The topic of our article today is “Knauf drywall size” and this is not without reason. Knauf plasterboard occupies a leading position in the construction market of our country. Therefore, many master builders will be interested in knowing its technical characteristics and scope of application.

Knauf plasterboard is most often used in repairs and construction as a finishing material:

- for interior decoration of room walls;

- for the construction of various figures and decorative elements;

- for the manufacture of suspended ceilings;

- for the construction of arches and various partitions.

What are Knauf plasterboard sheets? They are rectangular planes that consist of gypsum and special reinforcing additives. These planes are lined along the contour with special cardboard on both sides, which is very stable. The core contains a binder of G4 grade gypsum, manufactured in accordance with GOST 125-79.

Plasterboard sheets are produced in accordance with GOST 6266-97, thanks to which they fully meet the requirements of DIN 18 180, which is a German standard. The reliability and manufacturability of plasterboard is ensured by a semicircular thinned edge, which is used at joints.

The adhesion of the core to the facing cardboard occurs using special adhesive additives. Cardboard acts as a reinforcing frame, which is also a pretty good basis for subsequent finishing, be it decorative plaster, tiles, paint or wallpaper.

Plasterboard sheets

Drywall is divided into ordinary (GKL), moisture-resistant (GKLV), fire-resistant (GKLO), universal GKLVO (moisture- and fire-resistant), acoustic and gypsum fiber (GVL).

Any type of plasterboard sheet can be used for the following purposes:

- For leveling the ceiling, arranging suspended ceilings, creating ceiling decor. Finishing ceilings with plasterboard is one of the most popular types of work. Electrical wires and utilities, exhaust ducts are quickly and cheaply hidden, and unevenness and imperfections in the ceiling surface are smoothed out.

- For creating partitions, boxes and temporary walls. The weight and thickness of the material, its profile make it possible to build a partition that will not differ from the main walls.

- For leveling walls and surfaces. There is nothing better than a sheet of this material to make uneven walls look perfect.

- To create various relief elements, interior architectural compositions for any size.

- To fill unwanted voids.

The size of the plasterboard sheet on the small side is NOT correct!

KNAUF plasterboard is 5-7 mm smaller than the declared size. I DID NOT EVEN THOUGHT THIS HAD HAPPENED! My video diary about...

Drywall for finishing work must be selected based on its properties and purpose. Plasterboard sheets can be divided into:

- Regular plasterboard;

- Moisture-resistant gypsum board;

- Fire-resistant gypsum plasterboard;

- Universal GKLVO;

- Acoustic.

There is also a type of building material made from gypsum and cellulose - gypsum fiber sheet GVL.

Drywall is manufactured in three main standard sizes:

- 2000mm x 1200mm;

- 2500 mm x 1200 mm;

- 3000 mm x 1200 mm.

However, on the shelves of construction stores you can also find plasterboard with lengths of 1200 mm, 3500 mm and 4000 mm. The standard width of plasterboard sheets is 1200 mm (120 cm). However, sheets with a width of 625 mm are also available for sale. The standard thickness is usually 9.5 mm or 12.5 mm. Sheets with thicknesses of 6.6 mm, 8.0 mm, 14.0 mm, 16.0 mm, 18.0 mm, 20.0 mm, 24.0 mm are also produced. Drywall is easily cut with a stationery or construction knife. This way you can get any required sizes.

The Knauf company received its name from the surnames of the two brothers who founded it, Karl and Alfons. Its history begins in 1932, when Reinisch Gipsindustri und Bergverksunternemen was born. Their first product was building mixtures based on natural gypsum. A few years later they opened a factory in a town called Iphofen, and in 1958 they began producing plasterboard.

This type of material is resistant to open fire. It is often installed in rooms where there is a risk of fire and fire spread. If the wall has a flat surface and will not be subject to functional load, thin material measuring 8 millimeters can be used.

The thickness of the products starts from 0.65 cm - these are the thinnest models, and reaches 2.4 cm - for work with increased strength requirements for the product. There are other, specialized types of plasterboard sheets. In particular, the manufacturer Knauf is distinguished by the variety of these products, you can learn more from the video below: There are also small sheets on sale, up to 2 meters long, if you do not need a lot of material or have difficulties with delivery from the store.

With the help of gypsum boards, construction is carried out using “dry technology”, and it is these sheets that serve as the basis of the structures. And all other elements are used for their installation, connection and finishing. Each gypsum board consists of a flat gypsum core, framed with cardboard on both sides and along the long edges. Almost all brands of gypsum board are distinguished by a cardboard edge along the length of the sheet.

It usually has a smaller thickness towards the edge, which makes it possible to seal these places with putty when joining sheets, and also use paper, fabric or fiberglass for reinforcement. The result is a smooth and durable surface. On the reverse side of plasterboard sheets there are symbols that make it clear what type of edge is used in this sheet. And another example worth giving is gypsum fiber (abbreviated gypsum fiber).

This board consists of a gypsum base with the addition of cellulose fibers. It is very rigid and durable, not exposed to fire and has a smooth surface. Thanks to this, no primer is required before finishing. Gypsum fiber sheets are used in many cases - for example, when installing a dry floor, for outdoor work (including for assembling frame house structures). They can also be used in damp rooms.

When sheathing in several layers (as well as for technical areas), such a chamfer is overkill - it is better to choose sheets with a straight edge. A thinned edge should be chosen only for finishing with subsequent putty. If pallets with gypsum boards are placed on top of each other, the core may be crushed, the sheets may become deformed, and scratches and dents may form.

Drywall from this company can be used indoors, for which sheet options are available from two and a half to three and a half meters in length, but with a standard width. Like any professional company, Knauf produces not only a standard version of the sheet, but also one that suits for wet rooms, for the manufacture of structures in contact with fire, and mixed type.

Knauf plasterboard is very popular. GKL plasterboard (regular type) is produced in the form of sheets. The basis of a plasterboard sheet is gypsum, which is located between two sheets of cardboard.

To give plasterboard sheets certain properties, various substances are added to the middle part to improve its strength, moisture resistance and other properties.

Special processing of the only flammable gypsum board material - cardboard - makes this material generally non-flammable. Under the influence of open fire, sheets of drywall only become charred, and the moisture contained in the depths of the sheet prevents the movement of the flame.

GKL "Knauf" (regular plasterboard sheet 1 and other types) is an environmentally friendly building material, since it does not have any negative impact on the objects surrounding it, which is confirmed in quality certificates. In addition, gypsum board is also an excellent soundproofing material.

Tips for choosing

It is better to buy drywall in specialized stores that comply with storage conditions and have reliable large suppliers.

When choosing, pay attention to the following points:

- compliance of the dimensions and thickness of the sheets with the declared ones;

- the color of the sheet covering, which should be green for moisture-resistant drywall;

- availability of certificates and other documents confirming the quality and safety of the material;

- integrity of sheets, absence of damage, dents, cracks, scratches;

- There should be no bends or chips on the edges.

Important! Buy the type of plasterboard sheets that you need. You should not overpay for moisture-resistant or fire-resistant drywall for use in normal conditions - this is a waste of money.

To level walls or install partitions, choose plasterboard with a thickness of at least 12.5 millimeters. For ceilings, thinner and lighter sheets are suitable.

Having purchased drywall, pay attention to the neatness of the movers. If the store provides delivery, accept the delivered goods, checking for mechanical defects and manufacturer's markings on each sheet.

TOP 3 best products according to customers

Magma moisture-resistant plasterboard sheet 2500x1200x9.5 mm

315.00 rub.

Product code 12258

Intended for finishing and installation of non-load-bearing walls and partitions in buildings with high humidity…..

Magma moisture-resistant plasterboard sheet 2500x1200x12.5 mm

350.00 rub.

Product code 12257

Magma moisture-resistant plasterboard sheet 2500x1200x12.5mm (Building board for dry plaster moisture…..

If you are not sure of the quality of the material, you should not buy a large volume at once. Buy a few sheets to try. Try cutting the purchased sheet. The cut should be uniform and even, and the cutter should move smoothly.

Don't be tempted by the too cheap price. Buy plasterboard sheets from well-known, trusted manufacturers.

Drywall "Knauf": all types and sizes of sheets, technical characteristics

The reputation of Knauf drywall dates back to 1958, when the German company of the same name introduced new products to customers. Since that time, it has grown to become the world's largest manufacturer of plasterboard with technical characteristics that have become the standard. In 1993, the company expanded its activities in Russia, opening a lot of enterprises with modern equipment, uniform technologies and quality standards. Practical Knauf plasterboard, designed for quick and high-quality finishing of premises, is not stocked in construction stores.

Alternative mounting solution

When walls are leveled, the second installation method is often used, which involves the use of an adhesive base. This approach, according to users, is much faster and simpler than the previous one. In this case, you only need to apply glue to the sheets, and then press them tightly to the prepared surface.

If the wall has unevenness up to 4 mm, then the sheets can be installed using putty. When the unevenness is much larger and reaches 20 mm, the drywall can be installed with Perlfix glue.

Brand Features

Pros of Knauf drywall:

- simple and quick installation;

- Treatment of gypsum boards with water is excluded from the technology;

- there are no “dirty” operations during finishing;

- allows air to pass through and is resistant to fungus formation;

- gypsum has lower thermal conductivity than plaster, it retains heat better;

- affordable.

Without going into technical details, a plasterboard sheet is a layer of gypsum enclosed on both sides in a cardboard covering. This was the first drywall. Since then, this material has come a long way to improve. Now there are several modifications of drywall for different applications.

Reviews about installing moisture-resistant drywall with glue

If you have to level the wall using drywall, which will be installed with glue, then you should at the first stage revise the base. For this, experts advise using a building level, plumb line and rule. The surface is cleaned of the old finish, while trying to eliminate unevenness. The tubercles are knocked down with a chisel or perforator.

Home craftsmen advise applying markings on the wall to install the sheets. The surface is treated with a primer, which increases adhesion. Next, holes are made in the sheets for switches and sockets. The canvases are laid on metal or wooden slats. The glue should be placed in small heaps on the drywall. The distance between such slides should be 30 cm.

The sheet is lifted and applied to the wall. It is recommended to align its position horizontally and vertically using a rubber mallet. It is better to start pasting from the corner of the room, moving along the perimeter.

KNAUF-list (GSP-A)

In rooms where humidity and temperature are within normal limits, this type of drywall is used most often. It is inexpensive, cuts well and takes the given shape. It is attached not only to the profile, but also with glue. “Friends” with any type of finishing materials: it is covered with wallpaper, painted, covered with tiles, decorative stone. The ceiling version (9.5 mm thick) allows you to easily install modular lighting. Despite all its technical advantages, it remains an environmentally friendly material.

The gray sheet of GSP-A resembles a kind of sandwich of 2 layers of special cardboard, between which a gypsum core with reinforcing additives is placed. The edges are also covered with cardboard and have a semicircular thinned shape, in which a reliable, tight joint between the sheets is guaranteed.

Drywall categories

The main categories of gypsum boards differ from each other in the color of the sheet.

Plasterboard panels come in two categories - A and B. Most manufacturing companies sell plasterboard of category A, which is why the category is often not indicated in the technical characteristics of the product. Category B slabs are distinguished by the presence of small deviations from standard geometric parameters as a result of the use of old equipment.

The construction market offers the following types of drywall:

- GKL is a standard sheet of drywall with template parameters. They are the simplest type and do not have any additional characteristics. Suitable for use only in dry rooms. The appearance of the material is gray sheets with blue markings;

- GKLV – moisture-resistant plasterboard;

- GKLO – fire-resistant panels;

- GKLVO – products with complex properties;

- EGKL – flexible plasterboard;

- AKGL – slabs with increased sound insulation.

In order to choose the right plasterboards, you need to become more familiar with each type of this material.

Knauf-sheet moisture-resistant (GSP-N2)

This type of drywall is used for the same purposes as regular drywall, but in rooms with high humidity. It absorbs 90% less water than an ordinary one. Moisture-resistant KNAUF sheets (GSP-N2) of green color are distinguished by specific additives:

- antifungal compounds protect the material from mold, the appearance of which is inevitable in a damp room with poor ventilation;

- the waterproofing solution does not let water inside the material;

- polymer impregnation reduces the absorption rate.

The physical and hygienic properties of this type of gypsum board make it an ideal material for residential premises.

Moisture-resistant plasterboard is a win-win option for bathrooms, kitchens, toilets, finishing loggias, balconies, door and window openings and even basements, attics, and pool rooms.

Read more about the properties and scope of application of moisture-resistant types of drywall here.

How to calculate the required number of sheets

Method for determining the number of plasterboard sheets for a ceiling

To correctly determine the number of panels to perform certain jobs, you need to know the parameters of the sheets. The dimensions of the drywall can only be determined after all measurements have been taken; it is important to be sure to measure the area of the room. For example, for rooms with a wall height of 2.7 meters, three-meter sheets are purchased. A strip of 30 cm is cut from them. It is not practical to use panels 2.5 meters long and add a strip of 20 cm to them. This will increase the number of seams, the number of profiles required and the financial costs.

If the panels are purchased according to size, correct installation of the frame is guaranteed. The design will be reliable. At the same time, the time for repair work will be significantly reduced.

When working with the material, it is necessary to avoid seams. When purchasing panels, it is necessary to correctly determine the length and correctly place the sheets on the frame and on the plane in general.

It is possible to buy sheets, taking into account the surface area that will be processed. But then it is necessary to purchase approximately 15% of the panels additionally. Such costs are unreasonable. You can completely refuse them. To do this you need to know the dimensions. First you just need to do certain calculations.

Some calculation details:

- The thickness of the plasterboard for the walls is 12.5 mm. But the amount of material does not depend on this;

- If there are small door and window openings on the walls, it is not necessary to take them into account when calculating. GKL trimmings can be used to finish slopes;

- If there is more than one opening, the dimensions of the openings are large, or it is planned to use other plasterboard sheets for finishing the slopes, then it is recommended to exclude the area of the openings from the calculations performed;

- In the process of finishing the walls below and above, it is necessary to leave a special gap of 1 - 1.5 cm. Then it is covered with finishing materials or a plinth.

Knauf-sheet fire-resistant (GSP-DF)

The fire-resistant type of plasterboard is intended for heat-resistant coatings and structures, be it wall cladding, partitions, suspended ceilings in buildings where humidity does not exceed regulatory requirements.

Tests conducted by the Russian Research Institute of Fire Defense of the Ministry of Emergency Situations showed that Knauf plasterboard sheathing practically behaves like an ordinary non-combustible material.

The front side of the product is painted pink, the back side is gray.

All the features and applications of heat-resistant drywall are described in this article (plus a fire test video).

Scope of application of drywall

The construction of plasterboard partitions is one of the areas of application of the material.

Drywall is a multifunctional material. Used when performing the following work:

- Formation of partitions;

- Creation of structures of various designs;

- Closing window and door openings;

- Leveling walls;

- Warming of surfaces;

- Surface finishing;

- Repair and finishing work of previously erected structures.

KNAUF impact-resistant sheet (GSP-DFH3IR)

GSP-DFH3IR combines increased density with moisture and fire resistance, has increased strength and impact resistance. This universal material is used in rooms where the most stringent requirements are imposed on the finishing, including sound insulation.

For production, a special blue facing cardboard is used. The use of such cardboard with increased weight increases the bending strength of the sheet. For high-quality finishing, KNAUF sheets GSP-DFH3IR are the best option.

Work of figured form

One of the advantages of Knauf plasterboard is the creation of shaped elements on the wall, which can be used as gypsum plasterboard arches, on multi-level ceilings, and as a decorative decoration for partitions. For these purposes, Knauf 9.5 plasterboard, Knauf arched profile for plasterboard, fasteners and mixtures are used.

Arched plasterboard Knauf

There are two ways to bend drywall:

- Dry method: if the bend radius is large, then you can simply attach the sheet to the structure and secure it with self-tapping screws;

- Wet method. Using a needle roller, many holes are left on the sheet, which are moistened with water. This moistened sheet is placed on a specially created form and left for 10 hours. After drying, the gypsum board will take the desired shape.

There are several other ways to bend drywall, but they are not used as often.

Drywall and Knauf components have positive reviews. The quality of manufactured products is always at the highest level. Seam putty, reinforcing tape, Knauf drywall adhesive and other building materials are applicable to drywall - they show a long service life.

If you want to work with drywall, you should buy a profile for drywall, plasterboard, fasteners, hangers, and a single mixture. Then the plasterboard structure will be durable, multifunctional and modern in design. To accurately determine the amount of material required, use a calculator.

KNAUF-acoustics - large-format sound-absorbing panel

These are plasterboard sheets with perforations. Suitable for rooms with normal humidity. Through holes serve as resonators: the sound wave falls into a kind of trap and gradually fades. The noise-absorbing effect is further enhanced by a layer of non-woven fabric on the back side of the sheet. Depending on the design of the room, the canvas can be white or black. Perforation patterns have several options, depending on which gypsum boards differ in the degree of sound absorption.

Tests have shown that the noise absorption coefficient of KNAUF-acoustics plasterboard reaches 0.2. This is a very worthy indicator.

Perforation, in addition to sound dampening, has a memorable, stylish appearance. This is confirmed by all the photos illustrating the use of Knauf acoustic plasterboard. The company's products allow you to choose from several options with different types of holes: round, square, scattered round.

Such drywall creates real acoustic comfort, which is necessary in schools, universities, concert halls and many other public institutions, residential buildings, not to mention industrial premises. Installation of a ceiling or wall covering with such sheets is carried out at an accelerated pace, without significant labor costs.

Help: acoustic plasterboard reduces the level of noise in the room itself, reduces booming, fights the echo effect, and improves speech perception. But you shouldn’t count on soundproofing results - it won’t protect you from loud neighbors.

The features of acoustic drywall are described in more detail here.

Reviews about installation methods

Moisture-resistant plasterboard “Knauf” 2500x1200x 12.5 mm, according to buyers, can be laid in several ways. Among others, the frame method should be highlighted, which is used when the walls have significant unevenness. For creating interior partitions or decorative structures, the frame method is ideal.

In this case, consumers are advised to install the sheets on a metal sheathing, which is made from galvanized profiles. The frame is fixed to the wall with dowels and screws. Moisture-resistant plasterboard "Knauf" 12.5 mm cannot be installed on a wooden sheathing if the structure is intended to be used in a damp room.

For the frame, metal profiles of different sizes should be used. Among the main consumers, there is the W-profile, which is large in size and is used to make a general frame. The D-profile is necessary for the internal cladding, onto which drywall is reinforced in the next step. Each standard size has a guide profile with a smooth surface and a support profile with ribbed walls.

Knauf drywall size. Types and types of drywall sheets

The topic of our article today is “Knauf drywall size” and this is not without reason. Knauf plasterboard occupies a leading position in the construction market of our country. Therefore, many master builders will be interested in knowing its technical characteristics and scope of application.

Knauf plasterboard is most often used in repairs and construction as a finishing material:

- for interior decoration of room walls;

- for the construction of various figures and decorative elements;

- for the manufacture of suspended ceilings;

- for the construction of arches and various partitions.

What are Knauf plasterboard sheets? They are rectangular planes that consist of gypsum and special reinforcing additives. These planes are lined along the contour with special cardboard on both sides, which is very stable. The core contains a binder of G4 grade gypsum, manufactured in accordance with GOST 125-79.

Plasterboard sheets are produced in accordance with GOST 6266-97, thanks to which they fully meet the requirements of DIN 18 180, which is a German standard. The reliability and manufacturability of plasterboard is ensured by a semicircular thinned edge, which is used at joints.

The adhesion of the core to the facing cardboard occurs using special adhesive additives. Cardboard acts as a reinforcing frame, which is also a pretty good basis for subsequent finishing, be it decorative plaster, tiles, paint or wallpaper.

Sheet and marking colors

Based on the technical characteristics and capabilities of Knauf drywall, each variety has its own marking and color:

- Standard – gypsum plasterboard, gray with blue markings

- Moisture resistant - GKLV, green with blue markings

- Fire resistant – GKLO – pink with red markings

- Waterproof with high resistance - GKLVO, green with red markings

The marking of any type of Knauf drywall must include in the description:

- Manufacturer's trademark

- Sheet symbol (A, B)

- Type of material according to purpose (gypsum plasterboard, gypsum plasterboard, etc.) in the appropriate color

Markings are applied to the back of each sheet.

Knauf drywall size

The dimensions of Knauf plasterboard sheets are most often given in millimeters:

- the length of the sheets can be from 2000 to 4000 millimeters;

- sheet width varies from 600 to 1200 millimeters;

- The thickness of the sheets is 6.5, 8, 9.5, 12.5, 14, 16, 18, 20, 24 mm, which depends on the purpose of the sheets.

Quite often, plasterboard sheets are used, the size of which is 2500x1200x12.5 mm. A sheet having these dimensions has an area of approximately 3 m2 and a weight of approximately 29 kg. Drywall is packaged in packs of fifty pieces. One such package is enough to decorate an area of 150 m2.

Each sheet of Knauf drywall has special designations:

- the standard to which it is manufactured;

- geometric dimensions;

- type of end edge;

- group;

- letters that indicate the type of drywall.

Manufacturers and prices of drywall

Currently, you can purchase plasterboard sheets in various price categories. At the same time, the thickness of the sheet affects the price much less than its intended purpose and the manufacturer’s brand. All the largest companies strive to improve their own products to the greatest extent, which leads to an increase in their cost, but not always to a significant increase in technical and operational indicators. Therefore, let's study in more detail the features of drywall from the most popular companies among consumers.

Knauf

Knauf company emblem

One of the leading manufacturers of plasterboard sheets on the Russian market. The product of this company is very popular among consumers. The company creates various variations of drywall - from conventional to acoustic. The company also sells a wide range of products in various sizes - plasterboard comes in lengths from 1500 to 4000 mm and widths of 600-1500 mm. The cost of a regular sheet (2500x1200x12.5) is 310 rubles.

According to experts, the main advantages of Knauf plasterboard are:

- Impeccable product geometry;

- Higher density and strength than other manufacturers;

- Long service life.

Volma

Volma company emblem

The domestic manufacturer of plasterboard panels Volma produces high-quality products at an affordable cost, which is approximately 10-20% lower than the products of the Knauf company. The range includes standard, moisture-resistant, fire-resistant and combined materials, but there are no special gypsum boards - for example, Volma does not produce acoustic sheets. The cost of a regular sheet of drywall (2500x1200x12.5) is 275 rubles.

The main advantages of sheets from this company:

- Reliability;

- Stable technical and operational indicators;

- High bending strength.

Volma's plasterboard is gaining increasing recognition among buyers year after year due to the optimal combination of high quality and affordable price.

Magma

Magma company emblem

The material of this brand is almost not inferior in quality to Knauf products, but at the same time its price is 20-30% lower. The main advantages of Magma plasterboard include sufficient strength and reliability, ease of processing and good flexibility.

Types of drywall sheets

Depending on where plasterboard sheets will be used, they can be divided into arched, ceiling and wall. Walls and ceilings finished with plasterboard become absolutely smooth.

Important advantages of plasterboard are its fire safety and environmental friendliness.

In all rooms that are finished with such slabs consisting of cardboard and gypsum, a rather favorable atmosphere for human life develops.

1. Sheets for wall decoration, having a thickness of 12.5 mm, are most often used for finishing walls and creating partitions. Thanks to the use of plasterboard, the use of “dry construction” technology becomes possible. 2. Sheets intended for finishing the ceiling have a thickness of 9.5 mm. They are used to make suspended ceilings. In principle, wall plasterboard is also suitable for this purpose, but it weighs more and costs more. 3. For the construction of arches or any other structures that require changing the shape, arched plasterboard is used, which has a thickness of 6.5 mm. Thanks to this thickness, you can create a variety of elements that have a round or simply curved shape.

Edge Types

Each plasterboard sheet has an edge of a certain size and shape. The edges are needed to make it easier to apply the putty composition and reinforcing tape to the gypsum board joints. The classification of edges is as follows:

- Direct (PC) – intended for “dry” installation. The work does not involve laying joints. Often used in covering surfaces in several layers

- Thinned (UK) - after installation of the structure, the seams between the sheets must be covered with a special reinforcing mesh and plastered

- Rounded (ZK) – this provides for the use of putty without pre-glued tape

- Semicircular (PLC) also does not provide for gluing tape, but requires puttying

- Thinned semicircular (PLUC). Requires the use of tape followed by putty. The most popular type of edge.

Finishing and leveling walls and ceilings with plasterboard is popular and in demand. Such cladding is carried out quickly, does not require large financial costs for the purchase of putty, and reduces the time required to complete the work due to the fact that the material is large in size and requires less physical effort and special equipment. After installation there is practically no construction waste. Any design structures can be constructed from plasterboard, including the most complex ones. The quality is always top notch. It serves for a long time, does not deform, does not sag, and does not lose its characteristics and properties throughout its entire service life.

Types of drywall

Depending on the area of application, properties and technical characteristics, plasterboard comes in different types. At the same time, the size of Knauf drywall can also be different. Drywall can be ordinary, moisture-fire-resistant, fire-resistant and moisture-resistant.

Next, you will learn how to choose the right size of Knauf drywall based on the required characteristics:

1. Regular drywall is usually beige in color, and the lettering on it is blue. This type of plasterboard is used for cladding ceilings and walls, and also, using a metal profile, for the construction of partitions in rooms with normal humidity levels.

This type of drywall can have the following parameters:

- sheet length from 2500 to 4000 mm, sheet thickness 9.5 mm, sheet width 1200 mm, weight 9.5 kg;

- sheet length from 2500 to 4000 mm, sheet thickness 12.5 mm, sheet width 1200 mm, weight 12.5 kg;

- sheet length from 2500 to 4000 mm, sheet thickness 15 mm, sheet width 1200 mm, weight 15 kg;

- sheet length from 2000 to 3500 mm, sheet thickness 9.5 mm, sheet width 600 mm, weight 18 kg.

2. Moisture-resistant plasterboard sheets are green in color and have blue lettering. This type of drywall is used in rooms with high humidity - in the bathroom, in the kitchen, and also as a base for ceramic tiles. In this type of drywall, both the core and the cardboard itself are treated with a composition that prevents moisture absorption, so you will not have problems with mold and mildew. Moisture resistant sheets are often between 2500mm and 4000mm long, 1200mm wide and 9.5mm to 15mm thick.

3. Fire-resistant plasterboard sheets are painted in beige color and red lettering. Most often, this type is used in rooms that have special fire safety requirements, as well as to build attic spaces. It is necessary to pay attention to the fact that the core of such drywall has additional reinforcement, which includes at least 0.2% of the total weight of all fiberglass threads having a length of 3 to 30 mm. Thanks to this, it can maintain its integrity much longer in the event of a fire.

Drywall composition

Diagram of the structure of a plasterboard sheet.

Drywall is made from gypsum, which is covered with cardboard. Gypsum is an important component of this building material. It is this that gives gypsum board such important properties as density and strength. In order to improve quality, certain components are introduced into gypsum. An important part of a drywall sheet is the cardboard. It is used not only for the frame. It is also necessary to provide protection. Cardboard protects the gypsum core from all kinds of damage. Cardboard is great for finishing walls with materials such as paint, plaster and tiles.

One sheet of gypsum board consists of approximately 92% gypsum dihydrate and 7% cardboard. Surface-active substances, starch, and moisture make up 1% of the total mass of the leaf.

Consumers are often interested in whether drywall is dangerous.

GCR is an environmentally safe material. It is made from absolutely natural raw materials. There are no harmful components in it. The product has unique properties - it is hard and at the same time very flexible. That is why it is so valued.

Technical characteristics of Knauf plasterboard

With the advent of drywall, ideas that were previously only dreams began to be realized. Drywall is the material used to level ceilings and walls, make niches with lighting, oddly shaped furniture, and create multi-level figured ceilings. This building material can be used in the bathhouse, in the bathroom and outdoors. There are many companies on the construction market offering drywall of different markings, but the Knauf brand has occupied the highest level of trust and quality.

Knauf plasterboard is distinguished by its technical characteristics; it is more practical, durable, and justifies such indicators as: environmental friendliness, heat resistance, moisture resistance.

It is “Knauf” that is chosen to create curved ceiling shapes, arches, and serves as the basis for tiles on a gypsum plasterboard fireplace. This brand produces metal profiles, fasteners, hangers, mixtures and other materials and components for drywall.

Full contents of the material

What to look for when choosing drywall

It is necessary to store drywall in a heated and warm room.

During the purchase process, it is imperative to check the integrity of each sheet. The product must not be deformed or broken. Metal profiles must be selected from high-quality material, the required thickness and rigidity, since the quality of the entire structure depends on the strength characteristics of the frame. Excessively soft profiles bend and break during installation, which only prolongs and complicates the process of fixing the sheets. If necessary, the standard sheet size can be replaced with a more suitable one in a personal order.

Key recommendations from experts when choosing:

- In large and trusted construction stores, products generally do not sit in warehouses for a long time, thanks to this the level of quality is much higher than in construction markets.

- If such a possibility exists, check the storage conditions - increased temperature and humidity conditions in the room are considered the main reason to refuse to purchase.

- Examine each sheet for compliance with the stated characteristics and the presence of various defects.

Composition of plasterboard sheet

Knauf plasterboard is produced in large sheets with rounded borders. Knauf sheet production technology:

- the center of the sheet in thickness is gypsum;

- sheet plane – cardboard;

- specially processed paper on cardboard.

In order for drywall to meet its technical characteristics depending on its purpose, special agents are added to the composition of the gypsum. To differentiate, plasterboard sheets are painted in different colors.

When purchasing drywall, you should take into account the color of the sheet, its thickness, and markings.

Manufacturing technology

If you decide to purchase the material described in the article, you should be familiar with the Knauf technology. Drywall is made according to it in several stages:

- At the first stage, a mass of gypsum is formed, which is mixed with additives and fillers. The composition is placed between sheets of cardboard.

- Next comes gluing and folding.

- The sheets are dried, cut and packaged.

- Sometimes additional processing is required. In this case, antifungal compounds are applied to the canvas. That is why the material can be used in poorly ventilated areas.

Types and sizes of Knauf plasterboard

Based on the marking of drywall, its purpose is different. According to technical characteristics, the following types of gypsum boards are distinguished:

- Moisture-resistant plasterboard "Knauf" - GSP-N2. Special agents have been added to the composition of the gypsum, with the help of which the gypsum does not swell and does not absorb moisture. With these indicators, this drywall can be installed in the bathroom, toilet, balcony and other damp places. Moisture-resistant drywall has a green leaf color. The rounded shapes of the sheets allow for close contact with each other during installation, which will not provoke the appearance of cracks. You can buy moisture-resistant drywall both on the market and at a specialized Knauf sales point - 280 rubles.

- Fire-resistant plasterboard – GSP-DF. Reinforcing layers have been added to this drywall. In the event of a fire, reinforcing inserts stop the spreading fire. The cardboard is treated with a special glue that prevents the penetration of moisture when extinguishing a fire. Fire-resistant drywall can be purchased for RUR 500. per sheet.

- Acoustic - arched plasterboard is treated with fiberglass. It is a flexible sheet, durable with excellent insulating properties. The thickness of the sheet is on sale from 5 cm to 10 cm. To completely absorb sound, the sheet comes with perforations. There are also sheets with stripes and holes. This drywall costs 800 rubles. per sheet.

- Perforated plasterboard sheet is a combination of fire-resistant and moisture-resistant gypsum. It consists of several mixtures that perform several functions.

- Floor plasterboard and dry type TIGI board. Sheets of plasterboard are used to finish the floor; with the help of this plasterboard, the floor becomes perfectly flat, ready for further finishing. To install these sheets, glue is used to ensure the resistance of the drywall to external influences on it.

Color range of drywall and its markings:

- GKL – gray – blue;

- GKLV - green - blue, plasterboard weight - 25 kg, Knauf plasterboard sheet size - 2500x1200x12.5, 3000x1200x12.5;

- GKLO – gray – red. The weight of the plasterboard sheet is 30.6 kg, the size of the plasterboard sheet is 2500x1200x12.5;

- GKLVO - red - red, drywall weight - 25 kg, sheet size - 2500x1200x12.5.

The sheets have different weights and thicknesses. Heavier drywall is mounted on the floor and walls, on a rigid frame. Lightweight sheets of plasterboard are mounted on the ceiling. When working with drywall, you should calculate it for one room. To do this you need to use a calculator.

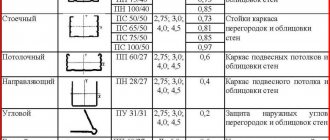

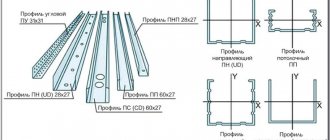

Profiles for drywall

The installation of sheets should begin with the installation of the frame, which requires metal profiles. A profile is an important detail, without which it is impossible to carry out high-quality construction of partitions, wall alignment, and ceiling cladding. For the production of profiles, cold-rolled metal sheets are used. The metal is pre-galvanized - this processing method allows you to obtain strong and reliable metal products that have a long service life and are not subject to corrosion.

The metal frame used for working with drywall is characterized by a lightweight design, which consists of horizontal (guides) and vertical (rack) elements.

Vertical profiles

Rack profile (PS)

Rack profiles (ceiling, also labeled as CD or PP profiles) are load-bearing elements of the frame structure, thanks to the optimal selection of which you can use the workspace expediently and economically. During work in rooms of various sizes, the amount of waste is minimal. There are the following sizes of supporting profiles: length – 2500 – 4000 mm, sheet width – 60 mm; shelf height – 27-28 mm.

Horizontal profiles

Horizontal profile (CH)

UD profiles or ceiling guide profiles (CNP) - horizontal or starting frame parts. When performing wall cladding work or creating a suspended ceiling, it is necessary to install these elements around the entire perimeter of the room. It is recommended to use perforated profiles to simplify the passage of drilling tools through them. The dimensions of the starting profiles are: length - 3 meters, height - 2.8 cm, width 2.7 cm. The thickness of the horizontal elements is 0.55 mm.

Arched profiles

Arched profile (PA)

These profiles are presented in curved and concave form. They are used when it is necessary to form a complex type structure with various bends. However, sometimes experts use ceiling profiles for these purposes. Arched profiles have cuts located along the edges; with their help, the profile can be given the desired shape.

Parameters of concave profiles: radius 0.5-5 m, length 2.6-4 m. Dimensions of curved profiles: radius 1-5 m, length 0.4-2.6 m.

Corner profiles

Corner profile (PU)

A corner or corner-protective profile is necessary to protect the corners and ends of partitions made of plasterboard from mechanical injury. There are special holes on the surface of the profile for penetration of the finishing solution. The corner profile is 3 m long and has different sections: 2.5x2.5x0.04 cm, 3.1x3.1x0.04 cm and 3.1x3.1x0.05 cm.

In addition, the following components are still needed for installing drywall:

- Corner connectors. They allow you to make a perpendicular connection of the profile to another rail.

- Anchor hangers. Mainly used for ceiling finishing. Connect the base and the ceiling.

- "Crabs" Connect the ends of the profile into a single-level plane.

- Profile extensions. They are installed inside the profile using self-tapping screws and are designed to extend the rail.

- Two-level connectors. Connect the frame strips crosswise.

- Direct hangers. They are the main elements of the frame and are a rectangular plate. The racks will be connected to the load-bearing floor.

Corner connector

Anchor suspension

Crab connector

Rail for extending the profile strip

Two-level connector

Suspension

Drywall installation

The technology for installing plasterboard sheets is practically no different from the installation process for other brands of Volma gypsum boards. Preparatory work includes:

- Cleaning the covering of a wall or ceiling.

- Treatment with primer or other antiseptics.

- Sealing cracks.

- Marking.

Knauf brand plasterboard can be installed by a person without experience. You should adhere to the algorithm of actions and not rush.

Algorithm for installing KNAUF moisture-resistant plasterboard on a wall and partition:

- Initially, you should select the type of frame. The guide profiles are installed first. They must be made of durable and rigid material, the dimensions of the profiles are ambiguous. Their range is great. After this, the racks and transverses are installed.

- Profiles for plasterboard of the Knauf brand can be metal or wooden bars.

- There are two frame options. In the first option, the profiles are attached to the wall. This is a rigid and durable design. The second option is that the profiles are mounted on special hangers. The frame turns out to be “walking”. This frame is very convenient for finishing walls in wooden houses.

- The created frame is filled with mineral wool, insulation and other soundproofing materials. This ensures warmth in the apartment, as well as silence.

- Installation of drywall is carried out using special self-tapping screws for drywall. The number of screws can be easily calculated using a calculator.

- When installing drywall to the frame, first whole sheets are mounted, then cut pieces.

- Self-tapping screws for fastening gypsum boards are screwed in with a screwdriver every 25 cm.

- After covering the frame, the drywall seams should be sealed. Prime the surface and putty. Putty for drywall is required based on gypsum.

- The last step before gluing wallpaper or other types of decor is to rub the dry surface with sandpaper and coat it with a primer again.

Installation basics and necessary tools

If the room has perfectly flat surfaces, the material can be fixed using a specially designed adhesive composition based on gypsum.

Before installing drywall sheets on uneven surfaces, it is necessary to install a frame. It can be built from wooden slats or made from ready-made metal profiles. The sheets are attached to the frame using screws.

For complex structures, the material is pre-moistened with water for greater flexibility and only then attached to the frame. Moistening can be done using a special roller with needles.

Working with drywall

Plasterboard sheets can be easily cut with a regular knife (preferably sharp) and can be sawn well, in addition to being flexible. Using special tools, you can cut out parts of any size and shape, as well as make the necessary holes in them. The fact that marking and cutting holes, for example, for sockets and switches, is possible outside the installation site, allows us to significantly reduce the time required for work.

If we compare finishing with plasterboard with finishing with plaster and putty, it is obvious that in the first case the work is completed twice as fast. With high quality, labor costs are reduced threefold in the manufacture of interior partitions if Knauf plasterboard is used. Knauf gypsum plasterboard sheets are mounted using accompanying materials, such as screws of various sizes, gypsum glue, tapes for sealing, etc.

Using drywall

In addition to interior decoration, flat sheets of plasterboard are widely used to level out uneven walls, which is why gypsum board is also called dry plaster. When working with gypsum plasterboard sheets, processes involving the use of water are eliminated, which simplifies the work and reduces its cost, making plasterboard even more attractive for both professionals and beginners in the field of construction and repair.

The lack of debris also makes working with drywall much easier. Not to mention the fact that finishing work carried out using this material can significantly save money and time. In our country, the Knauf gypsum board is most often used, the technical characteristics of which distinguish it favorably from a number of similar ones from other manufacturers.

In addition to gypsum plasterboard (standard plasterboard sheets), waterproof and fire-resistant sheets are produced. Moisture-resistant plasterboard sheets are used mainly in bathrooms and kitchens. When finishing communication shafts and air ducts, fire-resistant Knauf gypsum boards are used, the technical characteristics of which easily allow this.

In the manufacture of drywall, burnt gypsum is also specially used, which ultimately makes it possible to obtain tongue-and-groove slabs. They are highly durable and therefore are often used in the construction of interior partitions. Such slabs do not require any preliminary preparation before finishing. Partitions are made one-, two- and three-layer. Tongue-and-groove slabs are especially relevant in areas with unstable seismic conditions. Cables, dust removal systems, heating or plumbing communication systems are laid in the cavities located inside such slabs.