MDF panels perform not only a decorative role in a room. With their help, you can visually expand the space and create additional storage space. In Soviet-era apartments, this function becomes indispensable, especially on the loggia, which the owners were accustomed to using as a storage room. Plates of this material cover not only the walls, but also the ceiling. Finishing balconies with MDF panels has become popular relatively recently; the method is considered safe and environmentally friendly. This ensures thermal insulation of the entire room, maintaining a comfortable climate for people and plants.

What are MDF panels

The abbreviation is translated from English as fibreboard material. Used for finishing walls and ceilings of various types. Including for balconies and loggias. Decorative coating for vertical surfaces is similar to plastic panels. But they are made from natural wood raw materials. Their colors match the natural shades of wood, are pleasant to the touch, and have a rounded, smooth surface.

Made from wood processing waste. In fact, this is the twin brother of Soviet chipboard, but created using new technology. The composition does not contain dangerous resins or phenol. The presence of paraffin and lignin is allowed.

The basis of the composition is wood dust, which is obtained from sawdust. After grinding, it is dried and fired in ovens. When heated, lignin is released and processed into powder. Afterwards, the raw materials are pressed, panels are formed, and cut. Cover with melanin film with a natural wood pattern.

The structure is pliable, with properties similar to cardboard or plywood. Easy to cut, has excellent thermal conductivity. Can be painted any color.

Varieties

Production is carried out using the same technology; they differ only in external finishing:

- Veneered . The top layer is wood veneer. During production, several types of wood are used simultaneously. Externally, such MDF panels look natural and imitate natural wood. The cost of these products is the highest among those presented.

- Laminated . The most popular option, covered with melanin film. MDF panels for balconies are usually selected from this type of product. A lot of color options and images have been developed that are applied to the film. The top of the veneer is covered with a laminated film to create the effect of exclusivity and respectability.

- Painted . The outer coating of such slabs is paint. The color can be any, imitation wood is not used.

Preference in the choice is made based on the characteristics of the room where the finishing is done. Panels with lamination protect from moisture, while expensive ones with veneer protect from scratches.

Preliminary preparation of the loggia (balcony)

Before we begin covering a balcony or loggia with panels, let's start by preparing the workplace:

- We take out all the unnecessary items that are not needed for installation.

- We sweep and remove various debris.

- If the balcony is covered without preliminary insulation, then we remove all recesses, cracks, and defects in the walls and ceiling. We use mounting foam or sealant for interior work. Elimination of defects is necessary both to preserve heat in the room and to increase hydro and vapor barrier.

- Leave the treated surface until completely dry.

- We clean out the unevenness of the dried foam.

- We install preliminary steam and waterproofing of the working surface, covering the ceiling and walls with two-millimeter polyethylene film. For installation, you can use a special membrane, connecting the joints with liquid nails or regular construction tape.

- We prepare the supporting frame and the sheathing material itself.

Is it worth using MDF panels for cladding a balcony?

For this area of the house, materials that are highly wear-resistant, can easily withstand low and high temperatures, are stable, and are not heavy in weight are suitable. Finishing a balcony with MDF panels is one of the most popular design options. Consumers like the material for its performance properties, variety of colors, and ease of installation.

The cost, compared to similar types of finishes, is usually lower. There are a number of special advantages:

- externally look presentable;

- resistance to temperature changes in the environment;

- They are easy to care for, moisture resistant, and can withstand cleaning with detergents;

- variety of design options.

The material can be treated with any detergent, it is unpretentious. Warning: Aggressive chemical compounds should be avoided to avoid damaging the laminating film and the entire board behind it.

On the balcony, MDF plates perform a soundproofing function. Installation can be done with your own hands; it does not require special skills or the use of special equipment.

Characteristics of MDF boards

Construction MDF panels are a fairly universal element of modern cladding, attractive both in terms of their external qualities and ease of use.

MDF itself is considered a modification of the well-known fiberboard (fibreboard), but is manufactured using a different method and has an additional quality - increased resistance to moisture. This is facilitated by a special laminating film, which, in fact, is the main difference between the two building materials.

MDF is produced according to certain standards, intended for construction work in the form of finishing premises (walls, ceilings), manufacturing frame furniture. If the material is needed for wall cladding, then it is advisable to use standard panels - this simplifies the finishing itself and increases the speed of installation.

MDF boards have a number of serious advantages:

- The material looks like natural wood, but has flexibility and elasticity unusual for it.

- Suitable for covering complex and not perfectly straight frames.

- Using MDF, you can cover various defects in walls or ceilings; the panels do not require mandatory leveling of the surface before installation.

- The material is relatively easy to install and inexpensive.

- The laminated surface of the MDF panel allows you to apply decoration. It can be a pattern, texture or imitation of any complexity, for example: natural stone, wood. You can see the imitation options in our photo.

MDF panels This universal finishing material has only one serious drawback.

Although MDF has increased resistance to a humid environment, laminating film is clearly not enough. Like any fibrous or wooden material, MDF is afraid of constant dampness, therefore it is not recommended to install such material in such rooms. The interior decoration of a balcony with MDF panels requires maximum insulation from steam and moisture; it is desirable that the balcony be high-quality glazed and insulated. If there is a risk of increased moisture, for example, on the top floor of a multi-story building, then ventilate the balcony space more often.

How to take measurements correctly

Correct calculation of the square meters that will be required to finish the balcony will save you from wasting time on remodeling and re-searching for suitable material.

MDF boards look like boards in appearance. They come in different widths and heights. For balconies and loggias, moisture-resistant varieties are used. The thickness of the product must exceed 6 mm. The plates are fixed using a tongue-and-groove method. The calculation of the amount of material is based on the area of the walls and ceilings where the installation will take place. Another 10-15% is added to the required number of square meters for adjustment.

Plastic corners connect the joints and form corners. They are purchased according to the footage of the balcony in accordance with the length of the joints. The insulation is calculated based on the square footage of the area that needs to be protected, taking into account the presence of beams.

For the sheathing you will need longitudinal wooden beams. Suitable size 20*40 mm. Variety - metal profile. They are measured in linear meters and will be fixed in increments of 40 cm over the entire finishing area.

Preparation of sheathing and insulation

Before constructing the sheathing, you need to pay attention to the walls. There is no need to level them on the balcony, but some preliminary work is necessary. Balconies and loggias are specific rooms with high humidity and temperature changes, so you need to be sure that under the decorative finish there are no places where moisture accumulates and mold spreads.

Preparatory work with walls:

- clean off old finishes;

- seal cracks and loose areas;

- treat with an antifungal compound;

- coat with primer.

The panels can be attached to perfectly flat walls using glue without constructing a sheathing. But when finishing a balcony, it is recommended to install the sheathing at least on the outer wall - insulation can be placed in its cells, thus creating more comfortable conditions for using the loggia as a living space. In addition, finishing materials on an insulated balcony will retain their original aesthetic qualities longer.

What you need for DIY installation

No complex installation equipment is required.

You will need to use:

- screwdriver;

- hammer drill;

- screwdrivers;

- jigsaw or saw;

- for metal - with a grinder;

- building level;

- furniture stapler;

- polyurethane foam;

- self-tapping screws;

- staples, glue, clamps.

Also stock up on a simple pencil, ruler, and tape measure. For safety reasons, wear safety glasses and gloves.

Finishing material options

Wooden lining

It is better to use coniferous wood for cladding balconies. This type of lining is most resistant to changes in temperature and moisture.

Floor and wall cladding with wooden clapboard.

To ensure that the elements do not lose their visual appeal, timely protection against darkening during operation is necessary. You should also avoid damaging the surface.

The use of lining provides an effective finish and comfort in the room.

Finishing the surface of the walls with clapboard, linoleum was chosen as the floor covering.

PVC panels

Cladding with PVC panels is an economical finishing option. The elements can be easily installed on a wooden frame using self-tapping screws. If the walls are fairly even, there is no need to create lathing; in this case, special glue is used for fastening.

Covering with PVC panels.

Mandatory operating conditions: the indoor temperature must be + 5 degrees and above.

In order to preserve the appearance of the panels from fading in the sun, it is necessary to decorate the windows with curtains or blinds.

Drywall sheets

Using drywall, you can create curved shapes due to its good flexibility. The surface is painted, decorated with decorative plaster, wallpaper or artificial stone.

The base is drywall, the top layer is wallpaper.

A combination of decorative plaster and wallpaper with a bamboo texture.

Artificial stone and plaster.

The final finishing layer is wallpaper.

The main disadvantage is poor moisture resistance. It is better to use a moisture-resistant version of drywall (GKLV).

This method does not require large time and financial costs.

Cork

Decorating the loggia with sheets of cork.

The raw material for the manufacture of panels is cork oak. Sheets of pressed cork are produced in a small thickness. The flexibility of the material makes it easy to form and install elements yourself.

Cork material can be installed not only in an insulated room, but also on a cold loggia without double-glazed windows.

The sheets are resistant to sun exposure and do not absorb moisture or odors. The main disadvantage is the cost - from 400 rubles. per sq. m.

Siding

Siding in a completed project.

Vinyl siding is used for interior wall surfaces. The cost of the material is low - from 180 rubles. and more (per sq. m).

Main characteristics:

- Harmless to humans;

- High level of resistance to cold temperatures and fire;

- Light weight.

It is better to purchase white panels. This color is not subject to change over time; sun stains will not be visible on the surface.

MDF panels

There is a large selection of shades and textures of MDF panels on the construction market.

For production, compressed wood is used, which is pre-dried. The material is laminated on top. MDF surfaces can be colored (film) or replicate the texture of wood (veneer).

MDF panels imitating the texture of natural wood.

Pros: affordable price and possibility of self-installation. The downside is poor resistance to moisture and low temperatures.

Block house

The material is made of metal, wood or vinyl. The shape of the elements is a rounded log. The imitation of a log house in the decoration of the loggia looks impressive and rich. The use of a block house is not appropriate in small rooms, since the area will become even smaller due to the thickness of the material (3.6 cm).

Block house in the interior of the premises.

It is better to choose a vinyl block house. This will reduce the load on the floor and walls.

Lining made of plastic

This is the most economical way of cladding a loggia. Cost of 1 sq. m starts from 130 rubles. Feature of the material: practical, has good sound insulation and high thermal conductivity; elements can be installed even if the room is not insulated.

Plastic lining.

The operation of plastic lining is permissible both in cold conditions and at high temperatures.

Stone

Imitation of natural stone in the design of a balcony.

Artificial stone in the balcony space looks reliable and presentable. Manufacturers indicate a service life of 15 years or more. The stone surface can be used in different temperature conditions. The finish is not afraid of moisture and prevents the occurrence and spread of fire.

Disadvantage: the cost varies in the range of 400-2000 rubles (price per package).

Preliminary work

The first thing you should pay attention to is the walls. There is no need to level them, but preparation will be required. External premises have direct contact with the street. The walls should be free of cracks, gaps, and places where moisture can accumulate. Their presence can lead to the formation of mold and subsequent dismantling of the entire structure.

Preparing the walls

Pre-cleaning of the previous finish is carried out. Unstable areas and cracks are covered with a layer of protective material (concrete, plaster). For treatment against parasites, an antifungal composition is used. The top of the walls are covered with primer.

Pros and cons of plastic

Finishing a loggia with PVC panels or the same finishing of a balcony should only be carried out taking into account all the advantages and disadvantages of the material chosen for finishing. Let's take a closer look at the pros and cons of using PVC panels.

If we talk about the advantages, then, first of all, I would like to highlight the following:

Availability in terms of price. If you have average income and you simply don’t want to spend money on luxurious and expensive materials, but at the same time want beauty and quality, then choosing such panels is an excellent choice; When it comes to installing PVC panels, an important factor to consider is that these panels are lightweight and affordable in the designated plan

At the same time, if you do all the work yourself, then in the future such coating can be easily and simply repaired or disassembled yourself; It is important to note the durability of such panels. On average, they will serve you for a period of time, which will vary from other conditions, 25-50 years; Sheathing with PVC panels is an environmentally neutral option

In addition, the panels are resistant to rotting, they simply tolerate various detergents, which means they are easy to clean; Such material will not fade under the influence of solar ultraviolet radiation, but it is still better to take a couple of panels in reserve so that, if something happens, you can easily and quickly replace the damaged one; Despite the fact that PVC has a monolithic appearance, it is equipped with special ventilation gaps, which provide preventive measures to prevent the formation of nasty mold and fungi; Another advantage of the panels is that they have a cellular structure, and this provides additional sound insulation and increases the lifespan of heat on the balcony. In addition, the panels do not attract dust and particles, as they are not static at all;

When choosing panels made of polyvinyl chloride, you will be pleasantly surprised by the variety of colors, shades and different types of patterns.

Now it's worth considering the cons

It is important to understand that ideal materials do not exist, so if you decide to decorate a balcony or loggia with PVC panels, you should also take into account the disadvantages of the material.

Among them:

- The main disadvantage of such cladding is its relative instability to mechanical damage and impacts. If you accidentally touch such a panel with a sharp or hard object, it can easily be damaged. Also, with a slight (point) impact on the panel, it can easily and quickly deform and lose its original shape. This is where extra panels stocked up in advance will come in handy;

- Another important disadvantage is that when burned, polyvinyl chloride releases quite harmful and highly toxic compounds. Although, this same drawback can easily and safely be attributed to any other modern material;

- Of course, if you decide to create an “elite” work of art, then PVC is not your help here.

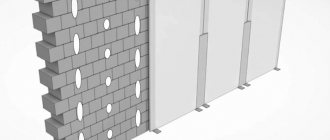

Installation of sheathing

The presence of a holding frame is an optional condition for cladding a balcony. It is possible to install the material with glue directly on the wall. In this case, experts recommend installing the sheathing only on the outer surface that is in contact with the street. It has direct contact with the street and needs insulation.

Grilles allow you to fill the space with insulation, which will maintain a pleasant indoor climate. Another advantage of having insulation is that the cladding will retain its original appearance longer at room temperature on the balcony.

Why wooden sheathing is preferable to metal sheathing:

- easier to install;

- according to its characteristics, it has the same moisture absorption system as cladding panels, the possibility of warping of materials is significantly reduced;

- it weighs less, which is especially important when installing external structures (balconies).

The location of the sheathing bars directly depends on the design of the cladding. They can be positioned horizontally, vertically or diagonally, as the owners of the room decide. According to the rules for installing the structure, the lathing is installed perpendicular to the direction of the MDF panels, in particular:

- horizontally if the panels are vertical;

- vertically if the slabs are horizontal;

- diagonally - not important.

horizontal direction of siding - vertical sheathing

Lathing installation steps:

- Measure equal sections on the wall in increments of 40-60 cm. Make marks using a marker and ruler horizontally and vertically.

- Install hangers according to the marks. They will help smooth out the unevenness of the wall if necessary, and even out the sheathing bars.

- Attach the beams and check that they are installed evenly. If necessary, adjust the tabs.

- Securely fasten the sheathing.

- Treat the timber with an antiseptic.

- Cut pieces of insulation according to the size of the logs and insulate the walls.

After this, you can begin installation.

Disadvantages of material on the balcony

Balcony cladding has several disadvantages that must be taken into account when choosing this material:

- Vulnerability to environmental humidity - the coating only protects the outside. If the material gets wet, it quickly darkens and gradually begins to deform. Therefore, before covering the walls, it is necessary to ensure waterproofing.

- Additionally, vapor and thermal insulation is required, because sudden changes in air temperature lead to the formation of condensation.

- The film on MDF wall panels is subject to mechanical stress, quickly losing its attractive appearance. If the material was used for floor covering, then due to the constant load it will wear out quite quickly.

- It is flammable, just like plywood. To prevent a fire, you need to secure metal sockets under switches and sockets.

- The cost is significantly higher than PVC and other materials.

Installation of MDF panels

Installation of decorative finishing is the main stage of cladding. There are several options for attaching material to the sheathing:

- glue-based, suitable for thin slabs for placement on small balconies; large areas require a different level of reliability;

- on staples or screws, suitable for warm rooms where the material is protected from temperature changes and will not change its physical properties;

- on clamps (special devices that connect the sheathing and the panel), the optimal method for external rooms.

Step-by-step instructions for installing slabs:

- Cut the material according to the height of the walls. Take into account the 3-5 mm that must be left for installing the corners. Create the necessary openings for electrical outlets.

- It is recommended to start installation from a window. The first panel is installed from top to bottom.

- The next one is mounted in the grooves of the previous one. On the reverse side it clings to the sheathing with clamps.

- At the corners, in order for the material to fit evenly, you will need to trim them. To maintain uniform placement, the corners on which the eye falls when entering the balcony are connected first and as smoothly as possible, invisible to the eye.

If there is a window sill or projections, the panels are cut according to their size.

How to cover a balcony yourself

How to cover a balcony without spending a lot of time on all the necessary work? Using MDF wall panels, you can complete your balcony renovation yourself in about 4 days.

First you need to prepare the area for work, mark it into sectors and calculate how much material will be needed. All irregularities should be filled with putty, leveling the surface of the walls as much as possible.

For the interior decoration of the balcony, you will need several sheets of this material of different sizes, and to line the loggias with MDF panels, you will need another 1-2 sheets.

Decorating walls with MDF panels begins with the need to build a frame. The base of the frame can be made of a metal profile and wooden planks. The resulting structure must be secured to the wall with self-tapping screws or nails. Wall cladding with MDF panels begins from the bottom up, installing them from the corner to the end of the row. A small gap of 2-3 mm should be maintained between the sheets. The remaining seams can be sealed with sealant.

Next comes the finishing of the loggia with MDF panels. It is necessary to follow the same procedure for assembling and installing the frame as inside the balcony. You can purchase a whole sheet that will cover the entire loggia. But such a slab may be too heavy to install, so it’s easier to purchase several smaller sheets.

After the sheets have been secured, we can consider that finishing the loggia with MDF panels is complete. All work can be done with your own hands, without outside help and using ordinary construction tools.

Frame for fastening MDF panels

Slopes

The horizontal slopes are added first, followed by the vertical ones:

- Measure the required length under the windows, above them, near the door.

- Cut the panel pieces according to the measurements.

- Installation is carried out on foam.

- Press them against the wall and leave to dry.

- After fixing the polyurethane foam, eliminate excess material;

- Secure with self-tapping screws. Leave some space for the final corners.

Step-by-step instructions for covering a loggia

In order to cover a balcony with plastic panels with your own hands, you need to follow simple instructions. The master does not require any special training for the job.

Preparing work surfaces

In order for the cladding to be of high quality and durable, you first need to take care of the base:

- First, we carefully inspect the walls for cracks and imperfections - we need to get rid of them favorably.

- Then you need to slightly enlarge the crack. To widen the gaps, you can use a grinder.

- Then the crack must be thoroughly cleaned of dust and debris.

- The resulting depression must be sealed with waterproof putty.

- The entire surface must be primed with a protective composition (sealing and antiseptic properties). There are a huge number of them on the construction market, but if you need an economical option, then you should use PVA putty. It has a low cost and acceptable quality.

Surface primer

Fastening the sheathing

The lathing is a special frame that is attached to the wall and on which plastic panels will subsequently be fixed. It comes in two types - wooden and metal. The latter is well suited for damp rooms, because... the profile will not absorb moisture and become damp, but the cost will be significantly higher than wood and installation will require certain professional skills.

High-quality installation of the grille, in the future, will make it possible to make partial repairs, replacing only one or several damaged plates. When completely replacing plastic with some other material, there is no need to change the sheathing - the old one perfectly withstands the same thickness of the material.

- Before installing the sheathing on the walls, you need to make markings. This will greatly simplify the installation of the guides. When drawing lines, you should use a level. Such actions will be useful later in checking the quality of installation.

- Before fastening, wooden blocks must be treated with a protective compound. To do this, you can take PVA putty or motor oil. This impregnation will protect the wood from rotting, mold and fungi.

- Now you need to fill the slats every 40-50 cm. The first one needs to be attached 5 cm from the ceiling, checking the clarity of the direction with a building level. All subsequent bars must go in strict parallel to the previous one.

- The planks are fastened using dowels or self-tapping screws with plastic tips. There is no need to rush to tighten the rail to the wall. A situation may arise when the level shows a skew and then you will have to add small plates to restore a perfectly flat surface. The dowel should extend into the wall by 3-4 cm (excluding plaster).

Lathing for plastic panels

Insulation of the loggia

How to cover a balcony so that it becomes not only beautiful, but also warm? This worries many who want to cover the balcony themselves. To do this you need:

- Choose insulation. The simplest is inexpensive foam. It is acceptable in density and is not afraid of moisture, which makes it the most popular option. Extruded polystyrene foam will significantly exceed polystyrene foam in its characteristics, but the price of such insulation will be much more expensive. Mineral wool is an excellent option, but there is one drawback - it requires additional waterproofing. Without it, when moisture gets on the material, the insulation immediately loses its properties.

- Place insulation evenly. The polystyrene foam should be placed tightly between the wooden sheathing, and the gaps should be filled with foam.

Finish line

The last stage helps to hide the imperfections of the cladding. The design of corners and joints gives the work a finished look:

- Start with the floor, attach the baseboard.

- Cut the corners for the joints according to their length. To ensure that the junctions of horizontal and vertical corners are even and aesthetically pleasing, they should be cut at an angle of 45 degrees. Then they will come together without layering.

- To fix the joints: coat the inside with glue, bend it at an angle inward, and press it firmly against the wall. Then spread the side wings and press tightly too.

- Treat small discrepancies between the window frame and panels with silicone sealant. Remove excess.

Installation is easy to do with your own hands, without involving workers and spending extra money. If necessary, dismantling is also easy.

Types of frame and its installation

The sheathing panels inside the loggia are mounted on a sheathing or a special frame made of a metal profile.

The choice of foundation matters. Wooden sheathing is used when the walls are relatively flat and the thickness of the insulation does not exceed 3 centimeters. The metal frame can be attached to the wall or have an independent system. Making it yourself is more difficult, but this design will last longer unchanged. To make a wooden base you will need:

- wooden beams or slats;

- roulette;

- level and angle;

- markers;

- saw;

- screwdriver;

- wood screw;

- liquid Nails.

If a layer of insulation is not needed and the walls are smooth, then the sheathing is fixed to the wall, and the panels can be mounted with liquid nails. The width of the base cells is determined based on the mass of the MDF sheets and their length. Before starting work, you need to take measurements and draw a plan that indicates how many frame parts of each size are needed.

The metal frame is made using:

- guides and slats made of metal;

- measuring instruments (plumb line, angle, tape measure);

- screwdriver;

- perforator;

- scissors for cutting metal.

The first stage of work is applying markings for fastening, oriented along the line of doors and window openings. According to the markings, the guides are attached with dowel screws. For screws, first drill a hole 3.5-4 centimeters deep.

To install MDF panels you need to make a supporting frame

Calculation of material quantity

To determine the amount of material, you need to make accurate measurements of the room. The size of MDF panels is 2600x238 mm. Based on this, it is necessary to calculate how many solid slabs will go on each of the walls. Next, you need to calculate the linear meters of the corners in order to cover them with corners.

Insulation is purchased based on the area of the walls being sheathed. A 20x40 mm beam will be needed to install the sheathing. Based on the width of the selected insulation, you need to determine the pitch of the sheathing and calculate the amount of timber required. As a rule, the sheathing pitch is 40-50 cm.

Ceiling installation: dryer installation

To lay the ceiling sheathing you will need a 20x40 mm cross-section batten installed at intervals of 40 cm.

However, if you plan to mount a dryer to the ceiling, the structure must be more rigid since the loads on such devices are quite large. It is considered optimal to use a beam with a cross-section of 40x60, fixed on a concrete base with anchors, at least every 80 cm (the smaller side is in contact with the rough ceiling).

Installation includes the following steps:

To ensure the ceiling is level, do not forget to align the bars with each other!

If there are significant unevenness of the concrete surface, they must be compensated with spacers (plastic, thin dry lath, MDF, fiberboard) of appropriate thickness.

If you are planning a small and lightweight dryer made of reinforced plastic, you can make bookmarks from the same bars.

We apply the dryer to the ceiling using markings

We fasten the block with three dowel nails

We measure the distance to the next bookmark

The process will become much more complicated if the floor is the last and there is no floor slab on top. In such situations, a so-called semi-loft or canopy is built, which usually requires a team of qualified builders. A rectangular structure is assembled from hardwood timber (oak, ash, birch, beech) or a thick-walled metal profile. The small leg of this design is rigidly fixed on the main wall of the building, the large leg will be the base of the ceiling, and the hypotenuse will be the slope (roof) of the canopy.

For plastic panels and drywall, a metal profile is perfect: