When building a house, a large role is given to interior decoration, in which it is necessary to select building materials that meet modern requirements. This especially applies to putty, because it is with its help that the walls of the building will be smooth, white, and safe. This paste-like substance includes all the necessary components for bonding to any surfaces and various additives for leveling the walls. Both gypsum and polymer putty perfectly fill all voids and cracks in plasterboard and gypsum fiber sheets and level even complex surfaces.

Therefore, before choosing which mixture is suitable for finishing, you must first of all imagine whether there is a high probability of increased humidity in the house. Gypsum-based mixtures will not tolerate it; they will simply swell on the walls and begin to fly off. They are shown only dry rooms and preferably without a sharp change in air temperature. If this occurs, it is better to treat the walls with polymer putty.

Also, dry plaster is characterized by a fear of any mechanical influences and vibrations, which can lead to its peeling from the wall surface. But in terms of cost, gypsum-based material wins. It is much cheaper than its polymer counterpart.

Features and Specifications

Gypsum putty

To prepare a working mixture based on gypsum, use:

- plaster (in some cases alabaster);

- water-soluble polymers;

- mineral fillers.

Due to the use of gypsum, marble flour and white quartz sand, the mixture has a white color, in some cases a slight yellowness is allowed.

Depending on the size of the fractions, putty is divided into two types:

- Starting Its purpose is to hide small surface defects, remove cracks and chips in the base, so large fractions of bulk materials are used in the starting mixture. It serves as the basis for the final leveling layer.

- Finish. To obtain a flat and smooth surface, only small fractions of bulk materials and special plasticizers are added to this putty. Application: final finishing. You can glue wallpaper or apply paint to the finished surface.

Scope of application of gypsum putty:

- elimination of minor defects (chips, cracks);

- masking the joints of sheet material;

- leveling the bases for subsequent gluing or painting;

- installation of stucco on the ceiling;

- design of arches, cornices and columns.

Manufacturers most often produce this type of putty in bags of 20-25 kg. To subsequently dilute the material with water to the desired consistency, follow the instructions printed on the packaging. In some cases, it is possible to purchase a ready-made paste mixture in a plastic container.

Considering the hygroscopicity of the base material, the use of this type of putty is only possible in rooms with normal humidity, and they are not suitable for a toilet, bathroom or kitchen. The finished surface “breathes”, allowing vapors to pass through.

Application of gypsum putties is possible on the following substrates:

Polymer putty

To prepare a working mixture based on polymers, the following materials are used:

- as the main component - acrylic, polymer cement or latex;

- fine-grained mineral fillers.

The difference between polymer putty and gypsum putty is the chemical method for producing dry matter.

(function(w, d, n, s, t) w[n] = w[n] || []; w[n].push(function() Ya.Context.AdvManager.render( blockId: “RA- 510923-1”, renderTo: “yandex_rtb_R-A-510923-1”, async: true >); >); t = d.getElementsByTagName(“script”)[0]; s = d.createElement(“script”) ; s.type = “text/javascript”; s.src = “//an.yandex.ru/system/context.js”; s.async = true; t.parentNode.insertBefore(s, t); >) (this, this.document, “yandexContextAsyncCallbacks”);

The following surfaces can serve as the basis for applying this material:

This type of putty is not used for metal surfaces.

Polymer materials make it possible to obtain a strong surface with a perfectly white color, which is suitable for both wallpapering and painting.

Polymer compositions are most often sold in finished form. The putty is packaged at the factory in plastic containers of various capacities. This material is completely ready for application to walls. When opening the package in a room at room temperature, the finished mixture does not lose its characteristics for 2-3 days.

To prepare the putty, use dry mixtures and water yourself. The ratio of water and powder, as well as the rules for preparing the solution, are indicated on the packaging. Manufacturers pack dry mixtures in paper bags of 20 or 25 kg.

When using putty to level external walls, it should be taken into account that for these purposes you need to choose an acrylic or polymer-cement mixture, because latex-based material cannot cope with the aggressive external influences of precipitation and temperature changes.

When choosing what is best for leveling walls, you should take into account the advantages of polymer compositions:

- versatility of use (except for leveling metal surfaces);

- better adhesion to any substrate compared to other types of putties;

- immunity to high humidity;

- no unpleasant odor;

- polymers make it possible to obtain surfaces with the highest strength characteristics;

- immunity to temperature fluctuations;

- no shrinkage during strength gain;

- immunity to the action of chemical compounds;

- the prepared solution can be stored for at least 10 hours;

- the mixture contains only environmentally friendly materials;

- does not require special skills when applying, a novice finisher can handle it.

Varieties, what are the composition

•Acrylic. Compositions based on acrylic resins are the most versatile option. They are suitable for any base, except perhaps metal. Can be used for interior and exterior work - as a leveler or the last layer before applying decor.

•Latex. Acrylate latex putties are elastic, but do not tolerate moisture well and cannot cope with pronounced wall defects. That is why it is worth resorting to their help only for finishing interiors. Like acrylic, latex adheres well to most materials.

•Polymer-cement. Their main component is cement improved with polymer additives. These putties are in demand when working with concrete, cement-lime, cement-sand and brick bases - both for deep leveling and for final surface preparation.

•Acrylic. Another example of universal mixtures. They are easily applied to brick, concrete, plasterboard, foam concrete, chipboard, extruded polystyrene foam and do not deteriorate even in direct contact with water.

•Silicone. Durable, but not the most affordable solution. Mainly moisture-resistant and vapor-permeable silicone plasters are used for facades.

Comparison of gypsum and polymer putties

A comparative analysis of the characteristics will help determine whether gypsum or polymer putty should be used in specific conditions:

- When using polymer compositions in rooms with high humidity, it should be remembered that this material is not hygroscopic and contributes to the accumulation of moisture on the surface. The gypsum base absorbs excess moisture, regulating the overall level in the room, but with excessive moisture, the gypsum base is destroyed;

- in terms of vapor permeability, the situation is similar - polymer compositions, unlike gypsum compositions, almost do not allow vapor to pass through;

- gypsum-based putty is more plastic;

- the level of environmental safety of gypsum solutions is higher than polymer ones;

- You can distinguish polymer materials from gypsum materials by their perfectly white finished surface. In gypsum mixtures there may be a slight yellowness, and therefore polymer compositions should be chosen for important objects;

- the cost of polymer materials is higher than gypsum.

How to properly putty with a polymer composition over paint

Experts recommend not applying putty to painted surfaces. It is optimal to clean off the paint before finishing work.

However, if it is necessary to putty the painted areas, the work is performed in the following sequence:

- the strength of the painted layer is checked;

- chipped areas are cleaned and processed with sandpaper;

- the surface is covered with a sand primer;

- The process ends with puttying work, which is characterized by thoroughness.

For treating painted surfaces, it is recommended to use putty based on polymer components. Gypsum putty does not hold firmly enough on such substrates.

Which putty and in what case is it better to choose?

The choice of type of leveling mixture depends on the base material.

Wooden surfaces

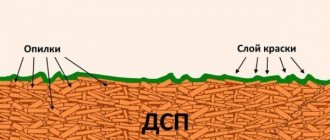

To prepare the wood surface for finishing, polymer compounds are used. They have excellent adhesion to plywood or chipboard, but before applying putty. the wood should be treated with antiseptic impregnations.

Drywall

In living rooms and office spaces, a standard gypsum mixture is usually used for leveling. To process drywall, it is not necessary to apply a starting layer, but before finishing it is necessary to seal the seams and the points where the sheets are attached. The joints are opened at an angle of 45 degrees, sickle tape is glued on and filled with putty.

The use of expensive polymer mixtures is recommended only in rooms with high humidity, where moisture-resistant drywall is installed.

Concrete

To level concrete and brick walls and ceilings, you can use any type of mixture, but you should take into account the operating conditions of the premises. For rooms with humidity above normal, polymer materials are suitable, and for rooms with normal humidity, gypsum-based leveling mixtures can be used.

Source

The cleanliness and safety of your home depends on the choice of putty

Walls treated with gypsum and polymer-based materials are environmentally friendly and have no pungent odors. The elasticity of the compositions allows them to resist wall deformations. Also, these types of building mixtures are fireproof and quite fire resistant. The only thing is that walls covered with plaster inhale vapors well and breathe. Polymers do not have this ability. Using modern technologies, they produce coatings that have soundproofing properties and to which antifungal drugs are added.

The choice of material for indoor work depends only on the owner, on his calculations, since all types of putties existing on the construction market have both positive qualities and disadvantages. To understand which putty is best suited for finishing premises, you need to weigh the pros and cons.

Which putty is better: gypsum or polymer, latex or acrylic?

The putty process is one of the components of painting repair and finishing work. Putty is a paste-like mixture that includes components such as binder, base, and various additives for leveling surfaces.

When the need arises to purchase putty, many are faced with the problem of choosing the right type, since construction markets present them in a huge assortment. Each of them is intended for different types of work, but which putty is better for this?

Brief description of the properties of polymer plasters

According to the type of application, all putties are divided into two types: starting and finishing. The starting ones use larger grains of sand - 0.3-0.8 mm. This results in a slightly rough surface.

They are used at the first stage to seal depressions and cracks. In finishing compositions, sand is practically dust with a very fine grain of 0.1-0.3 mm. This allows for a smooth surface.

Classification of putties

By degree of readiness

Dry putties are sold in bags or bags and have a lower cost compared to ready-made mixtures. The advantage of dry mixtures is their convenient transportation and storage. They also have a fairly long shelf life. Dry mixtures for the putty process can be prepared in the quantity and viscosity required at this stage of work. However, it is worth noting that the mixture prepared from dry putty must be used in a fairly short time. In addition, the dry mixture must be prepared strictly following the instructions indicated on the packaging and for its preparation you must have special tools.

Surface putty technology

Application of polymer mixture

When applying polymer putty, the most important thing is to adhere to the basic rules:

1. Apply the solution only to the prepared wall. It is necessary to remove dirt, grease stains, mold, etc. To degrease walls, gasoline or acetone is recommended. This is a very important stage, on which the adhesion of the putty to the surface completely depends.

2. Pre-treat the wall with a primer that contains antiseptics, which will be the best prevention of the formation of mold or mildew in the future. A primer is also needed for better adhesion of the solution to the surface.

Which putty is better - gypsum or polymer?

The result of the finishing work performed depends on the quality of the material used.

Gypsum-based putty is used for interior finishing of surfaces made of plasterboard, gypsum fiber and cement. It is used in cases where it is necessary to level out surface defects, eliminate unevenness and mask joints. Gypsum putty gives surfaces ideal evenness and smoothness, and makes them ready for such types of finishing as painting or wallpapering. In addition, various decorative elements of the interior, for example, columns or arches, are finished with gypsum putty. Gypsum plaster has moisture-resistant properties, which allows it to be used for finishing bathrooms and other rooms with high humidity.

Gypsum putty is made from gypsum and is sold in powder or paste form. On the market you can find putties that contain white gypsum or gypsum with a yellowish tint. In addition, they contain various additives of water-soluble polymers and mineral fillers, for which manufacturers use marble flour or white quartz sand. The size of the filler fraction determines the purpose of the gypsum putty - starting or finishing. The final property of the material depends on such components of gypsum putty as modifiers and plasticizers, which protect the surface from cracking and crumbling.

Polymer putties contain Portland cement, plasticizers, polymers and are mainly used in rooms with a low percentage of humidity. There are both starting and finishing polymer putties. Their feature is the rapid hardening of the applied mixture to the surface.

Video about which putty is better: gypsum or polymer

Comparison of gypsum or polymer putty:

- Unlike gypsum, polymer putty, when used in rooms with high humidity, contributes to disruption of the microclimate and retention of moisture in the room, while gypsum-based mixtures maintain humidity at the proper level.

- Also, polymer putty differs from gypsum in lower vapor permeability and weaker ductility.

- In addition, polymer putties contain synthetic components, while gypsum putties are an environmentally friendly material.

- And finally, polymer putties are more expensive than gypsum putties.

What is the best way to use putty for interior finishing?

Both dry gypsum and polymer-based putty are prepared only before using it for finishing. To do this, prepare the necessary equipment: a container in which the solution will be mixed, an electric drill with an attachment to give the substance the desired consistency, and a bucket of water for rinsing the attachment.

According to the instructions, pour the mixture into a prepared container with water and give it a little time to swell, then mix using a drill attachment. It is better to knead several times with minute breaks.

For startups, preference is given to gypsum-based putty. Before applying the material, the walls must be cleaned of dirt and primed with a deep penetration compound. If you use plasterboard for finishing, you must cover the joints between the sheets and the screw caps with a solution, having previously glued a sickle mesh to them.

If the quality of the surface is low, then the walls are treated in several layers, using a wide spatula. Be sure to dry each layer before applying the next one. Then they are polished using a special grater with an abrasive cloth. You can sand the walls with ordinary sandpaper or a mesh adapted for this purpose.

The finishing layer is used to finally level the walls, and it is made either with gypsum putty or with a polymer base. The latter does not require additional processing and has a dazzling white color. In addition, polymer is easier to work with: they are more elastic and have constant strength, so they can be sanded at any convenient time.

And the gypsum must be observed in terms of its adhesion to the base. You can’t let it dry as much as possible, otherwise you won’t be able to sand the surface. This happens approximately 4 hours after applying the last layer.

Gypsum and polymer putties have different layer thicknesses, which can be applied to the surface during interior finishing. Gypsum is applied in a thicker layer, so significant defects can be eliminated quickly. But it is not recommended to apply a solution thicker than 10 millimeters, because the strength of the plaster will decrease.

Working with gypsum and polymer putties.

But the polymer composition has a thin layer of application, and it is difficult and time-consuming to repair a significant defect. Of course, such putty is consumed per square meter in smaller quantities than on a gypsum base.

Recommendations from experts

Since you have chosen gypsum plaster for finishing work, be sure to take into account a few recommendations from experienced craftsmen. This will allow the task to be completed efficiently.

- Prepare the floor. It is advisable to cover it with cardboard, tin or polyethylene of a dense structure. This will protect your flooring and also allow you to use any mortar that has fallen on the floor.

- Work quickly. Even the most “tenacious” compositions will not give you much time. If you do not have much experience, prepare small portions so that you have time to work them out during the period of viability of the plaster.

- It doesn’t really matter whether you apply the solution from bottom to top or top to bottom. The main thing here is your own comfort. Work as it suits you.

- It is impossible to achieve an ideal surface with one movement of the rule and you cannot pay attention only to a separate small area. Treat the entire wall with the rule until the composition has completely hardened.

- If the walls are brick or block, use reinforcing mesh in addition to gypsum plaster. They are especially relevant for finishing new buildings with possible shrinkage.

- Be sure to remove beacons. The resulting cavities are sealed with plaster. If metal beacons are left, over time they will rust and ruin the appearance of the walls and have a destructive effect on the surface.

Working with gypsum plasters is not difficult. Each of the leading manufacturers does everything possible to ensure a high-quality end result, make the task easier for craftsmen and achieve ideal surfaces. It is impossible to say which plaster is better in the end. It all depends on the specific situation.