Metal tiles are roofing materials that are factory-molded sheets of galvanized steel with a relief surface. A polymer coating is applied to the surface. This material is suitable for covering the roofs of public buildings, private houses, and outbuildings. Metal tiles are considered one of the best coatings because they have an attractive appearance, increased strength, and comply with environmental standards.

What are the advantages of metal tiles

This material has a number of advantages:

- Metal tiles are light in weight . There are from five to seven kilograms per square meter. It is used to cover the roof, which has a complex structure. Thanks to its lightness, there is no need to reinforce the rafters. This roof does not load the walls and foundation.

- Due to the ease of installation of roofing material and the absence of the need for special tools, the cost of installation work is relatively low.

- This roofing material has a wide palette of colors , so you can choose any of them to suit the overall tone of the building.

- The tiles are made from thin sheets of steel, the thickness of which is from 0.4 to 0.7 millimeters. Thanks to its profile, it is able to withstand heavy loads .

- The sheet of roofing material is protected by galvanization and a polymer protective layer applied to the surface.

The main advantages of the material are durability, low cost and aesthetic appearance.

Advantages and disadvantages of metal tiles

Affordable price and improved performance characteristics allow metal tiles to occupy a leading position in the roofing materials sales market.

The positive aspects of its use are:

- light weight - about 5 kg/m2 , as a result there is no need to build a complex rafter system;

- does not require special installation skills;

- wear resistance;

- long service life;

- elegant and festive look, suitable for any design development.

Among the shortcomings, users and experts most often note:

- increased noise during rain or hail;

- the need to use snow retainers due to avalanche-like snowfall;

- a large number of fastening elements that are directly exposed to precipitation;

- A grounding device is required to protect against the build-up of static electricity.

NOTE!

It is necessary to note that there is a type of metal tile with an additional protective layer as a topping made of natural stone chips . Unlike classic spraying, this composite coating gives a solid appearance and protects the house well from noise penetration.

This type is recommended when protecting an attic roof, where high-quality sound insulation is required.

Roofing sheet composition

The quality indicators of metal tile roofs largely depend on:

- the required minimum thickness of the steel sheet is at least 0.4 mm . With a small slope, a coating with a thickness of less than 0.4 mm may not withstand the snow load. Increasing the slope, to reduce this impact factor, increases the possibility of increased wind load, which also negatively affects metal thinner than the specified value;

- emerging corrosion from possible damage during transportation or unprofessional work using a grinder when cutting sheets. It is important in cases where it is impossible to do without using a grinder to treat the cutting area with a protective compound ;

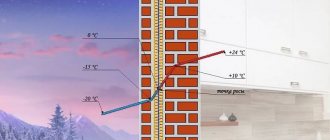

- mandatory presence of an anti-condensation screen made of waterproofing film. You need to know that a superdiffusion protective membrane cannot be used as such an anti-condensation material, since its use implies more frequent and prolonged exposure to moisture on the inner surface of the sheet.

What is slope

The roof slope is the angle formed between the roofing material and the ceiling.

Roof slope and roofing material Source stroim-dom.net

In documents it is indicated as a percentage or degrees. It is calculated by mathematically dividing the distance from the highest point at the intersection of the rafters, which is called the ridge, by one-half of the entire width of the building. The slope of the roof depends on:

- what material will the building be covered with;

- design frame and its main parts;

- how much the roof can withstand weather conditions;

- cost of work of master roofers;

- the weight of all layers used.

On a note! If the slope of a metal roof is changed from 22 to 45 degrees, the slope will increase by 20%. And this will significantly affect the cost of roofing materials, as well as the weight of the entire structure. In this case, the slope must be determined during the design of the entire building in order to have an idea of the load on the foundation.

Video instruction

The durability and quality of the roof directly depends on the correct selection of covering material. Not least important selection criteria are appearance and compliance with environmental standards. Among experts, the opinion has long been strengthened that metal roofs fully meet these requirements.

Of the three types of metal roofing material, the one that stands out is a profiled sheet covering that imitates natural tiles – metal tiles.

Its base is rolled steel, coated with an aluminum-zinc composition to resist harmful environmental influences. For increased stability, the finishing layer on the metal is additionally coated with a polymer coating . In this article you will learn how to calculate the roof angle for metal tiles and what factors affect the roof covering.

What does the slope of the roof depend on?

For those people who do not understand construction at all, it is very difficult to determine exactly what the minimum roof slope should be. Here you need to take into account natural factors that constantly affect the roof. These include:

- A layer of snow that will fall in winter. If the slope is greater, the snow will slide off on its own.

If the slope is small, the roof will need to be cleaned Source ko.decorexpro.com

See also: Catalog of companies that specialize in roof repair and design.

- Wind resistance ability . In regions where winds constantly blow, you need to keep the slope minimal so that gusts of wind glide over the roof and do not create a sail effect.

Since this material for covering a building is very light, sparse lathing is allowed, but when installing rafters, you must strictly adhere to the distance and angle at which they will be installed.

What factors affect the roof?

The main factors that negatively affect the condition and durability of metal tiles are divided into three types:

Short-term

- the weight of people and building materials during the installation and maintenance of the roof;

- standard snow loads;

- temperature climatic influences;

- wind loads.

Long-term

- snow loads below the established norm;

- impact due to deformation of the supporting base.

Special

- seismic impacts;

Correct calculation of all components when constructing a rafter system is guaranteed to ensure the resistance of the metal tile covering to the maximum permissible overloads.

Sheets of profiled metal have sufficient rigidity, so continuous sheathing is not required during installation. But when installing a rafter system, it is necessary to correctly calculate the pitch and angle of inclination of the rafter leg.

How many degrees should the minimum angle have?

The minimum slope of a metal tile roof is 10 degrees. A slope is allowed that ranges from 10 to 90 degrees. When choosing the optimal slope angle, you need to take into account that at a small degree the space between the roof and the ceiling cannot be used for any economic purposes.

If the highest roof angle is set for metal tiles, then going onto the roof to carry out technical work will be very difficult. Moreover, the larger the angle, the higher the ridge is located and, accordingly, the area that needs to be covered increases.

Thus, more roofing materials will be needed, and this will affect the budget. In addition, payments for roofing work will also increase Source bankfs.ru

When correctly calculating the roof slope angle for metal tiles, the calculator must take into account the following aspects:

- Roof tile model . It should be noted that most manufacturers indicate the minimum slope of a metal tile roof in the product description.

- What type of roof is planned: single-pitch or gable.

- How will snow be removed from the roof?

Having carried out all the calculations and taking into account the above points, provided that the length of the slope surface is 6 m.p., the minimum slope is set at 22 degrees. Naturally, this result is not indicated in the technical documentation. It is calculated by experienced craftsmen in the process of observing roofs already in use.

What influences the choice of slope angle

Weather conditions constitute a dynamic load. The magnitude and variability of this load depends on the combined relationship of these parameters.

- To keep water and snow on the roof as little as possible, the slope of the slope should be maximum - 35–45 degrees. Otherwise, even the most reliable waterproofing will soon cease to protect against leaks.

- At the same time, in case of strong winds, it is recommended to choose the angle of inclination as small as possible - 15–20 degrees. With this slope, the windage is minimal, which means the wind load on the roofing material is lower.

- The optimal angle is chosen taking into account the relationship between these factors: average and maximum precipitation and wind values for at least 10 years.

- The nature of the room under the roof influences. Non-residential attic space, especially not insulated, is not of particular importance. In this case, the angle is selected based on the weather conditions of the region and the roofing material. But if it is planned to equip an attic, the requirements for thermal and waterproofing of the attic floor come to the fore, and compliance with climatic conditions is taken into account secondarily.

The cost-effectiveness of the project is also important. It is easier to remove snow from a steep slope. However, additional equipment will be needed to maintain such a roof. On the other hand, with a very small slope, it is necessary to install more reliable waterproofing, which also increases the cost.

The aesthetic factor also matters. In some styles, steep slopes are an essential part of the design.

Carrying out calculations

To determine more accurately what the minimum slope of a gable roof made of metal tiles should be, you need to know two numbers:

- height from the top of the parapet to the ridge;

- width of the building.

To make the calculation, the distance from the parapet to the ridge is divided by the value of half the wall and the result is the desired angle.

For a pitched roof, the angle is determined by dividing the first value by the full second value Source builld.ru

To determine the result as a percentage, the resulting number must be multiplied by 100.

Important! In order for the result to be accurate, you need to measure the distance to the ridge not from the surface of the ceiling, since this is a gross mistake, but from the top of the parapet.

Naturally, there are exceptions in construction when the slope is only 10 degrees. But this is done in the case of special construction recommendations. It should be taken into account that with such a slope an increased load is created on the surface when snow falls. This way the sheathing is made continuous. In addition, a waterproofing carpet must be laid on it. Also, special gaskets are placed under the butt sides of the roofing sheets.

Step 3. Determine the slope requirements

In functional terms, pitched roofs are divided into three main types: ventilated, non-ventilated and combined. Let's consider each option in more detail.

Ventilated design

These are installed in closed buildings. Ventilation is provided by vents and special voids between the insulating layers, through which air passes, capturing droplets of moisture from the insulation and carrying them outside.

If such ventilation is not provided, then moisture will remain inside the insulation (and it still gets into it, albeit little by little), and the insulation will begin to become damp and deteriorate. And as a result, the entire roofing pie will gradually collapse.

Non-ventilated design

This type of pitched roof is mainly found on terraces and outbuildings. Typically, the angle of such a roof is in the range of only 3-6°, although there are no restrictions on it.

Ventilation in such roofs is not needed because the air in a room without walls or with wide doors often open (as in the case of a garage) itself ventilates well, carrying any water vapor outside. Which, by the way, are almost never formed in such buildings:

Hip roof area

The most popular roofing option today is the hipped roof, which involves the presence of 4 slopes located at an angle to the base. To calculate the area of a hipped roof we need

:

- calculate this value for each slope;

- add the resulting values together.

It is very important to check the results of your calculations several times, otherwise you may end up with a surplus or shortage of building material

In most cases, all construction and design companies have as initial data the projection of the roof, that is, the area of the base under it. Before starting the calculation work, we will divide the projection zone into simple component figures: trapezoids, triangles, rectangles and squares. The formula for calculating the area of each of these figures is well known to every schoolchild, so it will take a little time to get the result using a calculator

Taking into account that each element of the projection is at an angle, its area should be multiplied by the accepted cosine of the angle of inclination of the slopes. After adding up all the results obtained, we get the area of the hipped roof

As can be seen from the description, calculating this value will not cause any particular difficulties for people with an average level of knowledge of a school geometry course. For this reason, many builders assign the functions of performing such important tasks to their production workers: foremen, technical supervision workers and other engineering and technical workers.

One of the important conditions is to make calculations based on the eaves overhang, and not the edge of the building, otherwise the result will be incorrect.

The area of a hipped roof is calculated in compliance with the following rules

:

- it is necessary to take into account the area of the following elements: ventilation ducts, chimneys, the attic and its windows;

- the length of the slope is measured from the bottom of the ridge to the top of the cornice;

- for parapets, overhangs and firewalls, add 5% of the length;

- in order to calculate the required consumption of building material, you need to know the type of roofing, since each of them has its own consumption rates;

- when covered with bituminous shingles or rolled materials, the length of the slopes will decrease by at least seventy centimeters.

You should know that roll materials are the most economical option for covering roofs with complex shapes. They fit perfectly on almost any surface, their installation is not difficult and takes place in the shortest possible time.

Features of roofing material

The fact that metal tiles are so popular among the population in private construction can be explained by its positive aspects:

- Light weight. Possibility of constructing complex geometric shapes. There is no need to further strengthen the rafter system. There is no high load on the walls and foundation of the house.

- The installation technology is no different in complexity. Available even without special skills. No specialized equipment required.

- Large selection of colors. Can be matched to any home exterior.

- The slope of the roof can withstand heavy loads due to the profiled waves.

- Metal sheets are protected against corrosion by an external polymer coating.

Modern roofing coverings must have high functional and decorative characteristics, as they must provide a high level of protection and look attractive.

Metal tiles have gained popularity due to their long service life, performance properties and low price. However, it has its own characteristics and limitations on use.

During design, it is necessary to clearly understand what minimum roof angle is acceptable. The following will depend on it:

- Possibility of coating with one or another material;

- Design of the entire rafter system;

- Level of snow and wind load;

- Sediment removal efficiency.

Metal roofing can have a very slight slope. This is ensured by the rigidity of the sheets. Another advantage will be the possibility of unhindered removal of sediment due to minimal surface roughness.

Step 6. Deciding on the rafter system

And based on the selected angle of inclination of the roof and the loads planned for it, we determine the type of fastening of the rafters to the walls. So, there are three types in total: hanging rafters, layered and sliding.

Hanging rafters

Hanging rafters are the only option when the connection must be rigid, but there is no way to support the rafters between the side supports.

Simply put, you only have external load-bearing walls, and no partitions inside. Let's say this is a rather complex rafter system, and its construction must be approached responsibly. The whole problem is the large spans and the pressure that is exerted on the walls:

Or like in this project:

Layered rafters

Here the entire roof presses on at least three supports: two external walls and one internal. And the rafters themselves are dense, with a cross-section of at least 5x5 cm bars and 5x15 cm rafter legs.

Sliding rafters

In this rafter system, a log in the ridge serves as one of the supports. And to connect the rafters to it, special elements such as “slippers” are used. These are metal elements that help the rafters move forward a little when the walls shrink to avoid cracks. Very little! And thanks to this device, the roof easily tolerates even quite noticeable shrinkage of the log house, without any damage.

The point is simple: the more nodes there are in the rafter system, the more flexible and durable it is. The more a pitched roof can withstand the pressure of the weight of the roofing and snow without breaking. But there are rafter systems where the connection is generally static:

Calculate the height of a roof with one slope

To determine the height of the roof being built, you can use one of three well-known methods:

- geometric;

- trigonometric;

- online calculator.

The easiest way to calculate the slope of a pitched roof is to use online calculators. As a rule, they are configured to comply with SNiPs - “Load and Impact” TKP 45-5.05. However, it is worth considering that this method is best used only as an auxiliary one.

So we figured out how to determine the minimum slope of a pitched roof. We hope that you make the correct calculations and your roof will last longer than planned!

Step 5. Limiting the choice of roofing covering

Modern roofing materials also have their own requirements for the minimum and maximum angle of inclination of a pitched roof:

- Profiled sheeting: min 8° - max 20°.

- Seam roofing: min 18° - max 30°.

- Slate: min 20°- max 50°.

- Soft roof: min 5° - max 20°.

- Metal tiles: min 30° – max 35°.

Of course, the smaller the angle, the cheaper materials you can use: roofing felt, corrugated sheets and the like.

You will be surprised, but today, especially for low-slope roofs, the same types of roofing coverings are being developed that are usually used with a slope of at least 30°. For what? This is the fashion in Germany, which has reached us: the pitched roof is almost flat, and the roof is stylish. But how? It’s just that manufacturers are improving the quality of locks, making the overlap area larger and thinking more carefully about protection from dirt. That's all the tricks.

Roofing components

But before you begin mathematical calculations, you need to understand which components of the design can affect the final result.

Its elements include:

- lathing (serves as the basis);

- layer of heat, hydro and vapor barrier;

- rafter system;

- roofing material.

In addition, you should consider:

- climatic features of the region;

- purpose of the building;

- possible loads;

- the strength of the flooring material used.

If, when calculating the optimal angle of inclination of a pitched roof, all of the above factors are taken into account, the owners will be able to extend the life of the building, reduce the consumption of materials, thereby saving money.

Therefore, in regions with high wind and snow loads, it is recommended to create a roof structure with a minimum slope in order to ensure the building’s resistance to the external environment.

What should you remember when creating a rafter system?

Correct installation and assembly of each part of the roof is a guarantee of the reliability of the device for many years.

When constructing a rafter system, it is worth considering several important nuances:

- It is recommended to use coniferous wood (pine, spruce) as raw material.

- The logs should be pre-treated with special moisture-resistant and antiseptic solutions.

- The initial stage of rafter installation is laying timber along the entire length of the load-bearing wall (mauerlat), which is secured with anchor bolts.

- In the places where the rafters will be laid, you must remember to make nests, having previously calculated their size.

- The rafters are attached to the mauerlat and timber using slate nails.

- If the width of the building is more than 4 m, it is recommended to support the rafters to avoid distortion.

Important! In order to determine the correct size of the nests, it is worth taking into account the cross-section of the rafters. This will help avoid unnecessary gaps between parts of the structure.

Laying sheathing, hydro and vapor barriers

The next step in creating a pitched roof is to make the sheathing. The distance between the boards should not be more than 0.15 meters. Their installation is carried out strictly perpendicular to the rafter system.

Next, you need to attach the vapor barrier film with a construction stapler, and then apply insulation on top.

The next layer will be a layer of waterproofing material. It is advisable to make each strip from the roll with an overlap to the other, and treat the joints with sealant.

The final stages are calculating the angle of inclination and laying the roof.

It is important to note that the number of rows of sheathing depends on the size of the building and the selected material

Installation of metal roofing

This material is installed on the roof frame with the obligatory observance of the following recommendations:

- Sheets are cut using electric scissors, but in no case with a grinder.

- You should walk on already installed sheets in soft shoes, stepping between the waves.

- The sheets are mounted using special self-tapping screws with rubber gaskets. These fasteners do not tighten too tightly.

- Screws are screwed in when attaching sheets to the sheathing exclusively under the wave.

When covering rafters longer than 6 m, metal tiles are installed in rows along the height. The width of the horizontal overlap is determined depending on the angle of inclination of the slope. The higher the roof, the more water is retained on it during rain and the more airtight the joints must be. Therefore, if the angle of inclination of the roof rafters is 12-14º, the metal tiles are laid with an overlap of at least two waves. If this indicator is 14-35º, it is allowed to carry out installation with overlapping sheets of the upper row on one wave of the lower one.

What materials and tools will you need?

Since the metal tile material is cold and also noisy during rain, the roof sheathed with it is usually insulated. At the same time, mineral wool, rather than polystyrene foam, is often used as an insulator. The fact is that fibrous materials, among other things, are very good noise absorbers. In addition to mineral wool, for covering the roof with metal tiles you will need:

- vapor barrier membrane;

- waterproofing film;

- roofing screws and galvanized nails;

- thin steel wire;

- bars with a thickness of at least 3 cm for counter-lattice;

- boards for sheathing.

If the roof is not included, you will also need to purchase all the necessary additional materials: eaves strips, valleys, apron for the pipe, ridge strip, etc.

Tools you will need:

- drill, screwdriver;

- electric scissors for cutting metal tiles;

- long rule and roulette;

- construction stapler;

- hammer;

- folding ladder.

Assembling an insulating pie

Installation of the roofing pie when used as metal tile sheathing is carried out in the following order:

- On the attic side, a vapor barrier material is attached to the rafters. You can fix it using a construction stapler.

- A heat insulator is installed. It should be installed between the rafters. In order to provide a support for the mineral wool, boards are placed on top of the vapor barrier film from the attic side or steel wire is fastened in a zigzag manner.

- A waterproofing material is installed on top of the insulation. It must be secured in a horizontal direction with a sag of approximately 2 cm. Otherwise, when the roof frame moves, the film may tear. Fix the membrane to the rafters with bars.

- The chimney is waterproofed. The film is placed on it and glued with mastic.

- Install the sheathing. It should be nailed onto the bars using galvanized nails. In the areas where the valleys are located and near the chimney, the sheathing must be made continuous.

What criteria are used to choose the slope of the roof ↑

A slight steepness has its certain advantages. For example,

- efficiency, as material consumption is reduced,

- not only the weight of the structure is reduced, but also its windage - which means that the risk of damage as a result of heavy winds is minimal,

- simple arrangement of drainage.

However, at the same time:

- the need for airtight coating increases sharply. Such a slope is not able to protect the house from penetration: through the joints of individual sheets of metal tiles and the fastening points, rainwater can quite easily seep inside - after all, it falls at a larger angle.

- requirements for clearing snow from the roof surface are increasing. If the wind can, say, blow it away from steep slopes, then on gentle slopes it will most likely linger. And if the structure is not strong enough, then with a large amount of snow it may even collapse.

- The sheathing turns out to be heavier, and the fastening of the roof elements becomes more complicated.

- it is impossible to create large attics, attics, etc.

Metal tiles are not very suitable for pointed roofs. An angle of 45° is perfect for spontaneous melting of snow cover. However, there is another nuance here - the considerable weight of the coating itself, which is why it, in turn, can slide off the slope. The only way out in this case will be additional fastening of each covering element to the sheathing.

It should also be noted that with an increase in the steepness of the slope, as well as with the complication of the geometric shape of the entire roof, the need for additional material consumption arises.

Thus, it turns out that you need to look for a solution somewhere in the middle between a very steep and very flat roof.

Tests carried out at manufacturing plants, as well as long-term practice of using metal tiles in construction, have shown that the optimal slope of a roof made of this material is 22 degrees. In this case, water drains perfectly from it, and snow practically does not linger.

The choice of slope slope is also influenced by the shape of the roof:

- for single slopes, 20–30° is recommended;

- for gable slopes, respectively, 20–45°.

Sometimes, when listing the factors that influence the choice of slope slope, they forget, in addition to wind, snow load and the effect of increased moisture, they forget about the dependence on the presence of thermal insulation and heating pipes. Quite often you can notice that nearby houses with the same coating and approximately the same steepness of the slope “carry” different amounts of snow. This is directly related to whether the roof of the house warms up or not:

- if not, then there will be more snow;

- if so, then the amount of snow decreases, but it is enough to strengthen the thermal insulation, and the layer of snow will naturally begin to grow.

It is important to calculate the roof slope before thermal insulation, so that in the future there will be no problems with snow accumulation.

Positive and negative sides

When deciding, you need to take into account other factors that may have an impact. They can be positive and negative.

First, let's look at the positive criteria that influence construction.

- Possibility of arrangement of living quarters (attics) of large areas;

- For structures with large values, the possibility of water penetrating into joints and connecting elements is excluded. This helps to increase service life;

- In areas with significant snow precipitation on roofs over 45°, they may not be taken into account. You can save on installing snow guards.

- By correctly designing the ramp, you can do without the use of special fasteners.

Let's consider the negative points:

- Increasing the slope leads to increased material consumption;

- The weight of the roof also increases with increasing level of the slope. This is a direct increase in the load on the rafter system. Strengthening will be required;

- At sharp angles and significant heights, the windage increases. Strengthening is also needed.

- The drainage process becomes more complicated. A drainage system with greater capacity will be required. Sometimes this is problematic.

The process of calculating the optimal slope consists of finding compromise solutions that will take into account all the features of the construction of the structure and appearance.