Nowadays, machine-applied gypsum plaster is increasingly in demand and popularity.

Construction teams more often offer mechanized application, instead of the manual application we are used to. When asked why it is better than plaster intended for manual application, most builders find it difficult to answer. This is what scares customers. Everyone knows that plastering walls mechanically (mechanized) is much faster than conventional manual application. How is this result achieved? Maybe the quality is worse? In this article we will take a closer look at hand- and machine-applied plaster. Let's compare them and draw conclusions.

The essence of machine plaster

What is the difference between machine-applied plaster and manual labor? Widespread automation and mechanization of production processes has not bypassed plastering work. The physical labor of applying the mortar was taken over by the plastering station.

To work, water is poured into it and dry plaster mixture is poured. Special augers thoroughly wipe dry components and feed them into a mixing container, from where the mixture is supplied to the wall under high pressure through a hose and a mortar gun.

To prevent the solution from sticking to the working surfaces of the machine (tank walls and sleeve), special additives are added to it. The station operates only on factory-prepared dry mixtures. Gypsum plasters are used indoors, cement-sand mixtures are used outside.

This distribution is understandable:

- Plaster, where one of the components is gypsum, is not used outdoors;

- Cement-sand mixtures are much heavier than gypsum mortars. Therefore, it is much more difficult for a plastering machine to work with them, as a result of which the plaster feeding speed drops by 1.5-2 times.

At the same time, the wear of the screws increases, the replacement of which results in significant sums. Naturally, no one will plaster the premises with cement mortar.

Advantages and disadvantages of machine plaster

Craftsmen working at plastering stations usually note only positive aspects in the mechanized application of mortar:

- Lack of heavy physical labor;

- The speed of work execution increases by 3-4 times;

- Materials for machine application of plaster are cheaper than similar mixtures for manual work;

- The consumption of materials is less than when plastering by hand;

- The cost of the work itself is almost two times lower (from 220 rubles/m2 when working with a station and 550 rubles/m2 when applying 3 layers with a trowel);

- The quality of work is higher:

- the mixture is supplied under high pressure, which promotes better adhesion of the plaster to the wall;

- the plaster solution is more uniform in composition, as it is ground with two augers, as a result of which the surface of the plaster practically does not crack;

- errors in preparing the mixture are eliminated - its consistency is programmed into the station.

Professionals do not see any shortcomings. In their opinion, the question “which plaster is better, manual or mechanized” should not be on the agenda at all.

However, if you carefully study the operating technology of the plastering station, you can find both direct and relative disadvantages:

- The high noise level, which precludes work at night, is a relative disadvantage, since during the day the neighbors will understand and tolerate it;

- Work on three-phase current (available only in apartments with electric stoves);

- Long drying period for plaster - 7-8 days;

- A lot of time is spent on servicing the station at the beginning and end of the shift, which will certainly be reflected in the price of work for different volumes of plaster (preparing the station for work according to the regulations should last 2 hours and another 2 hours are spent on washing the equipment after its completion);

- You cannot plaster the walls in the bathroom and kitchen under the tiles with plaster. Manufacturers of dry mortars write on the packaging that the mixtures can be applied to walls in damp rooms, including the bathroom. But nowhere is it stated that tiles can be laid on such plaster. Practice shows that it breaks and lags behind on gypsum plaster. The plasterers of the machine station completed the work and left, and what happened to the tiles later, they may not know;

- Mandatory installation of plaster corners in internal corners, which increases the cost of work.

Perforated plaster corner.

Required tools and materials

In order for a beginner to perform plastering work, you need to stock up on all the necessary materials. As a rule, the following are used for plastering walls:

- spatulas of various sizes;

- trowel;

- falcon;

- grater;

- rule;

- level;

- tassels;

- clean container;

- drill mixer;

These tools will be useful to the plasterer during the work process.

Which is better, machine or hand plastering?

The above advantages of mechanical plastering would seem to unambiguously and unconditionally bury the old method of plastering - manual. However, in order to understand without prejudice which plaster is better, machine or manual, it is necessary to conduct a comparative analysis. Only then can you see the difference between these methods.

Since we are talking about individual customers here, we will simultaneously consider an individual house and apartment, that is, orders for work from 50 m2 to 250 m2.

- In terms of price, a dry mixture for plastering stations is cheaper than a similar one for working with a trowel. It sounds convincing and at the same time corresponds to the truth. But who said that when manual plastering, gypsum-based mixtures will be used? They are very inconvenient to work with and costly. The use of cement, sand and a concrete mixer leads to the fact that materials cost 2-3 times less when done manually. And the thicker the plaster layer, the more noticeable the difference.

- Indeed, when using dry mortar when operating a machine station, 3 kg of plaster is saved per 1 m2 (consumption 13 kg versus 16 kg, respectively). But when replacing it with cement-sand plaster, this advantage disappears due to the low price of the plaster mixture.

- The quality of work is higher. The difference between machine plaster and manual plaster in the area of plaster quality is imaginary. If technology is followed, there is no difference in quality. The problem of more intense surface cracking in cement plaster is solved with the help of fiberglass fiber. Its use more effectively keeps the plaster layer from shrinking and cracking than in gypsum mortar applied mechanically.

- Only by hand can you plaster the bathroom and toilet due to the gypsum mortar. The best option is to entrust this work to a tiler, so that there are no subsequent problems with the quality of the laid tiles - they will not shift the blame onto each other.

As we can see, the advantages of plastering stations have not yet been discovered. Perhaps they are included in the cost of the work, which is often the decisive argument.

Features of plastering work using a mechanized method inside a building

An automatic machine used for plastering walls implies differences in the methods of applying the mixture to different surfaces. For example, for ceilings and walls, the coating process has some features.

Initially, leveling the ceiling is practically no different from similar actions with walls:

- putty;

- plaster.

But, for walls, the frame method is often used - irregularities are covered with sheets of plasterboard or other suitable material. This option is not suitable for ceilings, since it significantly reduces the height of the room, which is especially noticeable with wall heights of up to 2.7 meters.

Advice! For rooms with high ceilings, it is possible to use the frame method, but it is necessary to accurately calculate the amount of shrinkage in the height of the room.

Which is cheaper?

Prices for machine plastering work start from 220 rubles/m2 (data for St. Petersburg), for manual plastering - from 250-300 rubles/m2 for the first layer due to the need for preparatory work and about 550 rubles/m2 when applying 3 layers.

At first glance, everything is obvious here. But it's not that simple. If everything is clear with the price tag of plasterers with a trowel, then on the other side it is formed on the basis of many factors.

1. The specified price applies to the volume of work from 2,000 m2 or more. As the volume decreases, the cost of plastering work increases. The customer may object - the machine station will complete the work in 5-6 hours. I will pay for them and win. But important points are missing here:

- It takes time to prepare the surface and install beacons. These will be included in the price;

- Unplastered slopes remain - they are done only by hand. They are not and cannot be in the price list. It will not be possible to invite someone from outside to do this work - professionals always refuse, since there is a lot of hassle and little money. Masters of mechanized plastering charge 1.5-2 times more for such work, since their work in general is valued much higher;

- The price includes the time of moving, preparing the station for work, and washing it at the end of the shift. These amounts are significant, but fixed. It’s one thing to divide tens of thousands of rubles into 2,000 m2, and another into 50-250 m2.

2. The price for work does not take into account the cost of electricity. The owner of the apartment will have to pay.

3. Another feature of machine plastering is that the price does not include work on installing plaster corners. They are paid separately.

To fully understand what is better - mechanized or manual plastering of walls, we will carry out an enlarged calculation of the cost of work per 100 m2 of wall.

Machine plaster:

- price - 350 rub./m2;

- layer thickness 1 cm;

- consumption rate of dry plaster per 1 m2 is 13 kg;

- the price of plaster is 410 rubles/bag (Volma, 25 kg) or 16.4 rubles/kg.

The cost of materials will be 42,640 rubles. Salary - 35,000. For simplicity of calculations, we will not take into account other costs. In total, you will have to shell out 77,640 rubles from the family budget.

When working manually you will need:

- cement M400 - 350 kg (14 bags weighing 25 kg at a price of 235 rubles / package) in the amount of 3,290 rubles;

- fine sand - 1,500 kg for the amount of 3,000 rubles. (30 bags weighing 50 kg at a price of 100 rubles per package);

- delivery with lift to the apartment - 4,000 rubles;

- fiberglass fiber - 200 rub.

Please note: cement prices can vary significantly depending on the manufacturer. Portland cement from the middle price category was selected for calculations. There is cement for 135 rubles/bag.

In total, it is necessary to purchase building materials in the amount of 10,490 rubles. The salary will be 55,000 rubles. (100 m2 x 550 rub./m2). The total cost of plastering work is 65,490 rubles.

Calculations without words show the advantages and disadvantages of each type of plastering work.

How automatic application equipment works

The automatic plastering machine consists of the following elements:

- hopper or funnel for mixture;

- screw device;

- special mixing tank or concrete mixer;

- water supply device;

- finished solution supply system;

- pump;

- control system.

There are mobile machines and stationary ones. Both varieties differ in design, method of movement, dimensions and other features, but the principle of their operation is the same.

On a note! Plastering machines are similar in operating principle, but have significant differences in performance, weight and other parameters.

Why do you need to plaster the walls in your apartment?

Page navigation

Any renovation of an apartment or private house cannot be done without plaster. Using this method of work, you can achieve the following effect:

- the plane is leveled;

- all visible defects, such as cracks, dents, chips, are eliminated;

- Painting and wallpapering is easier. This is especially important if repair work is carried out independently without the help of specialists;

- indoor humidity decreases. Walls become more resistant to moisture;

- corners and slopes are leveled.

It should also be noted that plastering the room is necessary to increase the thermal insulation properties.

Results

Plastering using pneumatic devices cannot be called an easy job - holding a gun or a ladle with several liters of solution suspended and applying the mixture evenly on the base from a fixed distance is difficult. But compared to manual plastering, this execution is still physically easier, and technically simpler - it does not require professional plasterer skills. By selecting the optimal distance to the surface in the first seconds of work, you can apply the solution without sticking, which is typical for manual plastering.

In addition, the productivity of this method is several times higher than the traditional version, so some of the physical effort is justified. The high speed of plastering not only reduces the duration of the process, but also brings the base closer to readiness for further finishing - the sooner the plastering is completed, the sooner it will mature.

As for the quality of the coating. The method of preparing the solution is the same for both pneumatic application and manual application, therefore the main requirement for both methods is to follow the instructions for using the mixture. Applying the mixture with a pneumatic tool ensures the coating is monolithic, as it does not leave cavities in it. But in high-quality hand-made plaster, the presence of cavities is so insignificant that it does not affect the characteristics of the coating.

When comparing manual finishing and station plastering, the difference in performance is also immediately apparent. Comparing prices makes machine plastering even more attractive:

However, savings are real only when finishing large areas. The “crew” of a plastering station consists of two or three people, among whom the earnings are divided, so the contractor is forced to inflate prices for small volumes. But in a situation where the renovation of a small apartment is limited by time, the higher price of machine-made plaster for a small volume justifies itself.

Tips for using a plastering machine

Machine plastering of walls is carried out using different machines - they all have their own technical features that need to be paid attention to.

When plastering walls by machine, you should pay attention to the advice of professionals:

- Compliance with electrical requirements. For example, the need for a three-phase connection.

- Algorithm of work or how, where and in what order to add the components of the mixture.

- The mixture is selected correctly - it must match the type of machine and the structure of the walls.

Mechanized plastering of walls is a convenient and almost universal method for leveling ceilings and walls, which allows for quick and comfortable work. Machine plastering of walls has both pros and cons, but in any case this method has proven itself to be the best.

Mixtures

The main parameter on which the quality of the treated surface depends is the plaster mixture. Conventionally, they can be divided into dry and wet. The second type of product is used by large construction companies. They purchase a ready-made mixture, which is delivered to them using concrete mixers. But the main ones on the market today are dry mixtures, which allow you to create plaster yourself.

Depending on the composition, dry products can be divided into 2 large groups:

This allows you to obtain a high-quality surface for decorative finishing within a few days after application.

The mixtures have high porosity, reducing solution consumption several times compared to cement compositions. When applied using automatic devices, you can get an almost perfectly smooth surface that requires minimal processing.

Cement-sand plasters. Universal mixtures that can be applied to almost any surface. Since the substance tolerates temperature changes and exposure to water well, many people use it to decorate the facades of houses.

The modern market offers many types of dry and semi-dry mixtures. Among all this diversity, several popular brands should be highlighted:

"Prospectors"

A gypsum-based mixture characterized by high adhesive properties. Intended for application on various types of surfaces, among which brick, concrete and foam block are optimal.

The manufacturer indicates that the composition can be used as finishing mixtures.

"Osnovit"

Another representative of gypsum plasters, perfect for interior decoration. The fine-grained structure of the components allows the solutions to be applied to the walls in a layer about 1 cm thick. In this case, the product consumption will not exceed 9 kg/m2. The plaster is suitable for treating walls and ceilings.

"Knauf"

The company is one of the leaders in the production of mixtures for finishing various surfaces. It should be noted its gypsum plasters, which contain various polymer impurities.

The color range of mixtures includes not only gray, but also pink shades.

"Volma"

One of the leaders of domestic production. Produces high-quality gypsum plasters for mechanical application.

The manufacturer claims that you can start grouting the walls after 4 hours after application.

After this treatment, the surface is ready for painting or wallpapering. The outer layer is practically indistinguishable from bases coated with special putty compounds.

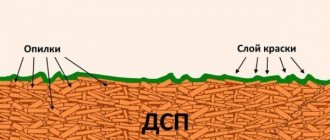

Please note that almost no one produces cement-based mixtures. Technically, this is not necessary, since it is quite easy to obtain such plaster

It is necessary to mix high-quality sand and cement in certain proportions to obtain the desired consistency of the solution.