to walls, it can cause sagging. It is easier to work with coarse-grained gypsum plaster. It is ground into grains with a diameter of more than a millimeter.

Gypsum plaster "Knauf" - "Rotband". The name of the line is translated from German as “Red Line” and is created by analogy with the color of a cigar band. Targeting a male audience. At the time of the creation of Knauf, gentleman builders smoked cigars en masse.

However, the name of the plaster also contains an indirect allusion to the color of the gypsum. It is rarely found in its pure form. Typically, a couple of percent of impurities are added to the 5% of polymers in the plaster.

As a result, consumers purchase gray or reddish Rotband. The latter is coarse-grained. Gray or pure white building mixtures are dust-like and more fluid.

The color of Knauf plaster is also important during finishing. The pigment in the mortar may show through thin wallpaper. If plaster is the finishing touch, it should fit into the color concept of the room. A pinkish tint is not always appropriate. Gray and white mixtures are more versatile.

Being hydrophobic, that is, a mineral that absorbs moisture, gypsum on walls can swell and be affected by fungus. Therefore, Rotband is not recommended for wet rooms.

In other rooms, offices and warehouses, Knauf plaster is durable because it has high adhesion. This is the ability of mixture particles to penetrate into adjacent surfaces. So “Rotband” reinforces them, filling the voids, and firmly adheres to the base.

Gypsum plaster is not frost-resistant. Cold rooms often have high humidity. The problem comes down to dampening of the building mixture. But it resists fire perfectly, like most stones.

Finishing putty Knauf Rotband Pasta Profi

Finishing putty “KNAUF Rotband Pasta Profi” is used at the finishing stage of interior finishing. It gives the walls a pure white color and masks the smallest cracks. Suitable for application in a thin layer (up to 0.2 cm) on a base made of concrete, plasterboard and other materials.

Consumption for continuous application is about 0.5 kg per m2. After drying, the KNAUF Rotband Pasta Profi putty can be applied with paint or wallpaper of any type.

USEFUL INFORMATION: Floor covering in an apartment: what is best to do?

Packaged in 5 and 18 kg

Decorative putty Knauf

Finishing, used as a layer before decorative finishing (painting, wallpaper) or for exterior work. Sometimes, with the addition of color, crumbs, or as a layer before cladding on the facade of a building.

Knauf-HP Finish

Suitable for kitchens and bathrooms with average humidity levels. Designed for finishing ceilings and walls indoors. Dries quickly. The minimum thickness of the coating is 0.1 cm, max – 0.3 cm. It can take on shades of pink and gray, this is normal, this is how natural mixtures of gypsum minerals work.

HP Finish

Specifications:

| Consumption | continuous layer 1 mm: 0.9 kg/m2 |

| Layer thickness, cm | 0,1-0,5 |

| Packing | Paper bag, dry mix, 25 kg |

| Fraction size (grain) | no more than 0.2 mm |

| Shelf life | 6 months in closed packaging |

Price from 169 rub. per package.

Knauf-Rotband Pasta Profi

Ready-made putty in the form of a paste containing vinyl as a base. Final treatment of any indoor surfaces with a thin, snow-white application. Ready to use without using water. Easy and flexible to work with. It has a very smooth structure and “clings” to the wall. Doesn't "chalk". Not suitable for wooden surfaces.

Rotband Pasta

Specifications:

| Consumption | For a continuous layer of 0.5 mm 0.5 kg/sq.m |

| Layer thickness, mm | 0-2 |

| Fraction size (grain) | no more than 25 microns |

| Complete drying time 1 mm | Day |

| Frost resistance | Minimum – no more than 5 cycles |

| Shelf life | 12 months in a sealed container |

Price on the Internet for a bag weighing 18 kg from 800 rubles.

Knauf-Satengips

Developed on the basis of gypsum. Prepares the surface for the final decorative stages (wallpaper, painting). Can be used on both concrete and plasterboard surfaces. Eco-friendly - without impurities. Does not leave chalky marks. Not suitable for outdoor use. Open mixture does not dry for up to 100 minutes. Before use, it is better to apply a primer and let it dry.

Satengips

Specifications:

| Consumption | For a continuous layer 1 kg/sq.m |

| Layer thickness, mm | 0-2 |

| Fraction size (grain) | no more than 25 microns |

| Complete drying time 1 mm | Day |

| Frost resistance | Minimum – no more than 5 cycles |

| Shelf life | 12 months in a sealed container |

The cost of a 25 kg package is 238 rubles.

Mode of application

Working with Knauf dry starting mixtures occurs according to the following scheme:

- Preparatory stage. Before using rough putty, you need to prepare the base. To do this, remove all contaminants from the surface. By the way, the recommended temperature of the treated surface should not be lower than +5 degrees. After this, the main surface must be primed. This is especially true for surfaces that absorb moisture well. For example: aerated concrete blocks or sand-lime brick. As a primer, you can use Knauf products: “Betonkontakt” or “Rotband-Grund”. These primers are diluted with water in a ratio of 1/3 and applied to the surface with a roller or paint brush. Further work can be carried out only after the primer has completely dried. After this, beacons are installed on the surface. These devices will help greatly facilitate the work process.

- Technological process. Let's look at the procedure for working with Knauf dry mixes using START HP as an example. The composition is diluted in the following proportion: 1 bag (25 kg) per 14 liters of water. After pouring, the mixture must be thoroughly stirred until a homogeneous mass is obtained. This can be done by hand or using a mixer.

The solution is applied to the base using a spatula. Before setting begins, it is necessary to level the putty along the installed beacons. It is worth noting that the prepared solution must be used within 30-40 minutes. If the putty will be applied in two layers, it is recommended to make the surface of the first wavy. To do this, you can use a special spatula.

Knauf polymer putties

Polymer putties are characterized by high elasticity and adhesion. They are easily applied to the wall surface, hiding minor imperfections and covering it with a thin waterproof film.

Polymer putties protect well from fire and withstand significant temperature fluctuations.

- They are strong and durable.

- They are not afraid of sunlight or atmospheric influences.

- Suitable for external work.

- The disadvantage is the high cost.

- This range of finishing materials is represented by Knauf-Polymer Finish putty.

Useful tips

- The putty layer should not exceed the values specified by the manufacturer. Otherwise, after drying, the composition may partially crumble.

- If the composition is applied in 2 layers, it is recommended to use reinforced mesh. A second layer is applied only after the previous one has dried.

- After using each portion of the mixture, equipment must be thoroughly washed.

- It is better to dilute Knauf starting putty with cold water. If the mixing water temperature exceeds +30 degrees, the putty may crack after drying.

- If you used Knauf composition for rough finishing of the walls, then it is recommended to also use products from this manufacturer for finishing.