Still, don’t forget the main thing

Today, the best way to install this flooring everywhere is with adhesive.

Whether it is glue for linoleum KS or any other is no longer of fundamental importance - the main thing is to use this particular product. And the choice depends on the type and operating conditions; fortunately, on the construction market you can choose glue for any conditions. Technologies for laying linoleum 30-40 years ago did not at all involve the use of any other means of fastening other than ordinary nails. And today the nails are “alive.”

Or you can simply lay linoleum, securing it only with baseboards. But, frankly speaking, such technologies are rare and not held in high esteem.

PVA glue for linoleum is one of the possible options, it is good for its ease of use, but it is important to choose the right manufacturer, beware of its excessive wateriness

The technology of “not having to worry” and simply nailing it to the floor is becoming obsolete, and you will really feel its lack when you need to move heavy furniture in the room. The slightest movement on the nailed linoleum will certainly cause waves, which will be very difficult to eliminate. And even without moving waves - a common sign of installation without glue.

Still, of course, glue is some nuances

So, of course, glue, but due to the large range and types of linoleums and adhesives, there are the following nuances of technology that need to be performed:

- before using any type of glue and on any surface, it must first be carefully leveled, vacuumed (and not just brushed off the dust) and degreased;

- the more porous the base of the bonded surfaces, the better the final result, therefore, other conditions being equal, leave your choice on options with greater porosity; Thus, you should not be surprised that linoleum on a pile, fabric and foam base adheres perfectly; Let’s not forget this aspect - in this case you have the opportunity to choose a cheaper glue option;

- when working with natural linoleum, use glue with a reduced moisture content, otherwise it will be actively absorbed into the base of the linoleum and cause excessive deformation;

Laying linoleum on glue - a sequential, step-by-step action of opening the entire roll on the floor above the layer of applied glue - pay special attention to the layer of glue directly under the rolled roll.

- Never use PVC glue when working with natural linoleum - due to the lower adhesive ability of polyvinyl chloride; violation of this rule will lead to significant changes in the structure of linoleum; keep in mind that the opposite is possible - natural glue is acceptable for use with PVC;

- More often, the base is joined to the glue immediately after applying the glue, however, water-dispersion adhesives require some time for the emergence and activation of internal chemical processes, so such glue requires time before applying linoleum;

- when using water-dispersion glue, it is also required that one of the surfaces absorb water, and since PVC does not absorb water, such linoleum can only be glued to water-absorbing substrates - concrete screed or wood;

- before placing the linoleum, it is recommended to unroll it and keep it in this state for at least a day;

- contact gluing technology involves applying glue to both surfaces to be glued - the applied glue dries for some time, and then the surfaces are connected to each other under pressure; This technology allows you to eliminate some kinks on the surface;

- You should not use a wet adhesive layer on a primed base - the glue will not set, since the water has nowhere to go;

It is important not to miss the moment when the instructions for use indicate the need to lay linoleum on glue

- it is very necessary to follow the manufacturers' recommendations for the consumption of PVA glue for linoleum - with increased consumption, the glue does not have time to dry sufficiently and the formation of air pockets inside cannot be avoided, and this is a direct path to “waves in three rows”;

- in residential premises it is recommended to use non-toxic, odorless and quickly drying acrylic-based glue;

- be especially careful when choosing glue if you are going to work with large areas; often a good alternative to glue in this case is linoleum mastic;

- if you do not feel like a professional in working with linoleum, you should not use epoxy and polyurethane adhesives, although they have one excellent advantage - ideal gluing of surfaces; but these glues are toxic and have an unpleasant odor, which, however, goes away quite quickly.

Helpful advice! Be especially careful when choosing an adhesive if you are going to install a system of artificial floor insulation - some types of adhesives release toxic substances under the influence of a constant, albeit low, up to 30 degrees, temperature, which is unacceptable in residential premises.

Glue for linoleum seams is a special case; here you can’t do without a dispenser

A special type of glue - cold welding

There is a special technology for gluing two sheets of linoleum, which is also called “cold welding”. There are two types of cold welding - A and B. Accordingly, these two letters can be found on the glue packaging so that you can make the right choice and not make a mistake.

According to technology “A”:

- the sheets are overlapped and precisely cut along the joint, ensuring zero gap;

- glue the seam with paper tape and pour glue into the slot;

- After 10 minutes the tape is removed, the seam is practically invisible.

Use in construction

Household PVA glue is not resistant to moisture, so universal mixtures are used in construction. Specialists use waterproof compositions in the form of an emulsion containing polymerizing components.

They provide the maximum level of adhesion and can be used on any surface. However, it is much more difficult to remove PVA with such components from linoleum.

The moisture resistance of the glue is marked with the letter “D”, and the degree of resistance is indicated by a value from 1 to 4. The composition is colorless and has a viscous consistency, and low consumption is considered an advantage.

Construction mixtures are resistant to ultraviolet radiation and demonstrate good strength. They dry quickly, do not shrink significantly and can be used for outdoor work, since frost resistance indicators reach -40 0C.

Commercial linoleum is best laid with glue

Examples

We bring to your attention examples of the most famous brands of linoleum adhesives; with a high probability we can say that one of them will be at your disposal:

- "Werner Müller" type "A" for cold welding. Suitable for welding both domestic and commercial linoleum, both short and long seams. The manufacturer's recommended consumption is one tube per 10 meters of seam.

- "Thomsit K 198" for heterogeneous and homogeneous PVC linoleums.

- "Werner Müller" type C for cold welding of wide seams. Consumption – one tube per 7 meters.

- "Homakol 208" is a universal water-dispersion adhesive based on PVA with resins.

- "Homakol 248" is a water-dispersion adhesive for gluing homogeneous and heterogeneous linoleum.

- "LINOCOL" - for gluing seams of PVC linoleum on a foam base. The result is a perfect, completely invisible seam.

- Forbo Erfurt 525 is a solvent-free dispersion adhesive with fast setting.

- "Forbo-Erfurt 522" is a dispersion adhesive for working on any type of floor.

- "Forbo Erfurt 523" is a light, conductive dispersion adhesive with high adhesive ability, but requires use on surfaces prepared with a conductive dispersion primer or on a mesh of copper tape.

- "Forbo Erfurt 578" is a frost-resistant adhesive for textile and vinyl coverings, capable of restoring its characteristics after defrosting, although it requires strict adherence to all technologies.

If you are laying linoleum on an electrically insulated floor, then, depending on the technology, it is often necessary to use conductive glue

conclusions

Sometimes a large assortment does not contribute to success, but only harms it. This can be fully said about the range of linoleum adhesives on the construction market. Try to figure out how to put these puzzles together so that they don’t go in waves.

But on the other hand, this situation forces the performer to constantly keep his nose to the wind and navigate as many sentences as possible. In any case, you cannot do without qualified assistance, and it should include both the degree of danger of the materials used, their consumption, and the appropriateness of use with this or that type of linoleum.

The recommended consumption of linoleum glue per 1 m2 is always indicated on the packaging - the consumption is a guideline, but we strongly advise you to adhere to it

You can study visual information in the video in this article.

Modern building materials stores offer a variety of means by which the coating is securely fixed to the screed. It is important that the material, after fastening, does not wave, does not crack, and is easily dismantled during subsequent repairs. Next, let's look at how to glue linoleum to a concrete floor? When choosing a composition, you need to take into account the type of coating, the area of the room to be covered, and the expected load on the floor.

Laying methods

The coating is attached to the concrete base in different ways:

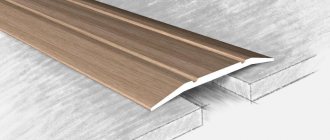

- No glue required. The material is held only along the perimeter by the baseboard and the fixing strip near the door;

- On tape. The flooring is attached with double-sided adhesive tape intended for construction work. Laying on tape is quick. During the installation process, you can glue individual strips;

- For mastic or adhesive. This method gives the most reliable results. Installation is labor-intensive, but allows you to forget about floor repairs for a long time.

When to glue linoleum

Before gluing linoleum to the floor, you should consider all the pros and cons. Attaching to the base makes sense if the material is spread for a long period of time. Short-term repairs involve installation without glue. When deciding on fixation, you need to consider the size of the room. In a spacious room it is not easy to fix the material without glue. In this case, the use of a binder is a reasonable solution.

What glue to use

Each type of coating is suitable for a specific binder composition. How to glue linoleum to the floor so that it sticks securely? When choosing a composition, you need to take into account the nature of the base, the type of surface, and the amount of further load on the floor. For fixation use:

- Dispersion glue. The product does not have a strong odor and is suitable for coating on a fabric, heat-insulating basis;

- Reaction composition. The adhesive is moisture-resistant, not afraid of sudden changes in temperature and difficult operating conditions;

- Bitumen mastic. The product is suitable for coating on a woven base;

- Synthetic adhesive containing artificial resin, rubber. The composition is well suited for material without a base.

Applying glue between joints

When gluing is not recommended

Fixing the material to the base is contraindicated if:

- The area of the rooms does not exceed 20 square meters. The material is spread in one large piece and secured with a plinth;

- The base is loose and unstable. Fixation to an unreliable screed is not recommended;

- The floor was painted, but the paint was peeling off in some places. Glue should not be used due to a possible reaction between the glue and the old coating. The floor may become stained;

- The basis is a screed, even a modern one;

- The floor is shaky, not strong, there are creaking floorboards.

Coating features

Among the majority of owners of apartments or private houses, linoleum remains the most favorite facing material, this is due to such positive qualities as:

- Durability.

- Easy to care for.

- Easy to install.

- Good moisture resistance.

- Wide range of colors and designs.

High-quality samples of products will successfully replace tiles, parquet and even laminate; any room in the building is suitable for laying the canvas, be it a kitchen, a nursery or a living room.

Often linoleum is laid in those rooms where it is often necessary to quickly carry out wet cleaning. To get rid of the feeling of cold that is characteristic of synthetic material, you should take care of the substrate, then staying in the house will become more comfortable and cozy.

A base made of felt or jute, in addition to thermal insulation properties, has a shock-absorbing effect, and thin samples of the coating will highlight all the defects of the coating, this should not be forgotten.

Glue to concrete floor

The coating is applied directly to the floor slabs after filling the joints with mortar and applying a leveling layer or on a semi-dry or wet screed. How to seal linoleum at home? The choice of binder mixture depends on the coating. The material on a woven basis, an insulating substrate, is fixed on the floor with dispersion compounds (Bustilat, Gumilax, ADM-K, etc.), bitumen mastic. Mixtures containing synthetic rubber and resins are used in the absence of a substrate.

Applying glue to concrete before laying linoleum

How to glue linoleum to a wooden floor

Wooden floorboards can serve as a good base for flooring. What glue should I use to glue linoleum in this case? PVA glue does an excellent job of fixing. The environmentally friendly, safe composition can be easily washed off with water in case of careless application. PVA is especially suitable for finishing floors in rooms with low traffic. Other options for adhesive compositions used for wooden bases are dispersion mixture and cold welding. Each of these compositions has its own characteristics and can be recommended depending on the type of coating.

Working moments

For high-quality gluing of surfaces, it is necessary to thoroughly mix the composition and achieve a uniform consistency. The recommended temperature is considered to be +10 0C and humidity no more than 80%.

PVA glue must be applied to a clean and dry surface. Only one part needs to be lubricated, as applying too much will reduce adhesion.

The recommended thickness is no more than 2 mm, and the product should not be touched until it is completely dry. However, it must be taken into account that it is much more difficult to wipe dried glue off linoleum than liquid glue.

The advantage of repairing PVA is its low cost combined with good performance characteristics. The glue is safe to use, and following the manufacturer's recommendations guarantees high-quality gluing.

What to do if linoleum starts to peel off

It often happens that the fixed coating peels off from the floor after some time and requires repair. How to fix the defect? If swelling occurs, you can make a puncture in the fabric using a thin awl. The air is then released and the area is ironed with a hot iron through a thin sheet of white paper. The glue melts and re-bonds the surfaces.

Gluing joints together

How to glue linoleum together if the fabric comes apart at the joints? The separation of the seam indicates a violation of the cold welding technology. The resulting defect can be easily eliminated - the seam is cleaned and degreased with alcohol and gasoline. Then the coating is carefully folded back and an adhesive is applied underneath it. Next, the joints are fastened by cold welding.

Technology for laying linoleum on the floor (general rules)

To reliably glue linoleum and ensure a long service life of the material, you need:

- Prepare a rough base in advance, use a linoleum backing;

- Let the purchased material “sit” in the room for 2-3 days, placing it vertically, then unfolding it;

- Use large pieces, minimizing the number of joints;

- Attach the baseboards during finishing only to the walls, which gives the coating the opportunity to change dimensions with temperature changes;

- Secure the edge of the flooring at the door with metal strips and self-tapping screws.

Conditions for performing work

For installation at home, the following tools and materials are required:

- Sharp knife;

- Notched trowel;

- A heavy roller or small roller for rolling the coating;

- Tape measure or long ruler;

- Double-sided tape or glue;

- Skirting;

- Metal strips;

- Linoleum.

Glue is applied, linoleum is rolled out with a roller

If you need to prepare the floor, you may need a self-leveling concrete mixture, a cement composition for cosmetic repairs of the base, and a drill with an attachment for preparing a leveling solution. In some cases, to level the subfloor, you need a plywood sheet, an angle grinder with a sanding attachment, a nail puller, or a needle roller.

Preparatory stage

Before sealing the floor, you need to thoroughly prepare the rough surface. The coating is attached only to a flat, dry base. Existing defects appear after laying the material, especially under heavy load, and reduce its service life. The concrete floor is pre-primed, which gives good adhesion when fixing the coating. We have made step-by-step instructions for you on how to lay linoleum on a concrete floor. A special compound is used to level the surface. After applying the mixture, the base must dry completely.

Lay plywood, the distance between nails is 10 cm.

The wooden floor is leveled with high-quality plywood with a thickness of 5 mm. If the flooring will be made on laminate or parquet, you need to make sure that the base is reliable and, if necessary, replace loose elements. The same goes for the tile base. Before laying, the floor should be cleared of traces of putty and other construction debris, and the surface should be cleaned with sandpaper.

Self-adhesive

The covering is fixed to the floor in the following order:

- Applying glue. The composition is evenly distributed using a notched trowel, first on one side of the material, then on the other;

- Accommodation. The material is laid on the floor, smoothed with a roller towards the corners;

- Coating adjustment. The flooring is pressed very tightly around the perimeter, the excess is cut off at the base of the wall. The corners are cut diagonally and tucked under the baseboard;

- Eliminating air. After processing the corners, the material is smoothed tightly over the entire surface;

- Sealing seams. You can glue linoleum at the joints using cold welding - a special glue designed to secure the edges. The product can be colorless or matched to the color of the coating.

How to glue linoleum joints?

When using multiple pieces of material, seams will form. How to glue linoleum end to end? The gap that needs to be sealed is cleared of moisture and dust. Before gluing linoleum joints, apply single-sided adhesive tape to the seam. Next, carefully cut the tape at the seam. Glue is squeezed into the resulting gap. After 10-20 minutes the tape is removed. After an hour, the floor can be used.

Applying glue between joints

Is it possible to glue linoleum to PVA?

When choosing a particular adhesive, you need to take into account the properties of the base and the characteristics of the coating. This fixation is suitable for a wooden base. It is important to note that dried PVA reduces the elasticity of the flooring. For this reason, it is better to secure the material in this way in places where there is no heavy load.

Scope of application

PVA glue is used in construction for gluing wallpaper and laying floor coverings. It is often used as an impregnation for wood to give the material water-repellent properties. And of course, you can glue linoleum with cold glue.

The division into the following groups is accepted:

- household - suitable for wallpapering, provides good adhesion to surfaces made of concrete, plasterboard, plastered brick, often used for working with cardboard and paper;

- stationery - used for household needs and creativity;

- universal - indicated by the marking MB, suitable for gluing paper, wood, glass and leather elements. Another area of application is repairing linoleum with PVA glue.

By adding 5-10% glue to the cement mortar, waterproofing properties and adhesion to the surface are improved. Adding 70g/10L to the plaster speeds up the drying time and improves the result due to a more even application.

General recommendations

Linoleum comes in two main types: natural and synthetic (PVC). Materials vary in characteristics and functionality. Based on this, you need to choose glue. If the packaging says that the composition is only suitable for natural linoleum, then it cannot be used for synthetic.

Why you should choose the adhesive installation method:

- the floor covering increases its wear resistance and strength characteristics, since it is fixed over the entire area;

- the appearance of “waves” and swellings, which most often form when moving furniture, is excluded on linoleum;

- seams secured with glue are stronger;

- When installed with glue, the service life of linoleum increases by approximately 50%.

Disadvantages of this method:

- the floor cannot be used until the glue has dried;

- laying with glue requires preliminary leveling of the base and creation of a screed.

Obviously, the advantages of this installation method are much greater than the disadvantages. If you decide to give preference to it, then you should decide which glue to glue the linoleum in your case.

Dispersion adhesive for linoleum

This glue is water-based and contains cellulose-glycolic acid, acrylic, latex, and chalk. Its advantage is the absence of harmful fumes and odor, that is, complete safety for humans. However, there are also disadvantages. Thus, dispersion glue is not suitable, for example, for a summer house, because after freezing it will not restore its original properties. Linoleum can also peel off due to high humidity. The conditions for its use are constant humidity of no more than 60% and temperature above 15°C.

There are three types of dispersion adhesive:

- acrylate (resin-based). It has high viscosity, is suitable for coatings based on jute, fiber, synthetics, and can withstand average traffic;

- Bustilate is the most popular type, suitable for felt-based linoleum;

- humilax (based on rubber and latex) - used for natural coating or synthetic, but on a felt or fabric base. Provides strong hold and rigid adhesion, low water content.

Why is it better to choose an adhesive installation method?

Experts advise laying linoleum without gluing only in small rooms (up to 10 sq. m.). If you do not have enough width of one panel and have to lay several strips, then the material also definitely needs to be glued.

Even in small rooms, linoleum that is laid in one piece can become deformed. Over time, pits may appear from the legs of moved furniture and chairs, as well as unsightly waves. At the thresholds and at the junctions of individual panels, cracks that spoil the appearance of the floor are formed, which are a consequence of the material drying out over time.

Over time, loose linoleum begins to wrinkle unsightly

A non-adhesive coating is easier to accidentally damage during operation. Experts say that the service life of linoleum glued to the base is 40% higher than that installed using non-adhesive methods.

The only drawback of this method of laying linoleum is that the panels are very difficult to dismantle if necessary, but if you choose a high-quality coating and carry out the installation according to all the rules, you are unlikely to repair the floor in your home again soon.

Properly laid high-quality linoleum will delight you for many years

How to glue linoleum to concrete?

The dispersion composition is suitable for any surfaces that absorb water well. You can glue linoleum with this glue onto a wooden floor, screed, or concrete base. It is optimal for synthetic coatings because they do not absorb water, and the adhesive must be applied directly to the base.

Reaction adhesive for linoleum (cold welding)

Compositions of this type enter into a chemical reaction with the coating base, melting it. It is used more often when laying commercial linoleum than household linoleum, and in order to glue joints, rather than the entire canvas. When used at joints, it forms a strong monolithic connection. Due to the fire hazard and pungent odor, it is not recommended for use in living rooms.

Types of glue for welding linoleum:

- type "A". Used only for new coatings, it forms a transparent, durable seam that is not visible to the naked eye. Suitable for hard linoleum;

- type "C". Allows you to remove large gaps (3-4 mm), suitable for old linoleum that has “disintegrated”. A rigid strip is formed between the edges of the coating;

- type "T". Suitable only for synthetic polyester-based surfaces.

Alternative to cold welding

After gluing the canvases, the joints can be joined using special equipment, namely by hot welding at a temperature of 400°C. To do this, use a welding gun into which a cord is inserted. A groove is formed at the junction. When the gun operates, a cord comes out of it, which fits into a groove and melts, connecting the edges of the canvases. After cooling, the seam is sanded. Cords are available in different colors.

Adhesive for linoleum KS, Moment, PVA, contact, conductive: consumption, photo and video

- Glue, which, after drying, creates a rigid connection between the floor and the coating (the most famous and often used when laying linoleum is PVA);

- wet gluing, applied with a roller or brush (for absorbent substrates);

dry gluing applied with a spatula (universal, including for non-absorbent substrates);

How to trim

Let's start with how to cut linoleum. There are two options - a knife and scissors. Both can work normally, they just have to be sharp.

Some people find it more convenient to use a stationery knife, but a shoe knife or a sharp kitchen knife will also work, although there are special ones. They have a retractable blade, like stationery knives, but their handle is curved and the blade almost does not bend.

On a utility knife, the ridges that hold the blade must be iron. In this case, the blade is more elastic and there is less chance that the cut will go to the side. It is precisely because the blade can “lead” that some craftsmen prefer powerful scissors. To make cutting easier, they make an incision, and then, without making cutting movements, they simply rip the coating along the intended line.

Now about where to trim. Roll out the linoleum so that it extends slightly onto the walls. If there are several canvases, an overlap of at least 5 cm is made at the junction. If there is a pattern, lay out the canvases so as to achieve a match. Then the connection point will not be noticeable.

How to treat the surface → Room decoration → How to choose the right paint → Surface treatment technologies → Leveling and finishing the walls → Selecting and applying a primer → Removal from the surface → Stretch ceilings and technologies → Reviews and testimonials