Wood is a very attractive decorative material. However, it is possible to obtain a high-quality finish of wooden products only after careful preparation of its surfaces. This is an extremely difficult task, since processing must be carried out in several stages. At each of them, technological errors are possible, and defects and flaws in the material are often discovered.

If every wooden part is rejected due to detected defects, the quantity of finished products can be reduced to zero. In addition, surface defects often appear on finished furniture. They appear due to operational errors or as a result of processes occurring in the mass of material. To solve most of these problems, putty is used. This is an effective and very common procedure that should be discussed in more detail.

How to cover up wood damage

No wood surface can remain in perfect shape all the time. Fortunately, there are many products available on the market that can cover up cavities.

One of them is wood putty. Which wood putty is best? There is no clear answer to this question.

- Much depends not only on the mixture, but also on the type of wood and work.

- Before you start choosing putty, you should determine for what purpose you plan to use it.

- There are many wood putty options available in stores.

- The colors are very varied, so there is a chance to find the one that best suits a specific surface.

You can also find white and colorless universal putties.

Wood putty is most often used in places such as: wooden stairs, parquet floors, furniture, frames, doors, as well as various types of structures. There is a modeling putty available that is primarily used on decorative and collectible items.

Examples of declaring the Commodity Nomenclature of Foreign Economic Activity of the EAEU, definition of the Commodity Nomenclature of Foreign Economic Activity code

HS codes, replaced from 09/01/2015

Comparison table of export rates in force on 08/31/15 with those coming into force on 09/01/15

Search the list of goods that have undergone customs clearance (more than 700,000 examples of declaration).

To obtain more detailed and up-to-date information, including real prices, use the “Average Contract Prices” information module and the “Tamplat PRO+” customs calculator.

Declaration examples on the website are for informational purposes only and cannot serve as a basis for making a decision on the classification of goods.

Pages: 1

- 3214900009 — TWO-COMPONENT PUTTY IN THE FORM OF PLASTIC MASS BASED ON POLYESTER RESIN, PIGMENTS AND FILLERS, MIXED IMMEDIATELY BEFORE USE

- 3815909000 — HARDENER FOR TWO-COMPONENT EPOXY PUTTY: BRAND “HEMPEL'S PROFILLER 35370″” CONSISTS OF A BASE, IN 10-LITER METAL CONTAINERS - 35 PIECE

- 3214109000 — TWO-COMPONENT EPOXY PUTTY, SOLVENT-FREE, BRAND: MIXING RATIO 1K1 BY VOLUME — WILL NOT CONTAIN

- 3214109000 — TWO-COMPONENT UNIVERSAL PUTTY BASED ON POLYURETHANE, FOR COATING, FOR PROFESSIONAL USE IN MECHANICAL ENGINEERING, MANUFACTURER

- 3214900009 — UNIVERSAL PUTTY UNI 1.8 KG WITH HARDENER - TWO-COMPONENT POLYESTER PUTTY FOR UNIVERSAL USE FOR PRIMED AND UNPRIMED

- 3214109000 — EPOXY PUTTY. THE COMPOSITION OF INCREASED WEAR RESISTANCE IS A GRAPHITE-FILLED TWO-COMPONENT EPOXY GLUE (PUTTY). SPECIAL

- 3214109000 — REPAIR PUTTY: REPAIR COMPOSITION FPRM 05901 — TWO-COMPONENT POLYMERCAPTAN-EPOXY MASTIC-PUTTER, IN TWO 25ML TUBES, CONSISTED OF K

- 3214109000 - TWO-COMPONENT EPOXY PUTTY (PRIMER) USED FOR MAINTENANCE AND REPAIR ON BOARD THE VESSEL. DOES NOT CONTAIN ETHYL ALCOHOL, NOT IN AEROSOL

- 3214109000 — PAINTING PUTTY. TWO-COMPONENT UV PUTTY, COMPONENT A - BASE, COLOR: BASIC

- 3214109000 — TWO-COMPONENT POLYESTER PUTTY (COMPLETE WITH HARDENER), FOR CAR BODY REPAIR, INCLUDED. JARS, DOES NOT CONTAIN GYPSUM AND CEMENT -UNI

- 3214109000 — 37225073 RADERAL GLASS FIBRE PUTTY 2507-TWO-COMPONENT FIBER GLASS PUTTY FOR REPAIR OF PAINT COATINGS IN THE AUTOMOTIVE INDUSTRY,

- 3214109000 — PUTTY. TWO-COMPONENT POLYURETHANE PUTTY FOR CONCRETE, CONCRETE FLOOR, WOOD, METAL. PURPOSE – PUTTY, SEALING INDIVIDUAL DEFECTS

- 3211000000 — COMPONENT FOR PREPARING PUTTY. ACCELERATOR FOR TWO-COMPONENT UV PUTTY, KLUMPP TRADEMARK

- 3214109000 — POLYESTER UNIVERSAL PUTTY IS A TWO-COMPONENT PRODUCT, THE PUTTY IS USED FOR LEVELING BEFORE PAINTING CRACKS AND DEEPENTS, APPLYING

- 2909600000 — COMPONENT FOR PREPARING PUTTY. HARDENER FOR TWO-COMPONENT UV PUTTY ART.159, COMPONENT B IN 1 L CANATS. COMPOSITION: 100%

- 3214109000 - EPOXY TWO-COMPONENT PUTTY, REMARK - ALIGNMENT OF SMALL DEFECTS ON THE METAL SURFACE BEFORE POWDER COATING, PACKING - PLASTIC

Which wood putty is best?

Different types of wood putty differ in their characteristics.

Therefore, the selection of the desired mixture should be approached thoroughly.

- If the putty is intended for a specific type of wood (pine, beech or ash), then it should be applied specifically to this type of wood. Most likely, it is suitable not only in terms of aesthetics (color), but also in composition (density and hardness).

- White wood putty is a universal solution. Sometimes the color can be not only white, but also beige. This type of putty has good adhesion, but due to aesthetics it is most often used only as a primer layer before painting.

- Clear wood putty is used to fill small holes or cracks in joints. It is usually slightly matte, durable and relatively easy to apply. But remember that when used on larger uneven surfaces, it will not be completely invisible.

- A two-part wood putty, consisting of a base and a hardener, allows you to tailor the characteristics of the joint to the desired properties quite well, but it requires a little practice to prepare. Products of this type must be applied as quickly as possible (after opening the package they may lose their properties). Most often, two-component putties are used only for large-scale work.

- Spray-applied wood putty does not typically provide the appearance of real wood, but once applied it creates a layer that is ideal for painting. Therefore, such compositions are used as wood putty under varnish - they increase adhesion, create an even layer and facilitate subsequent processing.

General information about the material

Fiberglass putty is a composition based on an unsaturated modified polyester resin, reinforced with special fibers and is a two-component product. In its original form, any polyester resin is quite hard, so various targeted additives are added to it to enhance ductility and elasticity. The fiberglass in the putty is intended to further enhance the strength of the material after drying.

Putty for external and internal work

Exterior wood putty must be highly resistant to temperature changes and favorable weather conditions such as frost, rain or solar radiation.

It is worth carefully reading the instructions for use indicated by the manufacturer, since some products are suitable for use, for example, only in shaded areas or not exposed to precipitation.

Wood putty with hardener intended for exterior use will likely be more expensive than wood putty intended for interior use.

Properties

Fiberglass putty is ideal for smoothing out various defects, chips, cracks and pits. It can be applied to products of a small or large area, and in the latter case a sprayer can be used to distribute it. There are special types of auto putties with reinforcing fibers for plastic - they have the highest quality of adhesion to this particular material.

Removing dents with fiberglass putty

The main properties of reinforced putties are as follows:

- vibration resistance;

- high strength;

- durability;

- short curing time;

- elasticity, stretchability;

- resistance to mechanical damage;

- Can be used on any hard surface.

How to make putty yourself

Is it possible to make putty yourself? There are recipes for preparing the mixture online, but professionals do not recommend using such a solution. In this case, there is no certainty that the putty produced is truly suitable for effectively covering cavities.

Low quality wood putty can even negatively affect the current condition of the wood. This is especially true for wood putty for exterior use. In the worst case scenario, the wood will be completely unusable.

Purchasing a ready-made solution guarantees the aesthetic appearance and quality of the material used.

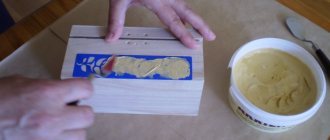

Preparatory stage

It is best to apply the material to clean metal, but if necessary, you can even work on old paint or varnish. Peeling, crumbling coatings are removed using a metal spatula or power tools. Areas affected by rust are sanded, completely eliminating the spots. Narrow cracks are widened slightly to make it easier to seal them with putty. Then, in relation to the working surface, do the following:

- processed with sandpaper for matting;

- clean from dust with compressed air, wipe with solvent;

- allow to dry completely.

Creation of models and furniture

The art of sculpting, finishing and creating furniture from wood requires special putties. The characteristics of such wood putties are different.

The main criterion here is the post-processing method.

- Classic one-component putties are excellent for filling small cavities or cracks.

- One-component putty, which is relatively soft, is definitely better suited for hand processing, while harder ones, usually two-component, are easily processed by machine.

- It is important to know how thick a layer of putty can be applied at one time. Some solutions can dry evenly even a few millimeters thick; for others, a millimeter is the upper limit.

- Sometimes putty mixed with dust or sawdust is used. They are available in the form of a liquid base, but when working with the material, dust and sawdust are formed; for example, you can wipe off the wood from the invisible side of the object with thin paper.

Such putties are perfectly matched in color and allow you to achieve an aesthetic effect at the cost of a lot of work.

FAQ

How large potholes can be filled with putty?

Most manufacturers do not recommend applying a layer thicker than 2 mm. Gaps and cracks should also not be wider than 2-3 mm. If they are larger, you need to glue in pieces of the same wood, then sand the crack and putty it (if necessary).

Which putty should I use to fill shallow dents on a polished or varnished surface?

The best option is to use a transparent composition. Epoxy materials can be used. For shallow flaws, it is more correct to use varnish - it is applied with a thin splinter, trying to get exactly into the recesses.

If you plan to do a solid painting, what kind of putty should you choose?

Any putty is suitable for solid painting. Here the selection criterion will not be the type of finishing, but the ease of working with putty, drying speed and cleanliness of processing. The best and inexpensive option is acrylic putty, but other types can be used

What tool is used to apply the material?

If the processing area is large, use the usual finishing tools - a spatula, a grater, an emery net. For small and delicate work, they use appropriate tools, even homemade ones - for example, cutting and sharpening narrow strips of plastic.

What is the duration of intermediate (interlayer) drying?

This indicator is different for all types of putty. Detailed information can be found on the material packaging. It is important to keep in mind that minimum values are usually indicated. It is recommended to leave the layers longer to allow them to set properly.