4.04.2018

The technology of building houses from sip panels is quite popular in our country. Both country houses and houses for permanent residence are built from such panels.

After building a house from SIP panels, you need to take care of the exterior finishing. The cladding of a house performs several functions at once, the most obvious being aesthetic. Without finishing, the cottage will look unfinished. However, cladding is also necessary to protect the building from external factors: moisture, wind, low temperatures. Without protection, the house will slowly collapse.

Another function of finishing is to provide thermal insulation to the home. A layer of mineral wool is placed under the finishing materials. How to decorate the outside of the facade? There are different finishing options with their pros and cons.

Do you dream of your own home, a holiday home or for permanent residence? There is nothing easier than doing this at TechnoSip.

Look at our catalog of projects, the prices will pleasantly surprise you.

up to 100 sq. m. from 100-200 sq. m. from 200-250 sq. m

Plaster finishing

Facade plaster is used even by designers when working with houses made of SIP panels. The material has a number of advantages:

- retains a bright shade for a long time;

- resistant to external factors, including ultraviolet radiation and high humidity;

- has an original non-standard texture;

- the coating can be repainted if necessary;

- Maintenance of the facade is relatively simple, the coating can be washed;

- plaster is affordable.

The coating allows air to pass through and “breathes,” which is very important for the microclimate of private homes. At the same time, the material does not allow moisture to pass through and protects the panels from water. The layer of plaster lasts quite a long time. Plaster is an environmentally friendly material made from natural ingredients.

The material also has disadvantages. The service life of plaster is still limited, so after 10-15 years the facade will require major repairs.

Disadvantages of SIP

Compared to brick, concrete, blocks, etc. a large overhead load is out of the question. Although, if you dig deep, then, in principle, as the manufacturers say, they can withstand up to two hundred kilograms! Which, in my humble opinion, is not even bad.

Scratches are a constant companion. Appearance will change beyond recognition over time. With inappropriate installation, drafts are a common problem. If you leave a small gap during the construction process, you will present yourself with great trouble in the future with solving this problem.

Condensate settling. Unfortunately, it is formed in abundant quantities, increasing the mass of the slab. As it freezes, it expands, destroying the inside and, over time, the front side of the panel. In turn, the SIP cladding, on the contrary, dries out and becomes smaller in size, as a result of which the formation of cracks is guaranteed.

Installation of clinker tiles

The original finishing of the facade will be provided by clinker tiles. This cladding will last for decades without losing its excellent performance properties. Clinker tiles are made from natural pure clay. During the production of materials, high-temperature firing of each product is carried out.

The tiles can be matte, glossy or have a natural untreated surface. Many manufacturers produce materials that imitate natural brick. The material has several advantages - it is different:

- strength and resistance to mechanical damage;

- long service life;

- low water absorption coefficient;

- aesthetics;

- ease of care.

A layer of thermal insulation can be installed under the clinker tiles. Moisture will not penetrate the cold protection materials and will not damage them. One of the main advantages of clinker is its ability to imitate brickwork or stone. At the same time, the home owner will not need to look for a professional mason and overpay for finishing.

Clinker has practically no disadvantages. The material is more expensive than plaster, but cheaper than brick and stone. It is affordable and lasts a very long time. If necessary, facades with such finishing can be subjected to spot repairs.

Hanging structures

Hanging structures involve the use of lathing on which finishing material is mounted. This method is becoming increasingly popular because it allows you to create a ventilated facade and use insulation of the required thickness.

The sheathing is usually made of wooden blocks or metal profiles. The latter option is preferable because it does not require pre-treatment of the sheathing elements with fire retardants and similar wood compounds.

Siding is considered a type of hanging structures. It consists of panels similar in size to the size of the boards. At the same time, the material has special grooves and locking systems, thanks to which it is assembled like a children's construction set. This type of installation makes it simple and quick; it is possible to carry out installation work all year round. The material has improved performance properties, including hydro-wind protection.

The sizes and design of the material are very diverse. These can be either colored models (bright glossy or calmer, neutral matte panels), or an imitation of the texture of any natural material (brick, stone, wood). The material is easy to clean - most surfaces have a self-cleaning function. Wet cleaning of coatings is possible.

The following main types of siding panels are distinguished.

Plastic. The base is PVC, as well as various modifiers and pigments. Such panels are quite durable, but under increased mechanical stress (impacts) they can crack. The material is moisture resistant, can withstand high and low temperatures, their sudden changes, and is resistant to UV protection.

Light weight (up to 5 kg/sq. m) does not require strengthening the foundation. The disadvantage is the low fire safety rating.

However, despite the treatment of wooden panels with special compounds, their service life is short. During operation, siding requires regular maintenance.

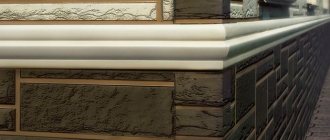

Separately, we should highlight the basement siding, intended for cladding the lower part of the building. It has thicker profiles, better weather resistance and moisture resistance, and resistance to mechanical damage. This is due to the fact that the basement of the house is more often than others subject to impacts and other damage, freezing, exposure to moisture and other negative environmental factors.

Basement siding is rather rectangular panels. Their width is usually equal to the height of the base and starts from 60 cm. This makes installation easy.

In terms of fastening and possible materials used for manufacturing, façade panels have some similarities with siding. They can have a square or rectangular shape and various dimensions. Some slabs contain insulation. The multilayer nature of the panels ensures their high performance properties.

Another popular wall-mounted material is sandwich panels. They are a “sandwich” in which a “middle” of insulation is laid between 2 layers of rigid material (usually metal). The strength and durability of the structure is ensured by using the hot pressing method. The front side of the “sandwich” can be painted in any shade, be smooth or have a relief.

Sandwich panels are highly resistant to fire and moisture and demonstrate excellent thermal insulation properties with low weight. The material is easy to install, and if a separate section is damaged, only that section can be replaced without going through the entire façade.

If previously they were used for cladding administrative buildings, now they are also used to decorate private buildings. This is due to the durability and reliability of the material, its weather resistance. Externally, the cassettes are squares and rectangles of aluminum, steel, and less often copper, coated with a protective polymer layer. The size and design of cassettes may vary.

Lining and block house: natural wood

How are houses decorated to make them look like cottages made of natural timber? For such purposes, lining with clapboard and block house is carried out. The materials are fixed directly to the SIP panel without profile systems. Lining and block house guarantee:

- aesthetic appearance of the house;

- favorable microclimate due to vapor permeability of materials;

- protection from external factors.

However, these materials have two disadvantages. Natural wood does not tolerate high humidity and temperature changes, so it can deteriorate. The coating will require serious care. In addition, both lining and block house are expensive materials. Class A lining will cost more than brick, stone or clinker.

The service life of external wooden finishing is questionable - it all depends on the climatic characteristics of the area.

Materials for cladding wooden houses

The cladding of a wooden house can be made with a variety of materials.

The cladding of a wooden house can be made with the following materials:

- vinyl, basement siding;

- fiber cement panel;

- porcelain tiles;

- wooden siding or block house;

- professional flooring, flat metal tiles and metal siding;

- wood.

Let's take a closer look at the characteristics of each material in order to decide what to cover the outside of the house cheaply and with high quality.

Vinyl siding

The characteristics of this product are suitable for almost any home and climatic conditions

The characteristics of this product are suitable for almost any home and climatic conditions. Vinyl siding is highly resistant to damage and temperature conditions. This material is relatively cheap, comes in a large number of colors, is easy to install and has a long service life.

Experts recommend that when choosing it, you should be guided by the following points:

- It is best to sheathe your home with light-colored siding, because... dark colors may lose their color when exposed to sunlight;

- install the product only in the warm season, the air temperature should not be below 0, this is due to the fact that in warm times the material bends well and is easy to cut, and in winter there is a possibility of getting a large amount of waste;

- Use self-tapping screws as fasteners, which must not be screwed in completely, because at the moment of thermal expansion, the siding conducts and it is capable of breaking the panels from the fasteners.

Fiber cement panel

Fiber cement panels are the same siding, the only thing is that it is based on cement and synthetic fiber

Fiber cement panels are the same siding, the only thing is that it is based on cement and synthetic fiber. In terms of performance, they are superior to vinyl. But among the disadvantages of these panels it is worth noting the following:

- high cost, unlike vinyl, fiber cement costs 3 times more;

- fairly weighty panels;

However, fiber cement panels can be considered a unique material:

- it doesn't burn;

- does not melt;

- does not change color;

- Shock resistant.

The photo shows a house covered with fiber cement panels

Porcelain tiles

Porcelain tiles will look good on the building

Porcelain tiles will look good on the building. Unfortunately, this is the only advantage of this material. Among the disadvantages it is worth noting:

- the tiles are too heavy, which requires the use of metal hangers;

- Porcelain stoneware is quite difficult to hang on a wooden structure;

- the cost of the product is very high.

Wood siding and block house

If you are looking for cheaper options to cover your home, wooden siding or side house is the best option

If you are looking for cheaper options to cover your home, wood siding or side house is the best option. These products will not only decorate the facade of the house, but will also give a feeling of warmth and naturalness. The advantage of the material is:

- natural decorative look;

- ease of installation;

- high strength;

- optimal price.

Wooden siding and block house are attached to the sheathing, which can be attached to the log and lumber wall. Among the disadvantages it should be noted:

- the product is subject to rotting processes;

- products react to weather conditions (wind, rain, snow, sun);

An example of covering a wooden house with siding

Metal siding

Metal siding is corrugated sheeting, only more decorative

Metal siding is similar to corrugated sheeting, only with a more decorative look. This material fades significantly less in the sun, which makes it possible to use dark palettes for building cladding. Unlike vinyl siding, metal siding does not break during installation, either in summer or winter, i.e. it can be laid at any time of the year. It is fastened with metal hangers and on a crate made of wooden beams.

Finishing with expanded polystyrene panels

Panels made of expanded polystyrene foam are used for finishing houses made of SIP panels. The material allows you to quickly provide thermal insulation and decoration of a residential building. Expanded polystyrene is 90% air and is made from sintered granules. The material is light, reliable, durable. It does not burn and does not allow water to pass through, but at the same time it allows steam to pass through perfectly.

Expanded polystyrene panels are a comprehensive solution for insulation and decoration. The products consist of two layers:

- inner layer of polystyrene foam for insulation;

- external finishing.

The outer part of the panels can be made of marble chips, clinker, wood fiber panels, porcelain stoneware, aluminum and other materials. Thermal panels can have a variety of textures and imitate brickwork, marble, natural stone, textured plaster, wood, slate.

The finish protects against external factors: cold, moisture, dirt, fungus. The disadvantage of this material is that polystyrene foam cannot be called durable. It may crumble and lose its properties. Typically, this finish is changed after 10-15 years of service.

Features and nuances of choosing facing material

When deciding what to cover the walls with, it is important to take into account not only the technical characteristics of the finishing material, but other conditions. These include the climate in the region of construction, the type of heat insulator used, the purpose of the facade of the building. In cold climates, it is not advisable to use “cold” cladding in the form of metal siding

A better choice would be clinker tiles on thermal panels or cement-bonded particle boards. In case of heavy rainfall and high air humidity, experts recommend abandoning natural wood (block house, facade board). The best option would be to cover it with moisture-resistant siding.

In cold climates, it is not advisable to use “cold” cladding in the form of metal siding. A better choice would be clinker tiles on thermal panels or cement-bonded particle boards. In case of heavy rainfall and high air humidity, experts recommend abandoning natural wood (block house, facade board). The best option would be to cover it with moisture-resistant siding.

In cases where the walls need to be made not only beautiful, but also warm, it is advisable to use thermal panels or fiber cement siding. If the frame is insulated with mineral wool, then external finishing is allowed in the form of siding or wooden planks. Finishing the facade of a frame house with mineral plaster is suitable if the walls are insulated with foam plastic.

A competent choice of finishing material will give the building a harmonious appearance, improve thermal insulation in the premises, and protect from external noise. A high-quality coating will please the eye for many years and provide comfort in life.

Facing with plastic siding

Plastic siding is a popular material for finishing private houses and office buildings, which differs:

- affordable price;

- resistant to moisture and dirt;

- simple installation;

- long service life;

- large assortment.

Facades made of plastic siding can be repaired locally, replacing only damaged parts of the finish. Service life depends on climate and external factors. The disadvantage of the material is that it does not look respectable and breaks under mechanical stress. In harsh climates, such material will not last even five years.

How to paint OSB board correctly

After the primer has dried, you can proceed to painting.

The slab is painted in good, non-rainy weather, at a temperature not lower than +5°C. The paint is mixed and applied to the prepared surface with a brush, roller or spray gun.

Soloviev Artem Vladimirovich

The first layer is applied in a thin layer, paint consumption should be minimal. If there are any unpainted areas left, you can go over them with a brush.

The first coat of paint is left to dry for at least two hours. The second layer is applied after the first has dried, in a thicker layer. You can apply a third layer (after the second has dried), this will give the maximum decorative effect.

A member of our portal with the nickname Urgenz calculated that it took 50 liters of paint to paint a house with an OSB facade measuring 14mx7mx6m, with gables and a protruding balcony.

The paint should be applied in an even layer without gaps or sagging, carefully treating the joints of individual parts. Specialized paint for OSB dries completely within 24 hours, and after a week the treated facade acquires full operational properties.

Urgenz has found a way to avoid mistakes with tinting.

Urgenz

If you are tinting, it is better to select the paint this way: choose a color in the color chart, make 5 liters (or less if packaging allows), bring it home, paint on OSB in two layers with an interval and see if you get the right color. Be sure to save the color number and proportions in case of subsequent repairs.

After painting, the joints between OSB boards are often visible to the naked eye, but this is not a problem, because they are always covered with overlays made of wood, aluminum or plastic. It is recommended to fasten them not with self-tapping screws, but with glue or liquid nails.

We invite you to look at various options for painted OSB facades.

As you can see, this finishing option is not only the most budget-friendly: with the right approach, it can be very attractive.

Here you will be able to participate in a discussion of the features of OSB painting, read an article about what problems can arise when using OSB in house construction and how to solve them, watch a video on how to build a frame house of unusual architecture.

Source

Advice from professionals

- SIP panels are lightweight, so they are usually installed on a shallow foundation. But at the stage of choosing a finishing material, care should be taken to ensure that the cladding will not place too much stress on the floors and foundations.

- If you plan to decorate your house by installing piece products on a frame, you should think about how the cladding of the corners will look. This can be done by joining and initially trimming decorative items. But such work requires skill and skill. To make it easier to design external corners, you should ask whether they can be purchased ready-made. These elements not only facilitate the installation process, but also ensure tightness.

Conclusion:

The level of skill of our team guarantees high-quality exterior finishing of a private home, any turnkey facade repair, regardless of volume and complexity. By contacting us, you will not only receive professional advice, but also be able to order the entire range of facade work. Our own production of sip panels allows us to build houses from scratch, including exterior finishing of any complexity.

The full cycle of construction services also includes installation of electrical wiring, sewer networks, ventilation and installation of heating systems. With us you will find everything from manufacturing a house kit to putting the building into operation.

Select a project Calculate construction costs

For more detailed advice on the issue you are interested in, please send us a message.

Types of wood

The quality of wood is determined according to the requirements of GOST 2696-83, GOST 8486-86, GOST 24454 and is distributed according to grades:

- highest grade or class “A”: large or small non-rotten knots are allowed at a distance from each other of more than 2 m, the number of shallow cracks is up to 10% formed as a result of drying the wood, the angle of inclination of the fibers from the center line along the length of the material is up to 5% , complete absence of parts of the root system;

- first grade or class “B”: there are no rotten or falling out knots with a diameter of more than 1 cm, through cracks with a depth of more than 1 mm and a length of more than ¼ of the length of the product are not allowed, bark elements and rotten areas, rottenness, mold, foreign materials, as well as gray islands on the surface;

- second grade or class “C”: not rotten or falling out knots and cracks with dimensions up to 2 cm, cracks with a depth of up to 1 mm and a length of 1/3 of the length of the material are acceptable, as well as minor color changes in the surface, there must be no rotten areas, affected by parasites, rotten, mechanically damaged, as well as inclusions of foreign bodies;

- third grade or class “D”: large or fused knots, cracks at the ends of the material or through cracks are not allowed, rotten areas, mechanically damaged surfaces, changes in natural color shades, different angles of inclination of the fibers are allowed;

- fourth grade or class “E”: includes all types of wood that do not meet the requirements of the quality standards described above.