Smooth floors are the key to a long service life of the floor covering and the absence of distortions in furniture and other interior items standing on the base. Achieving a perfectly flat floor surface in an apartment is not so difficult if you know how to do it. Many people will immediately remember about pouring a cement screed, but the base can be leveled without using this time-consuming and costly method. You can use GVL for the floor, which is especially important for those types of bases that are contraindicated for high loads.

GVL for floors

GVL for floors

Before we talk about how to level floors using gypsum fiber board, you should take a closer look at this material. The abbreviation "GVL" stands for gypsum fiber sheet. Unlike drywall, the material does not have a cardboard shell. It is not difficult to guess that GVL is a material based on gypsum mixed with various modifying and reinforcing additives, including ordinary cellulose. Each sheet is impregnated with a water-repellent agent, which acts as a kind of primer. The result of the entire production technology is large or medium-sized white sheets that have a uniform structure, are quite strong and reliable, non-flammable and have low thermal conductivity.

GVL sheets

On a note! Interestingly, gypsum fiber sheet is a kind of “descendant” of dry plaster.

Comparison of GVL with analogues

GVL is often confused with drywall, but these are two different materials. The first is significantly superior to the second in its technical characteristics - for example, in density. After manufacturing, each gypsum fiber board sheet undergoes a series of tests for suitability and absence of defects, only after which the material receives a certificate of conformity, which can be requested from the seller upon purchase.

Gypsum fiber sheet

Why is plaster still relevant, although there are gypsum fiber sheets and gypsum boards

It would seem that this finishing material should have long ago and hopelessly lost its position as morally obsolete. However, it continues to be used, and in the eternal rivalry, which is more reliable and better: plaster, gypsum fiber sheet or gypsum board, confidently holds on par with its competitor. And all because he has some qualities that are inaccessible to him.

- If the plastering work is carried out at the proper level, you won’t have to return to it again for about 30 years. Yes, you will change the wallpaper, re-paint or re-tile the tiles, but there will be no need to restore the base.

- The high cost of plastering work is the main argument when choosing between plaster and gypsum fiber sheets. However, this is a myth, blown out of proportion. The work of a professional, naturally, is not cheap. However, drywall experts will also cost you a pretty penny. But in terms of consumables, plaster is simply incomparable. If we consider impartially, it will cost 2-2.5 times cheaper than the famous designs.

- When choosing between plaster or gypsum fiber sheet, first of all you should think about the reliability of the resulting surfaces. The first one is shock resistant and absolutely indifferent to water. The second one can be broken by hitting it well with your elbow, but moisture causes it to swell and become deformed.

- The main advantage of plaster is that you can safely attach any heavy objects to it, from air conditioners and water heaters to heavy bookshelves and cupboards.

However, nothing is perfect in the world. The gypsum fiber sheet strengthens its position due to the inherent disadvantages of plaster.

- Plastering is a dirty process that requires cleaning, and not only in the room where the work is being done: traces of it somehow spread unnoticed throughout the apartment.

- An important argument against plastering is the delay in time. Before you begin the final finishing, you need to wait until it dries.

- With large defects in the walls, it is extremely difficult to achieve their smoothness with a layer of plaster.

- And the main thing: without being a professional builder, you are unlikely to be able to accurately determine how well the plasterer did his job. All the troubles will appear when painting or wallpapering, when it will be too late to make a claim.

Information on the purpose of the material

After GVL first saw the light, it found wide application in various construction fields. The material is also suitable for flooring - it is used to create a dry screed, which differs from the traditional one in that it does not require a long drying time and can be used even where the load on the floors should not be significant.

What is a dry floor screed?

Sheets of gypsum fiber are used for arranging subfloors both over concrete floors and over those made of wooden materials; they can also be laid on top of a finished cement screed for its additional leveling. A GVL-based screed or sheets simply laid on top of the finished base will allow you to immediately begin laying the finished floor covering.

Leveling the floor with GVL sheets

On a note! GVL screed is ideal for laying laminate, carpet, parquet and linoleum.

GVL is not only a leveling material, but also a sound-insulating and, to some extent, heat-saving material. However, at the same time, it “breathes” perfectly, that is, it allows air to pass through, which means it helps maintain an optimal microclimate in the room. The material is also able to absorb excess moisture in the air of the room.

Another important advantage of GVL is the possibility of installing floor heating systems, either water or electric, and combining them with it. The density of the sheets allows this to be done, and it is enough to use sheets with a thickness of only 10-12 mm. The material does not deform or collapse under the influence of temperature.

GVL sheets can be laid on top of a heated floor system

Note! GVL is used not only for arranging floors, but also for covering walls, ceilings, decorating window or door openings, creating ducts for communications, and internal partitions in rooms.

GKL

To produce sheets of this type, gypsum (93%), cardboard (6%) and starch with water (1%) are used. The gypsum base is secured with sheets of cardboard on both sides, which provides additional resistance to stress.

Manufacturers produce 4 types of material:

- GKL standard. Designed for premises with standard operating conditions. It differs from others in its gray tint.

- GKLV - option with moisture protection. The primer with which the finished sheets are impregnated does not allow the base to absorb moisture, making the products suitable for finishing structures with high humidity. It differs from others in its green tint.

- GKLO is a fire-resistant option. The sheets are pink in color and are suitable for furnishing premises where increased fire resistance of surfaces is required.

- GKLVO is a mixed option for arranging saunas. It is characterized by increased resistance to open flame and moisture, has a green tint with red markings.

The sheets can vary in size as follows: thickness from 8 to 16 mm; width from 600 to 1200 mm; length from 2000 to 4000 mm.

The products are used to form ceilings, walls, partitions, arches and other structural elements.

Advantages:

- low cost;

- has excellent thermal insulation characteristics;

- ease of installation;

- the plasticity of the material allows the formation of curved structures;

- not subject to combustion. Plaster can only melt at high temperatures, but cardboard will burn. To eliminate this drawback, it is treated with special compounds in fire-resistant versions;

- sheets treated with moisture-resistant impregnations can be used in rooms with high humidity;

- to repair a separate section of the surface, it is not necessary to dismantle the entire sheet - it is enough to cut a piece of plasterboard to size and repair the defect;

- the material is suitable for installation in any type of premises for any type of finishing;

- does not contain allergens and other harmful substances that can evaporate during prolonged use;

- Suitable for masking various types of communications.

Flaws:

- plasterboard is very fragile, this disadvantage must be especially taken into account when transporting the material;

- low strength. The sheets cannot be used as a base for hanging heavy objects and furniture (maximum weight 25 kg);

- low sound insulation rates. For partitions it is necessary to use additional mineral wool boards.

Material Specifications

Some information about what gypsum fiber sheet is is given above in the article, but the material has certain characteristics.

Installation of dry screed

Table. Technical characteristics of gypsum fiber sheets.

| Characteristic | Meaning |

| Length | 2500 mm |

| Width | 1200 mm |

| Humidity | No more than 1% |

| Breaking or bending strength | Over 5.5 MPa |

| Hardness | Over 22 MPa |

| Density | About 1200 kg/m3 |

| Thermal conductivity | 0.22-0.35 W/mx0C |

On a note! The length, width and thickness of gypsum fiber sheets may differ from those indicated in the table.

For a gypsum fiber base, sheets of different sizes are used. For example, there are standard sheets that look like ordinary drywall. Their dimensions are 1200x1500 mm. Their dimensions are determined by GOST R 51829-2001. They are also suitable for creating interior partitions. To create a level base, small-format sheets can be used, which are two ordinary sheets securely fastened together using special glue. In this case, the central axes of the sheets cannot coincide with each other; they will necessarily be displaced, due to which folds are formed - one of the simple options for a locking system that facilitates installation and provides a simple and convenient connection of several floor elements. The sizes of small-format sheets are 1200x600 and 1500x500 mm.

GOST R 51829-2001. Gypsum fiber sheets. Technical conditions. Downloadable file (click the link to open the PDF in a new window).

GOST R 51829-2001

Laying GVL on expanded clay

On a note! When leveling subfloors, sheets of different sizes can be used. The first layer is usually created from a small-format version, and standard gypsum fiber sheets are laid as the second.

Nuances

To perform all the work correctly, you need to consider the following recommendations:

- It is better to trim gypsum fiber boards with an electric jigsaw. This will create a smooth edge. But there is another way.

In the absence of a jigsaw or other power tool, a gypsum board sheet can be cut using a sharp knife or cutter

- The slabs are placed close to the walls, the shrinkage is leveled due to the glued tape.

- The elements should be fastened together with self-tapping screws, selected depending on the thickness of the sheets. The fixation must be extremely reliable and rigid.

- The technology allows you to place insulation between two layers of gypsum fiber; in this situation, parts with a chamfer are used.

If you are careful and take into account all the recommendations, the work will not take much time.

Advantages and disadvantages of GVL slabs

Like any other material, gypsum fiber board has its pros and cons, which will certainly affect the decision - to choose or not to choose this floor leveling option in each specific case.

Advantages of using GVL:

- versatility of the material;

- ease of installation;

- environmental friendliness;

- high speed of work and the ability to continue repairs immediately after installation;

- waste-free installation;

- high strength and the ability to withstand significant loads;

- ability to withstand exposure to moisture;

- non-flammability, absence of deformation processes when exposed to temperature.

Dry bulk screed

Disadvantages of GVL slabs:

- a sufficiently large mass that requires inviting another person to help;

- fragility during installation if the material is handled incorrectly;

- significant cost.

There are now a lot of fakes on the construction market, and therefore it is important to purchase gypsum fiber boards only from trusted manufacturers and with certificates confirming quality and compliance with GOST requirements.

Comparison of dry screed with traditional

Is drywall harmful?

It has a gray sheet color and blue markings. Moisture-resistant (GKLV) - used for decoration, bathrooms, toilets and kitchens. It has a green leaf color and blue markings.

Fire-resistant (GKLO) – for making air ducts and communication shafts. The leaf color is gray and the marking color is red. Moisture-resistant (GKLVO) - used for fire-resistant structures in wet rooms.

The leaf color is green and the marking color is red. Just by the name of the material you can determine what drywall is made of.

The main components that make up drywall are gypsum and cardboard.

Gypsum is a natural soft mineral. It is obtained from sedimentary rocks. Gypsum is dried and fired at a low temperature of 150–180 ° C, followed by grinding.

Since building gypsum is a natural material, it is safe and non-radioactive.

Types of GVL slabs

GVL sheets, according to their technical characteristics, are divided into two types - moisture resistant and ordinary, standard. Conventional ones are used more often for all work performed indoors, the main thing is that the rooms have dry air and optimal temperature conditions. But moisture-resistant ones, which are labeled as GVLV, have a special impregnation, which makes it possible to use the material in rooms that do not have optimal air humidity - bathrooms, saunas, basements, etc.

Important! When purchasing moisture-resistant sheets, you should check all the elements of the material in the pack for markings indicating that the sheet is moisture-resistant, since careless sellers can easily shuffle gypsum plasterboard with gypsum plasterboard, which is not always noticeable immediately upon purchase, but is revealed after delivery material in place. It is unlikely that those who carry out repair work will need the extra hassle of exchanging sheets.

Let's look at the pros and cons: how harmful is drywall to humans?

So from this side it cannot be said that drywall is harmful to health.

Cardboard is a type of paper; from the point of view of the “wrapper”, the environmental friendliness of drywall is also undeniable.

This is the composition of the usual material that is used to cover walls in living rooms. For those who don’t know, the “cover” color of the standard is gray, and the harmfulness of this drywall is excluded.

However, there are other types of upholstery:

Dry screed technology

Since GVL is most often used specifically to create a dry version of the screed, let’s consider what it is and what it consists of. Typically, the installation of this type of base begins with laying polystyrene foam - an insulating material. It is usually laid on a bedding, for example, expanded clay.

There are three main types of screed that can be made using gypsum fiber sheets.

- Basic , which is made on an expanded clay base-bedding having a thickness of 2 cm. This option is applicable if the base has been previously insulated and does not have sharp changes in height.

- Subfloor, made on foam insulation up to 3 cm thick. This option is ideal for floors that have small differences in height and require insulation.

Dry screed with expanded clay and insulating boards

- Prefabricated screed , which is also made using expanded polystyrene laid on expanded clay bedding. This option is used if the floors require good insulation and are very uneven - they have significant fluctuations in height.

Gypsum fiber floor installation

In general terms, dry screed consists of several layers. Its structure is like this.

- The vapor barrier/waterproofing layer is the lowest layer, preventing the penetration of moisture coming from the ceiling to the subfloor. Polyethylene with a thickness of at least 200 microns can be used as waterproofing on a concrete floor, and glassine is best suited for a wooden floor. By the way, vapor barrier is usually used only on the upper floors; on the ground floor it is better to use waterproofing materials, since there is much more moisture there.

- Compensation gasket , which is a tape attached around the perimeter of the entire room near the floor. It can be made of foam film, isolon and other materials. The material compensates for any expansion of the base that occurs due to changes in humidity and temperature. This tape also provides additional noise absorption. Its excess, protruding above the level of the laid gypsum fiber boards, is cut off after installation is completed.

- Leveling layer , which will be made from gypsum fiber board or other leveling materials (for example, plywood).

- GVL slabs act as pre-finish floor finishing . They can be additionally laid on top of plywood or other leveling material. The material is attached to the base with self-tapping screws or using special glue.

Dry screed diagram

On a note! If the floors have height differences of 10 cm or more, then it is necessary to install a third layer of gypsum fiber board, which has exactly the same thickness as the previous two in total.

Rules for covering surfaces with gypsum fiber sheets

There is quite a lot of information that reveals the rules for upholstering with gypsum fiber sheets. And when carrying out independent finishing and strictly following the established technology, mistakes are reduced to a minimum. Before you start upholstering surfaces, you need to thoroughly master the principles of leveling, install pipes and heating equipment, electrical wiring and other engineering elements. All windows and doors must be installed in the room.

Gypsum fiber panels are fastened to a frame - a wooden or metal profile. And the frame itself is attached to the base that is sheathed.

This finishing material does not contain toxic additives or toxins; the panels have noise-absorbing and sound insulating properties. On the front side of the gypsum fiber sheet there is a glued film, which is very important when carrying out cladding work. Among other things, this film also has decorative qualities, which is important for unique design finds. The use of gypsum fiber sheet allows you to avoid the need to level the planes. Because, due to the presence of a film, their surface is endowed with sufficient smoothness. And this fact again adds to the “advantages” of technology. After all, leveling requires the purchase of several tens of kg of putty material, and the procedure itself is quite labor-intensive. Therefore, both finances and time are saved. Upholstery with gypsum fiber sheets is a unique construction technology, thanks to which it becomes possible not to use “raw” leveling methods. Upholstering the surface with gypsum fiber on your own gives the designer a lot of scope for imagination. Fastening of gypsum fiber sheets occurs with the participation of a metal profile, so pay enough attention to the choice of the latter. This choice will be dictated by the type of room, the thickness of the walls and the height of the ceilings. The upholstery of gypsum fiber sheets on the walls ensures their ideal evenness. Repairs always involve a certain waste of time and money. Everyone is well aware of this and strives to save both. That is why the question of what to choose: plaster or gypsum fiber sheet will never lose its relevance. Both materials have already gained trust (one earlier, the other later, but with equal success). But people have not yet decided who they can trust more. Let's try to sort out the doubts.

Some information about the use of the material

In order to correctly lay gypsum fiber board on the floor, you need to know some nuances that will ensure an excellent final result of the work. For example, special sheets with a thickness of 10 mm are produced for floors - it is better to use them. Before laying gypsum fiber board sheets, it is important to pour a layer of expanded clay onto the base. It will provide additional leveling of the floor and help insulate the base. This is the most accessible and cheapest option. The optimal size of expanded clay fractions is 5 mm.

Types of backfill for dry floor screed

Also, guides are mounted on the base, which play two roles:

- guideline when adding base . In this case, expanded clay is poured to the edges of the guides, compacted and leveled using a long rule;

- support for gypsum fiber sheets . The installation will be more professional if the material has support and places for fastening.

Leveling the bedding layer

If the installation of gypsum fiber boards will be carried out on a wooden base, then it is important to properly prepare such floors beforehand. Preparation includes checking the floorboards for strength and, if necessary, replacing them. The floor is screeded if there are significant gaps between the individual elements. Although some craftsmen do not screed, arguing that if there are cracks, the floors will be better ventilated. So you can avoid this stage.

Also, GVL sheets on a wooden base must be laid in two layers, which will make the base reliable and durable. GVL sheets are usually mounted on wood if it is necessary to lay a floor covering that is demanding on the evenness of the base - for example, ceramic tiles, laminate. In other cases, the wooden base may not be leveled. The gypsum plasterboard layers are fixed in the following way: the first one is attached with self-tapping screws, and the second one is mounted on the first one using PVA glue (in this case, excess glue protruding between the seams is immediately removed). However, it would not be a bad idea to secure it with self-tapping screws. The two layers must be laid apart so that the seams do not coincide with each other. You need to move the sheets by about 20-30 cm. This will ensure that the base is as strong as possible.

Dry floor screed

Important! When laying gypsum fiber board sheets, it is important to ensure that the gaps between the sheets are not more than 2 mm. Also, if laminate or carpet is used as the finishing coating, the cracks must be puttied.

And one more condition that must be met during the installation of gypsum fiber board sheets if they have folds. At the extreme row, located near the walls, they should be trimmed. Moreover, trimming is done on already laid sheets.

Adapted dry screed Knauf

How to make a dry screed with perlite

Dry screed using German technology

Dry screed with vermiculite

Calculator for calculating expanded clay backfill for dry screed

Go to calculations

Prices for GVL from

GVL Knauf

Drywall is harmful to health

So from this side it cannot be said that drywall is harmful to health.

This is the composition of the usual material that is used to cover walls in living rooms. However, there are other types of upholstery:

- GKLV. This is how moisture-resistant sheets wrapped in green cardboard are marked.

GVL floor laying

Laying gypsum fiber sheets is not a difficult task and does not require any responsibility. The technology for laying gypsum fiber board on the floor is given step by step below.

Step 1. The base is cleaned. If necessary, the old wooden base can be removed. Floorboards or old parquet are dismantled, worn-out joists are removed.

Removing a wooden floor

Step 2. The base is treated with a primer, especially the seams, then they are all sealed with a special repair compound. All irregularities are removed as much as possible.

Particular attention is paid to seams

Prepared seams

Step 3. The cleaned surface of the base is covered with plastic film extending about 20 cm onto the walls. The strips of material are laid overlapping each other by at least 5-10 cm and glued together with tape. Next, edge tape is glued along the joint between the wall and the floor.

Polyethylene film laid

Step 4. The surface is covered with expanded clay.

Expanded clay backfill

Step 5. Using a laser level, install two guides. The level of expanded clay will be leveled using them.

Installation of guides

Attention! When installing the guides, it is important to use a level so that they are installed level and at the same height.

Step 6. The level (layer) of expanded clay is leveled using a rule laid on the guides and moving along them. You cannot walk on expanded clay after leveling.

Leveling the expanded clay layer

Step 7. GVL will be laid from the doorway. The first sheet is laid from the corner, then the rest. In this case, all joints are coated with glue.

Laying gypsum fiber sheets

Step 8. The joints of the sheets are additionally connected using self-tapping screws in increments of 35-40 cm.

Fixing sheets with self-tapping screws

Advice! If necessary, a regular jigsaw is used to cut gypsum fiber board sheets.

Step 9. This way the entire surface of the floor is covered. The folds of the last sheets must be sawed off.

The process of laying gypsum fiber sheets

Step 10. The surface of the laid gypsum fiber boards is treated with a vacuum cleaner.

Cleaning the coating

Step 11. The joints between the gypsum fiber board sheets are treated with putty.

Joints between GVL sheets are treated with putty

You can move on such a screed immediately after finishing the work, and you can also immediately carry out other repair work - for example, laying the finishing floor covering. But still, experts recommend laying the finishing coating no earlier than after 24 hours. This time is necessary for the screed to rest a little.

When installing the second layer of gypsum fiber board, it is necessary to lay new sheets perpendicular to the previously laid ones in order to increase the strength of the floor.

Frame installation of gypsum fiber sheets

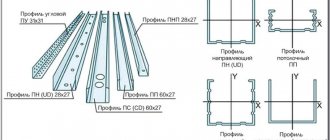

The frame of wooden slats is made of material with a cross-section of no less than 3.0 x 5.0 cm. The transverse dimension of the vertical posts is 2.5 x 7.5 cm. The fastening spacing does not exceed the width of the gypsum fiber material, recommended - 40 cm. The gypsum fiber sheet is placed on self-tapping screws of length not less than 30 mm in increments of 25 cm (with a slab width of 1.2 m). Glass wool is used for insulation. The slabs are installed starting from the middle of the room. A small gap is left between them, about 5-7 mm. The metal frame is much more reliable. It is made from galvanized guides and load-bearing wall and ceiling profiles with a thickness of 0.56-0.6 mm, and installation is similar to lathing under plasterboard sheets. Assembly is carried out as follows:

- The surface is being prepared. The old coating is removed. True, not all masters advise this, considering it an unnecessary waste of time and effort.

- Using a level, plumb line and pencil, mark the wall. For vertical racks take a ceiling profile. The guides are mounted in areas adjacent to the floor and ceiling.

Gypsum fiber sheet: frame installation method

- The brackets are attached to the racks with self-tapping screws, and the profiles are aligned using a folding cutter. The profiles are attached to the ceiling with dowels in increments of 60 cm or slightly less.

- Gypsum fiber sheets are installed from bottom to top or top to bottom with a small gap between them.

After installation, the resulting surface is treated with gypsum putty, the joints and places where screws are screwed in are completely covered.