A fireplace in a house or country house is a place of attraction for the whole family. It’s clear that you want it to be beautiful, but practicality also doesn’t hurt - soot and soot, dirt or tar from firewood, all this often ends up on the walls of the portal. For this reason, the surface must be easy to clean. In addition, the finish of the fireplace must be heat-resistant - although the sides of the fireplace do not heat up to the same temperatures as the stove, this requirement should not be neglected. Not many materials meet these requirements. This is heat-resistant plaster, special types of ceramic tiles and stone - natural or decorative.

Plastering fireplaces

A common type of finishing for fireplace walls is plaster. It is applied over the brickwork, followed by painting. The composition of plaster for fireplaces is made according to the same recipes as for finishing stoves, despite the fact that fireplace panels heat up less than stove panels.

If you decide to finish the fireplace with your own hands, you can prepare the mixture yourself, if you have experience in recognizing the fat content of a clay batch, or purchase a ready-made one.

There are several options for heat-resistant mixtures intended for heating devices on sale. They differ from conventional ones in that they contain various additives in the form of plasticizers and additives.

Some manufacturers offer two different types of dry mixes to use one as a base and the second as a finish, up to 3 mm thick. After covering with the second layer, the surface is ready for painting.

There are several recipes for preparing solutions at home:

- clay-cement, one part of clay and cement is placed on 2 parts of sand;

- lime, add one part sand and gypsum to 2 parts lime;

- clay-lime, one part of lime and clay should be placed on 2 parts of sand.

Once upon a time, chopped straw was added to lime-clay mortars for strength, then asbestos fibers, but now new materials have appeared to reinforce the plastered surface - these are fiber or glass fibers. They are added a little, up to 0.2%, mixed with the dry mixture, and then diluted with water.

It is better to buy slaked lime for the fireplace, since it has a thick, uniform consistency, and the sand is sifted and added, selecting the percentage, depending on the degree of fat content of the clay.

There is an old way to determine the fat content of a clay solution. You need to dip a piece of clean board into it; if the surface is covered with an even thick layer, then the solution is normal.

When lumps form, it is necessary to add sand, and when almost nothing remains on the board, it means there is not enough clay. The finished solution should look thick, plastic and uniform. If you plaster the surface of the fireplace correctly and carefully, in compliance with technology, then the special plaster will last a long time, without cracks or heaving.

Video description

The video will show how to line a fireplace with artificial stone:

But a fireplace trimmed with wood looks most original. Some might say that this is a complete violation of fire safety. But if you follow certain rules, you can get a chic fireplace for your living room in a classic style.

Firstly, it is necessary to select wood that will maintain its structure at periodically changing temperatures. And you only need to consider oak, hornbeam, maple or cherry. The density of other breeds is much worse.

Secondly, the material is generously treated with fire retardants. And even after this, it is necessary to move the wooden frame ten centimeters away from the bricks of the hearth. Only in this case will the heating of the wood not exceed permissible limits.

Thirdly, the firebox itself must be covered with a protective screen. To protect the tree from accidentally flying sparks from the hearth. And as a result, you can get an aesthetic finish from natural materials that will last for an extremely long time. Moreover, the type of cladding will not change over time.

Tiles and porcelain tiles in the fireplace surround

Selecting heat-resistant ceramic tiles for a fireplace is not entirely easy. There are cases when the glazed surface very quickly becomes covered with small cracks, which spoils the aesthetic appearance and complicates the cleaning process.

In order not to take risks, it is better to spend time, and sometimes a little more money, but find materials specifically designed for decorative finishing of fireplaces. These include the following types of finishing ceramics:

- terracotta - is a thick ceramic tile without glaze, its technical characteristics are close to brick;

- majolica is a type of terracotta tile, with a complex production process in which the front surface is covered with reliefs and painted with multi-colored glazes;

- clinker heat-resistant tiles, made from a complex recipe of a mixture of different clays and fireclay, have a noble color of fired ceramics from burgundy to light gray;

- porcelain stoneware - is a product produced using ceramic technologies, but with the addition of fine stone chips, quartz dust and coloring pigments;

- tiles are thicker ceramic parts that are embedded in the walls of the portal during construction work and fixed by securing wire.

Briefly about the main thing

When choosing materials for cladding a fireplace, you first need to pay attention to their weight. Natural stone or porcelain tiles have a very large mass. Therefore, they are suitable only for a private house, in which it is possible to strengthen the foundation of an existing fireplace.

In all other cases, it is better to stick to tiles. It weighs little and is easy to attach to the surface of the fireplace with glue. Moreover, its range is so wide that there is an imitation of almost all natural materials. From natural stone to wood of any species.

Ratings 0

Natural materials for finishing fireplaces

In the process of finishing a fireplace with stone, the order of preparatory work is somewhat different from others. Due to the large weight of stone slabs and shelves, it is necessary to install a mesh of steel reinforcement on the brickwork. Then you can lay the same type of stone or different ones to create patterns, on the same mortar that is used for plastering and laying ceramic tiles.

Cladding the walls of the portal with granite, marble, Armenian tuff or other rocks is a labor-intensive task, and the cost of finishing the fireplace will immediately increase. But it will serve as a decoration and heating medium for the home for many decades.

Rules for installing a fireplace insert

The quality of the fireplace's operation largely depends on how correctly all instructions were followed during installation. Thus, professional craftsmen recommend following the following rules:

- when determining the location where the fireplace will be located, it is important to ensure that the adjacent walls and ceiling surface can withstand high temperatures;

- the arrangement of the fireplace requires the presence of a smooth stone or ceramic base;

- as a safety measure, the base of the firebox should be equipped with a sheet of steel, the thickness of which should be more than 2 mm;

- The role of thermal insulation material will be perfectly fulfilled by basalt-based cotton wool, which must be laid between the surfaces of the floor and ceiling. This type of cotton wool is highly heat resistant (heating to 900°C will not cause any harm to it);

- one of the features of laying the firebox is the need for its gradual rounding, for which each of the subsequent bricks must be laid 6 cm closer to the beginning of the previous brick;

- the remaining mortar mixture formed after laying a row of bricks must be removed with a sponge;

- speaking about such a parameter as the thickness of the firebox walls, it should be remembered that at the side walls this parameter should be 20 cm, and at the rear edge - 10 cm;

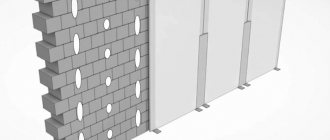

- provided that if the fireplace is installed in a structure made of stone, then its arrangement can be done near any desired wall. But if the main structural element of the house is wood, then before installation it is necessary to build a special layer of protection. For these purposes, you can use either standard bricks or building blocks;

- the diameter of the gratings mounted in the decompression chamber must correspond to the power of the firebox used;

- in order to prevent the surface from being damaged during the operation of the fireplace, it is important to extend the chimney pipe beyond the roof by at least 1 meter;

- those sections of the chimney that cross the attic must be treated with a layer of thermal insulation;

- the joint between the fireplace insert and the chimney pipe must be completely sealed;

- in order for the air necessary for ventilation to flow to the gas outlet channel, a gap of 5 cm must be provided at the fireplace outlet area;

- the minimum height of the firebox above the floor surface is 20 cm;

- control over the air supply to the firebox will be improved by installing a special throttle-type damper mounted in the ashpit;

- Excess condensate can harm the system, so it is important to provide for the possibility of its drainage from the pipe.

Artificial cladding details

If you want not to overload the brickwork, you can choose inexpensive faux finishes for fireplaces. Gypsum stone is produced by casting, which leaves sagging and irregularities on it.

Each element must be processed with a simple construction knife. The corner parts must be turned especially carefully to make them look beautiful; they are made at an angle of 45 degrees at the joints. When all the pieces are prepared and laid out on the floor, they can be taken in order and glued to the bricks using special heat-resistant glue.

Numerous photos of fireplace decoration show original examples of combinations of different types of materials. The stonework is perfectly complemented by a shelf made of carved wood, and decorative plaster creates unique compositions with ceramics or artificial stone.

Less popular methods

It’s worth talking right away about decorating the fireplace with tiles. The method is quite old, but today it is very rarely used. Firstly, such finishing is possible only when constructing a fireplace. You cannot cover an already finished hearth with real tiles.

Secondly, the installation is so complicated that it requires a highly specialized specialist. Tiles are already a very expensive pleasure. And the involvement of a master in the work makes such a fireplace truly “golden”.

You can line the fireplace with brick. In this case, there are two ways. They take plastic molded ceramic bricks and lay out the external walls. In the second case, the main masonry is refined. The seams are deepened and cleared. Then they are filled with special compounds.

The brick itself is also subjected to various treatments. Hydrochloric acid solution for color saturation. And before that, each element is polished or chamfered. The complexity of such finishing is so great that not every stove maker will take on the job.

Photo of fireplace decoration

Varnish on brick

Our user with the nickname Lokos spent a long time thinking about how to improve an old stove.

I found very expensive imported terracotta tiles and was prepared to buy them, but then I cleaned the old whitewash from the stove and was simply amazed at how old brick looked. What did he do:

- crashed into a glass door;

- re-saved the seams with masonry mixture;

- cleaned off all excess with a wire brush;

- primed;

- covered the seams with heat-resistant red-brown enamel;

- covered the doors with black enamel;

- I applied two layers of heat-resistant varnish to the bricks.

Insulation options

There are many non-combustible materials that can be used in this case. The easiest way to protect all surfaces from heat is to place a protective box around a red brick heat source. It is able to protect structures from heat and easily tolerates thermal effects. However, this decoration of the wall around the stove in the house looks a little unaesthetic and you can choose other materials:

- Porcelain tiles and tiles.

- Fiber cement boards.

- Factory-made protective screens.

- Metal sheets.

- Artificial or natural stone.

The easiest way to work is with a ready-made protective screen - you just need to select it according to size and install it on site. This option is also good because such finishing of walls near the stove or fireplace is done in the shortest possible time and without “dirty” or “wet” finishing work. The remaining options are more labor-intensive and have some nuances. Therefore, they need to be considered in more detail.