A single-pitched roof is ideal for an individual garage.

Moreover, this does not depend on what material the walls of the box are built from. The construction of this type of roof is more economical compared to a gable roof, where the need for materials is much higher and requires more labor.

Let's look at step by step how to properly build a pitched roof on a garage with your own hands.

Types of garage roof

Depending on the design, there are 2 main types of roofs, which are advisable to erect on a garage:

- Single-pitch;

- Gable.

Roofs differ not only in design, but also in complexity and installation costs. A gable roof is usually more expensive and more difficult to construct.

Shed roof

The best option for garages adjacent to or part of other buildings. This is especially true for garage cooperatives. Installation is carried out using inclined hanging rafters supported by 2 beams.

The structure of the rafter system depends on the area and layout of the facility.

- If the width of the garage does not exceed 4.5 m, a simple roof is constructed, consisting of rafters fixed on two supports at a certain angle.

- At a distance of 4.5-6 mm, it is necessary to erect a more complex roof, including additional struts to strengthen the structure.

Gable roof

This type of roof is erected only if the garage is a separate object. The design has the shape of a triangle. The side parts (gables) are covered with boards, metal or other material. This roof is suitable for a garage of any size.

The rafter system is erected in the form of two rafter legs fixed on the mauerlat and at the top of the structure. The supports of the rafters are the load-bearing walls of the building.

Advantages and disadvantages

The popularity of pitched roofing is due to a number of advantages:

- Ease of design and subsequent construction;

- Minimum consumption of materials;

- Construction speed;

- With the correct orientation of the slope, high strength and resistance to adverse weather conditions are ensured;

- Allows the most efficient use of under-roof space;

- Rainwater and snow are discharged in one specific direction;

- Applicability of all known types of roofing materials;

- Absence of corners representing potentially unreliable areas.

Of course, nothing is perfect. There are also disadvantages to a pitched roof that must be taken into account during construction:

- You cannot equip an attic, attic or under-roof space;

- It is impossible to install additional good thermal insulation if it was not calculated during construction;

- When there is wind from the high part, the pitched roof is not stable.

Installation of a pitched roof

The shed roof of the garage has a simple sloping design. In most cases, the supports are 2 beams mounted on load-bearing walls. It can have a different angle of inclination, based on the type of roofing material used and the planned load. The angle of inclination is formed due to the difference in the height of the walls.

Installation procedure:

- Installation of Mauerlat on load-bearing walls. These are the beams on which the rafters rest. It is optimal to use timber 10x10 cm or 12x12 cm.

- Fixing beams with anchors of sufficient length.

- Making fastening grooves in places where rafters are installed.

- Installation of rafters on the mauerlat. Nails or anchors can be used for fixation.

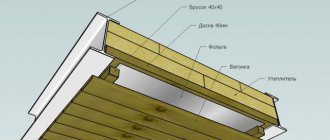

- Installation of wooden sheathing on rafters. For lathing, boards up to 4 cm thick are used.

Often the garage roof is made from ready-made reinforced concrete slabs. In this case, the angle of inclination should not exceed 15°. It is better to cover concrete floors with soft roofing material.

How to build a roof with a ceiling and attic space?

Now think carefully: you really won’t use the garage roof? Perhaps, if the walls are already strong and reliable, it makes sense to equip an attic? For example, under:

- own workshop;

- warehouse of necessary and unnecessary things;

- summer room for guests;

- billiard room;

- mini-greenhouse;

- a real sauna.

Why not? Many actually do this, and abroad they even try to use every horizontal and vertical meter to their advantage:

Therefore, we advise you that if the foundation and walls of your garage were originally built solid and designed for considerable loads, make attic rafters:

Next, think about a durable floor on which you can walk safely and even place furniture that is not too heavy:

And organize the roofing pie according to this principle (from the street side): roofing, waterproofing, thermal insulation, vapor barrier, internal cladding. Then you will use this room above the garage from early spring to late autumn, and in summer it will never be hot.

Construction of a gable roof

The gable roof for the garage has the shape of an isosceles triangle. To fix the rafters, a ridge is mounted at the top. The latter can rest on vertical posts. The rafters should protrude beyond the perimeter of the walls to form a canopy. To do this, about 50 cm is usually added to the length of the leg.

Technology for constructing a gable roof:

- Mount the mauerlat - beams made of wooden beams installed on the walls along the entire perimeter of the building.

- Make fastening grooves in the Mauerlat to secure the rafters.

- Make rafters from timber.

- Assemble “trusses” from rafters in the shape of a triangle.

- Secure the trusses to the Mauerlat using steel angles or anchors.

- Install the sheathing of the rafter system from boards.

The pitch between the rafters should be 0.7-1.2 m, depending on the planned load. To install the sheathing, it is optimal to use boards 2.5-3 cm thick.

Calculation

The importance of calculating the rafter system of a gable roof cannot be underestimated. During the design process, it is necessary to calculate the usable area and, based on the data obtained, decide how high the vertical posts will be

In this case, several factors come into play.

Load

When erecting a roof structure, it is important to calculate the maximum load on the roof of the house, on all rafters and beams. It may be necessary to strengthen the rafters, then adjustments are made to the project

For example, it may be necessary to use additional pads or timber with a larger cross-section than planned. The weight of the entire rafter system is also important. In this case, the calculation is carried out taking into account not only the cross-section of the lumber, but also the density and moisture content of the wood, and the pitch distance between the rafters is determined.

Today there is a special classification of loads on the roofing system:

- The main load concerns the weight of the truss structure, load temperature, snow and other weather factors.

- An additional burden concerns calculations of the influence of wind and ice.

- Force majeure loads are associated with man-made circumstances (a modern roof must withstand everything).

Slope

It is important to correctly calculate the angle of inclination of the slopes. With a standard house width of 6-8 m, the angle of the slopes is 45 degrees, but this is not enough for the space in the attic

With a tilt angle of 60 degrees, the structure will cost more, but the entire roof will be designed more successfully. At 45 degrees of inclination, you can choose any roofing materials. If the gable roof is initially planned to be asymmetrical, then you can easily arrange a residential attic in the attic space, but for this you need to calculate the usable area. A standard gable roof is usually selected. It is important to take into account the load on the roof due to wind and snow. As the angle of inclination of the slopes increases, the consumption of materials will also increase. But the performance characteristics of such a roof will differ favorably. If you plan to build a gable roof with unequal slope angles, then all work can be done in the original design. However, when designing, it is better to start from the classic design in the form of a symmetrical roof with an isosceles triangle at the base.

Step

The pitch of the rafters used to create the roof is one of the fundamental ones in the construction of the structure. There is a dependence of the pitch of the rafter system on the roofing material. The latter is used corrugated sheeting, slate, soft roofing or metal tiles.

Slate roofing is used everywhere. This roofing material is characterized by relative strength, low cost and resistance to temperature changes. However, the material has a certain weight, so it is necessary to provide the roof with a powerful rafter system. It is worth considering that for a slate roof there must be at least three points of support (in the center and along the edges).

In recent years, metal tiles have become quite widespread among roofing materials. The material is easy to install and has an attractive appearance. Metal roofing sheets are convenient to use because they are light in weight. In this regard, the distance between the rafters can be large (for example, 600-950 mm with sectioned timber 150x50 mm).

The corrugated sheet covering can be made of galvanized steel sheet with a special protective coating (from external weather influences). Modern corrugated sheets differ in color and corrugation width. Externally, this coating differs in design. The pitch between the rafters under the corrugated sheet will depend on the type of profile, the angles of inclination and the configuration of the roof. For the rafter system in this case, timber with a cross section of 50-75 mm is used. This can be a board 20-50 mm wide.

Roof

Before covering the garage roof, you need to decide on the roofing material. There are quite a few types of such materials on the market. The choice of roofing should be based on the angle of inclination of the roof, the stability of the rafter system and aesthetic requirements.

The heavier the roofing material, the stronger the rafter system should be. Typically, inexpensive and easy-to-install materials are chosen for garages - roofing felt, slate or metal.

Determine the height to which you want to raise the wall

To ensure the found slope angle of the pitched roof, it is necessary to raise one of the walls higher. How much higher we will find out by remembering the formulas for calculating a right triangle. Using them we also find the length of the rafter legs.

How to calculate the parameters of a pitched roof

When calculating, do not forget that the length is obtained without taking into account overhangs, and they are needed to protect the walls of the house from precipitation. The minimum overhang is 20 cm. But with such a small protrusion beyond the building, the pitched roof looks short. Therefore, overhangs of at least 60 cm are usually made on one-story buildings. On two-story ones they can be up to 120 cm. In this case, the width of the overhang is determined based on aesthetic considerations - the roof should look harmonious.

Example of a drawing in ScratchUp

The easiest way to determine how much the roof needs to be extended is in design programs that allow you to draw the building to scale and “play” with the overhangs. Everything should be displayed in 3 dimensions (the most popular program is ScratchUp). Twist through different sizes of overhangs, decide which one looks better (if there is no project), and then order/make rafters.

Ruberoid

Suitable for solid substrates only. It can be laid not only on a concrete slab, but also on a continuous sheathing of boards. Ruberoid is lightweight, protects well from precipitation and is affordable. Sold in rolls, so it is quite easy to install. You need to lay it in 2-3 layers.

Work order:

- Treatment of the rough roof surface with bitumen mastic.

- Installation of the first lining layer of roofing felt. It should be laid immediately after applying the mastic.

- Treating the base with bitumen mastic and laying 2 layers of roofing material.

- Re-treating the roof with mastic after laying the last layer.

The sheets must be overlapped, otherwise water will flow through the joints. Laying is done in the direction of inclination.

To heat up roofing felt and mastic before installation, you will need a gas burner.

Slate

The main advantages of slate are affordable price and long service life.

- A roof covered with slate will last about 40 years without repair. Lay overlapping sheets on a wooden sheathing.

- For fixation, special slate nails with wide heads are used.

- Due to the relatively high weight, the requirements for the reliability of the rafter system increase, so for its installation it is necessary to use a beam of a sufficiently large cross-section - at least 8x10 cm. For waterproofing, roofing felt is usually used, mounted on the sheathing.

Metal roofing

For garages, corrugated sheeting is usually used. This is an inexpensive, durable and lightweight material. Due to its lightness, you can reduce the cost of installing a rafter system by choosing beams of a smaller cross-section. Corrugated sheeting is installed in a similar way to slate, but in this case special self-tapping screws with rubberized heads are used.

When installing a metal roof, waterproofing must be done. Polyethylene film or roofing felt can be used as a waterproofing material.

The waterproofing is laid on the sheathing, and metal sheets are mounted on top. If necessary, the roof can be insulated by installing heat-insulating material from the inside between the rafters.

Why gable?

This garage will have a gable roof

. It will be easier to answer this question if you just know all the benefits:

- Great convenience and ease of installation. Having good instructions, even someone who does not have much experience in roofing can handle the construction of such a structure.

- Availability of components. All necessary elements can be purchased or ordered specifically for your project.

- Possibility to choose the best slope angle. This ensures good removal of precipitation, which means a long service life of the coating and other materials.

- If no roof space is planned, a cold attic will reduce the need for additional heating and ventilation.

- Convenient placement of various components in the under-roof space.

- The advantage of organizing an attic space.

- Choice of any type of roofing.

- Installing additional windows or skylights.

- Possibility of an individual approach.