Peculiarities

Unis tile adhesive contains cement, chemical components, and mineral additives. It shows all its best sides when temperatures vary from -5 to +30. It is convenient to work with a properly prepared solution; it retains its best properties for 3-5 hours. After application it remains flexible and waterproof.

After installation using this glue, adjustments can be made within 10-20 minutes. Complete hardening of the composition occurs within 24 hours, after which the base can be loaded. Glue from the Yunis company has optimal characteristics for use in a wide variety of conditions. It is only important to choose the appropriate glue for the purpose.

Connecting to the network is an alternative method

We took this cable:

The heating conductor (3) and the conductors (1 and 2), through which current flows, cannot be short-circuited

- This is what the end looks like.

- Cleaned it up.

- Using this terminal block I connected it to the wire.

The opposite side must be insulated. It is prohibited to bridge the conductors. And we must ensure that they do not bridge in any environment. You can buy a special plug for this. They cost around 300 rubles apiece. But you can do everything yourself using improvised means, such as heat-shrink tubing and a heat gun.

- Thermal gun.

- Heat-shrink tubing.

- End of insulated cable.

The plug is made as follows. We put on the heat shrink tube. We warm it up with a hairdryer. Afterwards we fill the entire structure with a heat gun.

The same procedure can be done with the terminal block to which the cable power is connected. You can also wrap everything with electrical tape just in case. If operating conditions are harsh.

Advantages and disadvantages

The key advantages of Eunice compositions will be good adhesive properties and fairly high strength. The adhesive provides reliable adhesion to almost any substrate on which tiles are laid. It retains its characteristics at low and high temperatures. However, there are restrictions - from -5 to +30 degrees.

Reference! Certain types of glue are frost-resistant and can be used in harsh climatic conditions.

Compositions from Eunice are environmentally friendly, as confirmed by relevant certificates. The glue can be used in medical institutions, schools, and kindergartens. The advantage will be the ease of use of the glue, and, importantly, it has low consumption. It is equal to 2-3.5 kg per square meter.

The disadvantages should be considered for each individual composition, because the Eunice series of products has unique technical characteristics and application features.

Consumption of adhesive composition per 1 m2

To calculate glue consumption, you need to read the manufacturer's instructions on the packaging. The average is 3.6 kilograms per square meter, taking into account that the layer thickness will be 3 mm. If you plan to make a thicker layer to match the size of the tile, then you need to make a calculation based on these data.

When working, you need to make sure that the composition does not get into your eyes; you can resort to wearing glasses, or do the work carefully. The mixture should be stored out of the reach of children.

When working, you need to make sure that the composition does not get into your eyes; you can resort to wearing glasses, or do the work carefully.

Unis 2000 tile adhesive is a domestic solution that allows you to get excellent results. It stands out for its high strength of joining tiles to different substrates. Among analogues, it occupies a leading position, being a strong competitor, to Hercules and Ceresit products. The glue is easy to work with, it is safe for health, and can be used in children's rooms and for tiling work, withstanding environmental influences for many years.

Technical features

Characteristics using the example of Unis Plus (the most universal composition):

- Temperature conditions for performing work are from -5 to +30.

- Consumption - about 3 kg per meter.

- Allowable correction time is 10 minutes.

- Complete hardening – 24 hours.

- Packaging: 5.25 kg.

- Frost resistance – from 35 cycles.

- Application thickness (optimal) – up to 15 mm.

- Mixing: 5 parts mixture to 1 part liquid.

Product advantages

Among the advantages of this product are:

- richness of assortment (for different types of surfaces);

- convenient packages of 25 kg;

- durability and efficiency;

- the glue is easy to dilute and apply;

- For each type of product, instructions for use are attached, which greatly facilitates working with this composition;

- The glue is manufactured in accordance with GOST and has all certificates of conformity.

Unis plus is a high-quality product at an affordable price, suitable for covering a variety of surfaces. The main thing is to follow the instructions for use, and the end result will please the eye for many years.

A comparison of tile adhesives from different manufacturers is clearly presented in the video.

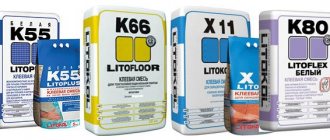

Types of adhesive mixtures from Eunice

The company's universal products include the popular Plus glue. It can be used for indoor and outdoor use. Works well when covering uneven surfaces. However, it is not recommended to use it for swimming pools, stoves, and chimneys.

Hi Tech glue is the most progressive, prepared using new technologies. It can be used for cladding from top to bottom, starting from the ceiling. After mixing, its properties last for 5 hours. Eunice Granite tile adhesive is prepared specifically for working with natural stone and granite. It is characterized by excellent strength, which allows it to be subjected to heavy operating loads.

Especially for surfaces in contact with water, there is Eunice Belfast tile adhesive. It is ideal for marble, mosaic, transparent tiles.

Plus

The distinctive features of Unis Plus glue allow you to purchase it for different types of work. It is often used for tiles, porcelain tiles, stone, mosaics.

The mixture is distinguished by improved strength and water resistance. It is recommended to use for interior and exterior work, especially when installing heated floors. Can be used for installation on old base.

Advice! It is necessary to use tile adhesive Plus on a non-deformable coating, for example, concrete, plaster, brick or cement. It's better if it's strong enough.

2000

Unis 2000 tile adhesive is intended for tiles and porcelain tiles up to 60 x 60. Can be used for tiling inside and outside. The composition can serve as a leveling material. It qualitatively fills unevenness and roughness. Used on cement and gypsum.

Distinctive properties of Yunis 2000 glue:

- The optimal thickness for applying the seam will be from 3 to 15 mm.

- Sold in 5 and 25 kg.

- You can work with the material for 10 minutes after application.

- Duration of operation is 3 years.

- Can be used at temperatures from -50 to +50.

21

Adhesive Eunice 21 is used for laying tiles on floors and walls. Suitable for use in rooms with high humidity levels. Can be used for porcelain tiles up to 30 cm.

Reference! Yunis 21, which is produced by a Moscow plant, can be used exclusively for indoor cladding.

Technical features of the composition called Unis 21:

- Layer – up to 15 mm.

- Frost resistance – more than 35 cycles.

- Drying time - 24 hours.

- The working period after applying the mixture is 15 minutes.

- Operating conditions – from -50 to +50 degrees.

- Packaging – 5 and 25 kg.

Hi Tech

This brand produces glue from Eunice specifically for complex work. With this composition it is possible to carry out installation from the ceiling, starting from top to bottom.

Material consumption is average, varying from 2 to 4 kg per square meter. The glue is prepared in the standard way - take 1 part liquid for 5 parts of the dry mixture. The permissible correction period after applying the composition is 15 minutes. Approximate layer – up to 15 mm. The product is available in 15 kg bags. The prepared mixture can be used for 5 hours.

Reference! One bag of the mixture will be enough to lay 7 meters.

Granite

Eunice Granite is prepared for large granite and natural flooring stone. It can be used for floors, walls, plinths. Can be used for heated floors and for application to old material. The glue is a thick mass, which prevents it from sliding off the walls. It has a relatively high degree of adhesion.

Other characteristics of Eunice glue intended for granite:

- To prepare, you need to dilute 1 part water to 5.5 parts of the mixture.

- Standard consumption – up to 3.5 kg per meter.

- After application, you can adjust the position within 10 minutes.

- The initial hardening of the solution occurs in 25 minutes.

- It is permissible to use the coating one day after work.

- Sold in bags of 25 kg.

Belfix

Belfix tile adhesive from Eunice is used for cladding in cases where standard cement mixture is not suitable. This composition is a white mass. It is suitable for natural stone, marble, mosaic. It features improved elasticity and resistance to sub-zero temperatures. Belfix is often used for walls, floors, swimming pools, and also heated floors. The glue is suitable in conditions with high humidity. It is used inside and outside, and also as a grout for joints.

Features of Belfix Unis:

- Prepared from 5 parts dry composition and 1 part liquid.

- Permissible temperature is from -50 to +70 degrees.

- The base can be loaded after 24 hours.

- Standard consumption - up to 3.5 kg per square meter.

- The layer thickness does not exceed 10 mm.

- The prepared mixture is good for 3 hours.

- Errors can be corrected within 15 minutes.

Fix

Fix is not so common; you rarely see it on the shelves of hardware stores. Its feature will be low cost. According to professionals, this glue is not the most reliable. It is usually used for kitchens, terraces, balconies, facades, baths.

Features of Fix glue from Eunice:

- Allowable thickness is up to 15 mm.

- Mixing is standard - 5 parts of mixture per part of liquid.

- Sold in 25 kg packs.

- Correction of the position is acceptable within 10 minutes.

- Loading is permissible after 24 hours.

Pool

Pool adhesive is made for ceramics, mosaics, stone, and is used primarily for swimming pools and water tanks, as well as in conditions with high humidity levels. Suitable for external and internal work. Can also be used for heated floors and on old tiles.

Features of the Pool composition:

- Mixing is standard - 5 parts of the mixture per part of the liquid.

- Correction of the plates is carried out within 10 minutes.

- It is permissible to load the surface 24 hours after work.

- The mixture retains its properties for 3 hours.

Horizon

Horizon product is used as liquid linoleum. It is used for self-leveling floors, as the mixture creates a seamless coating. Horizon is a universal product; it can level the surface in places where there is a difference in height.

The poured composition hardens within 3 hours. The leveler withstands moisture and withstands mechanical loads well. The mixture can also be used to install heated floors.

Warm glue

Warm Adhesive is used for strengthening and insulation. Suitable for glass wool, reinforcing layer, tiles, porcelain tiles, stone. It has proven itself well for finishing stoves and fireplaces. It is characterized by high elasticity.

Rapido

A new product from Eunice is Rapido adhesive for laying all types of ceramic and clinker tiles, as well as natural stone and porcelain tiles up to 60x60 cm in size. Can be used in rooms with any humidity. Withstands cold and heat. It is used for cladding facades of buildings, as well as indoors. Suitable for installing heated floors, it can be applied to old tiles.

Features of the Rapido composition from Eunice:

- Temperature conditions – from -40 to +70 degrees.

- Frost resistance – from 100 cycles.

- Correction after application of the substance is possible within 10 minutes.

- With a layer thickness of up to 6 mm, the surface can be loaded after 3 hours.

- Packaged in 25 kg packs.

- Layer – up to 10 mm.

- The recommended temperature for work is from +5 to +30 degrees.

U-100

The highly elastic adhesive U-100 is prepared for stone, ceramics, clinker tiles, porcelain tiles of any format. The adhesive can withstand heavy loads and can be used for cladding plinths, walls and floors. Often used in industrial and administrative premises, as well as for cladding parking lots, subways, and underground passages.

Distinctive features:

- Suitable for different types of tiles.

- Features increased elasticity.

- Well suited for high traffic areas.

- Suitable for industrial and residential premises.

- The operating temperature range is from -60 to +120 degrees.

- Laying tiles is recommended in conditions from +5 to +30 degrees.

- You can adjust the tiles for another hour after application.

- Frost resistance – from 100 cycles.

Maxiflex

Another new product is the super-elastic adhesive Maxiflex for deformable substrates. Can be used for any type of porcelain stoneware, ceramics, natural and artificial stone. Suitable for interior and exterior work. Suitable for terraces, balconies, landings, plinths.

Technical characteristics of the Maxiflex composition:

- Consumption – up to 1.25 kg per square meter.

- Packaged in 20 kg packs.

- Withstands 100 freezing cycles.

- You can load the surface 24 hours after completing the work.

- Layer thickness – no more than 1 cm.

- Operating temperature – from -40 to +100 degrees.

Super Plus

Super Plus adhesive can be used for any type of tile up to 70 cm in size. Suitable for rooms with high humidity levels. Can be used for industrial purposes when increased loads are needed. Withstands deformation changes. It is also resistant to unstable temperatures.

Features of Super Plus:

- To prepare, you need to take 6 parts of the mixture to one part of water.

- Withstands from -40 to +80 degrees.

- Adjustment is possible within 20 minutes after applying the composition.

- Consumption – up to 1.4 kg per meter.

- Frost resistance – from 100 cycles.

- Packaged in 25 kg packs.

On video: Eunice Plus tile adhesive. Main features, advantages, characteristics.

General characteristics of the Ceresit line

Ceresit adhesive has the following distinctive characteristics:

- Waterproof. “Ceresite” does not allow moisture to pass through and is therefore used for gluing tiles in the bathroom.

- Frost resistance. Resistance to low temperatures allows this glue to be used not only indoors, but also outdoors.

- Possibility of application to deformed coatings. The adhesive does not have to be used on a perfectly smooth surface.

- Durability. Since Ceresit is made on a cement base, it does not deteriorate for decades.

Preparation

The coating is prepared as follows:

- Old material (screed or plaster) is removed.

- It is leveled, the permissible differences remain no more than 1 mm per meter. Defects more than 1 cm deep must be smoothed out with plaster. It is recommended to use a product from the manufacturer for this purpose - Standard, Silin or Teplon.

- To increase adhesion, notches are made every 50 mm in a checkerboard pattern.

- The surface is dried and treated with a degreaser.

- In rooms with high humidity, it is recommended to use Eunice Hydroplast insulation.

- The surface is treated twice to increase adhesion.

- Before work, tiles and bases do not need to be wetted.

Advice! It is recommended to work with compositions from Eunice at a temperature of +5-30 degrees and at a humidity of no more than 75%.

The base must be dry and free of grease before applying glue. Before work, you need to remove not only the old material, but also other visible contaminants that will interfere with normal adhesion.

Data collection - what is needed for calculations?

In each individual case, the consumption of tile adhesive is influenced by many factors:

- type of base;

- type of tile;

- type of adhesive composition;

- application technology and craftsmanship.

It should be understood that you should start calculating only after you have decided on the type of tile and the quality of the base. Making calculations offhand, without having basic values, is fraught with a shortage of materials or large surpluses.

Let's start from the foundation. There is such a thing as thin-layer laying - it is possible if the surface on which the glue will be applied is very well leveled and has differences of no more than 3 mm. In this case, the norm is 5 mm of glue thickness, this is enough to adhere the tile and the base. The standard mixture consumption in this case is up to 5 kg per 1 square meter.

The adhesive mixture can also be used to remove unevenness - this is cheaper and faster than pre-preparing the floor, for example, pouring a screed. For thick-layer installation, special compounds are needed that can even out differences of up to 30 mm. Thick-layer laying is also necessary if the tile on the reverse side has a pronounced corrugated structure.

To save glue per 1 m2, it is also necessary to prime the base. Many people neglect this stage, not wanting to spend money on buying primer, but in this case they overpay for the amount of glue used. Where will it be spent? The soil serves to fill the pores in the base and provide strong adhesion to the materials. Without primer, the base absorbs a lot of glue, especially if the choice of composition has not been optimized for a specific type of base. So, brick absorbs much more moisture and glue than drywall. That is why manufacturers offer different compositions for different surfaces.

Instructions for use

The mixture is prepared as follows:

- Prepare a clean container and mixing tools.

- The dry part is poured into a container and filled with water (in the proportions specified in the instructions).

- The solution is mixed for several minutes until the desired consistency is obtained.

- Afterwards, the solution should stand for a while, no more than 5 minutes, then it is mixed again.

- Hand tools and a drill at low speed can be used for mixing.

- The prepared mixture must be used within 3 hours (for individuals, 5 hours).

Reference! Failure to follow mixing instructions and incorrect proportions will affect the quality of the glue. Adhesion deteriorates and other properties change for the worse.

Rules for carrying the composition onto the base:

- Using a spatula, apply the composition to 3-15 mm, then level it with a spatula or grater.

- For porcelain stoneware and large slabs, the size of the teeth should be large, from 8 mm. The weight of the cladding should not exceed the permissible limit.

- The tile is pressed onto the applied composition. It is important to ensure that the glue is distributed evenly under it. It is necessary to prevent the appearance of voids. To get a good result, professionals advise fixing with wave-like movements.

- It is necessary to apply a small amount of glue so that during the application of the tiles other areas do not lose their viability (the time is indicated in the instructions, usually up to 20 minutes.)

- When working outdoors or for large slabs, you need to apply adhesive to the tiles as well.

- After tiling, you can adjust the position of the tile for another 20 minutes (less for some compositions).

- Only 24 hours after work can you start grouting and loading the surface.

- When installing a heated floor, it can be used after 28 days.

Correct mixing

The quality of the finished solution, as well as the completeness of the process, depend on the correctness of the procedure:

- Do not add water to the solution. In this case, many lumps appear that are difficult to stir. The actions should be reverse. First, water is poured into the container, then a little solution is added. It is advisable to use a mixer. The amount of water is chosen according to the manufacturer’s recommendation.

- The procedure of adding powder to water has another advantage. Not only is stirring faster, but it also creates 2 layers of solution. The top one is dense; consistency is assessed by it. The lower one is a little thinner, but it is brought to condition during the period that is spent on producing a solution from the surface.

Manufacturers of dry mixes emphasize that the solution should be mixed a second time. This is required not only to break up any lumps that have appeared, but also to restore consistency. The resulting composition sets quickly, but it must be left for the time indicated by the manufacturer (at least 5 minutes). And then the mixer is processed again. This is required to restore the consistency and maintain the properties of the solution for 20-60 minutes.

You should learn about the duration and speed of mixing from the manufacturer’s recommendations. Some indicate that you can breed by hand. Manufacturers record recipes for preparing mixtures. How to dilute Ceresit tile adhesive? The packaging indicates the water consumption per 1 kg of mixture.

Advice from professional craftsmen

In addition to the instructions specified for each product, you must follow safety rules and general recommendations for carrying out work. If you have any questions, it is better to seek advice from a specialist or directly to the manufacturer.

When working with glue, professionals give the following recommendations:

- It is better to stir the composition manually or with a mixer at low speed. The more actively you mix the glue, the shorter its pot life.

- The wider the tile, the longer the trowel teeth should be.

- For a better appearance, instead of plastic crosses, you can use clips specifically designed for this purpose. This way the seams will be identical.

- You should never apply glue to the entire surface, as after 20 minutes it will become unsuitable for gluing tiles. You need to calculate in such a way that you can cover the area in 15 minutes.

Recommendations

Do not rush while stirring. It is necessary to accurately assess the consistency of the solution. To do this, dial a little on the trowel, and then tilt the tool. If the solution falls off in pieces, then you need to increase the amount of water.

The amount of liquid should be increased only when mixing the glue for the first time. After 2 mixings, if the glue thickens or begins to clump during work, then you should not add water. It is advisable to use a mixer to mix the solution. This is necessary to restore its consistency for a while, which will help finish the job.

If the solution flows or slides, then some time is needed for partial setting, and the next portion is prepared with the required amount of liquid. If the adhesive composition holds securely, then the mixture can be used.

Reviews

Customers like Eunice's tile adhesive. Various mixtures are popular among craftsmen and amateurs. The glue is easy to use, has low consumption, and the price fully corresponds to the quality. Some products still receive more good reviews because they are universal. Glue is sold in bags of 5 and 25 kg, so you can always calculate the required amount.

Its advantages include accessibility; glue can be bought at almost any hardware store. However, experienced craftsmen on the forums note that now the glue from Eunice has changed its composition, which is why the quality has become worse.

Important advantages include a strong connection and good resistance to moisture. It is also good that after mixing it remains in working condition for a relatively long time - 3-5 hours.

Eunice glue can be purchased for a variety of purposes, but it is important to make the right choice. The compositions should be selected taking into account the size of the tile, weather conditions, and base material. Universal glue is not always suitable; it is better to take narrowly targeted products.

Eunice tile adhesive (2 videos)

Clay Eunice (29 photos)

Preparation of glue

It is important to maintain proportions. How to dilute tile adhesive? The process may vary depending on the product. The store-bought glue contains:

- cement;

- additives: minerals and polymers;

- sand;

- plasticizer

How to dilute tile adhesive without a mixer? Although there is a plasticizer in the mixture, it can be purchased separately. A separately purchased plasticizer is used instead of water or mixed with water in an amount of 50% to 50%. The finished consistency has enhanced properties in comparison with the mixture obtained with water. The sand must be dry and sifted to prevent lumps.

Some manufacturers create products from slaked lime. It has plasticizer properties. As a rule, cement grade M-400 is used. It can withstand a load of 400 kg/cm2 area. To independently prepare tile adhesive, you must use M-500 or M-600.

Methods for checking how long floor tiles dry after installation

There is no way to determine if the floor surface is dry.

You can only try to detach one tile. If the tile moves, then the required drying time has not yet passed. In this case, you shouldn’t walk, otherwise you may not give the tile a chance to stick at all. But you can identify the tiles that are not stuck to the floor at all or which have come off. To do this, you need to knock on the tile a little. A duller sound indicates voids.

What to do with loose tiles:

- With maximum care, separate it from the base;

- Clean off any remaining adhesive;

- Using new glue, reattach the tile.

In this case, you must follow the instructions exactly and do not walk on the tiles ahead of time. Even if you are absolutely sure that the floor is dry, it is better to wait another half a day. After this, you can begin further work with the flooring, jointing the seams.

Expert's answer: how long does it take to dry tiles on the floor after laying video

No one wants the outcome of a long and labor-intensive process to be spoiled by one detail. You need to remember that walking on wet floors is prohibited.

At the same time, it is important to comply with all microclimate parameters and instructions so that the drying process of the tiles goes quickly and without problems.

To find out how long it will take vseproplitku.ru after its installation, the first thing you need to do is read the information indicated on the packaging of the tile adhesive. As a rule, the manufacturer always indicates in the instructions how long the adhesive composition takes to dry. In this case, the drying speed depends on the chemical composition, ambient temperature, humidity level in the room and the type of glue.

There are basic parameters for the characteristics of the adhesive mixture, which is used under normal conditions. Normal conditions mean a temperature of 20-22 degrees and air humidity of no more than 60 percent.

How long does it take for tiles to dry in rooms with unfavorable conditions?

Unfavorable conditions include low temperature and high humidity. If the room is cold, the tiles take a long time to dry. This process can take forever. In this case, the quality of the connection deteriorates significantly.

At temperatures below 5 degrees, the liquid in the adhesive mixture begins to freeze. This will allow the glue to simply harden but not dry out. With such a deviation from the norm, even quick-drying mixtures will not help.

What to do at low indoor temperatures:

- Even after a day or more, you cannot move on the tiled surface. Otherwise, the tiles will begin to crack and deteriorate. The liquid, which turns into ice, will begin to expand and deform the tile.

- Before installation, the glue must be heated to the required temperature. You should also heat the floor, not the air in the room. Heat guns are provided for this purpose.

- After achieving the desired parameters, it is necessary to strictly maintain the optimal temperature.

If such conditions are provided, the tile will harden after a couple of days.

But another important problem is high humidity. If this indicator is elevated, then you can try to lower it by heating the room

But before the new tiles are installed, the surface must be allowed to dry. It is worth considering that the glue quickly absorbs liquid. Even after drying, it can deform the tiles.

How to speed up the process

You should not resort to radical measures to quickly dry the tile material in order to put the plane into operation. Rapid drying will lead to peeling of the tiles and the appearance of defects.

For more gentle acceleration, install a fan near the open door of the room. The power of the wind flow should be minimal.

To speed up the hardening process of the mortar layer, the “warm floor” system is not used. It will lead to cracking of the facing plane.

The main thing is that the drying process proceeds favorably and that the ventilation system is in good working order. If it does not work or is absent, then the door to the room should always be open.

Consumers about Unis products

To objectively evaluate the advantages and disadvantages of Eunice dry mixes, we collected reviews from consumers who used glue from a domestic manufacturer:

- To finish the walls in the bathroom I used Eunice Basin glue. I laid tiles on old tiles and was pleased with the result. So far, all the tiles are in place, not a single one has come loose;

- I was not satisfied with the quality of the glue we produced. Just yesterday I was almost hit by a tile falling off the wall. True, friends who used the same glue claim that I could have gotten a fake. I don’t know if this is true or not, but I’m unlikely to risk using glue for Unis again;

- I have been working as a builder for more than 10 years and during this time I have become convinced of the quality of cement-based adhesives. Among the entire line of Unis products, it seems to me that the best option is Unis Plus.