Finishing work involves the correct choice of material in terms of the safety and reliability of the resulting coating. Situations arise when, instead of conventional gypsum boards, it is necessary to use fire-resistant plasterboard. These products are ideal for areas subject to constant heat, as well as for areas that require special protection due to their susceptibility to fire.

Fire-resistant drywall - what is it, pros, cons, scope of application

Fire-resistant plasterboard is a sheet of laminated material - gypsum board, covered in a cardboard shell. In addition to gypsum, the inner part includes clay, water and fiberglass, and the outer part contains a special impregnation of fire retardants. On the outside, the material has a characteristic red color.

Unlike standard gypsum plasterboard, fire-resistant plasterboard burns quite slowly or does not support combustion at all, depending on the conditions of fire spread. The period of direct flame retention ranges from 20 to 60 minutes and is determined by the following factors:

- The most compacted connection between cardboard and gypsum filler.

- Anti-flammable impregnation.

- Reinforcing structure made of fiberglass threads up to 30 mm long, preventing destruction under the influence of heat.

- Contains fireclay clay. Under the influence of high temperature, it sinteres and, strengthening the slab, prevents it from crumbling.

- Presence of crystal hydrates in the composition. When heated, they release water. As a result, the material becomes damp and extinguishes itself.

Structure of fire-resistant drywall Source pozharanet.com

All this makes it possible, if not to contain the spread of fire, then at least to slow down its spread until professional fire-fighting assistance arrives.

Advantages and disadvantages

The main advantages of fireproof gypsum plasterboard:

- Environmental friendliness, cleanliness, safety. Can be used in any room.

- High resistance to fire spread - up to 60 minutes.

- Increased moisture resistance - can be installed in rooms with a high degree of air humidity.

- Good noise and heat insulation due to the clay component included in the composition.

- Service life is at least 5 years.

- Convenient processing and installation.

- Versatility in finishing - suitable for plastering, painting, whitewashing, wallpapering and tiling.

- Preservation of the room microclimate.

- Reasonable price.

However, despite its good fire resistance, heat-resistant drywall creates a number of difficulties in installation and use - it is necessary to use special tools for cutting, high density and weight, the need for strengthening under loads, in addition, GKLO is not as water-resistant as GKLV or GKLVO.

Covering a room made of aerated concrete blocks with fire-resistant plasterboard Source pozharanet.com

Scope of application

Heat-resistant gypsum board has a wide range of applications:

- Finishing of main walls and load-bearing structures.

- Covering wooden surfaces to prevent fire.

- Manufacturing of fireproof boxes for laying communications.

- Construction of interior partitions.

- Creation of suspended ceilings.

- Insulation of chimneys.

- Finishing of stoves and fireplaces.

Note! GKLO can be equally effectively used to create interior partitions to prevent the spread of fire in the event of a fire. It can be used equally effectively for finishing fire-hazardous premises - boiler rooms, boiler rooms, walls in a bathhouse opposite the firebox - to prevent heating of building structures from hot elements.

See also: https://m-strana.ru/services/otdelochnye-materialy/

Fire resistance limit

The duration of the fire resistance limit determines the time during which the material will not be subject to destruction under the influence of open fire. The manufacturer indicates this limit with a number, which will indicate the time of resistance to open fire.

For heat-resistant drywall, this mark is designated as number 25. From the start of combustion of the material to the process of its destruction, 25 minutes can pass.

Even ordinary sheets of plasterboard can contain open fire for several minutes thanks to the gypsum layer, which is not subject to combustion.

In order for the material to be fire-resistant, double partitions are made in it, and cardboard is placed in the middle.

Varieties

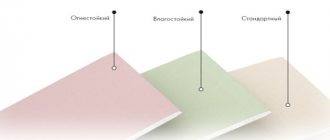

Modern manufacturers produce 4 main types of construction plasterboard:

- Standard. Gray in color, characterized as dry plaster for interior decoration with normal humidity.

- Moisture resistant. Green in color, it is resistant to dampness, fungi and mold.

Types of construction drywall Source stroy-podskazka.ru

- Fire resistant. Red in color, prevents fire.

- Moisture and fire resistant. Green in color, characterized by resistance to fire and humidity at the same time.

If ordinary gypsum board has a density of 800 kg/m³, then its fire-resistant analogue, due to the compacted fire-resistant gypsum included in the composition, is about 850 kg/m³. At the same time, increased strength and fire resistance is achieved by the presence of several impregnated layers.

Recommendation! One of the main disadvantages of drywall is its lack of strength with respect to external fasteners. Therefore, to mount heavy objects on the wall, it is necessary to use brackets with an increased contact area to maximize the distribution of the weight of the object being mounted over the surface.

Installation features

The room was made with your own hands.

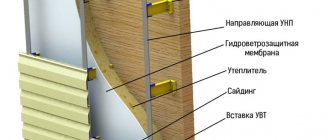

- During installation work with gypsum boards, only a metal profile for the frame should be used. No wood . When protecting wooden walls, foil mineral wool insulation is laid between the sheets and the walls. Expanded polystyrene or polystyrene foam should absolutely not be used.

Only a metal frame is used.

- External corner joints are reinforced with metal perforated corners. The remaining joints should be carefully taped with fiberglass tape (“serpyanka”) and treated with Fugen type putty.

For corners we use only a metal corner.

- Finishing sheets with putty and other types of finishing are no different from working with ordinary drywall. Due to the greater density and the presence of reinforcing fibers, cutting sheets and screwing in self-tapping screws is somewhat more difficult.

Otherwise, the finishing instructions do not differ from the generally accepted ones.

In general, installation is not much different from conventional construction work using gypsum boards. Here you should be more attentive to the joints; cut rectangular ends should be made with a chamfer of a third of the thickness. For the frame, joints and corners, use only non-combustible, fire-resistant materials.

Characteristics

A standard fire-resistant plasterboard sheet has the following set of technical characteristics:

- Dimensions – 250x120x1.25cm.

- Weight – 30kg.

- The category of combustion ability is G1 (corresponds to fireproof).

- Flammability class – B1 (meets fire resistance).

- Toxicity degree – T1 (non-toxic).

- Density – 850 kg/m³.

Finishing a fireplace using gypsum plasterboard Source gipsokarton-blog.ru

- The ability to conduct heat is 0.22 W/m².

- Smoke generation – D1 (does not produce smoke when exposed to fire).

Important! When choosing gypsum plasterboard for home finishing, among the main technical characteristics that you should pay attention to are fire-fighting properties (maximum temperature), as well as how fire-resistant and harmless the plasterboard is in terms of toxicity. This information is contained in the quality and fire safety certificate.

Is drywall flammable or non-flammable?

All building materials are divided into two main groups: non-combustible (NG) and combustible (G). To qualify as non-combustible, the material must meet a number of requirements that are imposed on it during the testing process. A sheet of drywall is placed in an oven heated to a temperature of about 750 ° C and kept there for 30 minutes. During this time, the sample is monitored and a number of parameters are recorded. Non-combustible material must:

- increase the oven temperature by no more than 50 °C

- give a steady flame for no more than 10 s

- decrease in weight by no more than 50%

Plasterboard sheets do not meet these requirements and are therefore classified in group G (flammable).

Criterias of choice

When choosing a fire-resistant plasterboard sheet, in addition to the technical characteristics and its purpose, you need to pay attention to the manufacturer’s brand. Since only an official factory can guarantee the declared properties of its products. Among the most popular brands are:

- Knauf.

- Belgyps.

- GYPROC.

- GIFAS.

- NORGIPS.

- Volma.

- Giproc.

- Rigips.

- Magma.

The prices and quality of products from the presented manufacturers are approximately the same. Therefore, when purchasing, first of all, the material must be checked according to the following criteria:

- External integrity - absence of cracks, breaks, potholes, etc. defects.

Only high-quality drywall will provide an airtight coating Source levelten.ee

- Coincidence of markings and inscriptions on the packaging and sign of the product - brand name, dimensions, model, GOST are indicated on the edge of the slab.

- Compliance with storage conditions - drywall must be kept at an ambient temperature of at least +10°C.

On a note! Fire-resistant drywall is not only harmless to the health of the residents of the house, but also useful - both as a non-flammable material and as a humidity regulator in the room. It easily absorbs excess moisture from the atmosphere, and when the air becomes excessively dry, on the contrary, it releases it, thereby stabilizing the home microclimate.

Valuable properties and disadvantages

Fire-resistant plasterboard, in addition to its fire-resistant properties, also has other positive properties that must be taken into account when choosing a finishing material.

In fire safety terms, a quality certificate will help determine the basic technical properties of the material in the event of a fire:

- Toxicity;

- Degree of smoke generation;

- Flammability;

- Flammability limit.

Each of the indicators has its own encodings, determined by an alphanumeric code, where the letter denotes the property, and the number indicates the degree of expression in increasing order. So the D-1 marking means that the material has the lowest degree of smoke generation. Index B2 says that flammability is rated as average, G1 says that the material is not flammable, and index T indicates the degree of toxicity.

Gklo wall

In terms of generally accepted standards and qualities of building materials, Knauf plasterboard, as a quality standard for gypsum plasterboard, has the following sheet technical characteristics:

- Side length 2500 mm;

- Sheet width 1200 mm;

- slab thickness 120-125 mm;

- weight 25 kg;

The slab has excellent sound insulation properties; compared to conventional slabs 2500x1200x12.5 hl, the non-flammable one retains 15% more noise than usual. The use of sheets as a finishing material makes it possible to create any shapes and designs using installation technologies standard for this class of materials. A non-flammable sheet is also simply cut and bent, like a regular one, however, during installation you need to be as careful as possible with moistening the surface - the sheets lose their properties when over-moistened. This is perhaps the only drawback, but using fire-resistant material like ordinary moisture-resistant drywall is extremely irrational.

Some manufacturers, such as Knauf, are constantly using new solutions to improve the design properties of their products. Sheets of Knauf fireproof plasterboard are produced with the ability to “breathe”, which allows you to create rooms in which there is no musty smell, mold and mold.

Briefly about the main thing

Fire-resistant plasterboard contains gypsum modified with clay and glass fibers at its core, and is covered on the outside with cardboard impregnated with fire retardants. Thanks to this structure, the material is able to hold back fire for 20 minutes to 1 hour without destruction. Its main advantages:

- Fire protection.

- Harmlessness.

- Moisture resistance.

- Sound and heat insulation.

- Durability.

- Versatility.

- Cheapness.

- Ability to maintain microclimate.

The disadvantages are expressed in the specifics of material processing and insufficient strength. GKLO is widely used for fireproofing, insulation, noise and thermal insulation. Among its varieties, fire-resistant and fire-moisture resistant stand out. When choosing, you need to pay attention to the technical characteristics, appearance, labeling and storage conditions before purchase. Installation of fire-resistant plasterboard boards is carried out using standard frame technology, but in compliance with recommendations regarding the specifics of the material.

Ratings 0

Test procedure

It is carried out when serial commercial products are put into production, and then periodically - at least once a quarter; and also when changes are made to the production process, new materials and additives are introduced into the recipes of raw materials. According to GOST, the test procedure for fire resistance is similar, but according to GOST 32614 it is carried out under more stringent conditions:

- Take three sheets of plasterboard or 6 sheets of GSP from a batch of commercial products.

- Two gas burners are directed onto the cut sample to achieve a value of 800±30℃ - for gypsum plasterboard until destruction, measuring resistance to open flame in minutes, normally not less than 20 minutes; 1000±50℃ – for GSP for 15 minutes (normal) or until destruction.

- All samples are subjected to tests, and if at least one of them does not pass them, losing its integrity, collapsing into two or more parts; then the tests are considered unsatisfactory, the batch of GKLO, GKLVO or GSP-DF cannot be accepted as a fireproof/fire-resistant material.

Similarities with conventional gypsum boards

As a rule, the sheets have the same format as regular drywall. At the same time, the mass of a standard sheet of 1.2 by 2.5 meters is 25 kilograms, which is also quite typical for ordinary sheets. Like regular plasterboard, non-flammable plasterboard is highly environmentally friendly, and at the same time allows the walls to “breathe”.

As for further finishing, there are no differences here either. You can also use plaster to seal the joints and polymer-based putty for the finishing. In addition, the material can be painted and wallpapered.

How does a material become fire retardant?

In addition to the increased density of the gypsum core, this type of material is characterized by additional reinforcing additives, as well as impregnation of the cardboard layer with special refractory compounds.

Interesting! Filament glass fiber acts as a reinforcing component that makes gypsum plasterboard heat-resistant. Its length can reach 30 millimeters, and the purpose of placing it in plaster is to maintain elasticity when exposed to high temperatures. In situations where regular plaster loses its strength, fire-resistant plaster has not yet reached its limit.