For the construction of structures that are constantly exposed to high temperatures, ordinary brick is not suitable. For these purposes, special refractory bricks are used. They come in several types, but fireclay bricks are the most popular. The qualitative and technical characteristics of fireclay bricks allow this material to be used both for industrial purposes and in private construction. Let's consider the main characteristics inherent in this material and its main types.

When building a stove or fireplace in a house, the need to use fire-resistant materials comes to the fore. That is why most buyers choose fireclay bricks. This building material can withstand extremely high temperatures and direct, prolonged exposure to flames. It is noteworthy that fireclay does not deform or crumble even with prolonged heating.

What it is?

Fireclay brick is characterized by a very simple composition; it is based on crushed, dried fireclay powder, the concentration of which is 65-70%. This substance is made from simple white clay, which is cleaned and fired for a long time, due to which it exhibits pronounced fire-resistant characteristics. Additionally, coke and graphite fillers and coarse quartz grains are introduced into the raw materials. The initial components are thoroughly mixed, then shaped and sent for firing and crimping.

It is the firing features that determine the basic operational parameters of the material. The duration of baking of the material is of great importance. So, if the raw material is kept in a thermal oven, then a glassy film appears on its surface. It is quite durable and gives the material special resistance to mechanical damage, but at the same time its fire resistance decreases.

If, on the contrary, the firing is insufficient, such a material will perfectly absorb and retain moisture within itself, and therefore its strength will be very doubtful. The best brick for stoves and fireplaces can only be obtained if you adhere to the “golden mean”.

The production of fireclay bricks is regulated by current standards, and its dimensions and weight can often vary significantly: from 2.5 to 6 kg, and the parameters are 230x111x65 mm, as well as 300x150x65 and 250x123x65 mm. In addition, products differ in the density and porosity of their structure.

Manufacturing technology

Among all types of bricks, fireclay is the most durable and resistant to strong heat and temperature changes. The material owes these qualities to its composition and specific manufacturing technology, which consists of firing a clay mixture with the addition of fireclay powder. As a result of exposure to high temperatures, brick acquires a characteristic gray-brown or yellowish color, by which it is easily distinguished from other varieties.

The composition of fireclay brick determines its performance characteristics. Depending on the proportions of clay and powder, several types of material are distinguished. The processing method, or more precisely, the baking time of the bricks, also plays a huge role. So, if you keep it in the oven, a strong glassy film will form on the surface, which will make the brick incredibly durable, but less fire-resistant. If you burn it not long enough, then such a material will absorb and retain moisture well, but will completely lose its strength. Only if you stick to the “golden mean” can you make a brick that is ideal for laying stoves and fireplaces.

To prevent the products from cracking during the firing process, a certain amount of special fireproof clay – fireclay – is added to them. Sometimes coke powder, graphite or coarse quartz are used instead. The result is different types of bricks with individual characteristics. Moreover, the result depends not only on the raw materials and processing method, but also on the characteristics of the fuel for firing and the resulting ash.

The production of fireclay bricks is carried out in accordance with GOST 390-69, and depending on what it will be used for, the production technology, weight and dimensions of the material differ. Thus, the weight of fireclay bricks can vary from 2.5 kg to 6 kg. Differences also lie in the density, porosity and composition of the bricks. There are uniform size standards that most manufacturers adhere to: 230x113x65 mm, 250x123x65 mm and 300x150x65. These are the most convenient dimensions for construction and transportation.

Read also: All about the specialty Forensic Science

The most commonly used brands of fireclay bricks: ShB No. 5, ShB No. 9, ShB No. 22, ShB No. 44, ShB No. 47. The letters in front of the number may be different, for example, PB, ShB, ShUS, ShL and others, but for domestic use it is better to choose bricks marked “ShB”. The first letter indicates that the brick is fireclay, the second means which fire resistance class it belongs to, and the number is the aspect ratio.

Lightweight brick

Lightweight fireclay brick has proven itself as a good insulator. It consists of peat, fatty clay, sawdust and other components of organic origin. During the firing process, they burn out, leaving behind pores of various sizes. This manufacturing technology makes it possible to obtain a very lightweight porous material with high energy-efficient characteristics.

Since lightweight bricks are made entirely of organic matter, they are an environmentally friendly material that cannot harm human health or the environment. At the same time, high fire resistance is maintained - the brick can withstand extremely high temperatures up to 1800°C.

Characteristics of fireclay bricks

The weight of products from various manufacturers ranges from 2.8 kg to 4.5 kg. This indicator affects the thermal conductivity of the material: the higher the weight of the stove brick, the lower its thermal conductivity. Thus, heavier bricks will keep your home warmer longer.

The amount of aluminum oxide contained in a material determines its resistance to the aggressive effects of high temperatures, alkalis and chemicals. Aluminum oxide also makes stove bricks porous. Due to this, it heats up for quite a long time, but, at the same time, retains heat longer.

In addition, the higher the porosity of the material, the lower its strength: under the influence of heavy loads, excessively porous bricks deform and crumble. In order to determine which of the various brick options has greater porosity, it is enough to hold the products in your hands.

Particularly dense brick has a porosity below 3%, high-density - 3-10%, dense - 10-16%, compacted - 16-20%, medium-density - 20-30%, highly porous - 30-45%, lightweight - 45-85%. , ultra-lightweight – above 85%.

These characteristics of fireclay blocks will help you choose a brand of products that are ideal for creating specific building structures. The optimal density for fireclay bricks is 1700-1900 kg/m3. This parameter affects water absorption, thermal insulation properties, adhesion to the mounting mortar and the weight of brick blocks.

According to the method of forming the blocks, fireclay can be cast from slip, molded by a semi-dry or plastic method, fused, thermoplastic pressed or hot pressed. Traditionally, kiln bricks have rectangular geometric parameters. But, to meet consumers halfway, factories also produce it in arched, trapezoidal or wedge-shaped shapes. Existing standards allow this. The variety of shapes and sizes of oven bricks allows the construction of structures of various designs.

Manufacturers of fireclay bricks are constantly improving production technologies for this material. They change the shape of the products and use special additives that improve the characteristics of the brick. So, recently a stove brick has appeared that can withstand extremely low temperatures.

But, in addition to the positive ones, stove bricks also have negative properties. Firstly, very dense blocks cannot be cut. Secondly, products even from the same batch often have different sizes. Thirdly, high hygroscopicity increases the mass of stove bricks and reduces its strength when heated. Fourthly, having low resistance to freezing, when the thermal device cools down, fireclay bricks begin to crumble. Fifthly, laying fireclay bricks requires a special mounting solution. Sixthly, this material is classified as expensive.

Application area

Due to its resistance to temperature changes and the effects of alkalis and chemicals, fireclay bricks have a wide range of applications. It is used in industrial enterprises in installations that emit active chemicals during combustion: blast furnaces, boilers, fuel chambers.

The solution used to create thermal devices is also important. Typically, the same ingredients used in brick production are used for mixing. This gives the oven a high level of heat resistance.

To lay fireclay bricks of the ShB-5 or ShB-8 brand, refractory clay containing crushed brick is used. The resulting solution is called “mortar” or “fireclay clay” .

Figured refractory fireclay brick

Fireclay brick, what is it and what components give it such unique properties? These products can be easily recognized even by their appearance - they are characterized by a yellowish-sandy color and a granular, uniform structure.

It owes its properties to production technology. During the manufacturing process, the raw material mixture is molded and fired at elevated temperatures. At each stage, specialists strictly control both the processing time of the products and the temperature indicators.

If a brick block is not kept in a kiln, it will not have sufficient strength. A violation of the technology can be easily determined even visually - such a product has a lighter shade than that specified by the standards.

High fire resistance rates are largely influenced by the composition of fireclay bricks. Products are made from special grades of clay (in other words, “chamotte”) and some additives. Aluminum oxide is mainly used as additional components. This is what gives fireclay blocks the strength and resistance to aggressive chemical influences for which the material is famous. Depending on how much aluminum oxide is added to the mixture, the porosity of the finished product varies. Porosity, in turn, directly affects the thermal conductivity of fireclay bricks.

The more porous the brick block, the longer it will take to warm up, but it will also cool much more slowly. But if the porosity indicators are increased, this negatively affects the strength of the product - it crumbles and deforms under the influence of heavy loads.

So, fireclay brick is extremely durable, fire-resistant, has high heat capacity and is resistant to negative environmental influences. What shortcomings does it have? Let's highlight a few:

- The blocks cannot be cut because they are very durable.

- Products often vary in size (even those from the same batch).

- The material is quite expensive.

Types of fireproof stones

- Basic. It involves the use of a lime-magnesium composition. Used in steel production.

- Carbon. Suitable as the main material for arranging blast furnace structures.

- Quartz. Its basic components are quartz and sandstone. This type of stone does not withstand proximity to any materials, with the only exception being metal. Does not tolerate exposure to various alkalis.

- Alumina brick – the most common type. The temperature range for its operation is 1000-1300 °C. Valued for its ability to withstand temperature changes. Alumina refractory brick is perfect for laying household stoves and arranging combustion chambers.

How to choose quality products?

In some cases, a darker color predominates on the surface. At the same time, it is covered with a smooth glass film. This is caused by the fireclay being overexposed during firing in the kiln. Burnt bricks have great strength, but due to the smooth surface there is no high-quality adhesion to the mortar, as a result of which the finished structure turns out to be fragile. However, such bricks can be used when constructing a foundation.

Only high-quality products have the above qualities. If the production technology is disrupted, the finished brick will lose about 75% of its positive qualities. For this reason, it is necessary to know the main differences between high-quality fireclay and be able to recognize them at the time of purchase. A brick made using fireclay powder should have a geometrically correct shape and have thin edges. The surface should be slightly rough, with a clearly visible granular structure.

If you knock on a well-fired brick, it will make a metallic and ringing sound. During the fall, it will not crumble into dust, but will break up into large elements. If a brick crumbles when it falls and a dull sound is heard upon impact, you have an insufficiently fired brick. The problems of this material will be increased hygroscopicity, low strength and insufficient thermal conductivity.

Criterias of choice

What should a private buyer pay attention to when purchasing products for his own fireplace:

- Appearance. The finished product must have a uniform, uniform color on all sides. For classic fireclay bricks, these are sandy yellow shades. Chips, cracks, and lopsidedness are unacceptable. The only time you can skip it is when used for auxiliary purposes, for example, building a podium. Deviations in size should not be more than 2 mm. The presence of a glassy film on the surface indicates that the refractory was overexposed in the oven, and problems may arise during the laying process due to poor adhesion to the mortar.

- Sound. Brick produced in accordance with all standards has a homogeneous structure, without internal cracks and foreign inclusions. Therefore, when it collides with a metal object, it produces a clear sound, without extraneous vibrations. Dull or rattling vibration indicates a violation of the integrity, uniformity of composition and structure, the presence of internal cracks and stresses caused by improper annealing.

- When examining the split brick, it is clear that the outer side is more richly colored than the inner. In this case, each of the shades for the outer and inner sides must have the same color. The presence of a dark-colored core indicates non-compliance with the firing conditions - the product was burned out.

Marking of fireclay bricks

Most often, fireclay bricks are marked with the letter “Ш”. Other letters and numbers indicate dimensions, technical characteristics, temperature properties and other parameters of the products. Each brand of fireclay brick has its own technical characteristics, as well as the weight and dimensions of the products. Accordingly, their prices also vary.

For example, what does the marking ShB 5 SL mean?

Ш – fireclay aluminosilicate brick, B – fire resistance class in accordance with GOST (up to 1400 °C), 5 – geometric parameters (230x113x65 mm), SL – product manufacturer (Sukholozhsky Refractory Plant).

If the second letter after Ш is missing in the marking, most likely this stove brick was made not according to GOST, but according to the manufacturer’s specifications. Within each brand there is a deeper classification: by size, shape, thermal conductivity.

Marking of the most popular fireclay brick products:

- SHA, ShB, SHAK are the most popular, universal fireclay blocks used for the construction of stoves and fireplaces; they are very durable, fire-resistant and have the best price/quality ratio;

- ShV, ShUS – oven bricks with high heat capacity, most often used in industry for lining the walls of gas ducts of steam generators and convective shafts;

- ShK – fireclay products used in industry for the construction of coke production equipment;

- ШЛ – lightweight, highly porous stove brick with fire resistance up to 1300 °C and a low expansion coefficient, used for lining hearths, has about 50 standard sizes;

- ШЦУ – double-sided end fireclay blocks used in the construction of rotating kiln structures;

- PB – fireclay bricks, most suitable for the construction of household barbecue stoves;

- PV – fireclay bricks, which are most often used for the construction of internal walls of fireplaces and chimneys.

The excellent properties of oven bricks are ensured by its production technology. The raw material mixture is molded and fired at high temperatures. Specialists strictly control the temperature and processing time of bricks at each stage of production. If a brick block is not kept in the oven for an insufficient amount of time, it will become brittle. Defective stove bricks differ from high-quality ones in a lighter shade.

When choosing stove bricks, you should give preference to material produced in accordance with GOST, since it is of higher quality. In addition, the size of blocks with the GOST mark is optimal for the construction of brick structures. You also need to pay attention to the labeling.

HOW TO FIND AND SELECT DEFICIENCY FRAMEWORK PRODUCTS

Defects for such a “responsible” brick are unacceptable. You can tell a quality brick by its metallic sound when you tap on it. If you hit it harder, it should not crumble, but should break into large pieces. If it crumbles into crumbs and makes a dull sound when you hit it, it indicates that it was underburned. Under no circumstances should it be used for its intended purpose (that is, for laying a stove), as it will fall apart, or will not heat and retain heat, because the brick will acquire an unpleasant property, which manifests itself in the active absorption and retention of moisture. Such (wet) fireclay bricks lose their quality by 75 percent compared to dry ones.

Fireclay (fire-resistant) bricks are produced and produced much less than silicate or ceramic ones. This is due to the specifics of this specialized building material. Therefore, in order to choose it correctly, you need to listen to the advice of professional craftsmen who understand quality and know suppliers. Fireclay bricks are more expensive than regular bricks, but much less is also required. Do not forget that the masonry mortar must contain refractory clay and crushed fireclay bricks.

SCOPE OF APPLICATION

Areas of application often depend not only on technical characteristics, but also on the shape of the building material. For example, fireclay wedge brick is used in the construction of tandoors, since with its help you can easily make a round structure without cutting (and it is very difficult to make, as you remember). Fireclay is also used for construction:

- Outdoor barbecues and barbecue ovens, which are operated in conditions of severe corrosive influence.

- Grub and chimneys in autonomous heating systems. Its almost unlimited shelf life makes it attractive for this type of building.

- Russian baths and chimneys. Environmentally friendly material that does not emit harmful volatile substances when heated.

- Fireplaces and hearths inside the house: lightweight fireclay bricks are very beautiful to look at and practical to use.

- Industrial premises, pipes, boilers, smelters. The thickness of the fireclay brick and its density play a role here; in industry, they most often use custom-made fireclay, which has half the density and shrinkage.

Now we have figured out where fireclay bricks are used, what characteristics and parameters they have, and why they are needed in general. Make the right choice and happy construction to everyone!

Composition, production and types of oven bricks

Based on the conditions arising from the combustion of solid fuel, stove bricks must meet three basic requirements:

- Heat resistance of at least 1000 °C without loss of strength during prolonged exposure.

- Low thermal conductivity provides protection to surrounding building structures.

- Thermal resistance The product must withstand a significant number of heating and cooling cycles.

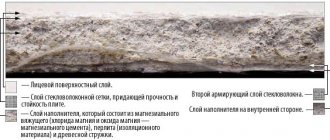

Fire-resistant stove brick is an excellent energy accumulator, in other words, it heats up quickly enough and gradually releases heat to the environment. Refractory bricks are manufactured at specialized factories using the technologies provided for by GOST 390-96. The composition of the raw materials used for the production of stove bricks as the main component includes refractory clay of special grades up to 70%. The introduction of certain types of charge into the molding mass makes it possible to obtain blocks with different properties; additives can include:

- graphite;

- coke in powder form;

- large fractions of quartz powder.

The technology for producing fire-resistant bricks using the semi-dry pressing method involves performing a number of operations in the following sequence:

1. Preparation of raw materials: grinding and kneading the clay, introducing the mixture, mixing until the composition is homogeneous. During this process, up to 8-10% water is added to the composition to achieve the required humidity.

2. The finished mass is loaded into a hopper, from which it enters a dosing carriage moving back and forth.

3. The molded brick is fed to the lower punch of the mold, which is lowered along with the workpiece.

4. The top of the press lowers and applies enough pressure to the brick to compact it.

5. Upon completion of the process, the lower punch pushes the block out of the mold onto the platform. At this moment, the carriage begins to move from under the hopper with the next portion of raw materials and moves the workpiece onto the conveyor belt.

6. The pressing process is repeated, and the raw brick is sent as the batch is formed for firing in a tunnel-type kiln at a temperature of about 1000 ° C.

This technology eliminates the operation of pre-drying the product and reduces its production time. This method of producing fire-resistant bricks is much cheaper than the plastic molding method, when a continuous beam is made from the prepared mass with a moisture content of 17-30%. The workpiece is cut into separate blocks by a special machine, which are fed for preliminary drying followed by firing.

The building materials market offers a wide range of fire-resistant oven bricks of the following types:

Fireclay stove brick

Semi-acid refractory brick

Dynasty refractory brick

Mullite fire brick

Corundum refractory brick

| Type of fire brick | Brands of refractory bricks |

| Chamotte | SHAK; ША-I; ShB-I; ShV-I(II); SHUS. |

| Semi-sour | PB-I; PB –II; PV-I; PV-II. |

| Dinas | DN |

| Fireclay and semi-acid lightweight | ShLA-1.3; ShKL-1,3; ShL-1.3; ShL-1.0; ShL-0.9; SHTL-0.6; ShL 1-6.4; ShL-0.4. |

| Lightweight mullite-siliceous | MCRL-0.8 and MCRL-0.7 |

| Mullite lightweight | MLL-1,3 |

| Lightweight corundum | KL-1,1 |

| Dinas lightweight | DP1-1,2 |

| Mullitocorundum | ISS-72 |

| Mullite | MLS-62 |

Technical characteristics of kiln refractory bricks depend on the type and brand; for convenience, they are summarized in the table:

| Index | Normal value for this brand of brick | ||||||

| SHAK | SHA | ShB | SHV | SHUS | PB | PV | |

| Fire resistance, °C | 1730 | 1690 | 1650 | 1630 | 1580 | 1670 | 1580 |

| Porosity of products, % | 23 | 24 | 24 | — | 30 | 24 | — |

| Tensile strength, N/mm2 | 23 | 20 | — | 22 | 12 | 20 | 15 |

| Additive content | |||||||

| Al2 O2 | 33 | 30 | 28 | 28 | 28 | — | — |

| Al2 O3 | — | — | — | — | — | 14 — 28 | 14 — 28 |

| SiO2 | — | — | — | — | — | 65 — 85 | 65 — 85 |

Advantages

- increased strength;

- high fire resistance;

- high heat capacity;

- sufficient resistance to various types of negative environmental influences;

- the possibility of trouble-free operation without deformation and wear for many years;

- Thanks to the smooth, dense surface, it is possible to install fireplaces and stoves without subsequent finishing.

Species division based on chemical properties

The characteristics of this classification are the composition of the refractory stone and the substances involved. There are the following three main categories:

- Sour group. This includes silica and quartz clay bricks, which are able to interact with an acidic environment without any damage.

- The main group consists of dolomite, magnesite, chromium magnesite. Contact with an alkaline environment will be problem-free for them. Most often, these bricks are used for the construction of structures in which there are constant sharp changes in temperature.

- The neutral group is represented by fireclay refractory, carbon and graphite types of bricks. They are characterized by resistance to alkaline and acidic environments.

Flaws

- Fireclay brick blocks, due to their high strength, are extremely difficult to cut;

- very high cost;

- installation requires a special solution;

- The laying of fireclay brick structures must be carried out exclusively by a highly qualified specialist.

Methods of application, installation methods, possible options for structures built from fireclay bricks are shown in photo and video materials. Excellent reviews from both builders and customers who have experience in the operation and use of fireclay brick structures make it an indispensable material in the construction of various objects and structures.

Price

Refractory bricks are used to build fireplaces, barbecues, and stoves. The price of the material depends on the brand, size, design features and manufacturer. To compare prices for October 2015 in Ukraine and Russia, 4 types of popular fireclay bricks were selected. When ordering a pallet, there are 350-360 bricks. The price is for 1 piece.

- The rectangular product ShA-5 in Russia is priced at 39.9 rubles.

- Similar to the previous refractory, SHA-8, differing in slightly larger sizes, costs 47.9 rubles.

- ША-22 (end wedge): price in Russia – 49 rubles.

- ША-45 (end wedge): the cost of the product in Russia is 41.2 rubles.

Main types

Many manufacturers met customers halfway and began producing fireclay stone of various types, differing in shape, weight and size, as well as manufacturing technologies and degree of porosity. Today, the following forms of fireclay are presented on the construction market:

- straight;

- arched;

- trapezoidal;

- wedge-shaped.

Thanks to this variety of forms, it became possible to erect structures with complex structures.

The following types of fireclay stone with different percentages of porosity are distinguished:

- ultra-lightweight (more than 85%);

- lightweight (45-85%);

- increased porosity (30-45%);

- medium-dense (20-30%);

- compacted (16-20%);

- dense (10-16%);

- high-density (3-10%);

- especially dense (less than 3%).

Such qualities make it possible to understand which brand is best to choose for the construction of specific structures.

As for the method of forming bricks, the following options are distinguished:

- fused;

- cast;

- hot pressed;

- thermoplastic extruded;

- molded using the plastic or semi-dry method.

Technologists at large factories continue to develop new product options. They add new components to the composition that improve its quality. In addition, production technology is improving, which makes it possible to obtain products with unusual properties. Thus, fireclay appeared, which has the ability to withstand extremely low temperatures.

Popular manufacturers of furnace material

There are a sufficient number of them on the construction market. The price of refractory bricks ranges from 16 to 60 rubles per 1 piece. They sell it in pallets of 320–360 pieces or by weight for 1 ton. The approximate cost of the material in both cases is up to 14 thousand rubles per pallet or ton.

Below are the most popular manufacturers of good quality heat-resistant bricks.

Wienerberger AG

An Austrian concern, which is considered the world market leader in the production of tiles and bricks. Its factories are located in 30 countries. Russia is also one of them.

A popular stove material is Terca brand refractory brick.

Lode

Lode is a Latvian manufacturing plant. Specializes in the production of various types of bricks.

The stove material produced by him, type M500, is popular - red, solid, with a high frost resistance. Suitable for laying indoors and outdoors.

Photo: preparing bricks for shipment

Has three working surfaces. It has several release forms. The semicircular one is in greatest demand. Its plus is its aesthetic appearance, due to which the lining of the stove looks neat.

Heylen Bricks

Belgian company. It has been producing bricks of all shapes and brands for more than 100 years. The products are distinguished by their strength, durability, and a rich palette of colors. This is one of the few companies that fulfills orders for the production of material for stoves, houses, cottages, garages, saunas, so that the client can bring his original ideas to life. The customer can participate in the production of the material itself.

The only negative is the high prices of imported products.

Vitebsk plant

The official name is OJSC Keramika. Production facilities are located in the Republic of Belarus.

Photo: Belarusian product

The main products are red ceramic bricks of the M180, M200 brands, which are used for cladding stoves and fireplace structures. The price is quite reasonable. But you should not work with this material in areas with high humidity levels.

Are fireclay bricks harmful?

There is a myth among uninformed people that fireclay bricks during operation can be harmful to human health. Is it so?

We hasten to assure you that the harmfulness of fireclay bricks has not been proven by any research. This material is made from environmentally friendly material – clay. Even though it has slightly different properties, it is still ordinary clay. And even when exposed to extremely high temperatures, fireclay bricks do not emit any harmful substances into the atmosphere. Otherwise, even pottery would be considered dangerous to human life.

Where can I buy?

This question is important for many home craftsmen. Definitely large specialized construction stores. It is better if the company is an official dealer of the manufacturer.

The most important thing is where to buy stove blocks. It is much more important to check their quality and all documentation from the sellers. Sometimes construction markets charge high prices for products from well-known brands. Use the data provided in this article and carefully check the quality and measure the dimensions of heat-resistant bricks. At the slightest deviation, think - maybe go to another store and look for quality material?

How to put it correctly?

The technology for constructing stoves and fireplaces from fireclay bricks at home consists of 2 stages:

- preparatory work;

- directly masonry.

At the stage of preparation for work, all future corners and walls are marked, as well as the production of the necessary adhesive mortar and preliminary dry laying. For permanent bricklaying, a special composition is used; it can be bought ready-made in a store, or you can prepare it yourself. You will need refractory powdered clay, high-quality fireclay sand, and industrial water.

First you need to grind the clay, then sift all the sand and add water to the resulting clay-sand mixture with constant stirring. The finished composition is left for two to three days, stirring from time to time. Clay and sand are taken in a ratio of 1: 2; some builders recommend adding salt or 3% liquid glass to the composition at the rate of 100 g per 10 liters of water.

Fire-resistant bricks are first cut and then fastened so that each subsequent row completely overlaps the seams between all the blocks of the previous row. This technology ensures the strength of the entire structure and also promotes normal load redistribution.

When installing with your own hands, pay special attention to the seams. If it is done incorrectly, that is, the seam is too deep or not completely sealed, drops of rain and snow begin to get inside (this applies to street structures), and when cold weather sets in, the masonry cracks. A fireplace that is cracked at the seams cannot perform all its functions in full, and its heat capacity is significantly reduced.

Masonry category

During the construction and repair of thermal units, the laying of refractory bricks occurs according to the following requirements, which determine its category:

- A maximum joint thickness of 0.5 to 1 mm corresponds to particularly careful masonry of category 1.

- Seams measuring 1-2 mm between bricks belong to category 2.

- Standard (ordinary) masonry is characterized by a joint thickness of up to 3 mm.

- The presence of mortar between bricks of more than 3 mm corresponds to simple refractory masonry.

Classes, brands of refractories, category of masonry - all this information must be specified in the working documentation. If there is none, then the thickness of the seams for different structural elements is determined based on special tables.

Fire brick for furnace

When choosing fireclay refractory bricks for a furnace, it is advisable to follow 4 principles:

- the ability to accumulate and retain heat for a long time;

- high mechanical strength;

- resistance to temperature amplitudes;

- ability to withstand the highest temperatures and open flames.

It would seem that! Why such difficulties when choosing fireclay bricks for a stove or barbecue - this is not building a house. However, the situation is such that fire-resistant and reliable building material is very important for laying the hearth.

The furnace has a lot of responsibilities and difficulties - to cope with a large number of negative aspects affecting it: the highest possible temperature conditions and sudden temperature changes. Such difficult conditions dictate the choice of special, most reliable bricks for the construction and finishing of the stove in the house.

The shape of the refractory brick is no less important - it must be correct with smooth edges, not have chips or damage, and most importantly - have a high-quality firing. The size of the kiln brick is also fixed and can be selected from only two options - 23 by 12.3 or 11.3 and 6.5 cm - these are the standard parameters used in classic drawings for laying out building materials.

The oven consists of several segments. So, if we have described the general algorithm, then the assembly of the ash pan and firebox is somewhat different from the assembly of the main structure. For these departments, exclusively yellow building bricks are used, while for the rest of the structure, classic red or Gzhel white are used.

The marking of fireclay refractory bricks for laying a furnace should also not be overlooked. For such work, the ideal material is in the marking range M150 - M 200. It was already mentioned earlier that these numbers mean the strength of fireclay.

Another detail that should not be overlooked is the color of the brick - it must be uniform and not contain any inclusions both outside and inside.

If you are planning to build a brick grill with your own hands or a large stove, you should not skimp on buying refractory bricks for the stove and buy silicate, slotted or hollow ones - such building material does not have fire-resistant qualities, does not withstand high and low temperatures, as well as temperature changes and has low thermal conductivity.

Selection of brand and shape

The standard dimensions of solid refractory bricks are 25*12*6.5 cm, the furnace module is 23*12.5*6.5 cm.

For ordinary masonry, the M150 grade will suffice; for a more complex, two-story masonry, M200, M250.

An inexpensive fireclay is suitable for laying the firebox - Ш5, ША5, Ш8, ША8. Factory-made bricks, narrowed in thickness and measuring 23*11.4*4 cm, are often used.

To decorate the combustion vaults, use grades Ш22–Ш45. The first number in the marking indicates the rib or end type of wedge.

There are shaped bricks that have the shape of an isosceles or equilateral trapezoid. The greatest demand is for ribbed wedge-shaped products in the following sizes:

- 23*12.5*6.5/4.5 cm;

- 23*12.5*6.5/5.5 cm;

- 23*11.4*6.5/5.5 cm.

The length of the base of the trapezoid is indicated through the fraction line.

Photo: possible brick shapes

The end shaped material is used for the arches of the firebox in the shape of a semicircle.

What kind of brick should the stove be made of?

Brick stoves are still popular and loved in almost every Russian country house or bathhouse. And if you are just thinking about building this structure that will provide comfort and warmth, then the following tips will be completely useful.

For efficient heat generation, absence of smoke and fire safety, only high quality building materials are used in the furnace masonry.

The stove consists of four fragments: the foundation, the firebox, the smoke circulation and the chimney. For each compartment it is better to choose a special brick suitable for the function of the fragment.

As a rule, fireclay bricks are used in stove masonry when laying the firebox, and ceramic bricks are used directly for the stove itself. Many neophytes may want to line the entire stove out of fireclay just to be on the safe side, but there is no particular need for this. Moreover, this would not be the right solution: the refractory brick gets very hot, which can lead to burns when it comes into contact with the skin, and financially, such a design would be unreasonably expensive.

Blitz tips

- When choosing refractories, do not chase a low price - on the contrary, this will indicate low quality of the product.

- When constructing a stove or fireplace, you cannot use a mixture of red ceramic and refractory bricks for internal cladding - they have different technical characteristics and there is a high probability of destruction of the masonry.

- If you have no experience in preparing masonry mortar, it is advisable to use ready-made dry mixes produced in factories.

Note. Fireclay and clay based on it are environmentally friendly materials, as they are made from natural raw materials.

Mortar for laying refractory bricks

A mortar for laying fireclay bricks is any of the many options for conventional building mixtures obtained by mixing a binder, filler, sealer and special additives.

Cement, lime, gypsum, clay, or any mixture containing the above materials can be used as a binding ingredient. Sand acts as a filler, and ordinary water serves as a sealer.

Solutions are classified according to the amount of binder present in the mixture, the properties of this binder, as well as the proportion between binder and filler. Simple mortar - only with cement, gypsum or clay, the class is indicated by two numbers separated by a colon. The first number is the amount of binder, and the second is the amount of aggregate.

Complex mortar - cement plus gypsum or lime plus clay acts as a binder. Here the class designation is in three numbers: the amount of main binder, additional binder and filler.

Solutions for laying fireclay substances may differ in properties:

- air - harden only in dry conditions;

- hydraulic - requires a moist environment to harden.

The proportions of binder and filler also affect the classification of solutions:

- fatty - this means an excess of astringent. The advantage of such solutions is their plasticity, and the disadvantage is large shrinkage after drying:

- normal - everything is in classical proportions;

- skinny - a small amount of astringent ingredient, which gives negligible shrinkage, and this is very important for facing work.

Differences in mortars for laying fireclay bricks by density:

- heavy - prepared on regular sand;

- the lungs are mixed with porous sand.

Features of laying heat-resistant blocks

There are a number of rules, compliance with which will ensure high-quality and durable masonry:

- The starting row is laid “dry”, without the use of an adhesive. When laying subsequent rows, an adhesive mixture is applied to the bottom and end surfaces, so that the thickness of the finished seam after laying does not exceed 5 mm;

- as soon as the brick fitting is completed, excess mortar should be removed immediately;

- the strength of the structure is ensured by laying the blocks with overlap (in a checkerboard pattern);

- the seams should be sealed flush with the side surface of the blocks. Recesses and unfilled seams will inevitably lead to cracks;

- when laying corners and decorative elements, the blocks are laid with the front side out;

- cutting fireclay bricks should be done with a grinder equipped with a diamond saw blade; using a trowel or pick to adjust dimensions is highly undesirable;

- the finished structure does not require any additional treatment with special compounds, primers, etc.

Strict adherence to these simple rules will ensure long service life and reliability of the structure.

Since structures operating in conditions of high and extreme temperatures are particularly critical, the correct choice of material is of particular importance. The use of fireclay bricks ensures high heat resistance, resistance to mechanical stress and sufficient fire safety of the structure. In addition, we should not forget that the use of ordinary ceramic or sand-lime bricks when laying heat-resistant elements will not only not give the desired results, but will also significantly increase the risk of fire.

What to cut with?

To produce fireclay blocks of non-standard sizes, production uses stone-cutting machines that provide high-quality cutting in large volumes and are equipped with a water supply system to cool the disk and prevent the appearance of fireclay dust.

At home, a stone cutting machine is a luxury. Therefore, to cut fireclay bricks, you will need to immerse the block in cold water for 20 minutes , and then cut with a regular grinder, using a diamond, cutting or abrasive disc. Moisture absorbed into the brick will ensure easy cutting and no dust. Before picking up an angle grinder, I strongly recommend that you read this article >>>