Knauf tile adhesive will provide you with high-quality and durable repairs. It is used when covering walls and floors with ceramic tiles, porcelain stoneware, and natural stone.

Its technical characteristics ensure strong adhesion to the surface of elements weighing more than 45 kg/m2. Which brand of Knauf glue is better to choose, and for which surface, how to calculate, dilute and use it, as well as reviews from craftsmen, read in our article.

Pros and cons

What people love about the Knauf adhesive composition is its ability to connect tiles to a wide variety of substrates, including concrete, brick, cement, and stone. The cladding adheres well to moisture-resistant materials, plasterboard, and gypsum fiber boards.

The advantages of Knauf tile adhesive include the following:

- Simple mixing technology. It is enough to follow simple instructions to get a high-quality solution that is easy to apply.

- Ease of use. The paste-like consistency prevents the glue from flowing off vertical surfaces; it lays down in an even, thin layer.

- Increased strength. This ensures reliable fixation and extends service life under medium and intense loads.

- Long viability. After preparation, there will be enough time for leisurely work, it is possible to adjust each tile.

- Good resistance to frost. The adhesive mixture can withstand about 27 freezing cycles.

- Increased resistance to stress after complete hardening after a week.

- Versatility. Application for mosaic, porcelain tiles, stone, granite and others.

The Knauf line includes several adhesive compositions with distinctive properties, so you can choose the most suitable one for individual jobs. Each glue fits perfectly, while perfectly hiding minor defects and allowing you to correct the position. Knauf makes the surface monolithic, resistant to moisture.

Reference! The characteristics of the adhesive allow it to be used in rooms with high humidity, for heated floors and on the street side. The composition has waterproofing properties, therefore it is combined with mineral and hygroscopic bases.

The glue has no significant disadvantages.

It is worth noting that for good adhesion, you need to be responsible in preparing the surface before applying the composition. It is also recommended to use it in certain conditions - at 20-25 degrees.

Product Features

Knauf products are produced by a domestic manufacturer, therefore they have an affordable price and are popular among professionals and amateurs. The scope of application is quite wide. Knauf tile adhesive is used indoors and outdoors for porcelain tiles and ceramics on various substrates, including tongue-and-groove slabs.

Reference! The finished mixture has a gray tint, is thick, with minimal fluidity.

The key feature of the composition is the strong connection of heavy dies, and not everyone, even expensive foreign mixtures, can cope with this task. This characteristic appears due to its good composition. The glue contains fine sand and high-quality Portland cement. There are also auxiliary components that provide a number of properties - moisture repellence, resistance to different temperatures.

What’s also good is that Knauf glue provides protection against the formation of mold and mildew. The product has quality certificates and meets all existing standards.

Distinctive characteristics of the Knauf adhesive composition:

- Versatility - good for use in insulation and finishing.

- Great for working with large and heavy tiles.

- Excellent adhesion to various surfaces.

- Convenient, uniform application in a small layer, resulting in minimal consumption.

Reference! The main area of use is laying moisture-absorbing slabs on flat bases.

To ensure reliable attachment to gypsum and surfaces in contact with liquid, high-quality processing of the base is necessary. The glue perfectly connects polystyrene, mineral wool, glass wool, polystyrene foam, and polyurethane.

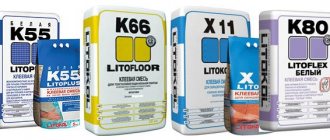

Varieties

The Knauf line of adhesives is represented by the following mixtures:

- Flex.

- Flizen Plus.

- Fliesen.

- Marble.

The universal and most popular glue is Fliesen. It can be purchased in packages of 5 and 25 kilograms. It is not designed for specialized installation, so it is distributed in a thin, uniform layer.

It is recommended to use a product for porous ceramics with the ability to absorb moisture. Can also be used for porcelain stoneware with moisture absorption from 5%.

Knauf Fliesen can be used for substrates such as concrete, plasterboard, plaster, screed. The approximate consumption of this mixture is about 3.5-4.5 kilograms. The cost for a 25-kilogram bag is about 290 rubles.

Key features of Flizen universal glue:

- Used for external and internal cladding and insulation.

- Does not contain elements toxic to humans.

- Has an improved level of grip on dissimilar surfaces.

- Provides easy operation due to its elastic structure.

- Not suitable for heavy dimensional tiles.

- Not recommended for tiles with low moisture absorption.

How to calculate consumption?

The consumption of the composition depends on the thickness of the applied layer when finishing, so the thinner it is, the larger the area it will be enough for. But at the same time, follow the general requirements when performing work. The most important thing is the thickness of the mounting layer, which should be at least 4 and no more than 8 mm, depending on the type of material.

For Knauf-Fliesen mixtures, the layer thickness is 4-8 mm, respectively, the consumption will be 1.7-2.9 kg/m2. For Knauf-Fliesen Plus and Knauf-Marble compositions it will be from 2.2 to 2.7 kg/m2 with a layer thickness of 6-10 mm

Analogues in the Knauf line

An improved version of Flizen Plus is prepared on the basis of cement with the addition of a mineral and binder component. Suitable for outdoor and indoor use on ceramics, stone, porcelain tiles on brick and concrete. Connects well with plaster, gypsum fiber board, gypsum board. Sold in packs of 25 kilograms. The average cost is 350 rubles.

The advantages of Flizen Plus can be set aside for a long time to adjust the position of the slabs. You can correct the cladding after gluing within 10 minutes. The disadvantages include a relatively high price with significant material consumption - up to 3 kilograms.

Elastic adhesive Knauf Flex is used for external and internal work, including the basement of the room. Created for different types of tiles, stone, porcelain stoneware. Can be used for horizontal and vertical bases. Suitable for heated floors.

Positive aspects of Knauf Flex:

- Moisture resistant.

- Various areas of use: for bathrooms, loggias, basements.

- Fastening on various bases - concrete, brick, stone, old tiles.

- Use after preparation for 3 hours.

- Service life – 12 months.

One of the disadvantages of this type of glue is that it takes a very long time to harden. To obtain maximum strength for subsequent surface loading, at least 7 days must pass.

Also, glue can only be applied to a pre-treated, flat surface. The cost for a 25-kilogram bag is 600 rubles.

Knauf Marble consists of polymers and auxiliary substances. Used for granite, stone and marble. It can also be used to attach mosaics and translucent tiles. The price is affordable - about 500 rubles for 25 kilograms of glue.

Glue selection

The choice of a specific tile adhesive is based primarily on the type of substrate. For the entire line of the Knauf brand, it can be concrete, gypsum plasterboard, gypsum board, PGP slabs, brick, ASG.

When working with various surfaces, it is important to pre-impregnate with high-penetration primers. This is especially true for porous substrates, for example, gas silicate or other material. The German brand produces a number of adhesive mixtures for work in different conditions: Fliesen, Fliesen Plus, Flex and Marble.

Each of them has characteristics and is designed to perform work in certain conditions. For example, the Knauf-Fliesen composition is not suitable for the base, but is used externally, while the Knauf-Fliesen Plus is completely universal.

Fliesen

A popular tile adhesive designed to perform a range of tasks when finishing walls and floors both inside and outside buildings. It has acceptable physical properties, sufficient elasticity and pliability. Apply a thin layer of 4 mm.

Recommended for working with tiles with a maximum size of 300x300 mm when laying them on the wall. It has moderate strength and optimal adhesion to concrete - no more than 0.6 MPa. Suitable for making screeds with a minimum layer thickness of 2 mm on surfaces not equipped with forced heating.

We also recommend watching - Knauf Fliesen tile adhesive: application features

Fliesen plus

Knauf universal tile adhesive can be used equally both inside and outside buildings. At the same time, it is also used for finishing the base part, as it has increased resistance to water and is able to withstand up to 75 cycles of complete freezing, maintaining the strength of the finish. It is easy to apply with a spatula and has acceptable elasticity.

Flex

A specialized adhesive composition, which is intended for installation of tiles with dimensions greater than 60x60 cm and a weight of 50 kg per 1 m2.

It contains special substances that greatly enhance adhesion, providing more reliable fixation of facing coatings.

Used with equal efficiency inside and outside buildings. Creates a durable mounting layer that is resistant to UV, physical influences and atmospheric factors.

Marble

A special dry mixture with white adhesive properties. Used to perform a wide range of tasks when installing heavy ceramic, marble, granite tiles and natural stone cladding.

It is used equally effectively both for finishing walls and for plinths. Able to withstand up to 75 cycles of complete freezing without loss of basic adhesive properties.

Specifications

Before purchasing an adhesive for a specific purpose, you need to carefully read the characteristics in order to avoid problems during the cladding process.

Technical features of the universal composition Fliesen:

- Moisture absorption coefficient up to 3%.

- Fast setting - no more than 2 days for a strong connection.

- Excellent adhesion to concrete - from 0.5 MPa.

- Economical consumption - up to 2.5 kilograms per meter.

- Resistance to temperatures from -45 to 80 degrees.

- Adjustment time after installation is 10 minutes.

On video: Rules for preparing Knauf glue.

Dilution of the mixture

Dry powder is mixed with water strictly in proportion. 250-300 ml of water is added to 1 kg of bulk mixture. A 25 kg paper bag requires 7-7.5 liters of water.

Water is poured into the container, the powder is poured out, and the resulting composition is thoroughly mixed with a construction mixer or a drill with an attachment. You need to stir until the solution in the container becomes homogeneous without lumps. Afterwards, the container is covered with a lid. After 5 min. When idle, the mixture is mixed again and is completely ready for use.

The prepared solution does not lose its properties for 2.5 hours. During this time, it is necessary to have time to work out the entire volume and only then begin a new batch.

If the mixture has thickened a little, you can mix it with a mixer, but diluting it with water is not recommended.

Important instructions for use

The work begins with preparing the base, without which the quality of the masonry deteriorates.

Stages of preparatory work:

- The surface is cleaned of dirt and dust, greasy stains, stains, and old plaster are removed.

2. The base is well dried and primed. Afterwards it takes some time to dry.

3. The glue is prepared according to the instructions, left for 15 minutes, then mixed again.

4. Apply the mixture with a notched trowel.

Reference! Within 10 minutes after fixing the tile, you can change its position. The finished mixture is suitable for use for 1.5 hours, some - 3 hours, which can be found in the instructions.

The glue is mixed at the rate of 1.5 liters of liquid per 5 kg of dry powder. Preparation is done using a mixer. The readiness of the solution is indicated by a homogeneous consistency without lumps. It is recommended to do the preparation in 2 stages. First mix and leave for 10-15 minutes. Then mix again, adding water or mixture if necessary, to obtain the desired consistency that will be convenient to work with.

Reference! When the calculation work will take more than 3 hours, you should prepare the mixture in small portions, because after this period the solution becomes unsuitable for gluing.

Features of applying Knauf glue to the prepared base:

- A spatula with teeth is used. First, the mixture is applied with a smooth spatula, then distributed with a serrated spatula. The tool should be held at an angle of 60 degrees.

- For exterior finishing and with a corrugated cladding texture, glue is also applied to the inside of the tile.

- After fixation, the coupling will occur within 10 minutes, during which time the position will be adjusted.

- If after applying the glue a crust has time to form, the layer is removed and a fresh solution is applied for high-quality adhesion.

Reference! When working with glue, you need to use gloves and protect your eyes from getting the solution. If this happens, you need to rinse the skin and mucous membranes under running water. In case of irritation, seek medical attention.

After work, all tools are washed in warm water. Remains of glue should be removed from the surface before it dries, because after that you will have to use special means.

Advantages

- Can be used with a variety of substrates and combines well with insulating materials.

- Various types of tiles and mosaics are glued. Due to the gray color it is not recommended for clear or glass cladding.

- A non-professional can work with the composition; to prepare it, it is enough to accurately follow all the instructions.

- Low fluidity allows Flizen to be used for gluing cladding to vertical structures.

- The mixture levels surfaces with height differences of up to 0.2 cm, due to which the number of repairs is significantly reduced.

- Forms a monolithic surface, correcting it, hiding microcracks in the screed.

- The adhesive joint has a long service life; the tiles will last a long time on any surfaces in heated, unheated rooms and outdoors.

- The seam is not affected by intense, dynamic loads, it does not deteriorate or collapse.

- The finished mixture is very plastic, which is why there is no need to soak the tiles before gluing.

- Sold in convenient packaging. Packaged in packs of 25 kg. The price is affordable, unlike analogues from other manufacturers.

Reviews from masters and amateurs

Knauf glue is popular due to its low consumption and versatility. It is great for professional work and DIY repairs. All information about the product can be read on the packaging, as well as on the manufacturer’s official website.

Working with Knauf adhesive mixture is pleasant and simple. The manufacturer cares about the quality of its product, which is why it remains in demand on the building materials market for many years.

Knauf tile adhesive: features and application rules (2 videos)

Varieties of Knauf tile adhesive (15 photos)

Surface preparation

The compliance of the ambient temperature with the optimal temperature regime specified in the instructions is checked. In hot weather, the glue dries quickly, and at temperatures below +5 °C it thickens or freezes.

- The base is cleaned of dust and dirt.

- The form lubricant is wiped off the concrete surface.

- The base is degreased with household chemicals or solvents.

- The old finish is removed.

- Water-based emulsion or any paint that is not resistant to water is washed off, water-resistant paints and varnishes are sanded off.

- The surface is dried; wet substrates cannot be coated with tile mixture.

- When installing a heated floor, it is disconnected from the power supply one day before the start of preparatory work.

- The gypsum screed and areas exposed to water are covered with waterproofing.

- If the thickness of the plaster on the base exceeds 1 cm, the excess is removed.

- Strongly absorbent substrates are primed. It is better to use soil from the same manufacturer.

For highly porous surfaces - Knauf Grundirmittel, for moderately porous - KNAUF Tiefengrund.