Home heating can be carried out using different systems and devices. Heated floor systems are now becoming especially popular. It is installed under the finishing coating. It provides excellent indoor air heating. In this regard, the demand for this design is constantly increasing. It does have a lot of advantages, but before installation you should also study the disadvantages. The most suitable type and category of electric heating is also selected.

Warm electric floor under laminate

Advantages and disadvantages

There are three types of electric heating, the design of which is based on different principles:

- water floor;

- cable;

- infrared.

The main feature of heating is that the heat sources are located under the finishing. The heat warms the floor and transfers energy into the room. Any of the varieties has the following advantages:

- uniform heating;

- high efficiency;

- no visible heating elements;

- absence of circulating dust, unlike radiator heating.

The main disadvantages include: significant energy costs when using electric heating, as well as the complexity of installation when installing water heating.

Is it safe to install underfloor heating?

Any electrical work can be dangerous if performed by an inexperienced person. However, when a heating system is installed by a professional, you can have peace of mind, regardless of what type of material the heating was placed under. Connecting the mats to the thermostat must be done by a licensed electrician, so do not do this work yourself.

Types of electric floor

According to the heating element used, the classification includes several types of electrical structure.

Cable design

Cable floor

When installing a cable circuit, heating occurs through the flow of current to it. The cable is placed on a tie.

For full heating you will have to wait a little more than 1 hour. To carry out repair work and troubleshoot the system, it is necessary to dismantle the laminated floor covering and damage the screed.

The main disadvantage is the need for screed equipment. This will require significant additional costs.

Heat mats (thermomats)

Thermal mats consist of fiberglass. Cables are attached to it in the shape of a snake. Installation of heating does not require installation of a screed.

It is most effective to secure the mats to the base using tile adhesive. The price for installing mats is approximately 30% higher compared to cables.

Heating mats under laminate are easier to install. Simply lay the mesh with wire over the surface of the rough base.

Infrared floor

In this design, the heating element is a special film. It does not require the use of screeds or glue.

During installation, the film is simply placed on the subfloor. The infrared layer heats not only the flooring, but also the furniture. The thickness of the system is minimal, so it can be organized indoors without compromising the height.

It is not difficult to organize repair work in a situation where the floor heating breaks down, because the system is not secured with glue or screed.

Infrared design

Film installation

Film installation has a number of features. This is due to its design and technical characteristics. There are several stages when installing film under laminate:

- preparatory. They include leveling the surface, and it is not necessary to fill the screed. If the base does not have obvious unevenness, it is enough to clean it from dirt and dust;

- isolation. The prepared surface should be covered with waterproofing and thermal insulation. It is important to know that the use of aluminum foil rolls for these purposes is strictly prohibited;

- laying heating material. First, you need to lay a heat-reflective film over the entire surface, fastening the individual pieces with tape. Then the infrared film is installed with parallel connection and connection. Copper strips are connected using contacts and insulated with bitumen fixative;

- testing. Connecting a network cable to the system, connecting a temperature sensor, testing in different modes;

- final. At this stage, the entire structure is covered with polyethylene, a substrate is placed and the laminate is assembled.

When is laying under laminate possible?

Before you try to combine heating and laminate coating, you need to study all the nuances.

The laminate includes two parts: a polymer front side and an MDF panel, that is, the base. It is the composition of MDF that poses a danger. It contains formaldehyde. But due to the low concentration, the coating does not cause concern. But when heated, a small amount of the substance can still be released into the surrounding space. Masters and experts say that this does not pose a threat to health at all.

But the higher the heating temperature, the greater the volume of formaldehyde. Its action in such a situation can provoke headaches, nausea, and inflammation of the respiratory system.

Manufacturers who value their authority carefully monitor the level of dangerous components, providing safety guarantees. So, it will not be possible to purchase cheap and at the same time safe material.

Warm electric flooring under laminate is most often done in the infrared version, much less often - in the cable version. In general, it is safe to install laminate flooring with heated floors.

Nuances of using infrared floors

It is necessary to sketch a plan for installing a heated floor under the laminate, including a diagram of the arrangement of strips and wiring. This will help prevent in the future the incorrect rearrangement of furniture and the creation of strong pressure on the surface in the places where the heated floor is installed.

It will also be necessary to eliminate the possibility of damage to the film or electrical wiring when installing interior items that require through fastening to the subfloor.

Having a detailed diagram of the location of the heating strips will allow you to determine a safe place for through drilling without removing the laminate. Carrying out such work at random can damage the heating system and get an electric shock.

Electronic thermostats are often equipped with two devices for measuring floor and air temperatures. When programming the system, it is impossible to use only the air sensor due to restrictions on heating the laminate.

There are two ways to correctly set the operating mode algorithm for a heated floor:

- Use only the floor sensor readings. For example, set the heating to turn on when the temperature is below 25 degrees, and turn it off when it reaches 29 degrees.

- Use the readings from both instruments. For example, set the heating to turn on when the room temperature is 23 degrees, and turn it off when either the air sensor readings reach 26 degrees or the floor sensor readings reach 30 degrees.

Breakage of the floor sensor leads to the need to replace it with dismantling part of the laminated panels, lifting the waterproofing film and the damaged heating panel. To avoid this time-consuming work, you can purchase an additional sensor, install it when installing the floor as a backup option, and route the wire from it to the thermostat.

Then, if the main device fails, you just need to unscrew the two wires from the non-working sensor in the thermostat and connect the contacts from the spare version.

Our recommended article will introduce you to the rules and features of organizing infrared heating of a wooden house.

How to choose a laminate

You should carefully and responsibly approach the selection of laminate flooring for warm electric floors. The main nuances that people pay attention to when choosing a material are:

- Thermal resistance. It reflects the thermal insulation properties of the coating. The bigger, the better. Maximum value 0.15 m2 K/W. It is influenced by the properties of the substrate: the higher the porosity, the worse the thermal resistance.

- Material class. This is a non-core indicator. The higher the cost, the better quality it is. For expensive laminate, a minimal amount of formaldehyde is used. The material wears out more slowly.

- Maximum temperature. You need to clearly know the maximum possible heating for the selected type of laminated panels so that they do not lose their properties. Usually around 30 degrees.

- Method of fastening panels. Laminate that is held together with glue is not suitable for heated floors. When heated, the adhesive composition loses its properties. Lock fastenings are suitable.

- Lamella thickness. The greater the thickness, the less heat penetrates into the room. Thick material does not transmit heat effectively enough. But thin types are too fragile and have weak fastenings. Optimally 8 mm.

Choice of coverage

Manufacturers recommend purchasing special types of panels. They are distinguished by improved performance characteristics for heated floors - they are not afraid of heating, are easy to install, and retain an attractive appearance for a long time.

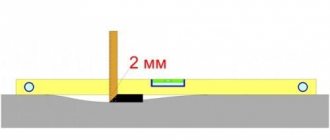

Do I need to use a substrate and what kind?

Laminate flooring without a backing will last no more than a year. It performs a number of important functions listed in the article “Which substrate to choose for laminate?” In combination with a “warm floor”, another one is added: to pass heat flows upward. This property is achieved due to the small thickness (the optimal value is 2 mm) and the presence of perforation (the heat transfer resistance coefficient should be in the range of 0.04-0.06 m2 x °K/W). In addition, the substrate must have:

Underlay for "warm floor".

- resistance to high temperatures - does not deform or melt;

- vapor permeability so that moisture accidentally trapped under the laminate is removed near the walls;

- environmental cleanliness.

These conditions are fully met by a perforated substrate made of foamed polyethylene, extruded polystyrene foam and balsa wood.

Electric flooring under laminate - we do it ourselves

Any electrical system can be made approximately in the following sequence:

- preparing the base;

- arrangement of waterproofing;

- arrangement of thermal insulation;

- laying heating elements;

- installation of a temperature sensor, connection of a heat regulator;

- test check of heating operation;

- screed formation - wet or dry;

- installation of the substrate;

- laying laminate.

Do-it-yourself installation

Concrete screed is required when laying cables or thermomats. When it is not possible to pour the screed, for example, on a wooden floor, then chipboard or boards are placed on the bases, leaving free space between them.

Next, metal sheets with grooves are installed. A heating wire is installed in them. Plywood is laid on a film system when it is planned to lay tiles or other material with a large weight on top.

Installation of infrared floor

To install the film system, you need the following materials and tools:

- infrared film;

- thermal insulation without foil;

- clamps;

- Temperature regulator;

- pliers;

- scotch;

- scissors;

- bitumen insulation;

- wires;

- screwdriver.

Stages of work:

- Removing the old finish coating.

- Leveling the base. If necessary, a self-leveling mixture is required.

- Thorough cleaning of the subfloor from sand, dust, and debris.

- Laying thermal insulation, the sheets of which are connected with tape.

- Installation of heated floors. The thermal film is cut into pieces of the required length with scissors. The film is placed on the insulation with the copper bus down. You can cut anywhere, the main thing is not to touch the heating elements.

- Connecting film pieces to each other with tape.

- Connecting the system. The opposite ends of the bus are insulated with special insulating tape. The contact clamps are attached to the film using pliers. The wires are attached to the terminals according to the diagram and must be insulated on both sides. Recesses are formed in the thermal insulation for clamps and wires. This allows the coating to not rise in certain places.

- Installation of thermostat. Wires are attached to it in accordance with the instructions and diagram.

- After installing the heated floor, the laminate flooring is laid.

Installation technology using the example of cable systems

Before installation begins, the floor is leveled, a screed of cement and sand no more than 0.3 cm thick is made for it. When necessary, additional thermal insulation is laid. The screed will take 3 days to dry. After this, the damper tape is secured, then the thermostat is attached to the selected location. The cable is laid strictly according to the instructions on the packaging.

After completion of the work, a screed of 3–10 cm in thickness is again formed. It will dry completely only after a month. Only then the finishing coat is applied.

The cable floor must be filled with a screed or a dry wood-metal screed is formed for it. Both cases require a substrate.

Installation of a cable structure

The main requirement for a laminate is the ability to conduct heat. For this purpose, the panels have special holes. The installation process includes the following steps:

- Cutting the ridge on the boards in the first row.

- Lay the first panel in the corner farthest from the door.

- Formation of the first row.

- Formation of the second and subsequent rows, their connection with the previous ones.

- Removing wedges.

- Installation of skirting boards.

Cable installation

When installing a cable for a heated floor, you must go through several mandatory steps:

- pouring a rough screed, leveling the surface, sealing cracks and strengthening the base;

- laying insulation. For this process, foil thermal insulation is used, which is held together with special foil tape, but we do not recommend using it. It provides little benefit. It is better to use extruded foam. This stage will allow you to avoid heat loss in the future and save energy;

- designing a detailed cable layout plan. At the same time, we take into account the places where furniture and household appliances will be located, since the cable will not be laid there;

- cutting a groove in the wall for the cable outlet for the thermostat and floor temperature sensor;

- laying the cable with its fastening using reinforced mesh or metal plates;

- installation of cables according to a previously developed plan. It is important that the heating cables do not cross or touch each other. This oversight can lead to burnout of the heater or even ignition;

- the thermostat is installed at a distance of 40 cm from the floor, and the temperature sensor should be installed strictly between the turns of the cable;

- connecting the power cable, thermostat and temperature sensor to the distribution box. Checking cable resistance and testing the system in different modes;

- filling the screed. As a rule, the thickness of the layer is up to 5 cm, but it is worth remembering that the thicker the screed, the more electricity is needed to heat it. But on the other hand, a thick layer of concrete retains heat longer in a heated surface;

- installation of the laminate after the screed has completely dried.

Tips for installing electric heating under laminate

Professionals give advice for more effective selection and installation of electric heating:

- In a high-rise building, only electric heating is allowed; it is unlikely that management organizations will give approval for the installation of a water system.

- To determine the location of the damage in the cable, you will need a special device. It will allow you to find a problem area even through a cement screed.

- The electrical system must occupy at least 70% of the room's area. This is the only way to achieve effective heating.

- Optimal operating power is 160 – 190 W.

- When purchasing laminate flooring, you should check the heating compatibility labels.

- Even high quality laminate should not be heated above 30 degrees. This will lead to the release of hazardous components.

- The minimum thickness of the laminate is 8 mm, otherwise it may deform due to constant heating.

- For residential premises, it is better to combine heating sources: floors, radiators.

- Correctly setting the heating intensity and adjusting it will help save energy costs by 20-30%.

- It is not recommended to place the electrical structure too close to heating devices, as the risk of its breakdown increases.

- When installing a screed, the floor must not be turned on until it has completely dried.

- The maximum length of infrared bands is 7 m.

Installation recommendations

Water heated floor

It is not recommended to use a water heated floor system to heat laminate flooring. This is due to the mandatory arrangement of the upper concrete screed. In addition, the optimal pipe diameter in such a scheme is 16 mm. As a result, this will lead to a significant rise in the surface and a decrease in the actual height in the room.

But for large areas and if there is an autonomous water cooling system, this may be one of the options for effectively increasing the temperature in the house. If the factors mentioned above do not play a significant role, then using a similar technology you can install water pipes to heat the floor surface.

High-quality heated electric floors under laminate can significantly improve the indoor microclimate without harming the expensive decorative coating. But to be sure, it is recommended to choose board models that indicate that they are designed for installation on heated floors. This will provide even more guarantee of their safety and normal operation of the entire system.

© 2022 prestigpol.ru