Laminate is a floor covering that has become fashionable almost from the first days of its existence.

It has very attractive qualities both in decorative and operational terms.

One of the most successful properties of the material is its ease of installation and ease of installation.

This quality, to some extent, was the reason for many unsuccessful attempts at use, when inexperienced and unprepared people made a number of mistakes when laying the material and received a negative result.

Neglect of the necessary preparatory work and inattention to operational requirements often negate all the advantages of the material and reduce its functional potential.

Conversely, careful compliance with installation and use requirements can increase the service life of the coating and ensure its maximum efficiency.

In this article we will find out whether it is possible to lay laminate flooring on laminate flooring or not.

What are the surface requirements?

The main requirement for the surface is the presence of a flat horizontal plane without sharp dips, dents or steps. The panels of the material have sufficient rigidity to compensate for minor irregularities , but if the base has too many irregularities that form areas with sagging panels, then during operation, cracks will appear at the seams in a short time.

The increased load on the locking joints leads to their failure, since the purpose of the lock is to tightly join the panels, and not to perform load-bearing functions.

The second, no less important requirement of the material for the condition of the base is the absence of moisture. Many subfloors are susceptible to capillary moisture. This is especially true for concrete floors located at the lower levels of buildings.

The supporting layer of the laminate is created from wood flour, connected with an adhesive composition (analogous to fiberboard or MDF), which is convenient in production terms, but requires the fulfillment of certain operating requirements.

The absence of moisture is the main one, the observance of which increases the strength and service life of the material.

Is it possible to lay laminate flooring on laminate flooring?

Laminate, correctly laid in compliance with all requirements, forms a smooth and dense surface. The old coating, which has lost its visual appeal, but has retained its mechanical properties, is a completely suitable platform for laying a new layer.

From an installation point of view, the old laminate serves as a leveling layer, creating a durable and soundproofing support layer between the subfloor and the new coating.

In this case, it is necessary that certain conditions be met:

- No noise when walking, no squeaks, no movement or sagging of panels.

- The new layer of material must be protected from moisture from the lower layers.

- The old coating should not have areas with missing, loosely fastened or destroyed panels that violate the geometry of the base.

- It is highly undesirable for the old coating to ever be exposed to large amounts of water (pipe burst, flooding, etc.).

In addition, it must be taken into account that laying a new layer of laminate will change the floor level, which will create a height difference with other rooms and will require adjusting the height above the floor of the doors.

Which floor can not be dismantled before laying a new one?

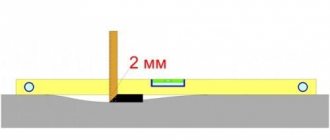

- The floor must be level and not have a significant slope. According to the norm, deviation on the surface is allowed, no more than two millimeters per m2.

- There should be no major defects on an old floor. If the damage is more than 35% of the entire surface, then it is better to dismantle it.

- When walking, there should be no creaking or audible pops that may occur as a result of the gap formed between the laminate and the base.

If the floors have significant damage, then it is clear that dismantling is necessary. But other defects can be eliminated during preparatory work.

Flatness rating

The condition of the base plane is an important parameter that affects the quality of the coating. In this regard, old laminate has fairly good performance, since there are usually no significant flaws on its surface.

However, a flatness check must be carried out in any case, since during the operation of the floor covering various situations may arise that affect both its own condition and the parameters of the subfloor.

The permissible deviation from the plane is considered to be 2 mm per meter of surface. You can check the condition of the coating by applying a flat, rigid strip, ruler or building level to the floor at different points in the room.

You can also determine the general condition of the surface by stretching a cord diagonally across the room. It will show how much the floor topography is deviated from the horizontal, has folds or protrusions.

IMPORTANT!

In practice, deviations exceeding the permissible 2 mm are possible. If they are expressed in the form of small depressions or protrusions, they can be neglected, since the substrate is able to compensate for small irregularities. You should only be concerned if there are obvious deviations from the plane that threaten to cause movement of the panels in the covering fabric.

Arguments against"

If we are talking about an apartment in a multi-story building, then there is one more point that cannot be ignored. The laminated board has a certain height. Laying it on top of the old flooring will reduce the height of the room. In apartments, as a rule, the ceiling is not too high. Why deliberately make it even lower?

Article on the topic: Wall panels for the kitchen for the apron: PVC, photo, plastic, decorative, MDF, how to attach, video

If the old laminated board was laid according to the technology, then the underlay was installed. This material has its own service life. Over time, it becomes deformed and ceases to perform its functions. Therefore, it would be a good idea to examine the condition of the substrate before laying a new decorative coating. But this can only be done by first dismantling the floor covering.

These are two more reasons indicating that it is better to dismantle the old flooring.

Advantages and disadvantages

Laying laminate over an old layer that has served its purpose has its pros and cons.

The advantages include:

- Lack of preparatory work.

- The presence of a flat plane, which provides a high-quality platform for installing the laminate.

- Laying the material will require less cost and time.

There are also some disadvantages:

- There is no way to assess the condition of the subfloor.

- The level of the floor surface changes, affecting the operation of the doors and creating a difference with the floors in other rooms.

- The direction of laying the laminate changes, which is not always convenient or consistent with the users' intentions.

- The possibility of creaking or other sounds appearing doubles.

It is necessary to understand that the disadvantages of this method are small, the consequences that may be caused by their existence do not threaten serious troubles. Thus, the condition of the subfloor is unlikely to cause significant concern, since all the problems would have already appeared during the operation of the old coating .

Changes in floor level are a predictable phenomenon that is the first thing people think about. Therefore, the possible problems are not so great as to abandon the plan.

Is it possible to coat laminate flooring with varnish or paint? Simple repair and its features

This technique assumes that the existing coating is in relatively good condition. To find out whether laminate flooring can be painted, you need to do a preliminary check. Scratches are removed by sanding. Large chips and cracks are filled with putty for wooden products. After the primer, apply paint and the required number of layers of varnish. The use of specific finishing materials is described in detail in the relevant manufacturers' instructions. Experienced craftsmen advise using acrylic-based compounds or others designed for such work and designed for appropriate external influences.

The floor must be cleaned before painting

Surface preparation

Preparatory work should begin by clearing the floor surface of all foreign objects. It is necessary to remove furniture, appliances from their rooms, remove floor lamps and other interior elements.

- Remove the baseboard . If any wires were hidden in it, you need to temporarily secure them to the wall using, for example, masking tape.

- Inspect the condition of the old coating. Any gaps found at the joints of the panels should be filled with sealant.

- Make sure that the new coating will not cause problems with opening the doors . If in doubt, door panels should be removed from their hinges (or hinges disconnected from frames) and temporarily stored in another location.

NOTE!

There is a way to check for moisture in the backing of the old coating or in the base. A piece of polyethylene is placed on the surface and pressed tightly along the edges. If after 24 hours condensation is detected on it, then the old coating must be dismantled and the base dealt with; it is impossible to install a new laminate in such conditions.

Deformation due to wear of the old substrate

The technology for laying laminate flooring requires the use of a substrate; it is also available under the old coating. During operation, the material wears out. If you lay a laminated board without dismantling the old coating, it is possible that the old laminate will begin to deform due to wear on the substrate. This in turn will cause deformation of the newly laid board. As a result, the service life of the coating will be less than that promised by the manufacturer. The condition of the substrate under the old laminate must be checked before laying the new one. However, the point is that this cannot be done without first dismantling it.

Selecting a substrate

The choice of substrate is an important issue on which the sound insulation of the coating depends. Laminate is demanding on the base, since the covering sheet is tightly connected and, in the acoustic sense, is a membrane that transmits sounds to all adjacent structures - the base and walls.

A coating without a backing produces quite a lot of noise, disturbing both the apartment residents themselves and the neighbors below. When laying laminate over a layer of old coating, the risk of noise increases, which must be taken into account when choosing a substrate.

In addition, the substrate must provide the possibility of some ventilation of the old coating, otherwise dampness will inevitably appear on the subfloor and, as a consequence, the occurrence of mold, mildew and other unwanted biology.

Taking all factors into account, you should choose a substrate with a relief that allows air to move under the floor covering. These types include isolon, polystyrene foam or similar types . Cork underlay reduces noise well, but contributes less to the ventilation of the space under the covering.

You should choose cork in cases where there is sufficient confidence in the condition of the subfloors (for example, there is a flooring made of boards with ventilation gaps).

Conclusions and recommendations

This article examines whether laminate flooring can be laid on laminate flooring and explores alternative technologies. The choice of the appropriate option depends on the actual state of the existing coverage, financial capabilities, and professional skills. Some technologies are not difficult to master on your own based on the instructions provided. Their correct observance will help to eliminate errors and implement the intended tasks with a reasonable investment of time and money.

Correct installation of high-quality laminate flooring provides excellent aesthetic and functional parameters of the flooring

Features of laying the finishing coating

The main requirement for laying a new laminate over the old one is to change the direction of the panels. Usually the perpendicular direction is used, but the diagonal direction can also be used. It gives an interesting visual effect, especially if there are chamfers on the front surface of the laminate.

Laying of hydro- and vapor barriers is not carried out, since the synthetic substrate itself is a good waterproofing agent . At the same time, the substrate should not be placed on the wall, as is done when installing waterproofing. This procedure will reduce the possibilities of ventilation, which are already very meager. In addition, the substrate is laid end-to-end, and not overlapping, as required by the installation of insulation.

Experts always recommend starting laying panels from the corner opposite to the exit. This rule is used traditionally, it appeared in those days when the main method of finishing the floor was painting.

For laminate flooring, it is not of fundamental importance, but from a practical point of view, this procedure is justified - there is less movement on freshly laid panels, and there is less risk of weakening the contact of the locking joints (especially if sealant is used during installation).

Installation of panels is no different from usual. The first row of panels is laid at a distance of about 1 cm from the wall, with the lock facing the wall. Subsequent rows must be placed one by one in a direction convenient for the master (from left to right or vice versa, it does not matter) .

The panels of the last row are adjusted in width and carefully laid, pressed against the canvas using wedges.

IMPORTANT!

Experts do not recommend making the length of the last panel in a row less than 35 cm, since a short section is not able to fully withstand the loads that occur at the extreme sections of the canvas.

The height of the room is reduced

In a private home with high ceilings this is not a big deal, but in apartment buildings sometimes every centimeter counts. When laying a new laminated board on top of an old one, it is necessary to lay a high-quality underlay between them, which means that the height of the room will be reduced significantly.

This fact should definitely be taken into account by those who have a ceiling height of 2.5 m or a little more. Dismantling the old floor will only take a couple of hours (and even less in a small apartment), it is better not to be lazy and do all the work as it should be. Visually “raising” the ceilings will help with the light decoration of the room and a pattern in the form of a vertical stripe on the walls.