About five years ago, foam adhesive for expanded polystyrene (EPS) appeared in construction stores. It ensures strong adhesion of materials. Manufacturers promise that this tool is convenient to use even without the help of specialists.

- Purpose

- Specifications

- Advantages

- Flaws

- Differences between polystyrene foam and polystyrene foam

- Adhesive foam for polystyrene foam: brands

- TechnoNIKOL

- Akfix 960

- Makroflex MF 901

- Ceresit CT 84

- Tytan Styro 753

- Foam adhesive consumption for polystyrene foam

- Application technique

- Storage rules

Professional builders are familiar with this adhesive composition. And for those who do not know what it is for and how to use it, the article discusses:

- purpose of the remedy;

- specifications;

- advantages and disadvantages;

- popular brands TechnoNIKOL, Makroflex and others;

- application technique;

- consumption, storage rules.

Features of foam fastening

When installing thermal insulation, first of all you need to think about how you plan to install the insulation. If a standard insulation scheme is envisaged, such as a wet facade, then the material itself is laid on a special mastic or glue.

The same applies to foam plastic. Moreover, expanded polystyrene is characterized by extremely low weight, which only increases its convenience in working with a variety of mastics.

After all, you don't have to worry about lightweight foam boards being too heavy for the glue to carry. Even the weakest solution can handle their weight.

However, standard mixtures (which builders simply call glue in everyday life) do not have special properties. Or they do, but working with them is not as easy as it seems.

These are rather archaic compositions that in their structure resemble standard tile adhesive. They do an excellent job of installing decorative elements, but working with insulation (especially if it is liquid foam) is a different matter. Here it is advisable to have specialized tools and materials.

Moreover, it is important to take into account that being a polymer material with a lot of air inside, foam can be damaged quite easily.

For example, if you apply an element that contains solvents to the surface of expanded polystyrene, it will simply eat through the slab. Moreover, this will take very little time, and it is almost impossible to prevent the process.

This is why builders so often decide to use modern adhesive foam for installation and fastening of polystyrene foam. This material was specially produced for maximum effective interaction with expanded polystyrene.

1.1 Properties of adhesive foam

Adhesive foam for insulating a frame house with polystyrene foam is an improved composition. It was originally conceived as a material for attaching foam thermal insulation. And therefore it has all the necessary characteristics or properties.

Expanded polystyrene boards that were attached using adhesive foam

Adhesive foam is sold mainly in cans. For example, AKFIX 960 adhesive foam is sold in cylinders and is enough to install approximately 12 m2 of insulation made of polystyrene foam, penoplex or any other material.

On the one hand, working with cylinders is quite convenient. And by and large, manufacturers had no alternative.

After all, foam adhesive is predominantly a polyurethane foam binder made from one component. A kind of polyurethane foam, only aimed at improved adhesion and adhesion to the foam.

That is, polyurethane foam, like installation foam, hardens upon contact with air. After just 20 minutes, most compounds like AKFIX 960 gain density and form a crust, and after another 20-30 minutes they can only be cut off with a knife.

Adhesive foam can be applied exclusively with a gun, even on foam moldings. Moreover, it is advisable to use specialized models for this, which were originally intended for professional application of compounds.

1.2 Pros and cons

Adhesive foam for polystyrene foam has a large number of advantages. Not only those we have already named, but also many more subtle parameters, which, nevertheless, also seriously affect the ease of use.

Main advantages:

- The cylinder is enough for an area of thermal insulation of 10 m2, and you can change it very quickly, and there is no need to knead or prepare the composition at all.

- The foam is easy to apply and also easy to cut.

- After 2 hours you can already work on the thermal insulation.

- Excellent adhesion to any materials, including metals.

- Eco-friendly.

- Easy to dose.

- Almost no expansion on foam.

- Performs fastening efficiently and tightly.

As you can see, there are a lot of advantages. Of these, it is important to immediately highlight a couple of points that, in fact, are decisive.

An example of attaching a foam canister to a professional gun

The first of these is the drying time. The second is the possibility of precise dosing and good adhesion to any base.

You need to understand that installing the same penoplex on a standard binder mortar is quite labor-intensive. The entire surface of the penoplex needs to be coated, then the slab must be glued, adjusted, excess mortar removed, etc. And after that, which is very important, wait almost a day until the mixture sets.

It’s not worth mentioning that if you didn’t calculate the work very correctly (and even if you did), then the subsequent installation of penoplex and its finishing can only be carried out the next day, and this is in the best case.

The second point is adhesion (especially important when insulating a pipeline with Thermaflex). Not every glue allows you to install even penoplex on the same smooth concrete. But penoplex is characterized by exceptionally low weight and small dimensions.

Adhesive foam eliminates all these problems. All you need to do is simply apply it to the surface of the penoplex. Then it's a matter of technique.

The slab is easy to glue, and it is just as easy to position (after all, very little glue is needed and it is applied in dense strips). At the same time, within 2 hours the slabs set and you can begin further work without wasting time.

This is why foam adhesive is so popular. It saves you time and nerves, while allowing you to operate with maximum comfort and efficiency.

As for the minuses, the following points can be noted:

- Adhesive foam is more expensive than standard solutions.

- It can only be applied with a pistol, and it is better if it is a professional tool.

But what's the problem with needing a gun for your job, you ask? Everything would be fine, but such a pistol is quite expensive. From hundreds of dollars for a high-quality low-level sample.

But you won’t be able to stick a lot of slabs with a simple gun, it’s too tedious a process.

Purpose of penoplex

“Penoplex” is a trademark, the boards themselves are extruded polystyrene foam, therefore in many instructions and other documents penoplex is labeled as EPS.

Before examining the types of glue and material installation techniques, let's briefly find out what extruded polystyrene foam (EPS) is, in our case Penoplex.

The material was born in the 30s of the last century in America. At that time, the US military-industrial complex announced a competition to create a lightweight, non-absorbent material for life jackets at sea.

The already known and widely used expanded polystyrene (foam plastic) was taken as a basis, but these slabs easily broke and crumbled into small balls. Then the developers used the extrusion method, which made it possible to make the slab monolithic and increase the strength characteristics by an order of magnitude.

Now there are universal models of insulation from Penoplex that can be mounted on different surfaces

If you do not take into account the dimensions, then visually all Penoplex slabs are the same, however, this insulation is divided into several specialized areas. The topic of the characteristics of each direction is quite extensive and deserves a separate publication, so now we will only outline the priorities.

- To insulate the foundation and basement sector, material labeled “Foundation” is produced. It is able to withstand the load when compacting the earth without deformation, plus it resists frost heaving processes well;

- Wall foam is considered the most popular. It is not designed for strong compression, but the price of this material is lower;

- Penoplayex marked “Roofing” is intended for laying into a roofing pie. The thermal insulation characteristics here are the same as those of the wall version, but the roofing version does not deform at relatively high temperatures, which is important when installing metal tiles and flat roofs in high-rise buildings;

- There is also a material marked “45”, it is intended for highly loaded surfaces. Simply put, it can be safely laid under a reinforced concrete screed when building a garage or house on a slab foundation.

Of all the types of insulation from the Penoplex brand, brand No. 45 is considered the most durable and reliable; these slabs can even be laid under roads and airfield pavements, but the price of the material is high

All boards from Penoplex are absolutely impervious to moisture and can be safely classified as a waterproofing coating. But on the other hand, this is the weak point of this insulation, so when arranging the roof or interior work, it is necessary to take care of additional ventilation, otherwise condensation will accumulate.

When choosing insulation, you need to start not from the price, but from the performance characteristics of a particular Penoplex model.

Foam Adhesive Manufacturers

If you purchased glue made in Germany or France, then this is the best composition that has exceptional properties. The next best quality compositions are Turkish, Estonian and Polish solutions.

If we talk about domestic manufacturers, then everything is debatable; you can find a good composition, but you can stumble upon low-quality glue.

You should not buy foam made in China. Such polyurethane compounds are short-lived and quite often toxic.

For work it is recommended to use:

- T-Avangard-K. Used for gluing insulation boards to concrete, brickwork, and gypsum plaster. Sold in the form of dry powder mixtures, which are diluted with water (5-6 liters of water per 25 kg). Mixtures of this type are available in winter (from -10 to +5 degrees) and summer (from +5 to +35 degrees).

- Tytan Styro 753. This one-component adhesive is sold ready-made, in cans. You can grind the surface and attach the dowels within 2 hours after gluing the insulation.

- Ceresit CT 83. Also sold in dry form, in packages of 25 kg. To prepare the mixture, 1 kg of composition will require 0.22 ml of water.

- TechnoNIKOL. Polyurethane foam has good adhesion and is often used in professional construction. TechnoNIKOL compositions are not afraid of moisture and, despite the fact that the foam was created for interior work, it can also be used for exterior decoration.

- Macroflex. The compositions of this brand are also available in winter and summer. At low temperatures the composition expands less. Macroflex 65 foam is characterized by an expansion of 100%.

Having chosen the highest quality composition, all that remains is to apply it correctly, taking into account all the nuances of working with foam.

So which glue should you choose?

When deciding on the choice of adhesive, you should proceed from the characteristics of the insulation. The speed of drying is also important, especially if the work will be carried out indoors. By the way, it is for this reason that interior finishing work is not carried out in winter, because at this time it is quite difficult to ventilate the home.

We suggest you familiarize yourself with How to remove second glue

A few more tips on what glue to use for laying penoplex.

- The consumption of the mixture per square meter depends on the specific brand and is necessarily indicated in the instructions from the manufacturer. However, it is better to buy glue with a small supply, especially if you plan to process uneven surfaces or the person who will carry out the work does not have the proper experience.

- Polymer mixtures are more suitable for application to walls and ceilings. Mineral analogues are more suitable for external use, while polyurethane ones are more suitable for indoor finishing (in particular, flooring).

- When choosing an adhesive for installing penoplex, you need to take into account the fact that when working, the slab of material often has to be moved and leveled, therefore, beginners are not recommended to use brands that dry quickly.

- For exterior work, it is better to use loose mixtures that have good adhesion to stone, brickwork and plaster. It is important that the purchased packaging is intact. If it is not airtight, the quality of the dry mixture is impaired.

- To waterproof the surface or seams, bitumen or polymer compounds are used.

- For wooden and reinforced concrete bases, choose polyurethane adhesives.

- Penoplex can be glued to a metal base using liquid nails, polyurethane foam or silicone sealants. Gluing on regular PVA will be inexpensive. It is first applied to burlap, which is attached to the metal, and then penoplex is attached.

- Insulating material can be attached to plastic, corrugated sheeting or chipboard using liquid nails.

- If both the ceiling and walls are insulated, it is better to use polymer compounds.

- It is better to use polyurethane mixtures for thermal insulation of the floor and when carrying out interior work, and mineral ones for exterior finishing.

- A universal product for all surfaces and rooms is foam adhesive.

Each type of penoplex glue has its own advantages and disadvantages. Bitumen options, for example, provide excellent waterproofing, but are odorous and often contain solvents. The latter are chemically aggressive and corrode penoplex. Therefore, the list of bitumen adhesives for it is limited. Usually they take Bitumast XPS without additives. It doesn't contain:

- diesel fuel

- gasoline

- kerosene

- benzene

- toluene

- polyester

- coal tar

- formaldehyde

- formaldehyde

Penoplex is “afraid” of all this. It is also not advisable for the insulation to be exposed to ultraviolet rays. Therefore, penoplex must be closed and does not serve as a final finish.

Acrylic compounds are harmless, odorless, but expensive. Expenses cannot be avoided if you need to attach penoplex to wood. Mineral mixtures work on concrete and brick, and polyurethane mixtures work on metal and other smooth, dense substrates. They will not attach insulation to wood.

Of the polymer adhesives, most people know polyurethane foam. However, it is expanding. Theoretically, the foam will secure the penoplex. True, you will have to press the insulation slabs to the base every 5 minutes, waiting for the end of expansion.

Titan Styro-753 and Insta-Stic are considered ideal for penoplex polymer adhesives. Both are sold, like foam, in cylinders, but do not expand during the process of attaching the insulation. Liquid nails work just as well. However, they are expensive, even with a spot application pattern. This is when the glue is placed on the base in such buns at a distance of about 25 centimeters from each other.

The most universal is the branded Fastfix. It fixes penoplex on any surfaces with the exception of Teflon, polyethylene, foil, silicone and bitumen. You have to pay extra for the wide spectrum of action and narrow specialization of the glue.

But Fastfix is easy to use, can withstand up to 130 degrees Celsius in short periods and 90 degrees of constant heating. Additionally, the glue “boasts” of no shrinkage and minimal thermal conductivity.

Foam adhesive consumption for polystyrene foam

Before work, the technician needs to make sure that the purchased product is enough for the entire scope of repairs. To do this, you need to study the packaging and find information about the consumption, which depends on the weight of the bases being glued.

For example, TechnoNIKOL foam adhesive has a higher concentration of active ingredients: 600 grams in a 750-milliliter container. Therefore, on average, one cylinder will be enough to cover 10 to 12 square meters of surface.

Experts advise making a preliminary calculation of consumption in order to stock up on the required number of cylinders of one brand. Don’t risk buying products from other brands later, because each manufacturer has its own quality of sizing.

Adhesive composition "Titan"

The Titan trademark belongs to the Polish company Selena. A significant part of the products are universal adhesives and sealants. During repairs, the help of professionals may not be required if you appreciate the universal Titan adhesive. For penoplex, the Professional Styro 753 series is most often used. The composition is resistant to atmospheric influences, can withstand multiple freeze-thaw cycles, and does not shrink.

In order for the surfaces to be glued to fit tightly to each other, stick together efficiently and serve for a long time, it is necessary to correctly calculate the consumption of glue for penoplex. If you do not have the skills to work with this material, much more glue will be used than what the manufacturer indicated on the packaging

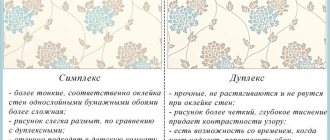

Differences between polystyrene foam and polystyrene foam

Foam adhesive for polystyrene foam and compositions for polystyrene foam have differences in structure. Foam plastic is foamed plastic. There are dozens of types of plastic, therefore there are also many subtypes of foam.

Every foamed plastic is foam plastic, and polystyrene foam is its subtype. Sometimes in construction stores they can be passed off as the same material, but this is wrong. Builders, on the contrary, urge to distinguish them by separate names. Yes, they are similar in appearance, but they differ in structure and properties. Therefore, different adhesive foams are needed for such materials.

Types of adhesive foam

The composition of any type includes isocyanate oligomers. Substances under the influence of ambient oxygen displace isobutane and propane. Foam adhesives are produced in metal cylinders, the capacity of which is 400, 750, 1000 ml.

Types of glue:

- universal;

- polyurethane for polystyrene foam, for XPS boards;

- for PIR and PUR panels.

The universal composition is produced in one-component form for internal and external use. Not only insulation is placed on it, but also decorative interior elements made of wood, tin, and plastic. It resists moisture and aging well, and adheres well to materials. Adhesive foam blue.

Polyurethane adhesive is used for installation of extruded and pressed polystyrene foam. This adhesive foam is also used for fastening lining, PVC strips, cardboard, and ceramics.

Foam adhesive for PIR and PUR panels turns gray after hardening. The setting time is increased compared to the universal material.

Price of adhesives for penoplex and reviews about them

The price of penoplex glue depends on the type of fastening composition. Mineral mixtures are usually sold in bags of different sizes. The maximum is 25 kilograms. Most manufacturers ask 300-400 rubles for them.

Polymer adhesives are sold in tubes, from which they are squeezed out using a mounting gun. The popular tube size is 750 milliliters. You need to pay 400-700 rubles. They ask for the maximum for specialized Fastfix glue.

Waterproofing compounds are usually sold in buckets. The running volume is 3-5 liters. If they are acrylic based, the fee will be about 2-3 thousand rubles. Bitumen glue is several times cheaper.

Product reviews help you make your final choice. However, in the case of fastening penoaplex, they are also contradictory. Rare reviews indicate all the conditions of the work performed. They omit either information about the basis or the working conditions.

It is difficult to find reviews about the service life of insulation after installation. However, there is a list of the most praised adhesives. In addition to those listed in previous chapters, it includes Eko Hacet, Laes, Penosil Fix and Go.

The adhesive with the highest cost is not necessarily a guarantee of high quality if the selection did not take into account environmental factors and the specifics of the work. The use of universal compounds, as a rule, reduces the cost of work than the use of highly specialized glue. Quick-hardening compounds can be used very economically (if the work is performed by a professional).

We use an inexpensive analogue

If there is a lack of funds, you can attach polystyrene foam to polyurethane foam. In order to reduce its consumption, install the insulation using a gun.

When choosing polyurethane foam for penoplex, polystyrene foam and other polystyrene foams, pay attention to its components. It should not contain toluene, alcohols, solvents, or other substances that lead to destruction of the structure.

The procedure for preparing the surface and applying the mixture to the slab does not change. Before gluing the foam, the wall must be moistened with water. Brick and concrete – generously, wooden – lightly.

There are some small peculiarities of fastening penoplex and polystyrene foam with polyurethane foam. They are due to the low speed of gaining the required density. When used in the same manner as adhesive foam, the slabs will need to be held in place for a long time (from 40 minutes to an hour). But this can be avoided.

After applying the composition, apply it to the surface for 3-5 seconds and shake the slab from side to side. Tear it off. Re-apply the mixture to it in a volume equal to half of the required amount. Wet the foam with water from a spray bottle.

Let the process of hardening and gaining density begin. The operating time will take from 2 to 4 minutes (during this time, prepare for the next installation). Then place the plate in place and press it firmly for 10 seconds. You can attach the next one.

This use case will significantly speed up the work process and eliminate the need to use supports and spacers.

How to use penoplex glue correctly

Regardless of the base and the chosen brand of glue, the general requirements for installing insulation should be taken into account. The surface must be cleaned and prepared for installation.

Important points

- Dry mixtures must be diluted with water only in the proportions specified by the manufacturer.

- Penoplex slabs must be laid as tightly as possible so that the gaps are as small as possible. In addition, the gaps must be filled with mounting foam or sealant in order to minimize heat loss.

- Particular attention should be paid to the temperature regime - most adhesives lose their properties (partially or completely) in the case of sub-zero temperatures.

- When using glue for penoplex, you must use a level to ensure that the surface is as smooth as possible.

- In the case of using a soluble mixture, the composition is applied to the insulation boards evenly, after which they are pressed and held a little so that it (the insulation) sets.

- Do not use “liquid nails”. Of course, such a mixture will fix the insulation boards, but the consumption will be very significant.

- If the adhesive composition is used from a tube, then it should be applied along the perimeter, and an additional “zigzag” is also performed over the entire area.

- Most polymer compositions harden within three to five minutes. You need to remember this during installation, and lay the insulation extremely evenly the first time.

Now - directly to the process of laying penoplex.

Penoplex, we insulate the foundation reliably and correctly

Previously, we talked about how to insulate a foundation on your own using penoplex; in addition to this article, we advise you to read this information and read about it here

Stage one. Preparatory activities

If all consumables and equipment are prepared, then you need to understand one important point: high-quality installation of penoplex can only be done on a clean surface. Consequently, both the walls (or any other surface) and the insulating material itself must be cleaned of all excess, and, if necessary, covered with a primer mixture.

Stage two. Direct installation

The installation of insulation should begin from the bottom (if we are talking about a wall) or from the edge (if the surface is horizontal). The first sheet of penoplex is taken, covered with an adhesive composition and leaned against the surface. You need to hold the sheet for so long that it no longer lags behind, only after that the next one is taken.

Note! The installation must be done with the utmost care (ideally, someone should observe from the side and tell you whether the connection is accurate). Moving the penoplex after the glue has set is quite difficult: in extreme cases, you will have to remove it, process it and reinstall it.

Stage three. Facing

After installing the insulation, the surface is usually covered, which is why it is necessary that the work be carried out in the warm season.

Video - Installation of penoplex

Specifications

To understand the functions of the tool, you will need to study its technical characteristics. The basis of the composition is polyurethane, a polymer with increased adhesion.

It is convenient to work with adhesive foam. It is resistant to water and moisture. Economical, sets quickly. Therefore, the insulation of facades takes place in a short time. Such compositions are resistant to temperature changes and have good heat-insulating properties.

Advantages

One package will be enough to treat ten square meters of surface. The master does not need to prepare the composition by stirring the components or diluting it with water. It is already ready for use.

Other benefits:

- After application, the adhesive seam almost does not change its shape and does not expand.

- Applying foam is convenient and easy. It will not be difficult to remove excess material. To do this, use paint solvents or a special cleaner, which is offered by many manufacturers of polyurethane foam.

- Primary setting occurs in 1-2 hours. Complete hardening of the composition will be completed within 24 hours.

- The resulting seams will be strong and reliable.

These factors are the opposite of most other adhesives. They need more time to harden, which leads to an increase in finishing time.

Flaws

Compared to similar products, mounting adhesive foams are sold at higher prices. This composition must be applied with a professional glue gun, which is not included in the kit, so you will need to purchase it separately.

However, not all manufacturers produce products that meet all the declared qualities. Therefore, first we recommend that you study the reviews of specialists about working with products from specific brands on the Internet.

How to choose the right polyurethane foam

To ensure high-quality fastening of insulation, professionals recommend following several rules when choosing a composition. Check them out:

- Great glue is never very runny. To determine its condition, it is enough to squeeze out a few drops. It is better to make purchases in specialized construction stores that have verification testers.

- The mixture should not be too dense. When working with polystyrene foam boards, too much dense composition will be required. A normal 800 ml cylinder is designed for a flow rate of 125 ml/m2.

- The composition must withstand sub-zero temperatures. Before purchasing glue, you need to read its description. The label must indicate the operating temperature. It must withstand its plus and minus values.

- The foam should not contain carbon dioxide or freon admixture. The presence of isocyanate oligomers is welcome.

- The polyurethane foam should set within 10-15 minutes.

- The degree of adhesion relative to foam plastic must exceed 0.8 MPa.

What to look for when choosing foam adhesive

In order to adhere the insulation for a long time and with high quality, when choosing polyurethane foam, you must consider the following recommendations:

- Good glue should not be liquid. This indicator can only be determined by squeezing out a little solution. Therefore, it is better to buy glue in large construction stores where there are “testers”.

- Density and vapor permeability of the composition. If the adhesive for polystyrene foam is denser, then a larger amount of the composition will need to be used for finishing. Normal foam consumption (with a cylinder volume of 800 ml) is about 125 ml/m2.

- The glue must be resistant to low temperatures. Therefore, look for formulations whose label states that they can be used in sub-zero temperatures. Also, adhesive solutions must withstand elevated temperatures.

- The adhesive should not contain freon or carbon dioxide impurities. But isocyanate oligomers, on the contrary, are welcome.

- The foam setting time should be 10-15 minutes.

- The degree of adhesion in relation to concrete should be at least 0.3 MPa, and to foam plastic not less than 0.8 MPa.

You also need to pay attention to the manufacturer of the composition.

Types of adhesives

The strength of the finishing work performed is directly affected by adhesion - the bonding force of the glue with the insulated base. Any adhesive composition offered to customers is always accompanied by instructions that describe in detail the main characteristics. The accompanying document describes the types of insulated substrates on which this particular adhesive for penoplex can be used, and the permissible humidity parameters. The temperature regime at which finishing work can be carried out is indicated, as well as the temperature range at which the finishing will last a long time and with high quality.

Adhesive compositions used for working with penoplex can be divided into several types:

- mineral (cement);

- gypsum based;

- waterproofing;

- polyurethane;

- composite polymers.

The most important difference between these groups of products is the component on which they are made. A composition based on cement or gypsum is recommended for use on dry substrates. Otherwise it will harden quickly. An alternative is to mix small amounts of glue and use it quickly. This fact cannot be considered an advantage, however, adhesive compositions based on such bases (cement and gypsum) are in greatest demand among buyers today.

Waterproofing adhesives for working with penoplex are usually made from bitumen.

When choosing an adhesive, one should not lose sight of the characteristics of the material that will be glued. When carrying out work indoors, you must definitely pay attention to the drying speed of the glue: any glue for penoplex has a rather corrosive odor, and in winter it will be difficult to ventilate the room well enough.

Application technique

TechnoNIKOL foam adhesive and other brands of such compounds must be used in strict compliance with the manufacturer’s instructions. To work correctly with such tools, they follow the following algorithm:

- pre-clean the surface from dirt and grease;

- put a nozzle gun on the glue bottle;

- foam adhesive for polystyrene foam is applied evenly (try to maintain the thinness of the layer required for gluing);

- then the glued part is placed on the surface with the material and pressed with force to secure it;

- the processed parts are left to harden for the time specified in the manufacturer’s instructions;

- It will take at least 1.5-2 days for the adhesive foam to completely harden.

Operating procedure

Work is best carried out in calm, warm weather.

To thoroughly adhere polystyrene foam insulation, clean the surface to the material of the insulated surface. Set the starting bar strictly horizontally.

Its width is equal to the thickness of the sheet used. Remove dust by rinsing or sweeping. Prime the wall using a roller or brush. Treat the surface of the foam with a needle roller to improve contact with the adhesive.

Sticking foam is carried out in the following sequence:

- prepare the cylinder for use according to the instructions for use;

- screw the cylinder onto the gun, avoiding distortions;

- apply foam to the treated surface of the slab along the perimeter in a continuous strip about 3 cm high, then in the middle along the long side (the distance from the edge to the layer is at least 20 mm);

- install the stove in its designated place;

- if necessary, adjust its position, checking it using a long building level or rule;

- carry out subsequent stacking of sheets from bottom to top;

- Fill the resulting joints with foam;

- After 30 minutes, cut off the excess that appears with a construction knife.

To adjust the position of the sheet, the same polystyrene foam is used. Use a gun to pierce the foam and pump in the adhesive composition. The leaf retains its relative mobility for 10-20 minutes.

The use of adhesive foam makes installation work as easy as possible. The work can be carried out by one person, both on the surface of the earth and at height.

Recommendations for the use of Titan foam

The combined use of Titanium foam and penoplex is not particularly difficult, although for high-quality and reliable fixation of the insulation it is recommended:

- before treatment, clean the surface and lightly moisten it with water, which will increase the expansion volume and setting speed;

- Before use, shake the container;

- when spraying, hold the container upside down;

- seams must be filled from bottom to top;

- after hardening, the excess foam is cut off, and the place of application is covered with any protective materials, since the “installation” is destroyed under the influence of direct sunlight (plaster, silicone or acrylic sealants).

When performing work, you should follow safety and industrial hygiene rules, do not spray near an open fire, and do not heat the used aerosol can over a fire or pierce it. Additional costs for purchasing fixing devices will pay off in winter, allowing you to save on heating.

Application technology

In fact, there is nothing complicated in the process of attaching polystyrene foam using special adhesive foam. After all, it was designed to simplify this process.

Adhesive foam is applied to the foam board along the perimeter, with one clear tape

But we will still outline the algorithm of work and take into account several interesting nuances that may affect the result.

It is important to understand that the installation technology does not differ depending on the choice of the adhesive foam itself for attaching polystyrene foam. That is, AKFIX 960 foam will be applied in exactly the same way as Ceresit C-84 adhesive foam.

There are, of course, certain differences, but they relate rather to the technical side of the issue, without affecting the general process.

For example, AKFIX 960 cools faster than Ceresit, and therefore, after application, the slabs will also have to be glued more quickly. But again, even here the difference will be completely insignificant. The point is about differences in a matter of minutes, nothing more.

Stages of work:

- We clean the surface of the polystyrene foam from dirt and dust.

- Clean the base. If the base quickly absorbs moisture, prime it.

- We load the cylinder into the gun.

- Apply foam around the perimeter of the slab.

- Apply another strip of foam in the center of the slab.

- We glue the slab in the right place.

- Let's correct its position.

- We lay the remaining slabs.

- We blow out the joints between them with glue foam.

- Cut off the remaining hardened foam with a knife.

- After 20 minutes you can still trim the slab.

- After 2 hours, the foam has completely cooled and you can begin further processes, for example, drilling dowels or applying the first layer of plaster.

After use, the gun must be washed. Moreover, this is done both mechanically and with the help of special cleaning compounds.

Let us remind you that you can buy polystyrene foam in Orel at a favorable price.

Mechanical cleaning consists of cutting off excess foam from the supply tube, and chemical cleaning is carried out using cylinders with cleaning liquid. They are connected to the gun and the barrel of the instrument is pumped at maximum pressure until it completely leaks.

2.1 Selection of adhesive foam for polystyrene foam (video)

What are the advantages of using foam in the case of penoplex?

Penoplex is used as a soundproofing material, and polyurethane foam is used to blow in the seams between the plates. At the same time, it qualitatively seals the seam. Another useful function offered by foam is gluing the foam board to surfaces, even vertical ones.

Even an inexperienced builder can do this kind of work. The slabs are glued unnoticed, however, the penoplex is securely fixed and they proceed to the next stage.

Application of foam with penoplex

Using this product instead of glue will help save money, applying the foam is much easier and requires less time to dry completely than glue. The use of foam is in no way inferior to specialized glue in terms of adhesive properties. Why do they buy it to simultaneously use it both for gluing penoplex and for blowing in seams and joints.

Taboo components for glue

There is a list of components that are prohibited for use in the manufacture of adhesive compositions for working with penoplex, polystyrene foam, extruded polypropylene foam. Under no circumstances should there be fuel and lubricants - kerosene, gasoline, diesel fuel. Among aromatic compounds, it is unacceptable to use benzene and toluene. Do not use polyester and coal tar, formaldehyde and formaldehyde, or any type of solvent.

Adhesive foam for polystyrene foam: brands

Builders consider the best products to be those made in Germany or France. In second place are Polish, Turkish, and Estonian manufacturers.

Experts advise giving up cheap Chinese products. Such products cannot effectively cope with their functions. We recommend choosing trusted brands.

TechnoNIKOL

TechnoNIKOL foam adhesive is a universal polyurethane composition for external and internal insulation of buildings. It is characterized by mold resistance and high adhesion to most materials.

Glue 500 PROFESSIONAL interacts well with PPS. It provides strong adhesion and strength to the seam. According to reviews from craftsmen, it copes with polystyrene foam better than other compounds.

Akfix 960

A one-component composition made in Turkey based on polyurethane, which is often found in building materials stores. Suitable for both expanded polystyrene and foam.

It is used for installation of thermal insulation of building facades. Sold in 900 ml bottles. It is moisture resistant, so it can be used in conditions of high humidity.

The consumption of adhesive foam is economical; one package is enough for several jobs. They can be carried out at air temperatures from -10°C to +30°C and humidity not exceeding 60%.

A professional gun is required for application. Before this, the surfaces must be cleaned of dust, dirt, grease and oil residues. Akfix 960 can be used for external work with materials based on mineral binders:

- brickwork;

- concrete, gypsum panels and slabs.

Makroflex MF 901

Makroflex MF 901 adhesive foam is a means for rapid gluing. Can be used for external and internal work. Macroflex interacts with metal, ceramics, wood, stone, glass, and foam. You can work with it in hot weather.

It is better not to use at sub-zero temperatures. The pre-treated surface must be cleaned, otherwise the gluing will be poor quality.

Ceresit CT 84

Ceresit CT 84 Express adhesive foam for PPS is often found in construction and hardware stores. It is produced in 850 ml cylinders. It is characterized by good adhesion, reasonable price, and ease of application.

Designed for installation on bases made of mineral binders:

- PPS slabs and sealing joints between them;

- Thermal insulation systems on the outside of new buildings and during the reconstruction of existing ones.

It is necessary to work with it at air and base temperatures from -10 to +40 degrees Celsius. Post-processing of the slabs can be carried out within two hours after gluing them. This is possible provided the outside air temperature is from -10°C and its humidity is not lower than 60%.

Tytan Styro 753

This is a mounting foam adhesive from a Polish manufacturer, blue in color, without shrinkage. Titan Stiro 753 is sold in cylinders with a volume of 750 milliliters.

It sets quickly, within an hour. It will take half a day to completely harden. It tolerates humidity, cold and heat well, so the adhesive is used for installing expanded polystyrene and polystyrene boards on building facades. One cylinder is designed to work with 10 square meters of surface.

Instructions for gluing penoplex

When you have chosen what to attach the material to, you can proceed directly to work. It is important to properly prepare the surface of the base; you can do this yourself. It should be cleaned of debris, dirt, and dried. If the manufacturer recommends, you must first prime the surface. Next, you should cut out the necessary pieces of the base material. How to cut penoplex? For this purpose, a stationery knife or jigsaw is used.

Installation technology

After drawing up an installation plan, you can begin gluing the product to the floor, walls or ceiling. Mineral wool is often used under penoplex.

There are several ways of gluing with glue:

- point,

- solid,

- borderline.

The dot method is more often used, in which liquid glue is applied with a spatula 100-200 mm wide. Then you should wait a certain time and press the material to the surface. After complete drying, the joints are sealed with polyurethane foam or the same glue. The second option is much more expensive.

Glue consumption

All useful information for the user, including material consumption, is always indicated on the packaging. The usual figure is 3.5-5.5 kg/one standard layer of material (for mineral mixtures). Glue in cylinders is more economical and consumes less (from 10 sq. m per cylinder).

Puttying penoplex

After the glue has completely dried, you can additionally fix the penoplex with dowels, this is more reliable. Next, puttying with finishing materials is performed. The putty must be applied smoothly, layer by layer, and the putty must be smoothed evenly. After the first layer, a mesh of metal, plastic, and reinforcing is attached. The thickness of the first layer is up to 1 cm, the second – slightly less. 2-3 layers are performed as desired, with the third layer usually done by spraying and up to 5 mm thick.

External foam protection

For external protection, special glue is used. Which one is used in this case? A product with high adhesion to the surface is suitable; you can choose the brands Ceresit, Master, Polymin. Some professionals prefer to use Gyprok, an insulation similar to plasterboard.

Gluing stone and tiles to penoplex

After the final stage of work, you need to think about finishing. Most often it is recommended to glue ceramic tiles, porcelain stoneware or artificial stone. This is done with tile adhesive with frost-resistant qualities; with its help you can easily and quickly finish floors and walls. It is imperative to apply several layers of plaster, preferably Ceresit ST 85 with reinforcing mesh. It is recommended to make a cement screed on the floor indoors, and then create a decorative covering.

Advantages of adhesive foam

Polyurethane foam glue is considered the best material for fixing polystyrene foam boards. This composition has many advantages. The main ones are:

- Easy installation. No special skills are required to start using this foam. Just read the operating instructions and you can start working.

- Big time savings. It takes much less time to glue one slab compared to dry mixes.

- Adhesive foam is not afraid of high humidity. It contains special components that contribute to the formation of moisture-resistant characteristics when the glue is completely dry.

- Prevents mold.

- Over time, the properties of the product do not change.

- Low thermal conductivity. Such a house will always be warm in winter and cool in summer.

- Low expansion. It never increases in size. The location of the foam plates is not disturbed.

- Excellent adhesion allows the foam to be used on any surface.

- It is highly economical. For 10−12 sq. meters you will need one cylinder.

- Installation of polystyrene foam boards can take place at a temperature of 5-35 degrees. The glue can withstand even temperatures down to minus 20 degrees, but no more than seven days.

- The foam has a long shelf life.

A partially used cylinder can be stored for 12 months after opening. In other words, damaged slabs can be replaced with new ones using the old composition.