After the letters are cut out, the question arises of how to paint the foam letters. Everything is simple here. First you need to know that polystyrene foam (expanded polystyrene) is unstable to the following solvents: ethyl acetate, benzene, gasoline, kerosene, acetone, alcohol.

Surface preparation.

The surface does not need to be treated before painting, but if you need to change the texture of a foam product or add strength, you can use the following methods: - Thoroughly coat it two or three times with PVA glue diluted with water. Let each layer dry. (after drying, the glue film stretches, which can bend thin products). — Add sand to the PVA, then the letter or other product will acquire a characteristic texture. — By the way, after PVA treatment, the product can be painted with almost any paint. — Prime with water-based paint. — Irregularities, blemishes and roughness can simply be puttied and treated with sandpaper. - Epoxy resin is used to add strength.

Painting of polystyrene foam products.

For painting you need to use acrylic paints. After using them, the letters will not be erased or become dirty. It is most convenient to use aerosol paint, but ALWAYS, without acetone and other solvents that foam is afraid of. You can use, for example, anti-graphic acrylic spray paint. This way the letters will look neater, and the paint layer will lie smoothly and evenly. For application with a brush, you can use Ladoga St. Petersburg acrylic art paints. Most often you have to apply two layers of paint. But the second layer already covers the surface completely. It doesn’t matter at all what you use to paint the letters, the main thing is that the design matches the surrounding environment.

Painting foam plastic with automotive enamels.

If you first prepare the surface and process the foam letter, you can paint it with almost all available paints. Almost all water-based varnishes and acrylic dispersions in water with additives are suitable for this. It’s better to find polyurethane ones, it’s too bad for the paint to stick to the acrylic later. Don't be afraid to paint! I use an inexpensive (70 rubles) domestic scuba tank, it dries quickly. A couple of layers, and then you can paint with any car paint from a can. You will be pleased with the result.

In addition to painting, you can use glitter, rhinestones and other materials used to decorate various holiday attributes to decorate letters. Finally, I would like to remind you that polystyrene foam is a universal material that is effectively used in advertising. Its cost and properties make it impossible to create absolutely any type of advertising in a short time. Therefore, it does not matter at all what the foam letters are painted with, since in any case they will look amazing.

How to paint polystyrene foam

Features of paint selection

Let's figure out what you can use to paint polystyrene foam. When choosing paint, you must take into account the fact that polystyrene foam is not resistant to chemicals such as acetone, white spirit and other solvents that are often used in paints.

Therefore, the choice is limited only to water-based coatings, which are called water-dispersion. These compositions include the following types of paints:

In fact, it does not matter what type of water-dispersion paint coating you choose, since the type of polymer practically does not reflect its properties. Therefore, when choosing paint, you need to pay attention to such characteristics as:

- Application area. Water-dispersion paints can be both universal, which can be used for interior and exterior work, and narrowly focused, i.e., intended only for interior work;

- Abrasion resistance. This property is important if the foam product is subject to mechanical stress;

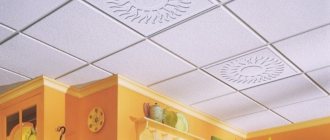

- Moisture resistance. Important in cases where the surface will be exposed to moisture. For example, moisture-resistant paint will be needed for painting fillets or ceiling tiles in the kitchen, where wet cleaning of the surface is carried out;

- Durability. This indicator is quite conditional, as it depends on the operating conditions of the painted surface. However, it gives a rough idea of the quality of the paint material;

- Covering power. The lower this indicator, the more layers of paint will have to be applied to paint the surface of the foam. Accordingly, paint consumption increases.

It must be said that the hiding power of water-dispersion paints is usually lower than oil-based, alkyd and other similar coatings. Therefore, they are applied in several layers.

Manufacturers usually indicate all these characteristics on paint containers.

Famous brands of water-dispersion paints

As an example, below are several brands of paint that can be used to paint polystyrene foam, with their main characteristics and cost:

| Tikkurila Euro 7 | PARADE W4 | Caparol Unilatex | Kreisel FARBA NANOTECH 006 | |

| Paint type | Latex | Acrylic | Latex | Silicone |

| Application area | For interior work | For interior work | For interior work | Universal |

| Abrasion resistance | Class 1 | Class 3 | Class 3 | Class 1 |

| Moisture resistance | Can be washed with non-abrasive detergents | Wet cleaning allowed | Wet cleaning allowed | Can be washed with non-abrasive detergents |

| Price in rubles 1 l | 470 | 400 | 200 | 350 |

Glazes

Glazes are often used to paint decorative foam products such as fillets, moldings and other decorations. These dyes are tinting agents and glazes. With their help, you can create various effects on the surface to be painted, such as:

- Malachite;

- Aged stone, etc.

The disadvantage of glazes is their high cost. A small jar can cost 1,500–2,000 rubles. Therefore, they are usually used only for interior decoration.

Proper insulation of external walls with penoplex: profitable and reliable

Recently, the process of insulating walls, both new and long-built houses, has become increasingly popular. At the same time, the building acquires an important advantage - it saves energy used to heat the room. After all, the materials used for wall insulation have high thermal insulation, and, as a beneficial side effect, high sound insulation. Today, insulating walls outside with penoplex is one of the most popular types of insulation. This is due to the properties of this material. Penoplex is the Russian name for extruded polystyrene foam, better known among the population as polystyrene foam.

Penoplex is used for insulating walls from the outside due to the following characteristics:

- very low thermal conductivity coefficient;

- low water absorption;

- lack of vapor permeability;

- compliance with all sanitary standards;

- resistance to mechanical stress;

- long service life;

- resistance to rot and mold;

- ensuring fire safety.

Due to these properties and very low price, penoplex is most often used for insulating walls outside.

Depending on what material the main walls of the building are made of, the insulation process has certain technological features.

Painting foam

We figured out how to paint polystyrene foam, now we’ll look at how to do it correctly. So, this procedure can be divided into two stages:

Preparing the foam surface

Before painting the foam, the surface must be primed. This operation is performed in the following sequence:

| Illustrations | Description of actions |

| Materials. To prepare the foam for painting, you will need a universal acrylic primer. | |

| Padding: |

- Wipe the surface of the polystyrene foam with a damp cloth or sponge and wait until the surface dries;

- Apply your own primer using a brush or roller. In this case, it is important to distribute it in a thin, even layer to avoid drips;

- After a few hours, when the primer has dried, repeat the procedure.

According to the scheme described above, only ordinary polystyrene foam is prepared for painting. If you are dealing with extruded polystyrene foam or even laminated foam tiles, you must first sand the surface to roughen it. After this, the sanded areas should be coated with a special adhesive primer (primer).

Painting

The process for painting foam is as follows:

| Illustrations | Description of actions |

| Preparing the Paint: |

- If the paint is thick, dilute it with clean water and stir. Information on the amount of water is contained in the instructions on the packaging;

- If necessary, add tint to the paint to give it color. To determine the amount of color, first mix it with paint in a small amount until the desired color is obtained. Then mix the main part of the paint with the color in the same proportions.

- Apply the paint in a thin, even layer using a brush. If you are painting large pieces, such as foam letters for a sign, you can use a sprayer. Make sure that the paint is applied in a thin, even layer. If the foam is see-through, do not try to paint it completely the first time;

- After the first coat of paint has dried, you need to apply a second one. As a rule, two or three layers are enough for high-quality coloring.

To prevent the foam from crumbling and breaking, it can be coated with liquid plastic before painting. This is how foam letters for signs and other products that will be subject to mechanical stress are usually strengthened.

When working with glazes, painting is done a little differently. As a rule, glaze is applied using a sprayer, after which the surface is rubbed with a brush or sponge, giving it a certain texture. Glaze of different tones can be applied even in two or three layers.

Prepare the solution.

Compositions for plastering synthetic insulation are usually sold in dry form. Suitable for all three types of material - foam plastic, penoplex and expanded polystyrene. They need to be diluted, making sure to follow all the manufacturer’s recommendations. It is possible to plaster polystyrene foam with your own hands.

Expert advice: To glue construction mesh, the compositions are diluted thinner than the product manufacturer advises. For the leveling layer you need an even thinner consistency.

Conclusion

Now you know what kind of foam paint exists and how to apply it correctly. Additionally, watch the video in this article. If some points are unclear to you, ask questions in the comments, and I will be happy to answer you.

Polystyrene foam is a popular material used in almost all areas of human life. Is it possible to paint concrete walls without putty and plaster? It is known in construction, where it is often used to create ceiling tiles, borders and baseboards.

These elements are available in white. Therefore, consumers often have questions about polystyrene foam: how to paint this material, what paint application technology to use?

Acrylic paint: tips for beginners

If you have questions about what acrylic paint for models is: in this video we talk about it. IN.

Consumables.

In general, applying plaster to penoplex and other synthetic insulation materials requires several days. It is possible to cope with the task on your own. Having studied the technology, polystyrene foam is easily covered with plaster with your own hands. The cost per 1m2 is much less.

An alternative option is to turn to professional craftsmen.

Then, for a square meter of facade finishing with foam plastic and plaster, you will have to pay about 200-500 rubles. Plus the price for the mixture is 160-600 rubles per bag of 50 kilograms. If the solution consumption is up to four kilograms when the reinforcement is fixed, and up to six when leveling, you will need to pay 40-120 per square meter for the material. The cost of the mixture can vary significantly. You can easily order it online or buy it at a finishing materials store. data-matched-content-ui-type=”image_stacked” data-matched-content-rows-num=”2″ data-matched-content-columns-num=”3″ data-ad-format=”autorelaxed”>

Advantages of painting foam

Products made from this material are usually used in various rooms of the room. They are characterized by durability, but after a few years they may lose their original appearance. Therefore, painting will update the ceiling tiles or baguette. In general, the following advantages of coloring foam can be identified:

- Protects new elements from dust, moisture, and grease stains. Especially if the tiles are used in the kitchen.

- Will refresh yellowed foam over time.

- It will make it easier to care for the coating and allow you to clean it without difficulty.

You can paint foam tiles in absolutely any color: classic white or the main shade of the interior. This will give the room a complete look.

Harm to the human body

The harm caused to a person when he stays for a long time in a room affected by fungi and mold has been confirmed by numerous scientific studies.

Mold and mildew cause the following serious diseases:

- tuberculosis;

- pneumonia;

- bronchial asthma;

- laryngitis;

- bronchitis;

- conjunctivitis;

- dermatitis;

- thrush;

- stomatitis;

- eczema;

- allergy;

- rheumatism;

- arthritis.

Dizziness, nausea, runny nose, and nosebleeds may also occur. Particularly dangerous is black mold, a pathogenic fungus that causes pulmonary aspergillosis. This disease can even lead to death.

Foam paint

Foam products are very sensitive to all solvents, so you need to be careful when choosing paint. The quality of the chosen product determines not only the appearance of the tiles or baseboards, but also their service life. The foam coating must meet the following requirements:

- High adhesion ability to the base of the surface.

- Moisture resistance.

- Dense structure.

- Resistant to various detergents.

- Ability not to fade when exposed to direct sunlight.

The paint must be water based. It is good if it does not contain solvents, white spirit and acetone, which have a detrimental effect on the foam. It’s easy to decide how to paint this material, since only two types of paints meet all the necessary requirements.

We are talking about acrylic or water-based products.

How to reinforce on a plane?

The technology for gluing reinforcing mesh onto a wall plane involves the following procedure:

- First, fragments one meter long are cut;

- then, taking a spatula 350 millimeters wide, apply the composition to the wall, creating a strip one meter long and ninety centimeters wide; It’s not worth cutting the canvas into larger pieces - it will be difficult to stick them, in addition, the composition dries out very quickly - it’s better to spread it out a little, stick one piece, then move on to the next one;

- applied with a thickness of about three millimeters;

- on the vertical sides it is not immediately glued to a distance of five centimeters from the edges; some experts believe that allowances should be left at least ten centimeters - this will create more stable joints;

- it is applied to the wall and smoothed with a spatula; movements are performed first from top to bottom, then from the center to the sides;

- it is important to ensure that the reinforcing material “sinks” into the solution; if this does not happen, the mixture is added a little; some experts believe that it should only submerge halfway; however, in any case, it is important that the solution is under the entire mesh (except for allowances); you should not skip sections - in the future, these “empty” places may cause peeling and disruption of the structure of the finish;

- the next layer is glued overlapping the previous one; their edges should overlap each other by about five centimeters; this will serve to create strong joints.

Important nuance: If you immediately glue the reinforcing layer, without leaving free edges, then when you further glue the next sheet, the glue will turn out to be too thick - the joints will stand out too much; and this can be visible even under a thick layer.

Acrylic paint

This type of coating has proven itself positively among substances of the water-dispersed group. It is distinguished by the following advantages:

- Protects against ultraviolet radiation.

- Characterized by a long service life.

- Dries quickly.

- Is safe for human health.

- Has no smell.

- Easy to apply.

- Resistant to stains and easy to clean.

- Not afraid of elevated temperatures.

- Differs in a variety of shades.

Among the disadvantages, the high price of acrylic paints should be noted: the better the product, the higher the cost. However, this minus is easily offset by the positive qualities that the water-dispersed material has.

A little about the tools

You should be careful not only in selecting the materials used, but also the tools used, otherwise painting foam ceiling tiles threatens to turn into a waking nightmare.

When choosing what to paint the tiles with, forget about wide and medium brushes. You spend too much time with them and will forever hate this kind of work.

Thin brushes can be useful for correcting errors made when painting large areas, but the main work is better done with other tools - spray guns (spray guns), and if they are not available, paint rollers.

Tip: If you choose a nap roller, keep the fibers short. This will save you from unnecessary problems after painting.

For rollers, purchase new attachments. They will guarantee easy and quick coloring. They will also require trays into which the paint will be poured. Make sure you reach the ceiling with your hand.

If this is not the case, take a roller with a long, preferably adjustable handle, or use a stepladder. The downside to using it is that you will need an assistant to hold it at all times.

When choosing a spray gun as your main tool, make sure that the paint you purchase can be used with it. Otherwise, the spray nozzle will quickly become clogged and the painting process will soon end.

Considering the specific location of the tiles (ceiling), take care of the following protective equipment:

- helmet or cap;

- robe (robe or overalls);

- gloves and shoes;

- transparent glasses.

They will guarantee that you will not have to wash your hair and all parts of your body after getting paint on them.

Water-based paint

When wondering what you can use to paint polystyrene foam, you should pay attention to a water-based coating, which has the following advantages:

- Lays flat on the surface.

- Is environmental.

- Has no smell.

- It is vapor permeable.

- Can be tinted well in a variety of shades.

- Has a low price.

However, water-based paint also has disadvantages. This paint is not resistant to dirt and does not tolerate wet cleaning. In addition, the coating is washed off with water over time and may peel off if applied heavily.

Is it possible to paint a varnished surface with acrylic paint? Despite these disadvantages, water-based paint is the most popular among substances of the water-dispersed group.

Operating procedure.

In order for the coating to remain securely on the synthetic insulation and serve as long as possible, it is important not to violate the technology of applying plaster on polystyrene foam. Finishing of foam plastic with plaster should be carried out in the following sequence:

- prepare the solution correctly;

- make reinforcement on the surface of the insulation under the plaster;

- grout the mesh;

- apply a leveling coating according to all rules;

- rub it in;

- prime the surface;

- apply finishing coat.

Recommendations for painting tiles

Knowing how to paint foam ceiling tiles, you can begin to take action. The technology of work consists of several stages: preparation of the room and tools, preparation of foam elements, and painting itself. The first stage involves the following actions: it is necessary to remove or cover the furniture, cover the floor and walls if they will not be updated. You also need to wear protective clothing, special glasses for your eyes, and a scarf for your head.

Tools you will need: rollers, brushes of different sizes, a stepladder, a container for paint.

At the second stage, it is important to consider whether you have new or old polystyrene foam , which is better than painting it, which is worth considering. If the tiles are new, then you need to carefully seal all the joints using sealant or putty, check whether the elements are well glued everywhere, and glue them if the corners come off. It is recommended to clean old tiles from dust.

It needs to be washed with a foam sponge and, if necessary, the joining seams should be renewed. Before painting, the ceiling tiles are well primed with a water-based solution.

The third stage is directly painting the foam. It includes the following important points:

- Tools you can use are a roller, brush or spray gun.

- Relief surfaces must first be painted with a brush.

- Do not put too much paint on the roller to avoid smudges and thick layers.

- It is recommended to use a small brush near the walls to avoid unwanted marks on them.

- You need to paint in one direction. It's better to start from the window.

- The second layer is applied perpendicular to the first after it has completely dried.

How to reinforce corners?

In order for the plastered surface of the penoplex to be smooth, it is necessary to secure the corners with a mesh. Slopes and window openings are also covered.

This is important: if you disturb the order, it will be problematic to obtain a good quality finish, since finishing corners and slopes after the walls are covered is much more difficult.

When gluing the mesh to the corners of the walls, it is worth considering some important nuances and following a proven scenario:

- cut a strip, thirty centimeters wide, and the length is equal to the length of the slope or about a meter;

- the strip is folded in the middle, smoothing the fold thoroughly;

- using a spatula, apply the solution to the corner; its thickness is approximately two to three millimeters;

- it is placed on the wall, pressed on with a spatula and smoothed, running the tool from the corner - along the sides and down;

- When the material is glued to the corners, they begin to glue it to the rest of the wall surface.

Why paint foam?

Foam-based products are used for both interior and exterior finishing and insulation work. It is used for heat and sound insulation of interior floors, partitions and walls, and in addition, many parts for decorating the interior of premises are produced from it. Often in the process of finishing work there is a need to paint polystyrene foam for one reason or another.

The first thing you need to think about is why paint polystyrene foam at all ? This operation is performed in two cases:

- Firstly, to create the effect of visual completeness and a holistic, harmonious interior, which consists of a combination of finishing elements, both among themselves and with the style of the room. It is unlikely that there will be connoisseurs of an interior in which white material with a bubble texture would be present as decor. Most, as a last resort, will prefer another type of finishing material that would fit more harmoniously into the decoration, please the eye and be combined with the surrounding environment. But polystyrene foam has too significant advantages over other finishing materials, especially in terms of price and ease of installation, that, as a rule, it is more rational to cover it with a paint coating than to look for a replacement in the form of another material.

- Secondly, a significant reason for painting is undoubtedly the need to protect it from the destructive effects of an aggressive external environment. For example, from exposure to bad weather in the form of precipitation, temperature changes, stormy winds and, ultimately, banal physical deformation of the material. All these factors seriously reduce the lifespan of foam products. As a rule, an unprotected foam coating very quickly, literally in one season, loses its original appearance.

Thus, applying paint and varnish to polystyrene material can be considered a logical continuation of finishing and decoration work.

Choosing plaster for the facade

The choice of external finishing must be approached seriously, because the service life of the insulation depends on it. Plaster allows you to solve the following problems :

- Protection from mechanical damage . Fragile polystyrene foam easily crumbles and dents, so it must be protected from impacts.

- Waterproofing . Expanded polystyrene, although poorly, still absorbs moisture (up to 2% by volume when fully immersed). At the same time, it takes a very long time to dry. Wet foam retains heat much worse. Its strength decreases.

- Sun protection . Ultraviolet rays dry the foam. Over time, it begins to crumble.

- Improving fire safety . The plaster layer will protect the insulation from fire.

What to paint

Construction foam is deservedly considered one of the most versatile materials. It is used for insulation, cladding and as a material for the manufacture of most decorative elements.

At the same time, due to its low cost, products made from it have an affordable price:

- Ceiling tiles based on polystyrene foam are an excellent choice as a finishing material for the ceiling, providing an aesthetic appearance and not requiring major investments. It is not afraid of water, so it can be installed in rooms with high humidity, such as a kitchen or bathroom, but unprotected foam itself is very fragile and can be easily damaged even by accident with bare hands. In addition, under the influence of direct sunlight, such tiles will certainly fade and acquire a yellowish tint.

- Also, foam panels are one of the most popular and widespread options for organizing thermal insulation of the walls of residential buildings. As a rule, they cover the outer parts of the house, its facade, which, unlike the premises inside the building, is constantly exposed to the negative influence of nature in the form of frost, ultraviolet radiation, and precipitation. Therefore, such a coating, which has a relatively fragile structure, requires not only careful handling during installation, but protection in the form of a paint coating for the period of operation.

- Today, very often for interior decoration, skirting boards are used for the ceiling, made on the basis of foam plastic. When purchasing, the color of such a decorative element is usually white. But often it is not the most suitable for a particular interior, and almost always the uncoated material is not very practical. Therefore, in some cases there is a need to change its shade to something other than white. In addition, sometimes the surface of such a plinth has defects, which can be especially visible after installation, when the light in the room is on. In this case, painting is the only alternative to redoing all the finishing work and replacing the baseboard. It will not only mask imperfections, but also add strength to decorative elements. One of the features of the plinth that is conducive to painting it is that during its installation, joints are formed between its different parts, which have to be primed with putty, and in order to hide all traces at the final stage, the plinth is covered with paint along the entire perimeter. Sometimes the need for painting arises suddenly, some time after installation, for example, after a roof leak, when stains appear on the white decor that cannot be cleaned. Then either buy and replace decorative elements, or paint everything and forget.

Types of primer mixtures

Primer mixtures differ in quality (composition), properties, and purpose. There are universal solutions suitable for both different types of work and for treating surfaces of various structures. Basically, all compositions are divided into strengthening and adhesive.

- Strengthening agents are used on porous structural surfaces. The main properties of such solutions are deep penetration into the base layers (up to 10 cm deep), the formation of a firmly protective film after drying.

- Adhesive solutions are applied to surfaces before plastering and other types of decorative cladding in order to improve the adhesion of materials. That is, here the primer serves as an intermediate layer that improves the physical and technical qualities of the finish.

The composition of the primer can be alkyd, acrylic, glyphthalic, phenolic, polystyrene, polyvinyl acetate, perchlorovinyl. Both the performance qualities of the solution and the possibilities of its use already depend on the composition.For facade work, a material with the following properties is used:

- increased water resistance;

- frost resistance;

- heat resistance;

- deep penetration, but also excellent grip;

- chemical inertness;

- biological inertia;

- ability to resist and neutralize efflorescence.

moisture resistance;

Primed polystyrene foam has a number of advantages, including the saving of solutions subsequently applied to it.

For the initial treatment of surfaces before applying the subsequent coating, a primer is simply necessary. Decorative wall cladding will subsequently hold up much better. In addition, deep-penetrating primer mixtures prolong the durability of base materials and improve their technical characteristics. Another useful property is a reduction in the consumption of subsequent solutions applied over the primer (glue, putty, paint, varnish).

Paint requirements

Despite the huge variety of types of polystyrene-based foam, there is a problem of its compatibility with paints and varnishes. The fact is that this material is susceptible to the negative effects of organic solvents, precisely those that are part of most paints and varnishes. Thus, in order to coat a foam product with paint and give its surface a beautiful structure, without harm to the material itself, you need to know the features of its compatibility with different coloring compositions.

Expanded polystyrene is resistant to most substances; it can be coated with mixtures of bitumen, lime solutions with water, and also painted with compositions that have a water-dispersion base. But compounds included in the class of organic solvents, for example, ethyl acetate, toluene or the well-known acetone, present in many types of paints, cause a change in the properties of this material, leading to its softening, shrinkage and ultimately dissolution.

Therefore, paints and varnishes for polystyrene-based materials must meet the following general requirements:

- the absence in their composition of substances capable of dissolving foam plastics;

- increased adhesion coefficient to penoplex and PSB;

- stability under the influence of destructive atmospheric factors, insolation;

- providing an aesthetic elastic coating.

Expert advice

In order to putty everything well and not have to redo the work again after a short time, you need to use the following expert advice:

- The putty must contain glue, otherwise the adhesion to the base material will be weak, and subsequently everything will fall off.

- Select the putty and type of reinforcing mesh based on the place of work (outdoors or indoors).

- A material with a suitable shelf life loses some of its properties, which means that adhesion to the foam will be poor.

- It is better to buy materials in a store where they were stored in a dry room at above-zero temperatures. At the market in open pavilions, everything freezes in winter and overheats in summer, and there is also a high probability of moisture getting in, which is why it spoils long before the expiration date.

- Instead of a special primer, the foam plastic can be coated with PVA glue in two layers.

- If there are several layers of putty, then between them you need to apply a layer of primer for better adhesion.

- You need to start laying the reinforcing mesh and puttying from the slopes.

- Putty must be purchased at the rate of 3 kg per 1 m2 to secure the mesh and 5 kg to level the surface.

Having studied the technology of working with putty on polystyrene foam, any owner who has any skills in construction will be able to do everything on his own. This will save on hired labor, and the money can be spent on better materials

Painting foam

In most cases, paints based on water emulsion and acrylic suspension are used for painting foam plastic. The choice of one type of paint or another depends on the location of the foam materials: inside or outside the building.

Inside the building

Inside the building, water-based paints and varnishes are almost always used. They are characterized by low cost, about 25-40 rubles per liter, but are unable to withstand moisture and heavy dust, which determined their specific use only for indoor spaces.

When applying such paint to the interior decorative elements of a room, the optimal viscosity of the paint is ensured, allowing you to hide the pores in the material under a uniform layer of coating. Before painting ceiling tiles, moldings, baseboards and rosette decorations, it is recommended to wipe them from cobwebs and dust with a dry cloth.

Painting is usually done with a brush and roller. However, in the case of painting decorative elements with a thin and intricate relief, not a brush is used, but a spray gun, which allows you to quickly apply a uniform layer of coloring pigment to the material. To avoid paint getting on the wallpaper, it is best to paint the moldings and foam cornices before installing them.

Outside the building

On the outside, acrylic-based solutions are used, which are highly resistant to the influence of aggressive external environments, but they are much more expensive - from 50 to 50 rubles and are not durable. That is, they need to be updated from time to time.

For the use of paints as a coating for polystyrene foam boards that provide thermal insulation for the external walls of a house, the characteristics of increased elasticity, resistance to precipitation and contrasting temperature changes are very important.

This composition is first diluted with water or a primer, due to which it acquires increased elasticity. Thorough mixing is required until a homogeneous consistency without lumps is required.

Another protective coating option for polystyrene materials is a thin layer of putty, after drying, which can be painted with any paint containing acid.

| Paint application: |

Types of primer mixtures

On sale you can find a fairly large selection of primers from different manufacturers that can be used for processing foam.

Preference should be given to trusted companies. You also need to carefully study the properties of a particular product so that with its help you can really get the desired result.

Primer for painting

Before you start painting foam, most experts recommend using a specific primer liquid. In this case, you must perform the following steps.

Remove dust, dirt, unnecessary elements or objects from the surface. The surface must be thoroughly cleaned, and then any foam crumbs that remain after treatment must be removed. You can begin to apply pre-purchased primer to the prepared foam sheets. The number of layers of material will depend on the quality of the foam, what type of paint and in what quantity will be used in the future.

Primer for plaster

At the moment, in construction, plastering polystyrene foam boards is a very common phenomenon. In addition to the attractive appearance of the facades, it is possible to significantly insulate the surface of the building. In this case, priming the foam will play a very important role. The service life of the plaster depends on how well the work is done.

Textured plaster must be applied to a primer that has a quartz filler. Most professionals recommend using a special polymer acrylic mixture that contains grains of quartz sand. If in the future the plaster will only be painted, then using a universal primer would be a good option.

We prime the foam with liquid glass

When painting foam plastic, special requirements are imposed on the composition of the selected paint.

It is important to take into account such indicators and characteristics of the material as elasticity, resistance to precipitation and moisture, and to changes in air temperature. Of course, modern products have excellent characteristics and fully meet the requirements. Moreover, almost every paint contains aggressive substances that can have an extremely negative effect on the structure of the foam. To solve this problem, it is worth using a special protective substance. Quite often in such situations, “liquid glass” is used. This is a kind of solution of potassium or sodium silicate. Due to the sufficiently high surface tension of the foam grains, it is possible to achieve a high level of material reliability. Liquid glass will not penetrate into the foam and at the same time will create a protective film that will significantly improve the characteristics of the material used.

On a note! In order to increase the elasticity of liquid glass several times, it is best to add to the mixture not water, as indicated on the packaging by the manufacturer, but universal primer.