The reputation of Knauf drywall dates back to 1958, when the German company of the same name introduced new products to customers. Since that time, it has grown to become the world's largest manufacturer of plasterboard with technical characteristics that have become the standard. In 1993, the company expanded its activities in Russia, opening a lot of enterprises with modern equipment, uniform technologies and quality standards. Practical Knauf plasterboard, designed for quick and high-quality finishing of premises, is not stocked in construction stores.

Brand Features

Pros of Knauf drywall:

- simple and quick installation;

- Treatment of gypsum boards with water is excluded from the technology;

- there are no “dirty” operations during finishing;

- allows air to pass through and is resistant to fungus formation;

- gypsum has lower thermal conductivity than plaster, it retains heat better;

- affordable.

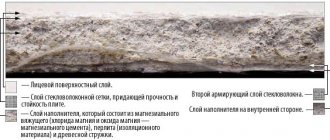

Without going into technical details, a plasterboard sheet is a layer of gypsum enclosed on both sides in a cardboard covering. This was the first drywall. Since then, this material has come a long way to improve. Now there are several modifications of drywall for different applications.

Knauf sheet

Let me remind you that KNAUF plasterboard sheet is technically correctly called KNAUF-sheet. By design, it is a sheet building material, rectangular in shape. The outer and inner sides of the sheet are layers of special cardboard. For some brands of sheets, cardboard is supplied from Germany. The colors of the outer and inner layers of cardboard differ in color. KNAUF sheet markings are applied to the inside of the sheet.

Between the sheets of cardboard there is a core of gypsum binder. The full composition of the core, as well as the technology for placing it between layers of cardboard, is kept secret.

KNAUF-list (GSP-A)

In rooms where humidity and temperature are within normal limits, this type of drywall is used most often. It is inexpensive, cuts well and takes the given shape. It is attached not only to the profile, but also with glue. “Friends” with any type of finishing materials: it is covered with wallpaper, painted, covered with tiles, decorative stone. The ceiling version (9.5 mm thick) allows you to easily install modular lighting. Despite all its technical advantages, it remains an environmentally friendly material.

The gray sheet of GSP-A resembles a kind of sandwich of 2 layers of special cardboard, between which a gypsum core with reinforcing additives is placed. The edges are also covered with cardboard and have a semicircular thinned shape, in which a reliable, tight joint between the sheets is guaranteed.

Sheet material selection criteria

Photo: KNAUF. Installation of a prefabricated floor base made of small-format KNAUF supersheets (GVLV) with a straight longitudinal edge

The choice of a specific sheet material is determined by many factors. For example, in country houses of permanent residence it is practically unlimited. It is only important to take into account the specific operating conditions of the sheets for finishing. For rooms with normal humidity, regular gypsum plasterboard is suitable, with higher humidity, as in bathrooms and kitchens, gypsum plasterboard.

In homes for seasonal residence, it is advisable to pay attention to the frequency and duration of these periods, say a six-month stay from spring to autumn or a vacation every weekend throughout the year. If, in the absence of the owners, the minimum required temperature of +5 ° C is maintained for a week, it is permissible to use moisture-resistant drywall.

If the temperature in the house is not much higher than the street temperature, experts recommend using GVLV. They withstand fluctuations in temperature and humidity without significant deformation. Note that slight increases in geometric dimensions with increasing humidity are a natural process not only for gypsum plasterboards, but also for gypsum fiber boards, but in the latter it is significantly less. In such close to “extreme” conditions, they will last longer and will be a more stable and reliable basis for finishing.

In corridors, storerooms, and boiler rooms, the impact resistance of sheet materials is important. GVL, as a harder, more durable material, can withstand loads and accidental impacts without significant consequences, which means it increases the repair-free service life of the finish.

Photo: ShutterStock/Fotodom.ru. Before installing the sheets, wiring and other communications are placed in the frame cavity. This process is much simpler and faster than labor-intensive wall gating

Accuracy comes first

Often, craftsmen who are accustomed to working with plasterboard, when switching to gypsum fiber sheets, increase the amount of damaged material. The fact is that drywall forgives a rather careless attitude during transportation and installation, mainly due to the cardboard lining. Whereas gypsum fiber sheets are a harder material. Claddings and partitions made from it can withstand increased mechanical loads; heavier objects can be hung on them, however, gypsum fiber sheets should be handled more carefully and carefully during transportation and installation.

On site, gypsum fiber sheets and drywall should only be stored horizontally (flat) on a flat surface.

The basic principles of working with gypsum fiber sheets are identical to working with plasterboard. For installation, the same metal profiles are used: racks and guides. But for attaching gypsum fiber sheets to frames, there are special self-tapping piercing or drilling screws with a double thread and a countersinking head. Professionals know this. But amateur craftsmen may mistakenly use ordinary drywall screws. However, it will not be possible to drown them in the solid body of the sheet. The hats will protrude. And so that they do not show through the finishing layer of paint or wallpaper, the surface will need to be leveled with a fairly thick layer of putty. You won’t have to spend time and money on additional work if you purchase screws designed for gypsum plasterboard with special threads and a reduced head.

Andrey Udalov

Product manager for dry construction at KNAUF

Installation of gypsum board cladding

7 photos

Photo: Saint-Gobain. The guide profile, with a sealing tape pre-glued to the underside, is attached according to the markings to the floor and ceiling

Rack profiles are cut 10 mm less than the height of the room and installed

If necessary, electrical wiring placed in protective corrugated pipes is passed through the technological holes in the profiles

Fill the frame cavity with heat and sound insulating material

Sheets of plasterboard, cut 10–15 mm less than the height of the room, are fixed to the frame with self-tapping screws for gypsum boards

After finishing the covering, the heads of the screws and the joints of the sheets are puttied. Reinforcing paper tape is laid along the joints and puttyed again. After the putty has dried, the places where the sheets are fixed and the seams are sanded.

The surface is dust-free and finishing is started.

Knauf-sheet moisture-resistant (GSP-N2)

This type of drywall is used for the same purposes as regular drywall, but in rooms with high humidity. It absorbs 90% less water than an ordinary one. Moisture-resistant KNAUF sheets (GSP-N2) of green color are distinguished by specific additives:

- antifungal compounds protect the material from mold, the appearance of which is inevitable in a damp room with poor ventilation;

- the waterproofing solution does not let water inside the material;

- polymer impregnation reduces the absorption rate.

USEFUL INFORMATION: Design of a two-level plasterboard ceiling for the kitchen: 12 photos

The physical and hygienic properties of this type of gypsum board make it an ideal material for residential premises.

Moisture-resistant plasterboard is a win-win option for bathrooms, kitchens, toilets, finishing loggias, balconies, door and window openings and even basements, attics, and pool rooms.

Read more about the properties and scope of application of moisture-resistant types of drywall here.

Gypsum fiber sheet

Gypsum fiber sheet (GVL) is a pressed board made from a mixture of gypsum binder and fluffed cellulose fibers evenly distributed in it, which play the role of reinforcing elements. The material is hard, durable, and has excellent fireproof and soundproofing properties. It is used for cladding walls, ceilings, decorating door and window openings, and creating partitions.

For places where the material must withstand the effects of moisture during periodic wetting and drying, moisture-resistant gypsum fiber sheets (GVLV) are intended. Their front and back surfaces have increased resistance to moisture penetration. Compared to plasterboard, gypsum fiber sheets have increased strength. Therefore, they are used as a base for finishing floor coverings in rooms with dry or normal humidity conditions. When finishing an attic in a wooden house, it is GVL that will ensure a high degree of fire safety, as well as simplicity and reliability of the structure.

Typical gypsum plasterboard sizes: 2500 × 1200 × 12.5/10 and 1200 × 1200 × 10 mm. Small-format sheets are convenient for floors where it is important to control the evenness of the base, and in small areas it is more convenient to do this. They produce gypsum fiber sheets (trademark Gyproc), USG. The price of a sheet 2500 × 1200 × 12.5 mm is from 470 rubles.

Knauf-sheet fire-resistant (GSP-DF)

The fire-resistant type of plasterboard is intended for heat-resistant coatings and structures, be it wall cladding, partitions, suspended ceilings in buildings where humidity does not exceed regulatory requirements.

Tests conducted by the Russian Research Institute of Fire Defense of the Ministry of Emergency Situations showed that Knauf plasterboard sheathing practically behaves like an ordinary non-combustible material.

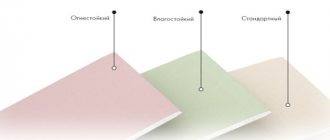

The front side of the product is painted pink, the back side is gray.

All the features and applications of heat-resistant drywall are described in this article (plus a fire test video).

How the marking of KNAUF sheets has changed

It can definitely be said that with the change in marking, the quality and characteristics of the sheets were not affected; it is likely that the declared supplies of cardboard from Germany improved their quality.

New marking of gypsum board sheet

The old designation GKL, a simple plasterboard sheet, was replaced by GSP-A.

According to its intended purpose, it is still the same material for construction and finishing, used for cladding interior walls of premises, installing non-load-bearing partitions and various types of suspended ceilings. In addition, it is used for the construction of decorative structures and sound absorption.

Note: All main production Knauf sheets are made with a PLUK edge, which means a semicircular thinned edge. An edge is made on the outside of the sheet and allows for better puttying of the sheet joints.

Other types of edges (flat, semicircular) are produced only to order and are quite difficult to find on open sale.

New marking of GKLV sheet

The old marking GKLV, which designated a moisture-resistant plasterboard sheet, changed the marking to GSP-N2.

In terms of purpose, this is still the same sheet building material used for cladding interior walls of premises, constructing non-load-bearing partitions and various types of suspended ceilings, BUT in rooms with high humidity.

You can distinguish a moisture-resistant sheet by the color of the cardboard. Unlike the gray color of a simple leaf, it is pale green.

Old GKLO marking

GKLO sheet meant a sheet with increased resistance to combustion, in other words, a fire-resistant sheet. New marking of GKLO, GSP-DF sheets. Reads like a GSP sheet type DF.

A distinctive feature of these types of sheets is the increased resistance of the core to fire. That is why they are used for cladding walls, installing partitions and suspended (suspended) ceilings in rooms with a high fire hazard. In addition, they are actively used for fire protection of walls and ceilings.

Old marking of GKLU sheets

The old marking of GKLU sheets meant reinforced plasterboard sheets. New marking for this type of sheet is GSP-DFH3IR.

This type of sheet is distinguished by increased core density, moisture resistance, fire resistance and impact resistance. In essence, this is an elite sheet of drywall that has absorbed all the qualities of the sheets described above. In addition, registered sheets of GSP type DFH3IR are lined with cardboard produced in Germany. It is blue.

Knauf-sheet moisture- and fire-resistant (GSP-DFH2)

It is more expensive because it combines moisture resistance and fire resistance. It provides a favorable microclimate for living and working. Its breathable sheets regulate indoor humidity. Does not contain toxic components, has an acidity similar to that of human skin. Cardboard color is green. The quality of GSP-DFH2 meets international standards.

Reference: heat-resistant and moisture-resistant gypsum plasterboards can resist open fire for at least 20 minutes.

KNAUF impact-resistant sheet (GSP-DFH3IR)

GSP-DFH3IR combines increased density with moisture and fire resistance, has increased strength and impact resistance. This universal material is used in rooms where the most stringent requirements are imposed on the finishing, including sound insulation.

For production, a special blue facing cardboard is used. The use of such cardboard with increased weight increases the bending strength of the sheet. For high-quality finishing, KNAUF sheets GSP-DFH3IR are the best option.

Addition

By the way, the markings and design of the branded KNAUF rack profiles have also changed. Now it is in Russian, on board the profile.

©Gipsokart.ru

More articles

- Important classification of drywall

- Moisture-resistant drywall

- Plasterboard sheet Gyprok, Types and characteristics

- The marking of KNAUF sheets has changed: KNAUF sheet GSP

- How to glue drywall to a wall

- How to cut drywall by hand

- Which Knauf sheets to choose for repairs and finishing

- Drywall sheet

- What to use to glue drywall to the wall

- Basic terms

KNAUF-acoustics - large-format sound-absorbing panel

These are plasterboard sheets with perforations. Suitable for rooms with normal humidity. Through holes serve as resonators: the sound wave falls into a kind of trap and gradually fades. The noise-absorbing effect is further enhanced by a layer of non-woven fabric on the back side of the sheet. Depending on the design of the room, the canvas can be white or black. Perforation patterns have several options, depending on which gypsum boards differ in the degree of sound absorption.

Tests have shown that the noise absorption coefficient of KNAUF-acoustics plasterboard reaches 0.2. This is a very worthy indicator.

Perforation, in addition to sound dampening, has a memorable, stylish appearance. This is confirmed by all the photos illustrating the use of Knauf acoustic plasterboard. The company's products allow you to choose from several options with different types of holes: round, square, scattered round.

USEFUL INFORMATION: GKL sheet - what is it? Dimensions and thickness, types of material

Such drywall creates real acoustic comfort, which is necessary in schools, universities, concert halls and many other public institutions, residential buildings, not to mention industrial premises. Installation of a ceiling or wall covering with such sheets is carried out at an accelerated pace, without significant labor costs.

Help: acoustic plasterboard reduces the level of noise in the room itself, reduces booming, fights the echo effect, and improves speech perception. But you shouldn’t count on soundproofing results - it won’t protect you from loud neighbors.

The features of acoustic drywall are described in more detail here.

What brand of drywall do you use?

Installation technology

The installation instructions for Knauf drywall are not much different from the installation technologies for other materials of this type (Volma, Magma). Before starting the work process, you need to prepare the wall. It is cleaned of old coatings, treated with primers and other protective compounds. If there are cracks and deep depressions, it is additionally plastered (you do not need to use putty).

Guides for Knauf

Step-by-step instructions on how to install moisture-resistant drywall from Knauf on walls and partitions:

- The first thing to think about is the structure of the frame. First, vertical supporting profiles are installed. They are wide metal guides made of steel. It has excellent rigidity and strength. After this, horizontal profiles are installed on top of the racks. Their pitch is determined based on the type of drywall and the area of work;

- The Knauf plasterboard profile can be used both metal (alloy steel) and wood. The standard diagram for a steel structure looks like this;

Frame diagram - By the way, there are two options for the frame: static and suspended. Static is attached directly to the wall; it is considered the most reliable and practical. The hanging one is installed on special hangers that allow the frame to “walk” along the wall. This is convenient for wooden houses in which the wall level may vary depending on the time of year and period of use;

- Hollow parts of structures must be filled with mineral wool or any other available material. This will reduce the thermal conductivity of the walls and also provide additional sound insulation;

- To install these building materials, you need to use special fasteners. Most often, self-tapping screws are used to attach cardboard to the frame. They allow for reliable and quick connection of individual parts of the structure;

- The cladding is carried out with standard sheets. It is recommended to trim them only when absolutely necessary. To do this, you need to run a hacksaw along the inner surface of the sheet, and then break the sheet at the point of the cut. The end is treated with a primer and leveled. This is necessary to obtain even and tight seams during further fastening;

- You don't need any special tools to install the sheets. To successfully carry out installation, you will need a level, a screwdriver, and a hacksaw. The pitch of the screws should be no more than 25 cm. The average calculation is 8 screws per sheet of Knauf drywall. The components cut into the structure strictly at an angle of 45 degrees;

- Damper tape is installed along the seams, which is then plastered. This will ensure even and smooth joints, completely ready for further processing. By the way, putty is necessary only at the junctions of individual panels;

Grouting example - Drywall does not need finishing, except for priming. In some cases, craftsmen also completely plaster it, but with the right choice of soil, even this technological process may become unnecessary. This sealing will improve the quality of the material and provide it with additional protective functions;

- After this, the installation sites of the screws are rubbed down and further processing of the cardboard is carried out. This could be painting, laying slabs, decorative stone, or wallpapering.

Video: Knauf plasterboard ceiling installation technology

Purpose and dimensions of KNAUF plasterboard

Building codes and regulations (SNiP) allow the use of Knauf plasterboards:

- when decorating walls indoors;

- for the construction of suspended ceilings;

- for the manufacture of all kinds of figures, decorative elements;

- for arranging arches and various partitions.

All types of Knauf plasterboard sheets have a rectangular shape and are manufactured in accordance with GOST 6266-97, fully meeting the requirements of the German standard DIN 18 180. Their feature, which ensures manufacturability and reliability, is a thinned semicircular edge, which has proven itself at joints.

GKL are divided into wall, ceiling, arched:

- Sheets with a thickness of 12.5 mm are usually used for finishing walls and installing partitions.

- To create ceilings, you can use plasterboard with a transverse dimension of the same 12.5 mm. But it is heavier and more expensive than 9.5 mm thick sheets specially designed for ceilings.

- 6.5 mm plasterboard is best suited for constructing arches or other structures with a shape other than rectangular.

USEFUL INFORMATION: How to glue serpyanka to drywall: sealing the seams with mesh

Size options:

- sheet length – 2000–4000 mm (in increments of 50);

- width - 600 and 1200 mm;

- thickness depends on the purpose of the product and is 6.5, 8, 9.5, 12.5, 14, 16, 18, 20, 24 mm.

Stages of drywall installation

It was already mentioned above that, like all manufacturers, Knauf’s technology for installing drywall is divided into two methods.

With glue

Everything will depend on the difference in the plane being processed. If this indicator varies within 2-5 mm, then the gypsum board sheets themselves are directly glued to the surface. For this, Perflix adhesive is used. It is simply applied in small slides to the back surface of the panel along the entire perimeter and in the middle along the sheet every 30-50 cm.

After which the sheet is applied to the wall and pressed with hands. You can move it for a few minutes to align it with the wall.

If the difference is large, then a frame is made from strips of plasterboard 10 cm wide on the wall, which is aligned in the plane of the wall, covering the difference. It is on this frame that the gypsum board sheets themselves are glued.

Using profiles

This option applies to any difference. This is a more complex process, especially when it comes to the technology of installing Knauf plasterboard on the ceiling. The algorithm of actions is as follows (we are talking about the ceiling):

- The level at which the ceiling structure will be constructed is determined. What is a laser level used for?

- A Knauf ceiling guide profile is installed along it (along the perimeter of the room).

- A breakdown is made on the ceiling itself, where the installation locations of the frame elements are determined. Typically these are lines every 60 cm.

- Direct suspensions are installed along them every 50 or 60 cm to the ceiling.

- PP ceiling profiles are attached to the hangers, the edges of which are inserted into the guides.

- All PCBs are aligned in one horizontal plane and fastened to the hangers with self-tapping screws.

- Every 40 or 50 or 60 cm, crossbars cut from PP are installed. They are attached to full PP profiles either with self-tapping screws, or with special parts that craftsmen call crabs.

- The frame is ready, you can proceed to the installation of drywall.

Back to contents↑

Marking

Each sheet of plasterboard produced by the company has its own designations, including:

- the standard to which it was manufactured;

- dimensions;

- information about the type of side edge;

- letter designation of the type of drywall.

For example, a moisture-resistant sheet with a standard size semi-circular thinned edge will be marked as follows:

GSP type N2 GOST 32614-2012 (EN 520:2009) PLUK 12.5-1200-2500

KNAUF moisture-resistant sheet (GSP-N2) is a gypsum building board whose core contains additives that reduce water absorption. Construction and finishing moisture-resistant material for wall cladding, partitions, suspended ceilings, as well as for the manufacture of decorative and sound-absorbing products in rooms with high humidity.

KNAUF moisture-resistant sheet (GSP-N2) is a rectangular material that consists of two layers of special cardboard with a layer of gypsum dough with reinforcing additives, while the side edges of the strip are folded with the edges of the cardboard (front layer). To form the core, gypsum binder grade G4 is used according to GOST 125-79.

KNAUF moisture-resistant sheets (GSP-N2) are produced in accordance with GOST 32614-2012 (EN 520:2009)

Knauf moisture-resistant sheets (GSP-N2) are produced with a semicircular thinned edge (PLUK), which is the most technologically advanced in terms of joint reliability. By agreement between the manufacturer and the consumer, it is possible to produce sheets with other types of edges. They differ from conventional KNAUF sheets due to the use of hydrophobic additives in the core material.

On each KNAUF moisture-resistant sheet (GSP-N2) there is a symbol, which consists of:

- Letter designation of the slab type - GSP-N2

- Standard designation

- Designations for the type of longitudinal edges of the sheet

- Numbers indicating the nominal length, width and thickness of the sheet in millimeters

An example of a symbol for a gypsum building board with a semicircular thinned edge, 2500 mm long, 1200 mm wide and 12.5 mm thick:

Gypsum building board GSP type N2 - GOST 32614-2012 (EN 520:2009) PLUK 12.5-1200-2500.

Application

It is used for the installation of lightweight interior partitions, suspended ceilings, wall cladding and fire protection of structures in buildings and rooms with high humidity, providing exhaust ventilation and subject to protection of the front surface, for example: waterproofing, waterproof primers, paints, ceramic tiles.

It has reduced moisture absorption due to the use of hydrophobic additives in the core material.

The application process includes the following main stages of work.

- Marking the design position of a structure made of KNAUF moisture-resistant sheets (GSP-N2)

- Installation of a frame made of KNAUF profiles for fastening KNAUF moisture-resistant sheets (GSP-N2)

- Installation and fastening of KNAUF moisture-resistant sheets (GSP-N2) on the frame

- Sealing of seams between KNAUF moisture-resistant sheets (GSP-N2) and recesses from screws with KNAUF-Fugen putty

- Priming the surface for finishing coatings

Recommendations

- Installation should be carried out during the finishing work (in winter with the heating connected), before the installation of clean floors, when all “wet” processes are completed and the electrical and plumbing systems have been installed, under dry and normal humidity conditions in accordance with SNiP 02/23/2003 "Thermal protection of buildings." In this case, the room temperature should not be lower than 10°C.

- Before installation, Knauf moisture-resistant sheets (GSP - N2) must undergo mandatory acclimatization (adaptation) in the room.

- The end edges of Knauf moisture-resistant sheets (GSP - N2) have a rectangular shape and when making a seam it is necessary to chamfer them (approximately 1/3 of the sheet thickness).

Advantages

- When using KNAUF moisture-resistant sheets (GSP-N2) during finishing work, inconvenient “wet” processes are eliminated.

- Labor productivity increases significantly.

- It is possible to implement unlimited in design, multi-variant architectural solutions, including the arrangement of curved surfaces.

- Overall savings in construction costs are achieved by lightening the building structure.

- Not only environmental cleanliness is ensured, but also a microclimate in the room that is favorable for humans.

- The material does not contain toxic components and has an acidity similar to that of human skin.

- It has reduced moisture absorption due to the use of special cardboard and hydrophobic additives.

- It has the ability to breathe, that is, to absorb excess moisture and release it into the environment when there is a deficiency.

- Meets strict global standards.

Specifications

| Cardboard color | green |

| Marking color | blue |

| Edge type | PLUK (semicircular thinned edge) |

| Main Dimensions | 2500x1200x12.5 mm |

| Weight of plasterboard KNAUF sheet size 2500x1200x12.5 mm (3 sq.m) | 29 kg |

| Package | Bag, 50 sheets (150 m2) |

Nominal geometric dimensions of KNAUF sheets

| Length, mm | Width, mm | Thickness, mm |

| From 2000 to 4000, in 50 mm increments | 600/1200 | 6, 5/ 8 / 9,5 / 12,5 / 14 / 16 |

Fire technical characteristics

KNAUF moisture-resistant sheets (GSP-N2) according to their properties belong to the following groups:

- G1 (flammability according to GOST 30244)

- B2 (flammability according to GOST 30402)

- D1 (smoke generating ability according to GOST 12.1.044)

- T1 (toxicity according to GOST 12.1.044)