Oil-based paints for interior decoration are quite common. The walls and ceiling were painted with it, or after a while the paint would crack.

Before the renovation begins, the question arises whether to clean the walls of old coatings or leave them. If you clean it, then with what specific product? A classic representative of oil-based products is MA-15 paint, the use of which is incredibly diverse.

The consumer can be one of several types, and it is also actively used in the construction and renovation of premises. Also, the paint must comply with GOST.

Description and purpose of paint

Pigments and various additives are used to create a color palette. On the shelves of construction stores you will find the following colors:

- Beige;

- White;

- Yellow;

- Red;

- Brown;

- Blue;

- Blue;

- Birch;

- Black and others.

Attention! The color of the paint depends on the pigment included in the composition: ocher, white, mummy, chromium oxide, red lead and others.

The scope is wide. Used for external and internal work indoors. Cover wooden, metal, concrete surfaces. Paint walls and floors. Has the following properties:

- High resistance to temperature changes;

- Protects the painted surface from rust;

- Gives an aesthetic appearance;

- Forms a durable coating;

- Resists mold, fungi;

- Easy to apply;

- The service life of the surface is not limited.

After complete drying, the coating is harmless and can be used for decoration in a children's room. The material has a high level of adhesion to other means.

General information

Description and purpose of paintwork materials

To obtain a color palette, pigments and various additives are used, and on the shelves of hardware stores you will find colors such as white, beige, red, yellow, brown, blue, blue, birch, black and others.

Please note that the color of the paint will depend on the pigment included in the composition - ocher, mummy, white, chromium oxide, red lead and others.

The scope of application is very large. They are used for indoor and outdoor work, and they cover concrete and metal surfaces, and also paint floors and walls.

They also have the following properties:

- High resistance to temperature changes.

- Protects painted surfaces from rust.

- Gives an aesthetic appearance.

- A durable coating appears.

- Resists fungi and mold.

- Easy to apply.

- The service life is not limited.

After drying, the coating will be harmless, and it can also be used for decoration even in children's rooms. The material will have a high level of adhesion to other products.

Material characteristics

The manufacturing company will indicate the characteristics on the packaging of the paint and varnish material. The quality certificate or passport also contains detailed characteristics from the manufacturers.

It is worth paying attention to the following:

The painted surface must be smooth, even and free from defects.- The complete drying time is a day at a temperature of +22 degrees.

- The proportion of dry residue will be 12%, and film-forming substances as much as 26%.

- The grind level is 90 microns.

- Viscosity according to the VZ-246 device at a temperature of +20 degrees will be from 54 to 140 (everything will depend on the color).

- The covering power of the film ranges from 45 to 210 grams per square meter (it all depends on the color).

- The drying time for one layer is 24 hours at a temperature of +22 degrees.

- The film hardness is 0.05 TML units, the light resistance of the coating is 2 hours.

- Resistance to water at room temperature is half an hour.

Apply paint and varnish material only to the prepared surface. Clean everything from dirt, grease and dust, and all cracks and irregularities should be filled with putty. The prepared surface should be treated with a primer based on glyphthal or alkyd for strong adhesion. A new wood product is coated with drying oil or a special wood primer.

Please note that only dry and well cleaned surfaces can be painted. Shake the paint material well before use. The operating temperature ranges from +5 to +35 degrees. It is worth using a roller, brush, and also a pneumatic spray gun.

MA-15 paint can be diluted with white spirit or even turpentine. The product should be diluted extremely carefully, and a large amount of solvent will affect the quality of the paint and varnish material. The solvent has a transparent color and a slight yellowish tint. The consistency is homogeneous, and the density of this product is 0.82 grams per 1 cm3. If storage conditions are met from the date of manufacture, the paint can be used for 1 year. It also belongs to the class of flammable liquids. Before use, frozen oil paint should be warmed to room temperature. This is approximately +20...+26 degrees. The paint contains drying oil, a suspension of pigments and driers.

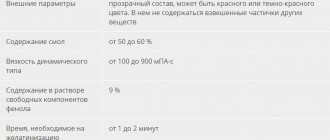

Specifications

The manufacturer indicates the technical characteristics on the packaging of the paint and varnish material. In the quality certificate or batch passport, you can also find detailed characteristics from the manufacturer. Let us draw your attention to the main ones:

- The surface to be painted must be flat, smooth, without defects;

- Complete drying time is 24 hours at a temperature of +20 C;

- The share of dry residue in the composition is 12%, the share of film-forming substances is 26%;

- Grinding degree – 90 microns;

- Viscosity according to the VZ-246 viscometer at a temperature of +20 degrees – 64–140 (depending on color);

- Covering power of the film – 45–210 g/sq.m. m (depending on color);

- Drying time for one layer is 24 hours at a temperature of +20 degrees;

- Film hardness according to TML – 0.05 cu; lightfastness of the coating – 2 hours;

- Resistance to water at room temperature – 0.5 hours.

Coating service life

The lifespan of MA-15 paint depends on three factors:

- Environment.

- Frequencies of physical impact on the painted surface.

- Fulfilling the requirements for preparing the surface to be painted.

In the first case we are talking about climate. In a moderate climate (from minus forty-five to plus sixty degrees), the paint will last about one year.

The second is how often any physical impact is applied to the surface. For example, you cannot paint the floor with MA-15 paint, because it is constantly walked on. Don't forget about dust.

And third, how well the surface was prepared before applying the paint. How many layers were applied, whether primer, putty was applied, the presence of rust, and so on - all this affects the service life of the coating.

If all requirements are met, the coating will last from one to one and a half years, after which it will have to be reapplied.

If all requirements are met, the coating will last from one to one and a half years, after which it will have to be reapplied.

This paint copes with its assigned tasks very well. It copes well with high and low temperatures, but does not tolerate intense physical impact. You can recommend it to your friends as a very good paint for applying to the external or internal walls of a house.

Drying time

Complete drying time is 24 hours. Depending on the room temperature and humidity.

How to dry oil paint quickly

Drying oil paints are the record holder among paints and varnishes for drying. The drying process can be accelerated.

Popular advice: open the windows, create a draft. Use a hair dryer. Hot air will speed up the process. The air in the room heats up and the humidity level drops. The solvent evaporates faster. The paint is drying.

Features of application

The algorithm for using MA15 paint is as follows:

- Surface preparation. Dust, dirt, grease stains, remnants of old coating, scale, and rust are removed from it. Cracks are puttied, irregularities are removed or sealed. The wet surface is dried. It is recommended to pre-apply an alkyd or glypthal primer to increase adhesion (adhesion of the material to the surface). For the first time, wooden products to be painted are impregnated with drying oil or a special primer is applied.

- Preparation of paint and varnish material. Before work, mix the paint and add a solvent if necessary. Pour in little by little - if you exceed the dosage, the quality of the composition deteriorates. If the paint has hardened, heat it in warm water to +20°C or slightly higher.

- Painting works. The paint is applied at a temperature of +5...+35°C, humidity not higher than 80%. The room is ventilated during work and after completion. The tools used are brushes, rollers or a spray gun, depending on the features and surface area.

- Drying. The paint dries in 24 hours if the temperature is about +20°C. Final polymerization occurs within 5 days under the same conditions.

Increased humidity prolongs drying time. Reduce the time by ventilating, heating the air with a hairdryer or heating devices.

Consumption per layer

Several factors influence material consumption:

- Method of applying paint. The most economical tool is a spray gun, then a roller; the most paint is consumed when applied with a brush. For a pneumatic gun, the most liquid composition is prepared, more solvent is consumed; for a brush - the thickest.

- Surface porosity, ability to absorb coatings. Wood takes more paint than metal. In terms of economy, metal is followed by concrete; then - brick.

- Paint and base color. If the surface being painted is dark, it will show through the paint. Therefore, it is recommended to prime it, choosing a suitable shade. Mostly the primer used is gray for light-colored paints and black for dark paints.

Under any circumstances, the first coat of primer will reduce paint consumption.

For painting 1 sq. m of surface requires 20-250 g of paintwork.

Optimal layer thickness

A correctly applied layer has a thickness of 25-30 microns. For it to turn out like this, you need to properly prepare the paint: too thick, like liquid, will not ensure the formation of a durable film. The thickness is also influenced by the qualifications of the craftsmen and the tool used.

Coating service life

The painted surface lasts at least 12 months without losing its protective and decorative properties. This is provided that the technology is fully followed:

- the surface is prepared, primed or 2 layers of paint are applied;

- the work was carried out under the recommended temperature conditions (-45...+60°C), acceptable humidity;

- there was no exposure to aggressive chemicals and abrasives.

Other MA paint series

There are a large number of oil-based paints and varnishes on sale. One of the most prominent representatives of minium MA 15.

Red lead MA 15 is used for painting metal pipes, roofs and other iron products. The resulting coating is resistant to sudden temperature changes. Has good adhesion to the surface. Primary colors are red and red-brown. Consumption per square meter is 0.1-0.25 kg.

MA - 05 is produced strictly in accordance with GOST. The consistency resembles a paste. Before application it should be diluted with drying oil. The proportions are indicated in the instructions. Used for interior decoration only. Can be applied with a roller and brush. Primary colors green, blue, red. Drying time until “tack-free” is 24 hours.

MA-0115 is used for painting metal and wooden structures. Except for the floors. Dries within 24 hours at a room temperature of +20 degrees C.

MA-22 is used for exterior work and interior decoration. There are no primary colors. The palette is varied.

MA-25 covers wood and metal to protect it from the destructive effects of external factors. Withstands sudden temperature changes. The coating is moisture resistant. Dries overnight.

Brief description of KM

The production of MA-15 oil paint is based on the indicators of GOST (state standard) 1503-71. The release process is established by many companies, including:

- Color;

- KraskoVo;

- Infrachem.

Combined drying oils of different brands (K2, K3, K5) or natural drying oil Oxol form the basis of the composition of KM. The following are added as additives: purpose-specific driers, fillers, pigments (colors). The composition is available in primary colors and their shades. To obtain the desired color, a pigmenting additive is added to the composition. This can be zinc white, chromium oxide, red lead, ocher and other substances. With the help of coloring, oil paint acquires the desired shade.

Removing paint from linoleum

Pay attention to the composition. If the composition contains drying oil, follow the instructions. Wet a rag in the solution and wipe the stain. Fill the rest with sunflower oil. After all, wipe the linoleum with soapy water. Another way. Soak a sponge or gauze in solvents (acetone, white spirit). Wipe the stain until it disappears completely.

Attention! Test the effects of the solvent on a small piece of linoleum. Some specimens may be seriously damaged by solvent exposure.

KM efficiency indicator or its consumption

Three criteria affect the consumption of oil paint:

- surface absorbency;

- application technology;

- LMB color.

Material consumption MA-15: 55-240 g/m2. Covering a metal base will require a minimum amount of CM, while wood will require a larger volume. Thickness of one coating layer: 25-30 microns. The two-layer coating has a thickness of 50-60 microns. If the base has not been previously treated with primer, then 2 layers of dye are applied. One coat is sufficient if primer has been applied. The thickness of the film depends on the skill of the painter, the thickness of the composition, and the application technique.

Oil paint finish

Is it necessary to clean the old enamel layer before repair work or not?

Primer for oil paint

Enamel makes the surface smooth and non-porous. This surface quality prevents high-quality adhesion of the new coating and the base. Whether or not to remove the old layer depends on its condition. If the entire area is in perfect condition, the layers will hold up well. It doesn't have to be cleaned. But if cracks and chips appear in places, you will have to get rid of them. Before applying the primer, clean the area from dust and dirt. After all the procedures, proceed to priming the walls.

Plaster over paint

You cannot plaster over paint. Clean the wall from the old layer in advance. There are five ways to get rid of old enamel on a wall. Remove everything carefully. After all manipulations, plaster is performed for the purpose of leveling.

Water-based emulsion for oil paint

You are going to update the color with water-based emulsion, but you don’t know what to do with the previous layer. A light-colored water-based dye will not cover a dark-colored oil base. Therefore, you need to either remove the layer of oil paint or choose a darker color of the water-based paint. Moreover, from a smooth surface you need to make it matte. Those. sand the paint with fine-grain sandpaper.

Is it possible to putty

First, examine the general condition of the wall. If chips appear in places. It's worth getting rid of them. All uneven surfaces should be filled with putty so that the wall becomes smooth. For better grip, it is better to make notches.

Is it possible to lay tiles over oil paint?

The unequivocal answer is no. The treated surface with an oil composition has a water-repellent effect. Tile adhesive will slide off a smooth surface. Before laying tiles, it is best to get rid of the old coating.

How to wallpaper

Without preparatory work, wallpapering will not work. As mentioned above, the walls are very smooth after coating. There is no need to completely remove the entire layer. Simply run sandpaper along the wall. To get a rough surface. After this procedure, the gloss will be replaced by a matte porous surface. In addition, all irregularities are leveled out. In some places it is necessary to apply putty. After completing all procedures, a primer is applied (primer + PVA glue in a 50/50 ratio).

Oil solution function

The material covers metal, wood, concrete, brick and protects other building materials. Used for painting outdoor and indoor surfaces. The demand is explained by the many advantages of the dye:

- resistance to temperature fluctuations;

- protective coating for metal against the appearance and spread of corrosion processes;

- decorating the covering layer;

- increased wear resistance and tolerance of mechanical loads;

- plasticity of the protective coating;

- resistance to UV rays of the sun;

- good tenacity with any base;

- acts as an antiseptic coating that protects against the appearance of mold and mildew;

- The material is easy to work with.

Important: the dried layer of paint is non-toxic and does not harm human health. Therefore, it is allowed to be used in children's rooms and institutions for children.

How to remove an old layer

It is easier to remove old paint than new paint. Wet drops spread over the surface, so it is better to leave them until they dry. To clean, you will need a solvent and a blade.

From linoleum

Dried stains are heated or rubbed with turpentine and then scraped off with a blade. The solvent must be used carefully. If you pour more than necessary, the design on the coating will be erased along with the paint. After removing the stains, wipe the linoleum with water and floor cleaner or soda.

Expert opinion

Zakharova Irina Yurievna

Cleaning professional with 15 years of experience. Our best expert.

Ask a Question

Old oil paint stains are removed by alternating heating and cooling. When the temperature changes, the drop will become hard and will come off if you rub it with a knife.

From clothes

When cleaning fabric, there is a problem with removing paint and traces of it.

See also

Features and color palette of metallic paints and how to apply them correctly

How to remove dried stains:

- scrape off the top layer with a blade;

- blot the remaining paint with a cotton pad soaked in solvent;

- Wipe off softened oil particles with a clean disc;

- treat the dark mark with ammonia, dishwashing detergent or heated glycerin.

The final stage is normal washing.

Red lead paint technology

Paint application is carried out according to the following scheme:

- Surface preparation. The base must be cleaned, dried, and free from corrosion. In addition, the material is degreased and sanded if necessary.

- Painting the surface using a brush or roller. In some cases, a spray bottle may be used.

- Cleaning the instrument after painting.

How to breed red lead

Not all craftsmen know how to breed red lead and therefore often make mistakes in their work.

Silver must be diluted immediately before staining. The powder composition is mixed with a liquid, for example, drying oil. It is worth diluting the paint, strictly observing the proportions: drying oil - 20% and red lead powder - 80%. Mixing of such paint and varnish composition is carried out in small quantities. Otherwise, the paint will end up with lumps. Before painting the metal with red lead, the composition is diluted with drying oil or white spirit.

Precautionary measures

When working with red lead, the master must strictly adhere to safety precautions. Flammable and toxic products must not be left near open sources of fire. The room where work is carried out must have good ventilation. When painting with silver and other compounds, the artist must protect his hands, skin, eyesight and respiratory organs. Store paint in a dry place where there is low humidity and ultraviolet radiation.

Rules for processing metal and wood

It is advisable to pre-treat metal products and structures with a primer. The following primers can be used: VL, GF, FL. When there is rust or corrosion on the material, it is necessary to first apply a rust converter. After this, paint is applied in two layers. If the metal structure is not rusty, then it is not allowed to be primed first, but can be immediately painted in two layers. Wood products are first treated with drying oil, after which they are painted in one or two layers.