Soundproofing room partitions is very important. Sound waves travel through surfaces with different strengths. Extraneous noise makes it difficult to relax or concentrate on important work. Soundproofing partitions help reduce the strength and intensity of sound vibrations: let's look at which ones to install in an apartment and how to properly install such structures.

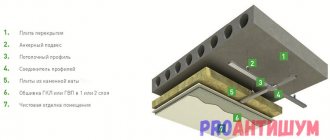

Ceiling soundproofing technology

Soundproofing the ceiling in an apartment under plasterboard is quite easy to install. You just need to add some elements and the absorbent material itself. The work algorithm is as follows:

- Along the perimeter of the room, along the walls, you need to mark lines along which the guide profiles will be laid. If the ceiling is planned to be one level, then this marking will determine its lower edge. Here it is worth considering that there should be a sufficient distance away from the ceiling for installing sound insulation and laying wiring for lighting. The minimum level of the suspended ceiling should be 100 mm lower than the load-bearing floor.

- Before proceeding with the installation of the guide profiles, a damper insulating tape is installed along these markings. A UD profile is installed on top of this lining, fixing it with dowels-nails in increments of 350-400 millimeters.

- The next step is to lay a soundproofing membrane on the ceiling surface. The canvas is fixed to the ceiling using dowels - umbrellas.

- Now lines are marked across the room where the main frame slats will be mounted. Vibrating suspensions are attached according to the marks. The distance between them should be about 800 millimeters, and between the transverse profiles within 600 mm. The hangers are secured with dowels - nails driven into the floor slab.

- Rack profiles are inserted into the guides and secured with clamps to them and hangers. And also transverse slats are made, which are also attached with bugs to the frame.

- When the base sheathing is ready, you need to lay the main sound insulator. (mineral wool). After which it is covered with a vapor barrier cloth and the wiring is laid under the lighting fixtures.

- After which the frame is sheathed with sheets of plasterboard using standard technology with wiring for lighting. Self-tapping screws for drywall are screwed in at a distance of 200 mm from each other, the sheets are joined on the profiles.

If the height of the room does not allow the ceiling to be lowered too low, then it is better to use pendant or overhead lamps for lighting rather than spotlights. Built-in “eyes” in too tight a space between the gypsum board and mineral wool can quickly fail due to constant overheating! Watch the video for the process of installing a soundproofing suspended ceiling.

Soundproofing a brick partition

Partitions made of red solid brick will have good sound insulation (hollow or sand-lime brick is not suitable). Red brick has high surface density and good internal losses.

The wall should be half a brick

(and not in a quarter) and must be plastered on both sides (total thickness ~140 mm). It is important not to skimp on cement mortar.

Building regulations prohibit the construction of brick walls in apartments

One could assume that we have found a suitable material, if not for one point that makes it impossible to use solid bricks in apartments! Current building codes prohibit the construction of brick partitions in apartment buildings - the floors are simply not designed for such a load!

Leveling walls with plasterboard

Often during construction or renovation, planning the surface of a wall or partition is much easier to do using gypsum plasterboard than with plaster. Usually this is also done using a frame, when plasterboard is attached to the wall on a profile. Before attaching the profile to the wall, you need to determine the point of its closest location to the wall and install floor and ceiling guides. Then installing the racks will not cause problems, since all of them are already structurally distant from the walls.

Further, all operations are performed in the same way as when installing a wall. It should be noted that the usual thickness of plasterboard for a wall is 12.5 mm and there seems no reason to reduce or increase it.

As a result of the work performed, a smooth wall is obtained and all that remains is to prepare its surface for applying the finishing coating.

There is a way to level a wall with plasterboard without a frame. It should be noted that the quality of the base surface must be quite high. Before attaching drywall to a wall without profiles, you must carefully remove all protrusions that could interfere with it. Installation technologies can be like this:

- attach the gypsum board part to the wall and drill the mounting holes. In this case, marks from the drill will remain on the base surface, which will be marks for the mounting holes;

- remove the part and use these marks to drill holes for installing plastic inserts;

- Apply cement or gypsum-based adhesive to the wall and level it with a comb spatula. You can also use polyurethane glue;

- install the part in place, secure it with screws.

How to install a supporting frame?

The correctness of the design and assembly of the frame determines how well airborne and structural noise will be absorbed and, accordingly, their transmission to other parts of the structure will be blocked. A solid partition with good thickness copes with this task perfectly.

Many manufacturers produce partitions in series that differ in noise absorption coefficient. For most residential premises, it is sufficient to use partitions with a noise absorption coefficient of more than 55 dB.

There are two options for soundproofing gypsum board partitions - using a longer profile and a thicker layer of filler, or using a gypsum plasterboard system with a two-row arrangement of profiles, fastened using flexible connections, gypsum plasterboard jumpers or directly to each other through a gasket.

Selection of soundproofing material

Different brands of plasterboard sheets have different soundproofing characteristics. The following sheets have maximum protection from extraneous noise:

- Knauf;

- Aku-Line;

- Volma;

- Magma.

The cost of the material is about 700 rubles per sheet.

Acoustic drywall is a sheet with a large number of holes. This design reflects sounds from the surface of the walls.

A soundproofed plasterboard partition is a multi-layer structure, for the installation of which materials with sound-proofing properties are used. This applies not only to drywall and filler, but also to framing and fasteners.

Materials for filling partitions

- Acoustic mats. A slab made of stone wool. The panel has a uniform surface, thanks to which sound waves are reflected from the surface. This material is environmentally friendly and safe.

Fiberglass based boards. The slabs are most in demand on the building materials market because they have a number of advantages:

- not subject to rotting processes;

- resistant to moisture;

- don't burn.

The sound insulation characteristics of the slabs are significantly higher than those of other materials.

Soundproofing material is presented in the form of sheets and rolls, the most popular are mineral, basalt and ecowool, felt.

Elastic materials that are mounted between supporting structures. The main function is to neutralize sounds from impacts.

Panels made of polyester and polyurethane foam. They are used to fill partitions and to install additional walls in the room.

In rare cases, the internal supporting surfaces are additionally glued with a backing made of cork or foil materials. However, in the case of plasterboard partitions, this option is ineffective.

Features of sound insulation of plasterboard partitions:

- The optimal choice is materials based on mineral wool.

- Foam is also used, but it only reduces the noise level and does not absorb it. Compared to other sound-absorbing materials, foam is ineffective.

- Sprayers are used as sound insulation - these are cellulose fibers impregnated with glue. During application to the surface, the thickness of the layer can be adjusted.

How to soundproof an apartment?

Thick concrete walls and high-quality floor joints are good protection against noise. But in panel houses, unfortunately, such protection is completely absent. Therefore, most residents of panel high-rise buildings think about the question of how to soundproof their apartment. To solve this problem, it is necessary to insulate not only the walls, but also the ceiling and floor from noise penetration, using sound-absorbing materials for this.

You also need to take into account that noise can enter the apartment in the following ways:

- through sockets and mounting boxes;

- through water supply and heating risers;

- through joints in walls, ceilings and floors;

- through windows and entrance doors.

Let’s take a closer look at how you can soundproof an apartment with your own hands.

Materials for soundproofing an apartment

Noise control methods depend on the materials used. This can be plasterboard, ceiling panels, mineral wool, rolled materials.

Since extraneous noise often makes a person nervous, makes it difficult to concentrate and can even become a global life problem, soundproofing is a reliable way to restore peace in the home.

First of all, you need to find the source of the noise, and then choose a way to eliminate it.

Often it is enough to soundproof the ceiling and floor, and in rare cases it may be necessary to protect the entire room.

Sound insulation methods and materials used

- Drywall. Before installing plasterboards, it is necessary to carefully seal all cracks in the walls through which noise can penetrate. Then plaster the walls. Installing drywall has some features. For example, if a source of extraneous noise comes from the wall, you cannot attach a frame to it, since sound will still pass into the apartment through the frame fastening. Therefore, it is recommended to install the frame to the ceiling and floor near the wall from which the noise comes. In addition, when installing the frame, it is recommended to use special rubber gaskets, which will be an additional barrier to noise. The gaps between the plates are filled with polyurethane foam. For reliability, a layer or two of mineral wool or gypsum fiber is laid between the plasterboard slabs and the main wall.

- Ecowool and ZIPS panels. The panels are attached to the surface, providing reliable protection against noise from walls, floors and ceilings. To install them, you need to make additional holes. In combination with ecowool panels, ZIPS will not only rid the apartment of extraneous noise, but will also keep the room warm.

- Ceiling panels. They serve as an excellent way to protect against noise from the ceiling. A wide selection of color palettes allows you to choose the right option for the harmonious design of the room. The ceiling panels are based on basalt fiber, which provides reliable sound insulation.

- Suspended ceiling. The suspended ceiling system has acoustic properties that can protect the apartment from extraneous noise coming from above.

- Rolled building materials. These materials are based on a special film with sound-absorbing properties. Before application, you should prepare the wall, the surface of which should be smooth and even. The material is attached to the surface with Bustilate.

Do-it-yourself installation of soundproofing panels

To install the panel, it must be level. It is better to do the laying horizontally, so that during the drilling of the hole as little sand as possible spills out of the product. The panel is placed facing outwards, and holes are made using a hammer drill and a Pobedit drill. The diameter of the hole should be 6 millimeters and the length 160 mm.

After drilling the holes, polymer dowels are used to fix the panel. The dowel is driven in so that the cap deepens by about three millimeters. A hammered dowel should not protrude from the sip panel. One sheet of sound insulation is installed on at least twelve fasteners.

Then it is necessary to lubricate the connecting surfaces with a special sealing compound to ensure reliable and high-quality adhesion. After treatment with sealant, a second panel is applied and the same work is performed. There are situations when the width of the panel does not fit in size and then it has to be cut. The most convenient and easiest way is to use an electric jigsaw.

Circumcision occurs quickly and efficiently

When working with an electric jigsaw, it is important to make perfectly even cuts, since the quality of all sound insulation depends on this. If sand spills out of the panel during cutting, it is poured back so that the material does not lose its insulating properties.

A special tape is glued over the cut surface, which not only holds the contents, but also provides sound insulation for the connection.

After installing the panels to the wall surface, the seams must be coated with a special sealant

When sealing cracks, it is important to ensure that residues do not protrude outward, as this can damage the cladding of the surface layer. After sealing all the cracks, apply a special soundproofing film

If there is no special film available, then even masking tape will do.

Installed soundproofing panels should not have any unevenness or protrusions, as such defects will negatively affect the quality of the next finishing layer. If there is still an unevenness, then to eliminate it you can try to tap the corner to the wall. You must use the hammer carefully so as not to damage the surface of the material. If such measures do not lead to anything, then you can try to carefully trim the inside of the drywall sheet in the place where there is unevenness. So, the installation of the soundproofing panels is completed, you can proceed to finishing the surface with sheets of plasterboard.

Frameless installation and its nuances

Compared to the frame type, installation without building a base is not so lengthy and complicated. But you need to carefully prepare the surface. It is advisable to completely level the walls to ensure maximum adhesion to the panels. After that, apply a layer of primer, without which hollow spaces will appear, preventing sound insulation.

After the preparatory work, attaching sound insulation to the walls is much easier. It is required to apply an adhesive composition, and after completion of the work, additional finishing with decorative elements is required. When using cork sheets, you can avoid decorating the room.

Frameless installation

- The surface is completely leveled, then treated with a primer until a smooth wall is obtained.

- Then, contact adhesive with a quick drying time is applied. It is advisable to use a composition with a short hardening time.

- After 5 minutes the panel is pressed against the wall.

- After that, tightly connecting each other, you need to install the remaining sheets of cork.

How to attach soundproofing panels?

Sandwich panels for noise insulation are rare due to their high cost. It’s difficult to call them a cheap solution, but they are capable of providing complete silence. Fastening is carried out with dowels and self-tapping screws.

- Installation begins from the bottom corner of the room. Usually from the left.

- It is necessary to trim the bottom row depending on the total wall area in the room.

- Using a drill, holes up to 6 cm are drilled into the panel, into which dowels are installed and secured to the wall.

- The joint between the panels during installation should be about 25 mm.

- After installing the last panel, sand the joints and treat them with sealant.

Installation of soundproofing panels

Result of work

The inside of the apartment should be comfortable. And one of the main aspects is silence. Interior wall decoration can be made both aesthetic and functional. Therefore, it is advisable to soundproof the room during major repairs, when planning and arranging the apartment.

Noise entry points

It is obvious to everyone that noise penetrates into our homes through wall partitions and ceilings, windows, balcony openings, and doors. To decide on the choice of soundproofing technology that you want to do yourself, you first need to analyze what or who exactly is bothering you. Often, you may be annoyed by noises that penetrate to you from neighboring apartments through the walls, ceiling, and floor.

Covering sound insulation with plasterboard

Find out exactly where the sound is coming from, if you live on the ground floor - sounds are unlikely to penetrate to you through the floor. If you got an apartment on the top floor, then the place that does not need soundproofing will be the ceiling. It also makes no sense to insulate the walls connecting your rooms to each other, since you can stop this noise yourself. If your house does not have an elevator, then it is also not necessary to insulate the wall bordering the staircase. Of course, if you have planned large-scale work and decided to use the “room-in-room” technique, then all partitions without exception will be subject to insulation, but this is a very expensive undertaking, both in terms of financial investment and time frame, so such work is rarely resorted to .

You should also know that it's not always just the walls. Houses that have been subjected to long-term use often have all sorts of defects - these include cracks and cracks that appeared during the shrinkage of the house, additional holes made by you or your neighbors, and various redevelopments

Before starting work, be sure to carefully examine your walls, ceiling, floor, from which the finishing has previously been removed, pay attention to the places where lighting is attached, recesses for sockets and switches. If you find a violation of the integrity of walls or ceilings, the first thing you need to do is get rid of them by sealing all the cracks and crevices, this will already bring a tangible effect

You can calculate defects invisible to the eye using simple and accessible methods:

- Determining damage to walls using a burning candle. Everyone understands that a candle flame reacts to the slightest fluctuations in air masses - walk with candles near your walls, carefully observing the flame, as soon as you notice the fluctuations, mark the location of detection. This area should be isolated first.

- Calculating cracks and crevices with wet hands. Under the influence of moisture, you will easily feel an unpleasant chill on the palm of your hand in those places where the integrity of the ceiling is compromised. Also mark the location of detection and follow further.

Places where noise penetrates must be puttied

After the study, carefully putty all marked areas. The preparatory work can be considered completed.

How effective is a partition in reducing noise?

Various sounds entering a home from the street (transport, work being carried out, etc.) exceed the noise emanating from neighboring apartments, but due to the psychophysiological characteristics of human hearing, it is these quiet sounds from neighbors that irritate (baby crying, music, loud voices etc.), therefore acoustic comfort should be taken into account. Maximum sound insulation can be achieved through the use and variations of components and components.

The overall soundproofing effect also depends on the choice of material for the middle layer.

Advantages and disadvantages

Knauf Acoustic sound insulation, like any building material, has its advantages and disadvantages. If we talk about the advantages of the material, there are a lot of them, and they are as follows:

Non-flammable material belonging to the “NG” group. Such characteristics allow the use of insulating boards in areas with increased fire hazard. The durability of the product makes it possible to use insulation boards for at least fifty years, while they do not lose their properties and characteristics. Due to the fibrous base of the panel, rodents, insects, fungi and mold are not afraid of. Such indicators make it possible to use insulating material under conditions of high humidity. The stove does not contain harmful components that have an unpleasant odor, so they can be used even in rooms for allergy sufferers and children. During the process of working with slabs, cutting and installation, a lot of dust does not form, which causes less clogging of the room being processed and saves time on cleaning. The soft base does not cause discomfort during installation of soundproofing. The elastic base easily returns the original shape of the slab structure. The product contains natural ingredients. The adhesive base consists of wood resins that do not have a negative effect on human health and well-being. Affordable cost of slabs. Compared to analog materials, the cost of acoustic kunaf sound insulation is suitable for an average family with an average income

Using such sound insulation you can not only effectively protect your home from noise, but also spend a minimal amount of time and money on it, which is important. @Knauf

@Knauf

Despite all the positive qualities of acoustic Knauf sound insulation, there is one minor drawback: during installation it is necessary to create a profile frame. This sound insulation takes up space in the room. To be more precise, on average the thickness of the insulation will vary around ten centimeters. Considering that the distance will be removed from each wall, the area of the room being treated will decrease somewhat. The insulating material simply has no other disadvantages, which explains its popularity among buyers.

Thin noise insulation MaxForte SoundPRO

When the area of an apartment or room does not limit the choice of materials, and you can install sound insulation of any thickness, this is convenient. But what if you can’t afford to waste precious centimeters of living space?

In this case, the innovative thin soundproofing material MaxForte SoundPRO is suitable for you. It has a thickness of only 12 mm, while its characteristics can compete with sound insulation with a thickness of 5 and even 10 cm! MaxForte SoundPRO is the latest material created specifically for sound insulation of residential and industrial premises.

Thin noise insulation MaxForte SoundPRO

Specialists from the Research Institute of Building Physics and the Department of Acoustics, Faculty of Physics, Moscow State University, took part in the development of the material. During the production of MaxForte SoundPRO, all the important points for the effective operation of the material were taken into account: the optimal density was selected (if the density is low, the sound will pass through, if the density is too high, along the “skeleton”), the length of the fibers, and their thickness. The sound-absorbing layer is calibrated and uniform over the entire area. The material is completely non-flammable. The composition does not contain harmful phenol-formaldehyde resins or any adhesives. Therefore, in addition to excellent noise insulation properties, MaxForte SoundPRO is safe for health.

MaxForte SoundPRO provides an increase in noise insulation from both airborne noise (loud TV, crying child, screaming neighbors) and impact noise (noise from stomping, grinding furniture, falling objects). It can be used to soundproof ceilings, walls and floors, which will give a significant increase of up to 64 dB!

Installation of thin sound insulation is very simple, and not only professionals can handle it, but also anyone who has ever held a hammer drill and a screwdriver in their hand.

MaxForte SoundPRO is mounted on the wall using ordinary plastic mushroom dowels, which can be purchased at any hardware store. It is hung on the wall using the “joint-to-joint” technology, after which it is covered with a layer of gypsum fiber board (gypsum fiber sheet). All sheet seams must be sealed with a special vibroacoustic non-hardening sealant. Afterwards, the sound insulation is sewn up with a layer of gypsum plasterboard (plasterboard sheet). The seams of the gypsum fiber board and gypsum board sheets should be staggered, that is, not coincide.

Installation diagram for MaxForte SoundPRO

You can see the installation of thin sound insulation MaxForte SoundPRO in the video.

Soundproofing materials

Drywall with acoustic properties

As you can understand from the previous section, to ensure sound comfort in a room, erecting false walls alone is not enough. And yet, the topic of our article is precisely the sound insulation of plasterboard partitions, and therefore further we will consider the materials used in them and the technology for constructing the most effective structures.

Modern industry offers us a wide range of soundproofing materials, and many of them can be used when working with gypsum boards. First of all, this is, of course, acoustic plasterboard developed by KNAUF.

KNAUF-acoustics

- Acoustic plasterboard panels are gypsum board sheets in which frequent holes are made.

- Surface perforation helps reduce the volume of reflected sound by increasing the sound-absorbing surface.

- A black or white non-woven fabric is glued to the back side of the panels. The non-woven fabric limits the propagation of sound waves inside the gypsum plasterboard partition, adding sound insulation to the noise-absorbing characteristics.

- Acoustic gypsum plasterboard is used both for external cladding of walls and ceilings (its aesthetic appearance allows this), and for installation inside partitions.

- The surface of gypsum board makes it possible to apply a variety of types of finishing to it, which is why it is one of the most popular and economical materials.

Materials for filling partitions

In addition to the use of gypsum plasterboard with special properties, it is possible to reduce the noise level passing through the partition by installing various materials under the cladding. These include soundproofing membranes and sound-absorbing boards.

Tecsound membrane

Membranes for noise reduction are fairly thin panels, usually supplied in rolls:

- The basis of the membrane is a polymer fabric covered with a layer of felt fibers.

- The thickness of the membrane can range from 2.5 to 10-12 mm, which allows the use of some types of membranes even in fairly thin partitions.

- The membrane acts as a sound barrier, preventing the passage of sound waves. Felt coating on its surface enhances the effect by absorbing part of the sound energy.

The most popular brand on the domestic market is Tecsound acoustic membranes.

Various porous materials are often used as an alternative or complement to membranes. Their structure provides effective sound absorption, due to which the sound insulation in plasterboard partitions is significantly increased.

KNAUF Insulation in slabs and rolls

The most popular include:

- KNAUF Insulation - fiberglass based boards. Quite expensive, but they perfectly insulate the room from loud sound, do not get wet, do not rot and practically do not burn.

- Acoustic mats Rockwool – panels made of stone wool. The homogeneous structure of the plates ensures the dispersion of sound waves and compensation of their energy. Environmentally safe, do not burn.

Polyester sound insulation

- Polyester and polyurethane foam panels. They can also be used in the construction of false walls made of plasterboard, but their characteristics should be carefully studied. Some substances are not recommended for use in residential construction due to their fire hazard.

- Styrofoam. Its only advantage is its low cost. It is ineffective as a noise reduction material.

False wall made of plasterboard

Sprayed coatings

A description of the variety of noise reduction products would be incomplete without mentioning spray coatings. They are widely used in modern construction, and we can use them for the construction of gypsum plasterboard partitions.

Sonaspray coating structure

The basis of this material is cellulose fibers impregnated with an adhesive composition. The mixture is applied by spraying onto the surface to be treated from specialized installations, which makes it possible to regulate the thickness of the sound-absorbing layer.

An example of such a mixture is Sonaspray: this composition is used for treating walls, ceilings, as well as spraying inside already installed partitions.

Soundproofing panel system (ZIPS)

ZIPS Vector

The purpose of the Vector panel systems is to improve the sound insulation characteristics of existing walls. The panel system is a complex of sandwich panels and plasterboard finishing up to 12.5 mm thick. The sandwich panel itself consists of external plasterboard walls and a fiberglass layer. To attach the system, no frame installation is required - the rigidity of the panels makes them self-supporting. The panels are also equipped with a system of tongue-and-groove locks, which facilitate installation and increase the strength of the structure.

Technical characteristics of ZIPS Vector

| Dimensions, mm | 1500x500x40 (53) |

| Panel weight, kg | 18,5 |

| Sound absorption index, dB | 18 — 20 |

| Flammability group | G1 |

| External noise reduction level, dB | 6 — 18 |

They are usually used in renovations, but there are no barriers to using them in new construction as part of a multi-layer finish. As effective soundproofing of walls in an apartment, modern materials such as wallpaper, painting, decorative plasters, and panels are used in residential and office spaces where the expected sound pressure does not exceed the limits of household noise. The maximum effect from the use of ZIPS is achieved only with strict adherence to installation technology.

ZIPS Module

Like the previous option, the “Module” system consists of two parts - an internal sandwich panel and an external gypsum board cladding. The internal insulation is a layered structure made of a plasterboard frame and mineral fiber from basalt rocks glued to it. This design provides the required rigidity, fire safety and environmental friendliness. To install ZIPS, there is no need to assemble additional frames - the panels are attached directly to the wall using dowels or self-tapping screws (ideally, special vibration-damping fastening units).

The tongue-and-groove locking system ensures the tightness and strength of the structure. The external finishing of gypsum board with a thickness of 12.5 mm allows you to stick wallpaper, putty, paint, and apply decorative plaster.

Technical characteristics of ZIPS Module

| Panel dimensions, mm | 1500x500x70(83) |

| Element weight, kg | 19 |

| Sound insulation level, dB | 12 -20 |

| Index Rw, dB | 12- 14 |

| Fire resistance | G1 |

The system is designed for soundproofing walls in rooms with an average sound pressure level - cafes, restaurants, shops, production halls and workshops, where the noise level can reach 100 dB. It is necessary to evaluate the level of effectiveness of the ZIPS Module only in combination with the properties of the wall material. On brick, concrete, cellular and ordinary concrete it can differ significantly.

ZIPS Cinema

The most powerful of the ZIPS - "Cinema" is designed to protect against noise penetration outside from rooms with a significant level of sound generation - cinema and concert halls, industrial workshops, machine rooms, boiler rooms and pumping stations. The system actively reduces the intensity of sound vibrations, starting from 80 Hz of the audible range.

Structurally, “Cinema” is similar to the “Module” system, only the layer of mineral fiber is much larger - up to 110 mm. This significantly increases the level of sound absorption without reducing the overall mechanical strength.

Technical characteristics of ZIPS Cinema

| Dimensions, mm | 1500х500Х120(133) |

| Noise reduction level, dB | 10 — 24 |

| Index Rw, dB | 16 — 18 |

| Element weight, kg | 21 |

| Weight 1 m2 | 39,5 |

The system is installed on brick, stone, concrete and plasterboard walls and partitions in rooms and halls for any purpose. The absence of toxic substances and synthetic resins allows the panels to be used in residential and public buildings without restrictions on environmental safety.

The choice of the best material for noise absorption and sound insulation of an apartment depends on the architectural features of the house - layout, configuration of rooms, wall material, exterior finishing options.

Ideally, specialists should be involved in the development of a soundproofing project - rarely does a soundproofing layer perform only one function, much more often it is only a component of a complex system designed to protect the house from excess noise, heat loss and moisture penetration into the wall mass.

Guide to Soundproofing Walls

Guide to Soundproofing Walls

The manual describes a method for soundproofing walls using a multi-layer structure of soundproofing material, plasterboard sheets and related additions. This is the best option for a beginner with an average budget.

Start by looking for all sorts of holes and cracks in the walls. Fill any defects found.

Fill any defects found

Consider the fact that sockets are also among the main sources of noise, especially in multi-apartment panel buildings. Therefore, before you start arranging soundproofing, you must prepare the sockets accordingly.

Turn off the power supply to your apartment or house. Additionally, check the outlet for no voltage using a special tester. After making sure that there is no current, disassemble the socket and remove it from the hole.

Checking the outlet

Fill the opening with mineral wool or foam rubber, seal the material with plaster or other suitable quick-setting mixture, and then return the socket back. Thanks to such a simple finish, the soundproofing properties of the outlet will be significantly increased.

Provide sealing and soundproofing of heating pipes at the points where they connect to the walls. Don't ignore this and the other optional activities mentioned. Even such little things can significantly improve the sound insulation of walls, and the work is very easy: you only need to seal the seams between the heating pipes and the walls using elastic sealant.

Use an elastic product - this material, unlike its inelastic counterparts, normally tolerates temperature changes.

After this, you can proceed to the main stage of work.

First step

Assemble the sheathing from a metal profile.

Use the guide profile first. First fix a special soundproofing tape at the place where the profile is attached to the wall. Thanks to the tape, sound insulation will be further improved.

Soundproofing tape

Attach the profile first to the floor, then to the ceiling, and then to the walls. At the joints of the profiles, fasten them with self-tapping screws.

Prepare the rack profile in the same order. It must be installed in the previously fixed guide profile with a pitch of 600 mm (standard value, otherwise be guided by the size of the selected soundproofing material).

Fastening profiles to the wall

Check the evenness of installation of frame elements with a level or plumb line. Finally fasten the rack profile to the guide using self-tapping screws. Cover the surface of the profiles with soundproofing tape to prevent loss of sound insulation properties in places where the frame comes into contact with the plasterboard sheets.

Second step

Fill the free space of the frame with the selected soundproofing materialSoundproofing the walls in the apartment

Fill the free space of the frame with the selected soundproofing material. In combination with drywall, soundproofing materials based on stone wool are most often used. Working with such materials requires the mandatory use of personal protective equipment - a respirator and gloves.

If you wish, you can give preference to another soundproofing material at your discretion.

Third step

Proceed to attaching the plasterboard sheets. To fix the drywall, use self-tapping screws or screws 2.5 cm long.

Soundproofing walls with mineral wool and plasterboard Puttying joints Do-it-yourself soundproofing of walls in an apartment

Prices for drywall and sheet materials

Drywall and sheet materials

Fourth step

Carefully seal the joints of the sheets with putty. Fill the gaps between the surfaces of the room and the sheathing sheets with elastic sealant.

At this point, the soundproofing of the walls is ready. Finally, all you have to do is treat the plasterboard sheathing with a primer and finish it with the selected material.

Good luck!

Step-by-step algorithm of actions

After drawing up a preliminary scheme and estimate, they proceed directly to procurement.

You will need an electric drill or hammer drill with a set of drills, fasteners (self-tapping screws, screws), a hacksaw or a grinder saw.

From the materials you need to prepare a metal profile for the frame, gypsum fiber sheets, and noise-insulating filler.

It is necessary to follow the procedure approved by standards and technologies. The master builds an insulated partition in one day. If you do the work yourself, you need to be patient. It’s better to spend 2-3 days, but do it conscientiously.

Space marking

According to a pre-drawn diagram, markings are applied to the floor, walls, and ceiling. A building level must be used. It is recommended to use a laser device that will immediately highlight straight lines - all that remains is to draw everything along a ruler or tape measure with a pencil.

If there is no equipment, you need to measure each point separately with a tape measure. Marks cannot be placed relative to each other; they must be measured from identical points within their planes.

For example, first measurements and markings are made on one wall, then on the other. But you cannot first mark one surface and then transfer the marks to another, this will lead to strong errors.

Mark sheets of drywall that will not be used entirely. You need to cut off small pieces to create minimal joints between the elements.

Preparation of material

The assembly of partitions with sound insulation begins with the installation of a frame structure. You will need to accurately draw and calculate all sections of the frame, measure, and cut profile blanks.

If you use wood instead of metal, you will need to sand the cuts to prevent destruction of the wood structure, and also impregnate them with protective antiseptics.

They make a frame around the perimeter of the frame to firmly fix it on walls and horizontal surfaces. A substrate is placed in the places where the structure adheres to the base. The interlayer will provide a better level of insulation.

Frame installation

According to the applied markings, a self-adhesive seal is attached to all edges of the room. Then, the starting profile is mounted to the ceiling on metal dowels. It is necessary to immediately treat the hardware with sealant to reduce noise.

Example of a finished frame

Fix the profile along the lower horizontal, then proceed to installing the vertical elements. This is the most critical stage, at which it is necessary to lay wide cells to insert sound insulation, but narrow ones so that the filler does not fall out of place.

The opening of the future passage is made with a beam, which is inserted into the profile.

Filling the frame

When the preparatory part is completed, they proceed to filling the partition frame with soundproofing material. There are no specific restrictions on the choice of raw materials for insulation; each case is individual and may require different types of products.

Filling frame voids

You can significantly simplify the task if you immediately sew up the frame with gypsum fiber sheets on one side, and put sound insulation into the remaining space - nothing will fall out. You need to take care in advance about the removal of the necessary wires and a protective casing for the wiring.

Craftsmen advise starting to lay sound insulation from the bottom up, placing solid elements first, then sections.

It is possible to increase the soundproofing properties of wool if you cover it with a layer of membrane on top.

How to sew up the structure

To close the building, regular gypsum plasterboard is used, which is used to cover the second side of the new wall. The stitching is carried out in two layers: first, a full covering of plasterboard is carried out in a convenient order, then a new layer is applied with partial offset to cover the joints of the previous one.

Finished wall

Overlapping the seams between the sheets is required to prevent noise from leaking through the joints - these are additional sound insulation measures.

Upon completion of the installation work, the external joints are treated with sealant, after which it has dried, you can begin decorative finishing.

The general process of constructing a soundproof partition can be seen in the following video:

How to enhance the soundproofing effect of an existing wall

When the wall is ready or was built correctly before purchasing a home, you can try to increase the level of sound insulation. The solution is finishing with cork wallpaper.

Cork material is created from crushed tree bark; the finished product has a somewhat porous structure. The raw material partially has the properties of insulating heat, noise and moisture. With proper use of wallpaper, you can make the wall functional and decorative.

Cork finishing in the interior

SIP panels are a sandwich material made from two sheets of OSB and a layer of expanded polystyrene. Thicker formats are used in the construction of houses, thinner ones are used for cladding partitions for cladding.

Panel sound insulation is easy to use and saves installation time due to adhesive installation.

Various types of structuring of structures and materials of partitions

Partitions according to their design can be divided into single-layer and multi-layer structures:

- Single-layer partitions. For construction, dense material is used, bound together by “mortar”. These can be brick, plaster, expanded clay concrete and even reinforced concrete wall structures.

- Multilayer partitions. Constructed from two or more alternating layers. For example, a frame-sheathing plasterboard partition, a frame partition on one or two frames with environmentally friendly fiberglass, etc.

Drywall and wool

All the abundance of different variants of wat has the following characteristics:

- Doesn't light up.

- Does not deform when exposed to temperatures or compression.

- Does not come into contact with various environments.

- Easy to install.

Instructions for making sound insulation using these materials are as follows:

- Attach a water barrier to the walls and insulate the joints.

- Assemble the frame from wood or metal profiles according to the installation technology.

- Distribute the cotton wool evenly behind the frame, secure it, try to avoid uncovered areas.

- Attach sheets of drywall, putty the joints, and plaster the surface.

- Complete the repair work with any type of finishing (painting, wallpapering).

Soundproof wall cladding

Let us remind you that for structural strength, the fastening step of the profiles should not be less than 50 centimeters, the sheets are attached both in the middle and along the edges, adjacent sheets are attached to the same guide. The tools that you will need for such work can be found in every home: a screwdriver, a level, a plumb line, a ruler, a pencil, a stationery knife - this is the minimum set with which you can easily carry out your plans.

Cost of soundproofing partitions

Let's consider two options for soundproofing partitions:

- Basic version, with a thickness of 100 mm. Maximum sound insulation of wall structures at low cost (plasterboard partitions). They have sufficient rigidity and the ability to withstand heavy loads. Due to their simple design, they are popular when solving sound problems in apartments, offices, and recording studios. Cost - from 380 rubles per m 2 of double-sided partition.

- Reinforced version with a thickness of 150-160 mm. It is distinguished by the use of a design with separate frames. The partition consists of two parts, independent of each other and installed in parallel, without touching each other. This option is often used for local separation of a bedroom from a children's room or for soundproofing a room with video and audio systems (cinema). The cost of a double frame starts from 500 rubles, depending on the material.

Soundproofing of plasterboard partitions

Properly selected material for soundproofing plasterboard partitions is the key to peace and quiet. By protecting against intrusive conversations, music or TV in the next room, it helps maintain nerves and healthy relationships.

A typical modern interior partition is made of a wooden or metal frame covered with plasterboard on both sides. Such a wall does not resist the passage of sound well. If a similar redevelopment has been made in the apartment, then only soundproofing of plasterboard partitions will save you from noise.

Best materials

The most effective material that completely guarantees results does not yet exist and is unlikely to ever be made. There is also no universal, one-size-fits-all guide to follow when making a room barrier.

The effectiveness of activities depends on each stage. The very first is the installation of the frame. Its design will simply ring if you do not take protective measures - insulate the floor and ceiling from it. Without using a damper tape, it is impossible to achieve any significant results. An excellent damper is the proven Vibrostek-M tape.

As for the frame, there is not much to think about what to choose from - either wood or a metal profile. Their indicators are approximately the same, and little depends on the choice in favor of one or the other.

The panels covering the frame play a significant role. Acoustic plasterboard produced by Knauf or similar products from the Aku-Line line manufactured by Giprok can significantly reduce penetrating noise.

A responsible approach to the task requires that the sheets be laid in 2 layers. Just one layer does not give a quality result. Acoustic triplex, a specialized three-layer material for sound insulation, can also be used as sound insulation under drywall.

A good triplex is produced under the SOUNDLINE-dB brand.

The main role is played by the layer of aggregate laid between the panels. Sound-absorbing boards SCHUMANET-ECO have good performance and suitability for domestic use in apartments.

If the partition has already been built, there is not much to choose from. But it is not necessary to disassemble it and rebuild it. Sound absorption can be significantly improved by using wall membranes. Thanks to them, the volume of reflected sounds directed at the surface of the walls is reduced.

The process of installing sound insulation in a plasterboard partition

A good result depends not only on the materials, but also on how correctly and responsibly the sound insulation is done. Here we can highlight the following, most significant stages:

- Soundproofing a plasterboard wall in an apartment begins with mounting its frame on vibrating tape. It is laid in two layers, attached to the walls, floor and to each other with vibration sealant;

- Frame installation. It is advisable not to place sockets and switches on the future wall - sounds are transmitted very well through them. A rational solution would be to make the distances between the profiles correspond to the size of the soundproofing slab;

- Installation of plasterboard sheets of partitions on one side. Acoustic plasterboard is installed with perforations facing outwards;

- Laying sound-absorbing slabs in the interior partition. Their thickness determines what the thickness of the interior partitions will be;

- The final stage is when the slabs are covered with gypsum boards. To do everything correctly here, the joints need to be sealed with vibration sealant.

Required Tools

Soundproofing plasterboard partitions are the easiest to construct. But for this you need to stock up not only on materials, but also on tools.

The minimum required for a beginning builder includes:

- a spirit level, a laser level or a regular construction device;

- screwdriver;

- plumb line;

- roulette;

- screwdriver set;

- metal scissors;

- drywall cutter;

- Ruler and pencil.

Without this minimum, work cannot begin. But if you have additional tools, installation will be faster and easier. For example, you can trim drywall sections with a special plane, and use a grinder to cut metal profiles.

Filling the frame and covering with sheets

In the case of using materials to improve acoustic properties, first a finished frame made of profiles is attached to one side - sheets of plasterboard. Next, the voids are filled with the selected material (trimming to size and fixing the slabs). After the partition is filled, “sew up the second side with plasterboard. Pay attention when attaching the second side - make sure that there is no piece of mineral wool or other filler between the profile and the sheet of drywall - this can lead to bumps on the surface of the drywall.

Soundproofing and sound absorption - acoustic Yin and Yang

Only a combination of two materials that are different in their nature of interaction with sound can truly create a reliable barrier to noise. Thus, sound insulation is a characteristic of materials that affects their ability to reflect sound, preventing it from passing through a wall or partition. In a building structure, the sound insulation capabilities are primarily influenced by mass. For example, the thicker the wall, the more difficult it is for sound vibrations to overcome such a barrier.

To indicate this quality, an index (erroneously called coefficient) of sound insulation (RW), measured in decibels, is used - the index of glass partitions, timber, brick partitions, concrete and other materials indicates what level of noise they are able to reflect. Soundproofing materials directly include dense, massive materials - brick, plasterboard, MDF boards, concrete.

The opposite of soundproofing is sound absorption. Materials that have this quality, instead of reflecting noise, absorb it. To do this, their structure must be heterogeneous - cellular, fibrous, granular. To measure this parameter, a sound absorption coefficient was introduced, which is measured in the range from 0 to 1. At a zero value, sound should be completely reflected, and the closer the parameter is to unity, the more sound absorption increases. However, such materials do not yet exist - the maximum sound absorption value reaches 0.95.

Sound-absorbing products are divided into three categories according to the degree of rigidity:

- Soft - materials that have a pronounced fibrous structure, with randomly located fibers. Cotton wool, felt, glass and basalt wool are the most striking examples. Their sound absorption coefficient is the highest - from 0.7 to 0.95, with a small volumetric mass - up to 80 kg/m 3. To achieve a good effect, the thickness of the layer of such materials should reach at least 10 cm.

- Semi-rigid - slabs with a fibrous or cellular structure. Such materials are mainly made from the same mineral wool or foamed polymers. Their volumetric mass is an order of magnitude higher than soft sound absorbers - up to 130 kg/m 3, with a sound absorption coefficient from 0.5 to 0.8.

- Solid - products made from granulated or suspended mineral wool, porous aggregates such as pumice and vermiculite. Their mass is the highest - up to 400 kg/m 3, the sound absorption coefficient on average fluctuates around 0.5.

Why noise is dangerous - the Ministry of Health warns

The close proximity of a house to a highway, noisy enterprises, or living in a panel house sometimes leaves people with the imprint of constant fatigue. We get so used to noise that we don’t take it into account at all when looking for the causes of insomnia, irritation, and frayed nerves. However, it is chaotic sound waves that are often the cause. The fact is that the optimal noise level, measured in decibels (DB), should not exceed 40 dB during the day, and 30 dB at night. What we usually call silence has a completely measurable level of 25 dB.

This is the most optimal value for our body, and if it is less, another uncomfortable sensation will arise - a feeling of ringing silence.

A person can tolerate a noise level of up to 60 dB calmly for some time, but if the sound increases and continues for a long time, the person may experience an attack of hysteria, or at least become very irritable. It was not for nothing that in ancient times besieging troops created loud noise around a fortress or castle both day and night - one could endure the lack of food, share water and fight to the last drop of blood, but after several days of lack of sleep and exposure to noise, the people under siege were ready anything to stop this torture by sound.

That is why, before moving to a new apartment, it is worth experimentally determining the sound insulation coefficient of the rooms and, if necessary, protecting yourself from extraneous sounds. Fortunately, there are a great many materials that can implement this task; you just need to approach the issue competently and take into account all the features of the propagation of sound waves.

Theoretical basis

Before installing insulating layers, it is necessary to understand the nature of the functions they are intended to perform, as well as some basic terminology.

Sound insulation is a set of measures and technical solutions aimed at reducing the level of noise coming from outside.

The noises themselves are conventionally classified into three groups :

- Impact - occurs as a result of mechanical impact on the surface and initially spreads in a solid medium (blows, knocks, squeaks, etc.)

- Structural - formally they are a type of percussion, but due to their specificity they are classified as a separate group. They arise due to the relative mixing of structural elements relative to each other, which is typical, for example, of frame houses. Structural noise can include, in particular, creaking parquet flooring.

- Acoustic - the most common group, which includes all sounds emanating from external sources and entering the structure of walls and partitions from the air. Examples of acoustic noise include human voices and music.

If sound insulation is a general concept that characterizes different areas of activity, then noise absorption is a narrower, physical sphere, indicating the degree of dispersion of sound waves in a solid medium.

In practice, both of these phenomena are inextricably linked with thermal insulation as a way to prevent heat loss as a result of heat exchange with the external environment.

Therefore, the modern building materials market includes many combined products that provide comprehensive sound and heat insulation of surfaces, although there are also “highly specialized substances. You can learn more about them and other insulating materials in the next section.

Useful tips

To increase the sound insulation of a plasterboard wall, use a double frame rather than an ordinary one. This will increase the thickness of the air gap and eliminate vibration between the metal frame elements. Two independent frames do not directly transmit vibration to each other.

Use double flashing on the outside of the wall, but never add additional gypsum membrane on the inside. This will increase the cost of the structure and at the same time reduce sound absorption. Instead, it is recommended to lay sound-absorbing material (sealing tape), which absorbs some of the vibration.

Installation rules

The main soundproofing material is located between the supporting surfaces of the partition, which means that there can be several layers of it.

The most widely used are fibrous materials, which are supplied in rolls or sheets, depending on the specific density of the substance. The form of manufacture also imposes some specific requirements for installation.

Soft roll insulation is usually cut into sections equal to the height of the frame gaps. One of the sections will have to be cut lengthwise. All sizes are made with a margin of 5-10% to ensure tight fixation of the insulator in the gap.

In the case of installation of sheet soundproofing materials, their precise molding may be necessary, which is important, first of all, when the elasticity of the substance is low.

If there is an air gap behind the insulator layer, it is permissible to install plates on the frame to prevent sheets from falling out of the gaps.

Some nuances may arise when dissimilar noise and heat insulation layers are installed simultaneously. In this case, the heat-insulating layer is placed first, starting from the side of the sound source. As a rule, its width is selected in accordance with the width of the frame.

After this, they lay down a plastic film and begin installing sound insulation, for which it is most convenient to use sheet materials. They are placed in the frame of the other side of the partition or in the free space between them, which sometimes requires the installation of auxiliary fasteners.

Sound insulation of airborne and impact noise - examples

The main characteristic for materials that insulate against airborne noise is the sound insulation index. In order for you to get rid of neighborly conversations, this figure must reach at least 50 dB. If during the construction of a house this problem can be solved by increasing the thickness of the structures or using ready-made blocks, then in an apartment where every centimeter counts, this method is completely irrelevant.

An acceptable option is a combination of different materials in a multilayer structure, alternating soft and hard products with varying degrees of density. Drywall can be rigid; it will be responsible for sound insulation. Soft materials, such as glass wool or mineral wool, will absorb sound. The effective thickness of cotton products in such structures is at least 5 cm and at least 50% of the internal space of the structure.

Increasing the sound insulation index of the floor is possible by installing an acoustic ceiling. Since the height of most rooms is already small, manufacturers and consumers try to save as many centimeters as possible. Semi-rigid and rigid materials for sound insulation in this case will help create the first layer of sound insulation, the second can be plasterboard or a suspended ceiling. The stretch ceiling membrane itself has a good degree of sound insulation, but it is even better to purchase special acoustic stretch ceilings that have a multi-layer perforated structure that perfectly reflects sound.

Porous materials stop the sound waves of impact noise. Their elastic structure repels sound vibrations, causing them to lose strength. One of the striking examples of such elastic materials is sheets of technical cork and polyethylene foam. Most often, they are used when installing floating floors, underlays for laminate and parquet, and when sealing joints.

When performing sound insulation, you should take into account the thickness of the floors - if in luxury housing they use slabs with a thickness of at least 200 mm, then in panel houses they are much thinner. In the first case, it is enough to lay a layer of technical cork on the floor with a sound insulation index of 25 dB; in the second case, you will have to make a multi-layer structure using cotton and semi-rigid materials.

Materials with high sound absorption coefficient

Sound-absorbing materials can be divided into the following types:

- Porous sound absorbers (also called fibrous). Made from porous materials - kaolin, slag, pumice, vermiculite with a binder (for example, cement);

- Porous, with perforated screens;

- Resonant;

- Layered structures;

- Piece or volumetric.

Airborne noise insulation index of brickwork

Sound insulation of a brick wall is achieved by increasing the thickness of the walls, but the thickness is limited by the weight of the structure. The main thing is that the wall material and the binding solution form a sealed structure without any holes or cracks. In addition to the correct materials used when constructing walls and partitions, good sealing of all channels for noise entering the room is of great importance. Simply put, all cracks and holes through which sounds enter the room should be sealed. A comfortable, harmless sound background for humans is considered to be noise with a power of twenty to thirty decibels.

Anything above this indicator puts a strain on the nervous system. But noise above eighty decibels causes one or another harm to the body. For your information, the sound background in the subway is one hundred decibels. Walls and partitions in the apartment represent barriers to various noises.

How comfortable and peaceful you can live in your home depends on how the walls are arranged. When designing walls and partitions, noise such as voices, laughter, sound from a working TV, loud music, noise from a working elevator is taken into account. These include noisy neighbors, a constant flow of traffic, noise from construction sites, and so on. It is not surprising that in such an environment a person dreams of silence.

I want to come home, close the door and isolate myself from the noise, stress, and bustle. Have a good rest, relieve stress, or just get some sleep without anyone disturbing you.

Foam plastic - pros and cons

At first glance, polystyrene foam seems to be the best choice. After all, it is cheap, lightweight, and retains heat. However, let us remind you that it is poisonous, flammable, and its soundproofing properties are not as good as many people believe.

It is worth separately recalling its poor environmental properties: polystyrene foam is harmful to health and emits fumes even at room temperature. Therefore, in attempts to save money, it is used mainly externally and in cold regions where it does not emit evaporation as actively. Do not use foam in children's rooms and bedrooms.

Polystyrene foam is flammable!

The effectiveness of the foam layer as a soundproofing material is ten times less than that of special pads. Expanded polystyrene only blocks impact noise. However, a layer 5 cm thick retains as much noise as a special 0.3 cm pad. Think about whether it is worth saving so much to get a similar result.

Another misconception is the advice of amateur masters. They claim that the foam should be installed on the walls and ceilings, and then the surface should be plastered. But such cladding does not increase, but reduces sound insulation qualities!

If such an operation is carried out on both sides of a concrete or brick partition, then the ability to absorb and reflect sounds will decrease catastrophically. It will transmit sound in the mid-frequency range, like a drum.