Any type of material requires preparation before painting. In order to improve adhesion, as well as increase the protection of the surface from all kinds of influences, priming is used. Gf 021 is a type of primer with which you can treat metal, plastic, wood, as well as every m2 of relief surface for its subsequent coating with paint and varnish products.

Gf 021 is a type of primer that can be used to process metal and plastic.

GF-021: what is it

In the 1980s, consumers were offered “rusty paint” or a special material for priming wood and metal surfaces. Production was regulated by GOST 25129-82. The purpose of GF-021 is to improve adhesion when painting small architectural forms, buildings, interior items, floors both indoors and outdoors. The primer can be applied to any ferrous metals, including those containing rust. After drying, it acquires a red-brown color. The surface is matte, without gloss.

Technical parameters of primer GF-021:

- painted components and parts made of steel or cast iron can be used at ambient temperatures from -400C to +600C. The material is not recommended for use to protect heating radiators and engine components from external influences;

- with a single-layer coating, consumption is 60-100 g/sq.m. m.;

- a film with a thickness of 25 microns dries completely in 24 hours at an air temperature of 200C;

- fresh composition consists of 50% volatile organic substances. They evaporate during the drying process;

- After complete drying, the GF-021 primer can be sanded, removing excess. Good adhesion is maintained;

- Contact with salt water for 24 hours or with machine oil for 48 hours will not damage the coating. No need to repaint or apply a new layer.

The latter characteristic is especially important when processing parts and assemblies of vehicles and marine vessels. If there is no primer layer, a short contact with mineral oil is sufficient to completely or partially destroy the paintwork.

The composition, which meets the requirements of GOST, contains no caustic, poisonous or poisonous components. But when working, it is recommended to follow standard safety measures and use protective gloves, since liquid soil can cause allergies and skin irritations. After drying, the surface can be touched without risk to health. It is better to carry out grinding in a respirator to prevent dust from entering the respiratory tract.

How to prime a metal surface

Surface priming takes place in several stages:

- preparatory;

- direct application of primer.

Preparation

If the surface is properly prepared, the primer application procedure can be of the highest quality possible, without the need for further painting. This feature ensures the smoothness and uniformity of the GF 021 coating.

Step-by-step surface preparation for priming:

- cleaning of material, elimination of rust, removal of debris, dirt, dust;

- elimination of visible protrusions, dents, burrs.

If finishing is carried out indoors, then door and window openings must be protected with construction tape or film.

Application of primer

The optimal ambient temperature for work is considered to be from 5 to 40 degrees Celsius. Humidity in this case should not be more than 80%. It is not recommended to prime walls in strong winds, as well as during snow and rain.

Options for applying GF 021 per m2 of surface:

- Pneumatic spray. It is worth setting up the equipment according to the instructions from the manufacturer. When working, you should maintain a distance of 20–40 cm from the nozzle to the wall.

- Airless spray. The distance from the device nozzle to the surface should be from 30 to 50 cm.

- Manual application. Experts recommend priming the material using a lint-free roller or a brush with natural bristles.

- Stripe coloring. To paint welding seams, end edges, and other hard-to-reach places, GF 021 is applied before the surface is completely treated.

Priming is carried out in 1 or 2 layers. The thickness of the single-layer coating GF 021 is 15 – 20 microns. The drying time of the soil is not long; the surface is considered ready for painting within a day.

How to dilute

If the viscosity deviates from the norm, GF 021 must be diluted. For this procedure you can use the following substances:

- white spirit, turpentine, solvent;

- solvent or xylene;

- xylene with white spirit;

- solvent RE-3V, 4V.

The volume of solvent should not exceed 25% of the total soil. Stirring is carried out by stirring with a drill or an attachment - a stirrer.

Common Mistakes

The main mistakes made by the master when priming:

- ignoring the removal of grease stains will lead to them coming to the surface over time;

- painting the material until the primer is completely dry;

- use of PVA glue or water-based composition in the work.

Primer GF-021: main components

Alkyd or phthalic varnish was initially chosen as the base. It has excellent adhesion and is easy to apply to a dry surface of any material. To impart special properties, the primer contains the following:

- driers and anti-corrosion additives. In most cases, this is phosphoric acid or a wood processing product;

- iron and zinc oxides. They give the soil a special color;

- solvents and thinners. If GF-021 seems too thick, you can add solvent P649 or P650 to it, but in the total composition it should not be more than 20%.

Advantages and disadvantages

Advantages of glypthal primer:

- Creation of high-quality additional anti-corrosion protection;

- Improving interlayer adhesion - between a wooden or metal surface and enamel;

- Reducing the consumption of coating materials applied as the next layer;

- Resistance to temperature fluctuations within -45 - +60 °C.

The primer is quick-drying - the drying time of one layer declared by the manufacturers is 24 hours at a temperature of +20 °C. However, in practice, the primer takes longer to dry and is sensitive to lower temperatures during this period - this is its main drawback. The product is also not a penetrating primer, that is, it does not fix loose materials and fragile surfaces.

Properties, technical specifications

The soil properties specified in the documents will only be preserved if stored correctly. It should be stored only in the original sealed container, in a place where there is a normal level of humidity and there is no direct sun. The material is resistant to sub-zero temperatures and can be stored even at -20 °C. The shelf life guaranteed by the manufacturers

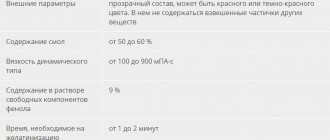

Technical characteristics of the GF-021 primer are given in the table:

| Film color and texture. Film appearance | Red-brown (gray, white), semi-gloss or matte texture. Homogeneous, smooth, without delaminations and craters |

| Grinding degree | 40 µm |

| Conditional viscosity | 45 |

| Drying time to the third degree at a temperature of 20? C | 12 hours |

| Flexural elasticity | 1 mm |

| Impact strength | 50 cm |

| Film hardness | 0,35 |

| Film adhesion | no more than 1 point |

| Film resistance to static liquid exposure 20? C | |

| sodium chloride/mineral oils | at least 24/48 hours |

| density | 1.25-1.3 kg/l |

| Consumption per layer | 60-100 grams per square meter |

| Non-volatile substances,% | 54-60 |

TEST METHODS

4.1. Sampling - according to GOST 9980.2.

4.2. Preparing for the test

Plates for applying primer are prepared in accordance with GOST 8832, section. 3.

Film hardness is determined on glass for photographic plates 9´12-1.2 according to TU 6-43-0205133-03-91.

The elasticity of the film during bending is determined on plates made of black tin according to the technical documentation, 20 x 150 mm in size, 0.25 - 0.28 mm thick.

The remaining indicators are determined on plates made of steel grades 08 kp and 08 ps according to GOST 16523, size 70´150 mm, thickness 0.8 - 0.9 mm.

Conditional viscosity, degree of dilution, mass fraction of non-volatile substances and degree of grinding are determined in undiluted primer.

When determining other indicators, the primer is thoroughly mixed, diluted to a viscosity of 22 - 24 s using a Tina VZ-4 viscometer with a nozzle diameter of (4.000 ± 0.015) mm at (20.0 ± 0.5) °C with solvent or xylene, filtered through a sieve with mesh No. 01-05 (GOST 6613) and applied with a paint sprayer to the prepared plates.

When determining the resistance of the film to the static effects of a 3% solution of sodium chloride and mineral oil, the primer is applied in two layers on both sides of the plate.

Drying each layer at (105 ± 5) °C for 35 minutes. When determining other indicators, the primer is applied in one layer.

Drying a single-layer film at (105 ± 5) °C - for 35 minutes.

The thickness of a single-layer dried film should be 15-20 microns, two-layer - 30-40 microns.

After drying, the plates are kept for 3 hours at (20 ± 2) °C before testing.

4.1, 4.2. (Changed edition, Amendment No. 1).

4.3. The color and appearance of the primer film is determined visually in natural diffused light.

4.4.Determination of the degree of dilution of the primer with a solvent

120 - 130 g of primer is weighed with an error of no more than 0.1 g and diluted with solvent or xylene to a viscosity of 22 - 24 s using a VZ-4 type viscometer with a nozzle diameter of (4.000 ± 0.015) mm at (20.0 ± 0.5) °C.

Dilution rate ( X

) as a percentage is calculated using the formula

where t -

primer mass, g;

m

1 - mass of solvent used to dilute the primer, g.

4.5. The mass fraction of non-volatile substances is determined according to GOST 17537.

A sample weighing (2.0 ± 0.2) g is placed in a drying oven and maintained at a temperature of (140 ± 2) °C. The first weighing is carried out after 1 hour, subsequent weighings are carried out every 30 minutes until the weight remains constant.

It is possible to determine the mass fraction of non-volatile substances under an infrared lamp at a temperature of (142 ± 2) °C. In case of disagreement in the assessment of this indicator, the final result is the determination in a drying cabinet.

4.4, 4.5. (Changed edition, Amendment No. 1).

4.6. (Deleted, Amendment No. 1).

4.7. Film resistance to static action of 3% sodium chloride solution

Before inspection, the samples are kept in air at (20 ± 2) °C for 1 hour, then examined with the naked eye.

4.8. Determination of the sandability of a primer film

The plate with the dried film prepared according to clause 4.2 is sanded with sandpaper with a grain size of 4 - 5 according to GOST 6456 or GOST 10054.

4.7, 4.8. (Changed edition, Amendment No. 1).

4.9. Determination of film resistance to nitro enamel

Three layers of enamel NTs-11 (GOST 9198) or NTs-25 (GOST 5406) are applied to the primer film prepared according to clause 4.2 10 minutes after drying.

Each layer of nitro enamel is dried at (20 ± 2) °C for 10 minutes.

The thickness of each enamel layer should be 20 - 25 microns.

The enamel film should not peel off, wrinkle, or crack.

4.10. Film resistance to static effects of mineral oil

After the test, the plate is kept in air at (20 ± 2) °C for 2 hours and examined with the naked eye.

(Changed edition, Amendment No. 1).

4.11. Delamination Definition

A glass graduated cylinder 2 - 100 according to GOST 1770 is filled with diluted primer to the 100 cm3 mark and left at rest at a temperature of (20 ± 2) °C for 24 hours, after which the volume of the separated layer in the upper part of the cylinder is determined.

(Introduced additionally, Amendment No. 1).

Manufacturers and prices

The universal primer GF-021 GOST 25129 is offered by Omega, Lakra, Tex, Unisil, Prestige, Autotrade and Zebra. The material produced in accordance with GOST is red-brown, and the shade is not standardized. However, they sell soil in both gray and white colors (they are produced according to specifications).

The manufacturer must attach a certificate of conformity, a hygienic certificate, and a quality passport to each batch of primer. The documents confirm that high-quality raw materials were used in the soil production process and that the resulting material complies with regulatory requirements. And since the raw materials are used domestically, the cost of the material is affordable.

GF-021 soil can be supplied in retail or industrial containers - 0.9 cans; 2.8 kg or metal containers 25; 50; 250 kg respectively.

PACKAGING, LABELING, TRANSPORTATION AND STORAGE

5.1. Packaging - according to GOST 9980.3, group 5.

5.2. Marking - according to GOST 9980.4.

The purpose, method of application and precautions for handling retail primer are specified in the mandatory appendix.

5.3. Transportation and storage - in accordance with GOST 9980.5. The transport container must additionally be marked with a danger sign in accordance with GOST 19433, class 3, drawing. 3, classification code 3313 and manipulation sign “Sealed packaging” according to GOST 14192.

Sec. 5. (Changed edition, Amendment No. 1).

Rules for preparing surfaces for priming

Primer GF-021 is needed for preparation for subsequent application of enamel. Recommended compatible materials for the primer film are enamels of types UR, HV, PE, HS, EP, ET, MCh KF, MS, NTs, PF, MA, AU.

For metal surfaces (structures of industrial facilities, garages, support poles), a primer can also replace painting, thanks to the formation of a uniform, durable layer of gray or brown color. The resulting film lends itself well to sanding without the sandpaper sticking.

Before priming the product, the following preparatory work is carried out:

- The primer is mixed so that its density is uniform and diluted with a solvent. If a dense film forms, it is removed from the soil surface.

- Before painting, the metal surface is treated with sandpaper or special compounds and degreased. If an old metal part is being processed, it is advisable to remove rust from it mechanically.

- The surfaces to be primed must be free of cracks, protruding welds, burrs and sharp edges.

Carrying out priming work - the main nuances

The instructions regulating the use of GF-021 primer specify that the material can be applied with a roller, brush or spray gun, as well as by pouring or jetting. Apply the primer in 2 layers in a thin layer, smoothly, without sharp strokes. In this case, usually the total thickness of the coating does not exceed 18-25 microns.

Work on both metal and wood is carried out only in rooms with good ventilation, since the material has a pungent odor. For safety, gloves are also used, since the material is dangerous for the skin and mucous membranes (this only applies to liquid soil, not dried film). It is not allowed to carry out work near an open flame (the product is flammable) and at temperatures below +5? C.

The applied primer becomes matte after drying. It can be used as a base layer or enamel applied on top. Before further coating, the primed surface is sanded with P600 or P800 sandpaper - the surface becomes smooth and the paint applies without defects.

SAFETY REQUIREMENTS

2.1. Primer GF-021 is a flammable and toxic material, which is due to the properties of the solvents included in the primer (Table 2).

Solvent vapors included in the primer have an irritating effect on the mucous membranes of the eyes, respiratory tract and skin.

table 2

| Component name | Maximum permissible concentration in the air of the working area of industrial premises, mg/m3, | Temperature, °C | Concentration limits of ignition,% (by volume) | Hazard Class | |

| flashes | spontaneous combustion | ||||

| Xylene | 50 | Not lower than 24 | Not higher than 450 | 1,0-6,0 | 3 |

| Solvent | 50 | 22-36 | 464-535 | 1,02 | 4 |

| White spirit (nefras-SCH-155/200) | 100 | 33 | 270 | 1,4-6,0 | 4 |

(Changed edition, Amendment No. 1).

2.2. During production, use, and testing of the primer, fire safety and industrial sanitation requirements in accordance with GOST 12.3.005 must be observed.

2.3. All work related to the manufacture, use and testing of the primer must be carried out in workshops equipped with supply and exhaust ventilation and fire safety equipment in accordance with GOST 12.3.005.

2.4. Precautionary measures: sealing production equipment, providing workers with personal protective equipment that meets the requirements of GOST 12.4.011.

2.5. Coating with a primer after drying does not have a harmful effect on the human body.

2.6. Monitoring the state of the air environment - in accordance with GOST 12.1.007 and GOST 17.2.3.02.

(Introduced additionally, Amendment No. 1).