The reputation of Knauf drywall dates back to 1958, when the German company of the same name introduced new products to customers. Since that time, it has grown to become the world's largest manufacturer of plasterboard with technical characteristics that have become the standard. In 1993, the company expanded its activities in Russia, opening a lot of enterprises with modern equipment, uniform technologies and quality standards. Practical Knauf plasterboard, designed for quick and high-quality finishing of premises, is not stocked in construction stores.

Brand Features

Pros of Knauf drywall:

- simple and quick installation;

- Treatment of gypsum boards with water is excluded from the technology;

- there are no “dirty” operations during finishing;

- allows air to pass through and is resistant to fungus formation;

- gypsum has lower thermal conductivity than plaster, it retains heat better;

- affordable.

Without going into technical details, a plasterboard sheet is a layer of gypsum enclosed on both sides in a cardboard covering. This was the first drywall. Since then, this material has come a long way to improve. Now there are several modifications of drywall for different applications.

KNAUF-list (GSP-A)

In rooms where humidity and temperature are within normal limits, this type of drywall is used most often. It is inexpensive, cuts well and takes the given shape. It is attached not only to the profile, but also with glue. “Friends” with any type of finishing materials: it is covered with wallpaper, painted, covered with tiles, decorative stone. The ceiling version (9.5 mm thick) allows you to easily install modular lighting. Despite all its technical advantages, it remains an environmentally friendly material.

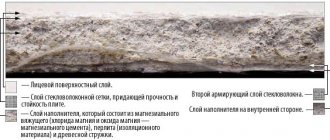

The gray sheet of GSP-A resembles a kind of sandwich of 2 layers of special cardboard, between which a gypsum core with reinforcing additives is placed. The edges are also covered with cardboard and have a semicircular thinned shape, in which a reliable, tight joint between the sheets is guaranteed.

Knauf company and its sheets

Knauf sheets are the most popular, but not the only sheet products. In addition to plasterboard sheets (GKL), Knauf produces:

- Acubord soundproofing panels;

- Perforated gypsum board sheet Acoustics;

- Knauf super sheets (GVLV, GVL, floor elements - EP).

It should be noted that in addition to sheet products, the company produces all the necessary components for frame and sheathing structures, as well as finishing materials.

Knauf-sheet moisture-resistant (GSP-N2)

This type of drywall is used for the same purposes as regular drywall, but in rooms with high humidity. It absorbs 90% less water than an ordinary one. Moisture-resistant KNAUF sheets (GSP-N2) of green color are distinguished by specific additives:

- antifungal compounds protect the material from mold, the appearance of which is inevitable in a damp room with poor ventilation;

- the waterproofing solution does not let water inside the material;

- polymer impregnation reduces the absorption rate.

USEFUL INFORMATION: Design of a two-level plasterboard ceiling for the kitchen: 12 photos

The physical and hygienic properties of this type of gypsum board make it an ideal material for residential premises.

Moisture-resistant plasterboard is a win-win option for bathrooms, kitchens, toilets, finishing loggias, balconies, door and window openings and even basements, attics, and pool rooms.

Read more about the properties and scope of application of moisture-resistant types of drywall here.

Types of drywall

Depending on the area of application, properties and technical characteristics, plasterboard comes in different types. At the same time, the size of Knauf drywall can also be different. Drywall can be ordinary, moisture-fire-resistant, fire-resistant and moisture-resistant.

Next, you will learn how to choose the right size of Knauf drywall based on the required characteristics:

1. Regular drywall is usually beige in color, and the lettering on it is blue. This type of plasterboard is used for cladding ceilings and walls, and also, using a metal profile, for the construction of partitions in rooms with normal humidity levels.

This type of drywall can have the following parameters:

- sheet length from 2500 to 4000 mm, sheet thickness 9.5 mm, sheet width 1200 mm, weight 9.5 kg;

- sheet length from 2500 to 4000 mm, sheet thickness 12.5 mm, sheet width 1200 mm, weight 12.5 kg;

- sheet length from 2500 to 4000 mm, sheet thickness 15 mm, sheet width 1200 mm, weight 15 kg;

- sheet length from 2000 to 3500 mm, sheet thickness 9.5 mm, sheet width 600 mm, weight 18 kg.

2. Moisture-resistant plasterboard sheets are green in color and have blue lettering. This type of drywall is used in rooms with high humidity - in the bathroom, in the kitchen, and also as a base for ceramic tiles. In this type of drywall, both the core and the cardboard itself are treated with a composition that prevents moisture absorption, so you will not have problems with mold and mildew. Moisture resistant sheets are often between 2500mm and 4000mm long, 1200mm wide and 9.5mm to 15mm thick.

3. Fire-resistant plasterboard sheets are painted in beige color and red lettering. Most often, this type is used in rooms that have special fire safety requirements, as well as to build attic spaces. It is necessary to pay attention to the fact that the core of such drywall has additional reinforcement, which includes at least 0.2% of the total weight of all fiberglass threads having a length of 3 to 30 mm. Thanks to this, it can maintain its integrity much longer in the event of a fire.

Sheets of such plasterboard can be from 2500 to 4000 mm long, 1200 mm wide and 12.5 and 15 mm thick. These sheets weigh from 10 to 16 kg.

4. Moisture- and fire-resistant plasterboard sheets are painted green and have red lettering. It has the properties of the two types described above. It is used in areas that may be exposed to high temperatures and moisture. The sheets are exactly the same dimensions as fireproof.

Depending on what characteristic properties a particular drywall has, it can be classified into one of the groups:

- GOST30244 – group G1 (flammability);

- GOST 30402 – group B2 (in terms of flammability);

- GOST 12.1.044 – group D1 (smoke generation);

- GOST 12.1.044 – group T1 (toxicity).

Knauf-sheet fire-resistant (GSP-DF)

The fire-resistant type of plasterboard is intended for heat-resistant coatings and structures, be it wall cladding, partitions, suspended ceilings in buildings where humidity does not exceed regulatory requirements.

Tests conducted by the Russian Research Institute of Fire Defense of the Ministry of Emergency Situations showed that Knauf plasterboard sheathing practically behaves like an ordinary non-combustible material.

The front side of the product is painted pink, the back side is gray.

All the features and applications of heat-resistant drywall are described in this article (plus a fire test video).

KNAUF-Fireboard

Construction and finishing material for finishing premises subject to increased fire safety requirements.

Non-combustible KNAUF-Fireboard boards are specially developed by KNAUF to meet increased requirements in the field of fire safety of buildings and structures.

KNAUF-Fireboard looks like an ordinary gypsum board, but has high fire-resistant properties. Repeated tests have shown that KNAUF Fireboard can contain a flame for more than an hour without losing its technological properties.

Application:

KNAUF-Fireboard is used as a fire-retardant cladding material in frame-sheathing structures of partitions, wall cladding and suspended ceilings on escape routes and in halls in buildings of various functional purposes, number of floors and capacity, in other building structures where, according to fire safety requirements, the use of non-combustible building materials (NG) fire hazard class KM0. These requirements are given in table. 28 and 29 Appendices to the Federal Law of the Russian Federation of July 22, 2008 N 123-FZ “Technical Regulations on Fire Safety Requirements”.

KNAUF-Fireboard is the optimal option for finishing technical premises, especially those places where there is an increased risk of fire: boiler rooms, workshops, garages, chimney areas, etc. Walls made of this material are designed to localize a fire in one room and prevent the flames from escaping outside.

In Europe, Knauf Fireboard has been used for many years. It is widely used for finishing emergency exits in office and shopping centers: where there are escape routes. In addition, it can be used as an additional non-combustible cladding that is attached to existing wall structures.

Advantages:

The main task of KNAUF-Fireboard plates is to contain the spread of fire, and thereby ensure the evacuation of people. Today, of all the non-combustible materials on the market, only it has proven its effectiveness in fighting fire. It is important that Knauf Fireboard is an absolutely safe environmental material.

The fundamental difference between the behavior of Knauf-Fireboard boards and other sheet gypsum products under standard fire tests is that after evaporation of crystallization moisture from the gypsum core, the product does not crack or collapse for a longer period of time. In addition to the reinforced gypsum core, this is achieved by the presence of non-flammable fiberglass, which serves as a fire-resistant reinforcing frame of the product. This property of KNAUF-Fireboard boards ensures higher fire resistance of structures based on them.

Knauf-sheet moisture- and fire-resistant (GSP-DFH2)

It is more expensive because it combines moisture resistance and fire resistance. It provides a favorable microclimate for living and working. Its breathable sheets regulate indoor humidity. Does not contain toxic components, has an acidity similar to that of human skin. Cardboard color is green. The quality of GSP-DFH2 meets international standards.

Reference: heat-resistant and moisture-resistant gypsum plasterboards can resist open fire for at least 20 minutes.

KNAUF impact-resistant sheet (GSP-DFH3IR)

GSP-DFH3IR combines increased density with moisture and fire resistance, has increased strength and impact resistance. This universal material is used in rooms where the most stringent requirements are imposed on the finishing, including sound insulation.

For production, a special blue facing cardboard is used. The use of such cardboard with increased weight increases the bending strength of the sheet. For high-quality finishing, KNAUF sheets GSP-DFH3IR are the best option.

KNAUF-list: everything you didn't know about!

Currently, when constructing interior partitions, leveling walls or finishing ceilings, “dry construction” technologies using plasterboard are widely used. What is it, what types of material are there, and what are the advantages of such technology, let’s look at the example of KNAUF sheet. And besides, let's talk about well-known myths, the presence of which, however, is typical for any popular technology.

So, the basis of “dry construction” is the use of KNAUF sheet plasterboard, which is very popular not only among professional builders, but also among customers.

Types of KNAUF drywall

Photo KNAUF

KNAUF produces plasterboard in several modifications for rooms of varying functionality. Thus, for ordinary rooms with normal and dry humidity conditions, gypsum building board type A (GSP-A) is produced. GSP-A is produced with a semicircular thinned edge, ensuring the creation of a tight and reliable joint. The cardboard is painted gray, which makes it easy to identify on the store shelf.

For rooms with high humidity, such as kitchens, bathrooms or restrooms, KNAUF moisture-resistant sheet (GSP-N2) is produced, containing additives that reduce water absorption. The visual difference of the KNAUF moisture-resistant sheet is the green facing cardboard. Cardboard is an ideal basis for applying any finishing material (putty, wallpaper, paint, ceramic tiles, etc.).

Photo KNAUF

For premises that are subject to increased fire protection requirements, KNAUF produces fire-resistant GSP-DF plasterboard with increased resistance to open flames.

KNAUF sheet Sapphire

Photo KNAUF

The KNAUF plasterboard sheet Sapphire (GSP-DFH3IR) deserves special mention. This is a high-quality KNAUF plasterboard sheet with an additional set of properties that surpasses all modern analogues. Its name is memorable - Knauf-leaf Sapphire. And in terms of the totality of its characteristics, it can only be compared with the natural mineral sapphire, a very valuable stone of the highest class! The natural mineral sapphire is distinguished by its unusual strength and hardness, thanks to which the stone is very durable and resistant to external influences. So the KNAUF sheet Sapphire combines all the best properties of moisture-resistant and fire-resistant “plasterboard”, has a high core density, greater impact resistance and the ability to withstand heavy loads (for example, when hanging heavy objects), and better sound insulation characteristics. It is intended for premises whose finishing requires high quality surfaces, impact resistance, moisture and fire resistance and sound insulation.

KNAUF sheet Sapphire, lined with German-made cardboard, smoother and more durable, pleasant gray-blue color. It stands out effectively against the background of standard sheet products. The use of such cardboard not only significantly increases the bending strength of the sheet, but also makes it possible to achieve high quality surfaces even without additional continuous puttying. When constructing new partitions or replacing old ones, installing suspended ceilings, or cladding walls, feel free to use this unique product.

KNAUF sheet and Harmut dowel

There is a common myth that you cannot hang anything heavy on a hollow plasterboard structure. This statement has no basis. The main thing is to use the correct fasteners! The KNAUF-Hartmut dowel allows you to easily hang a plasma TV, a heavy mirror, a wall cabinet or a book shelf on a cladding or interior partition made of KNAUF sheet.

One dowel can support up to 35 kg of weight with a single-layer sheet partition and up to 65 kg with a two-layer one. For suspended ceilings, the load on KNAUF-Hartmut is up to 6 kg per dowel, which allows you to fix even a heavy chandelier. With the combined use of KNAUF-sheet Sapphire and KNAUF-Hartmut, the possibilities for fastening heavy interior elements, furniture and lighting fixtures become almost limitless.

KNAUF sheet has many advantages compared to alternative finishing methods.

Environmental friendliness

Let's start with the cornerstone of all building materials. Let's look at the components from which it is made. The KNAUF sheet is based on a gypsum core with reinforcing additives, lined with cardboard on both sides. Gypsum, as a base, is a material with an acidity similar to that of human skin. It does not emit harmful substances and toxic components, as is now commonly said “non-phonite”. In addition, finishing with sheets of plasterboard helps create a microclimate in the room that is favorable for humans. The sheets seem to “breathe”, normalizing the level of humidity in the rooms; when there is an excess of moisture in the air, they absorb it, and when there is a lack, they release it back.

Freedom of creativity in the interior

KNAUF sheet provides endless opportunities for realizing creative ideas when creating both residential and work spaces. Redevelopment of premises or zoning has never been so affordable and easy to implement. With its help, prefabricated interior partitions and suspended ceilings are created, including complex multi-level shapes, with the possibility of integrating lighting fixtures. KNAUF sheet is excellent for cladding walls that require leveling. Thanks to the physical properties of plasterboard, it is also possible to create curved surfaces for the implementation of unique architectural forms in interiors. Using KNAUF sheets, you can easily create arches, niches, communication boxes and much more.

Convenience and speed of work

The absence of “wet processes” is another undeniable advantage of KNAUF sheet. Firstly, thanks to this property, there is no need to wait for a long time for the plaster to dry, but you can immediately begin finishing. Secondly, the construction site is much cleaner. Thirdly, the format and weight of the material allow you to work with it alone.

Availability and proven technology

A historical alternative to drywall is masonry using blocks or bricks and then plastering. These professions are specially trained, and it is unlikely that an ordinary person without experience will be able to carry out the construction of partitions at a sufficiently high level. In the case of KNAUF sheets, everything is much simpler. Whatever idea you come up with, whatever transformation of your living or working space you have in mind, Knauf already has the appropriate technological solution for this, backed up by the necessary instructions and consumables of the highest German quality.

Aesthetics

Drywall allows you to create not only perfectly smooth surfaces without applying numerous leveling layers, but also complex architectural forms to create a unique interior that look no less solid and reliable than monolithic reinforced concrete. Or take, for example, such an operation as installing a suspended ceiling. What can be done using a Knauf sheet cannot be done from any other materials, be it concrete or a PVC suspended ceiling.

Soundproofing

Partitions and ceilings made of plasterboard themselves have an increased level of sound insulation. At the same time, the best effect is achieved when installing KNAUF sheets in two or three layers, which significantly increases this indicator. For example, a partition with two-layer cladding with a thickness of only 100 mm has a sound insulation index of up to 56 dB. Knauf solutions help to effectively protect your living rooms from external noise.

Reliability and durability

Having completed the finishing using KNAUF sheets, you will close the topic of repairs and finishing materials for a long time. Because if you follow the installation technology and choose the right “partition reliability class,” you will get a guaranteed result. The reliability of KNAUF complex systems has been tested by long-term operation not only in our country, but also in Europe, in particular in Germany, where plasterboard sets the tone for repairs. KNAUF is real German quality, and the phrase “German quality” in itself is a brand, firmly entrenched in the mass consciousness as a guarantee of the best result.

KNAUF is the first company in our country that began producing KNAUF sheets in accordance with the new GOST - 32614-2012, thereby ensuring that its products comply not only with international standards, but also, which is very important, with domestic ones. What does “products comply with GOST” mean? This means that it fully satisfies the requirements for strength, reliability, and environmental friendliness for construction and finishing materials. And any philistine talk about the fragility and unreliability of drywall has no basis if we are talking about KNAUF products, where the name itself is a guarantee of quality.

KNAUF-acoustics - large-format sound-absorbing panel

These are plasterboard sheets with perforations. Suitable for rooms with normal humidity. Through holes serve as resonators: the sound wave falls into a kind of trap and gradually fades. The noise-absorbing effect is further enhanced by a layer of non-woven fabric on the back side of the sheet. Depending on the design of the room, the canvas can be white or black. Perforation patterns have several options, depending on which gypsum boards differ in the degree of sound absorption.

Tests have shown that the noise absorption coefficient of KNAUF-acoustics plasterboard reaches 0.2. This is a very worthy indicator.

Perforation, in addition to sound dampening, has a memorable, stylish appearance. This is confirmed by all the photos illustrating the use of Knauf acoustic plasterboard. The company's products allow you to choose from several options with different types of holes: round, square, scattered round.

USEFUL INFORMATION: GKL sheet - what is it? Dimensions and thickness, types of material

Such drywall creates real acoustic comfort, which is necessary in schools, universities, concert halls and many other public institutions, residential buildings, not to mention industrial premises. Installation of a ceiling or wall covering with such sheets is carried out at an accelerated pace, without significant labor costs.

Help: acoustic plasterboard reduces the level of noise in the room itself, reduces booming, fights the echo effect, and improves speech perception. But you shouldn’t count on soundproofing results - it won’t protect you from loud neighbors.

The features of acoustic drywall are described in more detail here.

What brand of drywall do you use?

Purpose and dimensions of KNAUF plasterboard

Building codes and regulations (SNiP) allow the use of Knauf plasterboards:

- when decorating walls indoors;

- for the construction of suspended ceilings;

- for the manufacture of all kinds of figures, decorative elements;

- for arranging arches and various partitions.

All types of Knauf plasterboard sheets have a rectangular shape and are manufactured in accordance with GOST 6266-97, fully meeting the requirements of the German standard DIN 18 180. Their feature, which ensures manufacturability and reliability, is a thinned semicircular edge, which has proven itself at joints.

GKL are divided into wall, ceiling, arched:

- Sheets with a thickness of 12.5 mm are usually used for finishing walls and installing partitions.

- To create ceilings, you can use plasterboard with a transverse dimension of the same 12.5 mm. But it is heavier and more expensive than 9.5 mm thick sheets specially designed for ceilings.

- 6.5 mm plasterboard is best suited for constructing arches or other structures with a shape other than rectangular.

USEFUL INFORMATION: How to glue serpyanka to drywall: sealing the seams with mesh

Size options:

- sheet length – 2000–4000 mm (in increments of 50);

- width - 600 and 1200 mm;

- thickness depends on the purpose of the product and is 6.5, 8, 9.5, 12.5, 14, 16, 18, 20, 24 mm.

AQUAPANEL Outdoor

Cement board AQUAPANEL External Universal environmentally friendly sheet construction finishing material.

AQUAPANEL External is used in buildings of various architectural and construction systems:

- frame-panel wooden housing construction;

- in buildings on a steel frame;

- in monolithic frame housing construction;

- repair and restoration of facades;

- when cladding external walls, balconies, loggias, finishing plinths;

- when installing external suspended ceilings, soffits, roof overhangs.

AQUAPANEL External is used for the construction of non-load-bearing external frame-cladding walls of element-by-element assembly on a steel frame with or without an air gap.

In addition, AQUAPANEL External serves as the basis for various facade finishing options, including cladding with natural or artificial stone, and can be used in a plaster-type facade insulation system.

The installation process includes the following stages of work:

- Cutting AQUAPANEL External slabs.

- Installation of a metal or wooden frame.

- Installation of slabs.

- Sealing of seams and continuous plastering of the entire surface with KNAUF-Sevener plaster and adhesive mixture.

- Decorative surface finishing.

Recommendations:

- It is recommended to store the slabs under a canopy to protect them from direct moisture. Wet panels must be dried before installation.

- Before installation, the slabs must be acclimatized. The temperature of the material and the environment should not be lower than +5°C.

- The slabs must be mounted horizontally!

- Rack profiles are installed in increments of 600 mm.

- For ease of installation, the slabs have auxiliary markings. The places where the screws are attached are marked with crosses.

- Before applying KNAUF-Diamant facade plaster, treat the surface with KNAUF-Izogrund primer.

Advantages:

- High moisture resistance without swelling and crumbling.

- High resistance to fungus and mold.

- No harmful impurities.

- Increased resistance to extreme weather conditions (wind, rain, snow, temperature changes, etc.).

- Easy and quick installation.

- Possibility of creating curved surfaces with a bend radius of up to 1 meter.

- Manufacturability in processing.

- Elimination of labor-intensive surface treatment processes.

- The dry construction technique eliminates long drying times.

- No special tools required.

- The speed of installation reduces the time and cost of construction work.

- Impact resistance and durability.

Marking

Each sheet of plasterboard produced by the company has its own designations, including:

- the standard to which it was manufactured;

- dimensions;

- information about the type of side edge;

- letter designation of the type of drywall.

For example, a moisture-resistant sheet with a standard size semi-circular thinned edge will be marked as follows:

GSP type N2 GOST 32614-2012 (EN 520:2009) PLUK 12.5-1200-2500