10/07/2019 There are many skeptics who claim that insulating a house or apartment from the inside is not the best option. But, in some cases, it is simply not possible to insulate the walls from the outside. Internal thermal insulation is becoming practically the only way that can provide a home with warmth and comfort and reduce energy consumption.

How to insulate a house from the inside, what features of the process need to be taken into account - we tried to cover the topic to the maximum. In the publication you will find the following:

- Features of internal insulation of a house: what is important to know first;

- Preparing the room for internal insulation;

- Insulation of walls from the inside with polystyrene foam; Selection of expanded polystyrene for internal insulation;

- Installation of extruded polystyrene foam for internal insulation;

- How PIR boards are installed for internal insulation;

- Selection of mineral wool for internal insulation;

Basic principles of internal thermal insulation

The correct choice of thermal conductivity of insulation makes work on internal insulation as effective as creating an external thermal layer, provided that the heat barrier is correctly placed.

Not every heat-insulating material is suitable for insulating a house from the inside. It must meet certain properties to achieve the assigned tasks:

- Low permeability.

- No secretions harmful to human health.

- Waterproof.

- Ability to maintain configuration under mechanical loads.

It is important to know! The vapor permeability of insulating materials should decrease, that is, the insulation must provide more reliable protection for vapor than a wall. This purpose guarantees the free exit of moist air through the thickness of the wall to the outside.

To avoid problems with insulation from the inside, first of all, you need to determine the location of the dew point. Its correct position should be in the wall or insulation, but not at the junction between them.

Changing the location of the dew point Source mynovostroika.ru

If this happens, then the accumulation of moisture and, as a result, rot, mold and mildew on the surface is inevitable. This situation is possible due to the large thickness of the insulation, since the wall is completely insulated from internal heat.

This also happens as a result of low vapor permeability. Walls made of brick and concrete are especially susceptible to this phenomenon. In this regard, internal thermal insulation in such houses is justified only in non-alternative options.

But in buildings made of timber or logs, such a layer of insulation is quite acceptable; you just need to maintain a gap between the wall and the insulation. Therefore, in order to meet all the requirements for internal insulation, you must first make a frame on the wall from a vertically located beam along the width of the insulation size.

Then a waterproofing film is spread and secured along the wall and insulation material is placed between the slats. It, in turn, is fixed with transverse strips and then a vapor barrier film is stretched on top.

When walls are insulated internally, such a “pie” is created Source moydom-irk.ru

Insulation of walls inside and outside the house - differences

Wall insulation is carried out both inside and outside .

If it is necessary to insulate walls, then, as a rule, one insulation option is chosen: either from the inside of the load-bearing wall or from the outside.

It is also possible to insulate a wall on both sides, but this is not always necessary : insulation options are chosen based on climatic conditions, construction features, and individual preferences.

Indoor insulation is installed on the inside of the building.

The disadvantages of this option are the following:

- the free space of the room decreases;

- the likelihood of dew point formation inside the wall or between the insulation and the wall.

Internal insulation of the walls of a house is good because:

- weather conditions will not affect the work schedule;

- If the building has cladding, it is possible to preserve it unchanged.

IMPORTANT!

When installing internal insulation, it is necessary to install a reliable vapor barrier inside the building.

Insulation of external walls is carried out from the outside of the building. With this type of thermal insulation, the usable area of the structure is preserved; there is no need to install a vapor barrier layer . However, if the cladding of the building has already been completed, it must be dismantled.

Types of materials and selection criteria

In order to avoid problems during the further operation of the house, you need to choose the right insulation. In addition to physical properties, it also has mechanical parameters. Within this characteristic, the following materials are determined for insulating walls inside the house :

- Mineral wool is a product produced in rolls, produced in different thicknesses.

- Bulk insulation is a material in the form of polystyrene foam granules, has a different configuration and size.

- Foam blocks are insulation, which includes foamed concrete, sand, bone glue and pine rosin.

- Plates are insulating material in the form of plates, which are made by pressing and gluing and have different sizes and thicknesses.

Internal wall insulation with slab heat insulator Source teplostroy.by

See also: Catalog of companies that specialize in insulating country houses.

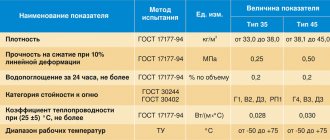

PIR insulation is a modern analogue of extruded polystyrene foam

PIR insulation appeared on the market relatively recently. Therefore, they need to be considered separately. This heat insulator is a three-layer material consisting of an inner layer of polyisocyanurate foam, covered on both sides with aluminum reflective foil.

In fact, PIR (or polyisocyanurate foam) is a special type of polyurethane with a rigid structure, ultra-low thermal conductivity and increased strength parameters. Due to this, it has successfully proven itself as a heater for internal thermal insulation of any premises, from bedrooms to balconies and loggias.

A special property of this insulation is the additional reflection of heat back into the room due to the foil. Thus, the thermal conductivity coefficient decreases to an unprecedented 0.022 W/m*K, water absorption is only 1% (this is when immersed in water for a day). But the main thing is that the vapor permeability of PIR insulation is reduced to zero due to the same foil coating.

For internal insulation, an excellent solution would be to choose materials such as:

- LOGICPIR universal insulation L 1190x590x50 mm. It has the optimal thickness for medium and large rooms, equipped with an L-edge to prevent the formation of cold bridges.

- Insulation LOGICPIR Balcony L 1185x585x30 mm. It is used on the bottom of small unheated balconies. L-edge present.

- Insulation LOGICPIR Balcony L 1190x590x50 mm. Recommended for insulating a heated balcony, as well as a balcony that is part of a living space.

How PIR boards are installed for internal insulation

The aluminum surface of Pir-plates does not allow high-quality fixation of the insulation using the traditional adhesive method. In this case, the technology with plastic mushroom dowels with plastic nails is used.

The very essence of the technology does not differ from the fastening of polystyrene foam described above. After completing the installation of the last slab, the joints are glued. The gaps between the floor and the slab can be filled with polyurethane foam. Next comes finishing. Instead of dowels, you can use wood sheathing. The beam presses the insulation against the wall, after which the cladding is carried out with panels, lining, gypsum board and other materials. An example of installation can be seen in the photo instructions:

Penoplex is an environmentally friendly material for insulation

This heat insulator is a popular modern insulation material that exceeds foam in its qualities. This granular polystyrene mixture has many advantages:

- moisture resistant;

- fireproof;

- environmentally friendly material;

- neutral to chemical influence;

- ideal sound insulator;

- a light weight.

It showed excellent performance under mechanical loads and at low temperatures.

Production of penoplex - solid slabs before further processing

Selection Criteria

Before you insulate the walls from the inside in a private house, you need to get acquainted with the parameters by which these materials are divided. First of all, you need to know the following features:

- Thermal conductivity . It should be low enough.

- Weight . Lightweight products do not require additional fastening.

- Vapor permeability . The higher this property of a material, the more effective its use, since less moisture penetrates and the walls remain drier.

- Possibility for further finishing.

And also, it must have a long service life, allowing replacement no more than once every 12-14 years.

Application of mineral wool

The technical characteristics of this material today allow us to consider it one of the most popular insulation materials. Its main advantage is its low cost and low degree of thermal conductivity.

And also an undeniable advantage of mineral wool is its versatility. It can be applied to any uneven surfaces of any shape: roofs, ceilings, non-standard openings in walls.

All work with mineral wool must be carried out in protective clothing Source skmig.ru

Mineral wool is divided into three types:

- Basalt.

- Slag-like.

- Glass wool.

All varieties of this insulation are united by one property: due to the interweaving of fibers, air spaces are formed inside it, providing a low level of thermal conductivity.

It is important! Mineral wool easily absorbs moisture, so it is recommended to use it as insulation inside the house only in addition to the outer insulating layer.

We insulate the walls from the inside using polystyrene foam

When choosing between mineral wool material and expanded polystyrene, you need to keep one nuance in mind. This insulation has low vapor permeability, so it is not recommended to use it on walls with high vapor permeability (timber, logs, porous concrete).

It will be more effective to use for thermal insulation of brick walls and blocks with low moisture permeability. An adhesive mixture is used to glue this material.

When fixing the insulation, in addition to glue, special nails with heads are used.

Special fasteners with wide caps for insulation materials Source pro-uteplenie.ru

Installation of slabs is carried out sequentially in several stages:

- The surface is being prepared. Cleaned, primed and marked with beacons.

- A rail is fixed at the bottom to support the PPS sheets so that there is no displacement during connection.

- Apply glue to the surface of the wall and the plane of polystyrene foam.

- Apply, align and glue the insulation sheets. It is recommended to do this some time after applying the glue.

- The slabs are additionally secured with nails. They are driven in so that the caps are slightly recessed into the polystyrene foam.

- Then a mesh is applied to the slabs, and the surface is treated with plaster mortar with finishing rubbing. After drying, the panels are ready for further finishing: painting or wallpapering.

On a note! Despite the fact that internal thermal insulation is positioned as an alternative to external insulation in bad weather conditions, insulation of walls inside the house is recommended in the summer when the partitions are heated and in the absence of precipitation.

When should you use foil wall insulation?

To insulate a dacha from the inside, in some cases it becomes especially important to use thin materials, but with a high thermal insulation ability. One of these can be considered penofol, one side of which has a foil surface.

With equal thickness to other insulation, its efficiency is 50-80% higher, which makes it possible to use materials with a minimum thickness for thermal insulation, thus maintaining the size of the usable area in the room.

Such insulation with foil is made of foamed polyethylene with a reflective layer applied to it, which should “look” towards the room during installation.

Installation is not difficult and is carried out using glue and/or dowels, but it requires obligatory maintenance of the gap between the insulation and the layer of external finishing, as well as effective ventilation in the room.

The main obstacle to its use in dachas is the rather high price of the material and the need to perform additional work. But this material has undeniable advantages, among which we should highlight:

- moisture resistance;

- possibility of use in a wide temperature range, therefore, more often than for finishing residential premises, foil penofol is used in baths and saunas;

- high efficiency, including due to reflectivity;

- excellent heat, steam and waterproofing characteristics, thanks to which it is possible to create a stable microclimate in the room for which it is used as insulation, which, in turn, can significantly reduce heating costs.

Stages of work

First of all, before insulating the walls of a house internally, it is important to know that the dew point will change - the place where moist air turns into condensation.

Consequently, if you choose the wrong material or its thickness, then such insulation can worsen the condition of the walls: mold, mildew, or destruction of the partition will appear.

It is important! In order to avoid irreparable mistakes, it is better to entrust all calculations for choosing insulation, as well as installation work, to specialists from a trusted construction company.

Before starting work on wall insulation, certain rules must be followed:

- Remove old coatings to the base of the surface, clean, remove possible formations of mold or mildew.

- Treat the wall with an antiseptic and primer solution. At the same time, give each coating a chance to dry.

- When using polystyrene foam, plaster the surfaces with the placement of beacons, which will allow for a more even plane. Allow to dry for at least two days.

- Laying the material.

- Finishing the wall.

What do they recommend?

Experts note that a good insulation option is Ursa M-15 fiberglass mats, as well as fairly high-quality and comfortable Ursa P-15 slabs. At least, these insulation options have become especially popular, which is why much more attention should be paid to them. In general, it is possible to browse a wide variety of construction forums. Before you, a huge number of people insulated their homes on their own, so here you will find hundreds of pages discussing the strengths and weaknesses of various insulation materials: an hour or two of reading and you yourself will begin to understand this area.

If we talk about everything that is available to you, then it is worth noting stone or mineral wool. Such insulation will boast absolute non-flammability, as well as soundproofing, which will allow great savings for those who make a music studio out of their home or would like to be in silence; classic sound insulation costs a lot of money.

Separately, we note glass wool, the popularity of which in industry is simply off scale. This material has a low thickness, which allows for dense and reliable insulation in a small volume. The level of thermal conductivity of the material is significantly reduced with the help of air gaps. Here we note expanded polystyrene and extruded polystyrene foam, which are not expensive, but at the same time do their job perfectly. Polyethylene foam, which is easy to use and does not require any kind of hydro- or vapor barrier, will effectively protect your home from the cold. Usually this is an excellent opportunity to do everything extremely economically, while not forgetting about quality.

Video description

Insulation instructions in the following video:

Advice from professionals

When carrying out such work, you need to pay attention to the following points:

- Vapor barrier will help if you make a hermetically sealed joint at the seams.

- The thermal insulation layer should not have a high vapor permeability parameter. In the case where this indicator is higher near the wall than that of the insulating material, steam will escape outside.

- To achieve complete adhesion of polystyrene foam to the wall, the beacon method of applying plaster and the method of leveling the glue with a comb are used. This allows air bubbles to pass between the wall and the insulation.

On a note! To prevent moisture from appearing on the walls, a high-quality ventilation system must be installed in the house - hoods and valves on the windows.

Natural ventilation must be calculated no less carefully than forced ventilation Source sovet-ingenera.com

How is installation done?

Don’t be alarmed, the installation of insulation has already been done independently by a variety of people. There is a proven step-by-step scheme that will allow you to make durable and reliable insulation

To begin with, the technology for laying insulation requires some precautions - the work should be carried out in:

- respirator;

- glasses;

- cap or hat;

- hood;

- You should always wear gloves on your hands;

- After completing the work, the clothes are washed separately from the rest.

It is not difficult to follow these rules, but they will raise the level of comfort and safety in the work being carried out to the limit. Let us note that many people ignore the use of a respirator, which is a big mistake - there is something to breathe in, and then you will need to seek help from a doctor, and it is difficult to imagine what this can lead to. The key instructions for laying insulation on walls are the following sequence of actions:

- We start by very carefully foaming all the seams and cracks, of which there are usually a very large number on the outer sides of the walls. Polyurethane foam is perfect for this and is easy to use, so you will be satisfied with the result;

- Next, we must take care that the insulation fits very tightly to the heated part of the house and fills all the space inside the frame. If there are any voids along the edges of the wooden frame, everything is corrected, even if this place is made of small cut pieces of insulation;

- then we check that the edges of the insulation do not wrinkle inward - everything must be strictly parallel;

- we check all connections - the insulation is laid end-to-end, even a small gap is a huge loss in the quality of insulation. If the insulation is laid in several layers, this is done as when laying bricks: a new layer overlaps the previous joint;

- Next, you need to take care of placing the insulation even behind the junction box, behind wires and other elements - there should be no gaps or gaps at all;

If you acted carefully and responsibly, you will need to cover the insulation with the material that you chose for this, but this is a completely different task, it has its own subtleties and rules - the insulation for your home is completed and a comfortable winter awaits you.

Classification of insulated flat roofs

The external simplicity of a flat roof can lead to deep bewilderment for home craftsmen who want to quickly erect a roof over private property. Those who consider flat roofing a budget option will also be surprised.

If the roof is built wisely: with the proper number of waterproofing layers, with insulation of the required thickness, with parapets, drainage and its heating, in the end it will cost quite a lot, but also work flawlessly.

Flat roofs of the following categories are subject to insulation:

- Combined

, they are also without attics. Their roof structure is combined with the ceiling. Insulation is carried out by laying thermal insulation with accompanying layers on top of the base. The advantage of combined systems is that they practically do not require winter clearing of snow cover. After all, the ceiling is regularly heated from the inside. Minor snow deposits can be easily removed by the natural force of the wind, which is why it is recommended to equip such roofs not with parapets, but with lattice fencing. Disadvantage: the condition of the roof is difficult to monitor. The slightest damage will result in leaks, followed by serious restoration of the roofing pie. - Attics

, which have two subtypes within the category. The attic floor of the first subtype is supplemented with a light superstructure on top. It is clear that in such cases the ceiling should be insulated. In the scheme of the second subtype, the attic superstructure and the ceiling are independent structures. This means that insulation is acceptable for both of them. The advantage of attic structures is the free monitoring of the condition of the roof and timely detection. Owners can dry out the roofing pie by simply ventilating the attic. Among the significant advantages is the ability to carry out insulation upon completion of roof construction. The disadvantage lies in the impressive cost, which, however, pays off through long-term operation and rare repairs.

The second category of attic roofing systems means that the insulation can be located either within the superstructure or above the ceiling. However, the second option for laying insulation for a flat roof is a priority.

According to the second scheme, an air chamber is formed between the roofing and the thermal insulation system. This is an attic that divides the structure into two parts with different temperature backgrounds.

The difference between the external and internal temperatures of the attic roof will not be as significant as it is with structures without an attic. The temperature change will not be so sharp and destructive. Plus a minimum of condensation, which is the secret to the longevity of attic roofs.

Mistakes when laying fiberglass mesh

The reinforcing layer of wall insulation provides protection from mechanical damage. It is made from fiberglass mesh and reduces thermal deformation, increases strength and prevents the formation of cracks.

The mesh must be completely immersed in the adhesive layer

It is important that the mesh is glued without folds. We also do not recommend using cheap Chinese mesh

They are not alkali-resistant, which will lead, over time, to corrosion by the solution, which means the plaster layer will not be sufficiently protected from temperature and mechanical deformation.

In places vulnerable to loads, an additional layer of reinforcement is performed - in all corners of window and door openings, mesh strips measuring at least 35x25 are glued at an angle of 45°. This prevents cracks from forming in the corners of openings.

To strengthen the corners of the house, corner profiles with mesh are used.

Types of stone wool

Basalt-based insulation is available in several modifications. Rolled fabric (the width of which is usually 1.2 m, and the length varies from 7 to 12 m), from most manufacturers has a low density - only 35 kg/m³. This material can only be used for horizontal laying in areas without any load. Such solutions do not occur very often.

The large area of the rolled fabric allows it to be laid with a minimum number of seams, and therefore cold bridges

The most popular is stone wool in the form of slabs (dimensions 0.6-1 m by 1.2 m and thickness from 30-200 mm). The main factor determining the scope of their application is density. Depending on this, the material is divided into several grades.

P-75

(density 75 kg/m³). Used for insulating surfaces with minimal load, for example, interior partitions and ceilings.

P-125

(125 kg/m³). Suitable for thermal insulation of floors, interfloor ceilings and facades.

PZh-175

(175 kg/m³). Designed for thermal insulation of reinforced concrete and metal walls and ceilings.

PPZh-200

(200 kg/m³). The material of maximum density is used for insulating roofs and floors under screed.